- Offer Profile

-

HURCO® develops and manufactures CNC vertical and horizontal machining centers. In addition, as a® CNC machine manufacturer with over 50 years of experience, HURCO offers individual solutions as well as the industry's fastest CNC control MAX ®5. As an efficient international manufacturer, our high-quality products are used in the aerospace, mechanical engineering, medical technology and energy industries as well as in transport and computer technology.

Our vision has always been to create a CNC control system that enables companies to program CNC machines quickly, thereby realizing shorter setup times and significantly increasing profitability.

3-AXIS-MACHINING CENTERS

-

Efficient processing with HURCO - 3-Axis-Machining Centers

Whether you call it a milling machine, a machining center, or a machine tool, Hurco has the right CNC equipment to make your business more profitable. In fact, each machine tool we manufacture and each control feature we develop is designed with customer profitability as the top objective. While there are numerous reasons to choose Hurco, the high level benefits of Hurco CNC machine tools are highlighted below. Delivering machining centers that are rigid and reliable is a given. Our manufacturing team is relentless when it comes to quality and attention to detail. Like you, they take pride in what they do. So, you can count on your Hurco CNC machine to last.

3-AXIS-MACHINING CENTERS - Standard

VM 10 i - 3-Axis-Machining Centers

-

Efficient design with a small footprint.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 102 - 610

- Table working surface W x D (mm): 762 x 406

- T-Slots (DIN 650): 3 x 18 H8 x 100

- Load max. (uniform distribution) (kg): 1500

- Travels

- X-Axis (mm): 660

- Y-Axis (mm): 406

- Z-Axis (mm): 508

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 10,000

- Spindle Power (kW): 11

- Spindle Torque max. (Nm): 74

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 28 / 28 / 28

- Automatic Tool Changer

- Number of stations: 24

- Tool diameter max. (mm): 80

- Tool length max. (mm): 250

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 3,264 x 2,930 x 2,564

- Machine weight (kg): 2,850

- Content coolant tank (l): 62

- Chip auger: Optional

- Table

- FACTS AND FIGURES

VM 10 i Plus - 3-Axis-Machining Centers

-

The plus in display and technical features optimizes ease of use and efficiency.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 102 - 610

- Table working surface W x D (mm): 762 x 406

- T-Slots (DIN 650): 3 x 18 H8 x 100

- Load max. (uniform distribution) (kg): 1500

- Travels

- X-Axis (mm): 660

- Y-Axis (mm): 406

- Z-Axis (mm): 508

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 12,000

- Spindle Power (30min Rating) (kW): 11

- Spindle Torque (30min Rating) (Nm): 61

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 28 / 28 / 28

- Automatic Tool Changer

- Number of stations: 24

- Tool diameter max. (mm): 80

- Tool length max. (mm): 250

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 3,264 x 3,384 x 2,564

- Machine weight (kg): 2,850

- Content coolant tank (l): 108

- Chip auger: Standard

- Table

- FACTS AND FIGURES

VM 20 i - 3-Axis-Machining Centers

-

Exceptional large travels for complex maching applications.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 102 - 610

- Table working surface W x D (mm): 1,168 x 508

- T-Slots (DIN 650): 5 x 18 x 100

- Load max. (uniform distribution) (kg): 1800

- Travels

- X-Axis (mm): 1,016

- Y-Axis (mm): 508

- Z-Axis (mm): 508

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 10,000

- Spindle Power (kW): 15

- Spindle Torque max. (Nm): 99

- Retention knob: ISO 7388/II B

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 28 / 28 / 28

- Automatic Tool Changer

- Number of stations: 24

- Tool diameter max. (mm): 80

- Adjacent sides empty (mm): 120

- Tool length max. (mm): 250

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 3,722 x 3,312 x 2,542

- Machine weight (kg): 4,150

- Content coolant tank (l): 122

- Chip auger: Optional

- Table

- FACTS AND FIGURES

VM 20 i Plus - 3-Axis-Machining Centers

-

The plus in display and technical features optimizes ease of use and efficiency.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 102 - 610

- Table working surface W x D (mm): 1,168 x 508

- T-Slots (DIN 650): 5 x 18 x 100

- Load max. (uniform distribution) (kg): 1800

- Travels

- X-Axis (mm): 1,016

- Y-Axis (mm): 508

- Z-Axis (mm): 508

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 12,000

- Spindle Power (kW): 15

- Spindle Torque max. (Nm): 82

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 28 / 28 / 28

- Automatic Tool Changer

- Number of stations: 24

- Tool diameter max. (mm): 80

- Tool length max. (mm): 250

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 3,722 x 3,312 x 2,542

- Machine weight (kg): 4,150

- Content coolant tank (l): 200

- Chip auger: Standard

- Table

- FACTS AND FIGURES

VM 30 i - 3-Axis-Machining Centers

-

Large-work envelope for high-performance machining

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 102 - 610

- Table working surface W x D (mm): 1,321 x 508

- T-Slots (DIN 650): 5 x 18 x 100

- Load max. (uniform distribution) (kg): 1800

- Travels

- X-Axis (mm): 1,270

- Y-Axis (mm): 508

- Z-Axis (mm): 508

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 10,000

- Spindle Power (kW): 15

- Spindle Torque max. (Nm): 99

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 28 / 28 / 28

- Automatic Tool Changer

- Number of stations: 24

- Tool diameter max. (mm): 80

- Tool length max. (mm): 250

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 4,086 x 3,312 x 2,543

- Machine weight (kg): 4,250

- Content coolant tank (l): 122

- Chip auger: Optional

- Table

- FACTS AND FIGURES

VM 30 i Plus - 3-Axis-Machining Centers

-

The plus in display and technical features optimizes ease of use aand efficieny.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 102 - 610

- Table working surface W x D (mm): 1,321 x 508

- T-Slots (DIN 650): 5 x 18 x 100

- Load max. (uniform distribution) (kg): 1800

- Travels

- X-Axis (mm): 1,270

- Y-Axis (mm): 508

- Z-Axis (mm): 508

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 12,000

- Spindle Power (kW): 15

- Spindle Torque max. (Nm): 82

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 28 / 28 / 28

- Automatic Tool Changer

- Number of stations: 24

- Tool diameter max. (mm): 80

- Tool length max. (mm): 250

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 4,086 x 3,312 x 2,543

- Machine weight (kg): 4,250

- Content coolant tank (l): 200

- Chip auger: Standard

- Table

- FACTS AND FIGURES

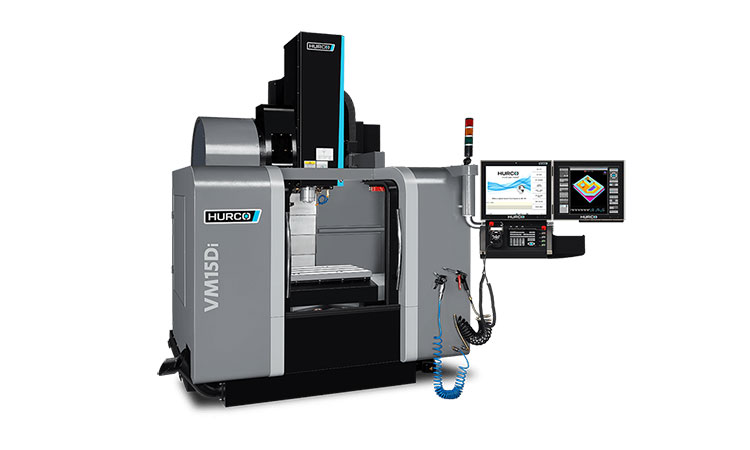

VM 15Di

- Travels

- X-Axis travel (mm): 762

- Y-Axis travel (mm): 407

- Z-Axis travel (mm): 508

- Table

- Spindle nose – table (mm): 102 - 610

- Table working surface W x D (mm): 900 x 406

- T-Slots (DIN 650): 3 x 18mm x 100mm

- Load max. (uniform distribution) (kg): 1500

- Spindle

- Spindle Taper (DIN 69871 A): SK 40

- Spindle Speed max. (rpm): 12.000

- Spindle Power (kW): 17

- Spindle Torque max. (Nm): 107

- Retention knob: ISO 7388/II B

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 36 / 36 / 30

- Automatic Tool Changer

- Number of stations: 24

- Tool diameter max. (mm): 80

- Adjacent sides empty (mm): 120

- Tool length max. (mm): 250

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 3.501 x 3.541 x 2.868

- Machine weight (kg): 3.360

- Content coolant tank (l): 200

- Chip auger: Standard

- Travels

3-AXIS-MACHINING CENTERS - High Performance

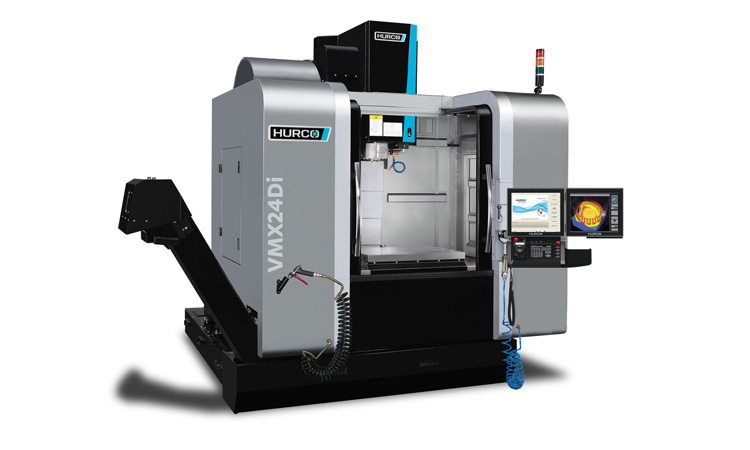

VMX 24 Di - 3-Axis-Machining Centers

-

Big capabilities in a small package.

TABLE

- Spindle nose - table (mm) 152 - 762

- Table working surface W x D (mm) 760 x 510

- T-Slots (DIN 650) 5 x 18 H8 x 100

- Load max. (uniform distribution) (kg) 1.360

TRAVELS

- X-Axis (mm) 660

- Y-Axis (mm) 406

- Z-Axis (mm) 508

SPINDLE

- Spindle Taper (DIN 69871 A) SK40

- Spindle Speed max. (rpm) 15.000

- Spindle Power (kW) 9

- Spindle Torque max. (Nm) 57

FEEDRATES

- Rapid traverse X/Y/Z-Axis (m/min) 38 / 38 / 32

AUTOMATIC TOOL CHANGER

- Number of stations 30 / -

- Tool diameter max. (mm) 80

- Tool length max. (mm) 300

- Tool weight max. (kg) 7

FURTHER DETAILS

- Floor space required (mm) doors open, incl. control unit and chip conveyor 3.930 x 4.046 x 2994

- Machine weight (kg) 4.748

- Scraper type chip conveyor Standard

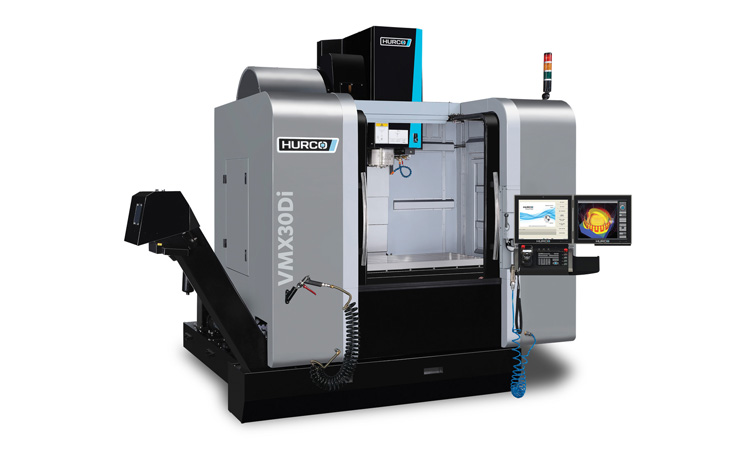

VMX 30 Di - 3-Axis-Machining Centers

-

Intelligent design and sophsticated technology.

TABLE

- Spindle nose - table (mm) 152 - 762

- Table working surface W x D (mm) 1.020 x 510

- T-Slots (DIN 650) 5 x 18 H7 x 100

- Load max. (uniform distribution) (kg) 1.360

TRAVELS

- X-Axis (mm) 762

- Y-Axis (mm) 508

- Z-Axis (mm) 610

SPINDLE

- Spindle Taper (DIN 69871 A) SK40

- Spindle Speed max. (rpm) 15.000

- Spindle Power (kW) 15

- Spindle Torque max. (Nm) 96

FEEDRATES

- Rapid traverse X/Y/Z-Axis (m/min) 38 / 38 / 32

AUTOMATIC TOOL CHANGER

- Number of stations 30 / 40

- Tool diameter max. (mm) 80 / 76

- Tool length max. (mm) 300

- Tool weight max. (kg) 7

FURTHER DETAILS

- Scraper type chip conveyor Standard

VMX 42 Di - 3-Axis-Machining Centers

-

The CNC workhorse for high performance and flexibility.

TABLE

- Spindle nose - table (mm) 152 - 762

- Table working surface W x D (mm) 1.270 x 610

- T-Slots (DIN 650) 6 x 18 H8 x 100

- Load max. (uniform distribution) (kg) 1.360

TRAVELS

- X-Axis (mm) 1.067

- Y-Axis (mm) 610

- Z-Axis (mm) 610

SPINDLE

- Spindle Taper (DIN 69871 A) SK40

- Spindle Speed max. (rpm) 15.000

- Spindle Power (kW) 15

- Spindle Torque max. (Nm) 96

FEEDRATES

- Rapid traverse X/Y/Z-Axis (m/min) 38 / 38 / 32

AUTOMATIC TOOL CHANGER

- Number of stations 30 / 40

- Tool diameter max. (mm) 80 / 76

- Tool length max. (mm) 300

- Tool weight max. (kg) 7

FURTHER DETAILS

- Floor space required (mm) doors open, incl. control unit and chip conveyor 4.572 x 3.713 x 3.048

- Machine weight (kg) 6.500 / 6.809

- Scraper type chip conveyor Standard

VMX 50 Di - 3-Axis-Machining Centers

-

Performance and flexibility for demanding applications

TABLE

- Spindle nose - table (mm) 101 - 711

- Table working surface W x D (mm) 1.500 x 660

- T-Slots (DIN 650) 6 x 18 x 100

- Load max. (uniform distribution) (kg) 1.818

TRAVELS

- X-Axis (mm) 1.270

- Y-Axis (mm) 660

- Z-Axis (mm) 610

SPINDLE

- Spindle Taper (DIN 69871 A) SK 40

- Spindle Speed max. (rpm) 15.000

- Spindle Power (kW) 22

- Spindle Torque max. (Nm) 140

FEEDRATES

- Rapid traverse X/Y/Z-Axis (m/min) 32 / 32 / 24

AUTOMATIC TOOL CHANGER

- Number of stations 30 / 40

- Tool diameter max. (mm) 80 / 76

- Tool length max. (mm) 300

- Tool weight max. (kg) 7

FURTHER DETAILS

- Floor space required (mm) doors open, incl. control unit and chip conveyor 5.066 x 4.032 x 3.216

- Machine weight (kg) 9.080

- Scraper type chip conveyor Standard

VMX 24 i - 3-Axis-Machining Centers

-

Big capabilities in a small package.

- TABLE

- Spindle nose - table (mm): 152 - 762

- Table working surface W x D (mm): 760 x 510

- T-Slots (DIN 650): 5 x 18 H8 x 100

- Load max. (uniform distribution) (kg): 1500

- TRAVELS

- X-Axis (mm): 610

- Y-Axis (mm): 508

- Z-Axis (mm): 610

- SPINDLE

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 12.000

- Spindle Power (kW): 9

- Spindle Torque max. (Nm): 95

- FEEDRATES

- Rapid traverse X/Y/Z-Axis (m/min): 38 / 38 / 32

- AUTOMATIC TOOL CHANGER

- Number of stations: 30

- Tool diameter max. (mm): 80

- Tool length max. (mm): 300

- Tool weight max. (kg): 7

- FURTHER DETAILS

- Floor space required (mm) doors open, incl. control unit and chip conveyor: 3.930 x 4.041 x 2.725

- Machine weight (kg): 4.750

- Content coolant tank (l): 367

- Scraper type chip conveyor: Standard

- TABLE

VMX 30 i - 3-Axis-Machining Centers

-

- Table

- Spindle nose – table (mm): 152 - 762

- Table working surface W x D (mm): 1.020 x 510

- T-Slots (DIN 650): 5 x 18 x 100

- Load max. (uniform distribution) (kg): 1.500

- Travels

- X-Axis (mm): 762

- Y-Axis (mm): 508

- Z-Axis (mm): 610

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 12.000

- Spindle Power (kW): 13.4

- Spindle Torque max. (Nm): 214

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 38 / 38 / 32

- Automatic Tool Changer

- Number of stations: 30 / 40

- Tool diameter max. (mm): 80 / 76

- Tool length max. (mm): 300

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 3.939 x 4.059 x 2.724

- Machine weight (kg): 5.050

- Content coolant tank (l): 366

- Scraper type chip conveyor: Standard

- Table

VMX 42 i - 3-Axis-Machining Centers

-

The CNC workhorse for high performance and flexibility.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 152 - 762

- Table working surface W x D (mm): 1.270 x 610

- T-Slots (DIN 650): 5 x 18 x 100

- Load max. (uniform distribution) (kg): 1.750

- Travels

- X-Axis (mm): 1.067

- Y-Axis (mm): 610

- Z-Axis (mm): 610

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 12.000

- Spindle Power (kW): 18

- Spindle Torque max. (Nm): 239

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 38 / 38 / 32

- Automatic Tool Changer

- Number of stations: 30 / 40

- Tool diameter max. (mm): 80 / 76

- Tool length max. (mm): 300

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 4.572 x 3.708 x 2.945

- Machine weight (kg): 6.850

- Content coolant tank (l): 484

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

VMX 50 i - 3-Axis-Machining Centers

-

Power and flexibility for demanding applications.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 101 - 711

- Table working surface W x D (mm): 1.500 x 660

- T-Slots (DIN 650): 6 x 18 x 100

- Load max. (uniform distribution) (kg): 2.000

- Travels

- X-Axis (mm): 1.270

- Y-Axis (mm): 660

- Z-Axis (mm): 610

- Spindle

- Spindle Taper (DIN 69871 A): SK40 / SK50

- Spindle Speed max. SK40 (rpm): 12.000

- Spindle Speed max. SK50 (rpm): 8.000

- Spindle Power (kW): 18 (SK40) / 22 (SK50)

- Spindle Torque max. SK40 (Nm): 239

- Spindle Torque max. SK50 (Nm): 353

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 32 / 32 / 24

- Automatic Tool Changer

- Number of stations: 30 / 40 (SK40) // 30 (SK50)

- Tool diameter max. (mm): 80 / 75 (SK40) // 125 (SK50)

- Tool length max. (mm): 300

- Tool weight max. (kg): 7 (SK40) / 15 (SK50)

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 5.059 x 3.921 x 3.240 (SK40) / 5.049 x 4.378 x 3.014 (SK50)

- Machine weight (kg): 7.650 (SK40) / 9.150 (SK50)

- Content coolant tank (l): 894

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

VMX 60 i - 3-Axis-Machining Centers

-

High performance for any machining application.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 102 - 711

- Table working surface W x D (mm): 1.680 x 660

- T-Slots (DIN 650): 6 x 18 H8 x 100

- Load max. (uniform distribution) (kg): 2.000

- Travels

- X-Axis (mm): 1.524

- Y-Axis (mm): 660

- Z-Axis (mm): 610

- Spindle

- Spindle Taper (DIN 69871 A): SK40 / SK50

- Spindle Speed max. SK40 (rpm): 12.000

- Spindle Speed max. SK50 (rpm): 8.000

- Spindle Power (kW): 18 (SK40) / 22 (SK50)

- Spindle Torque max. SK40 (Nm): 239

- Spindle Torque max. SK50 (Nm): 353

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 32 / 32 / 24

- Automatic Tool Changer

- Number of stations: 30 / 40 / 60 (SK40) // 30 (SK50)

- Tool diameter max. (mm): 80 / 75 / 75 (SK40) // 125 (SK50)

- Tool length max. (mm): 300

- Tool weight max. (kg): 7 (SK40) / 15 (SK50)

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 5.607 x 3.936 x 3.240

- Machine weight (kg): 8.650 (SK40) / 9.850 (SK50)

- Content coolant tank (l): 894

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

VMX 64 i - 3-Axis-Machining Centers

-

The speed, accuracy and reliability you need.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 127 - 890

- Table working surface W x D (mm): 1.676 x 889

- T-Slots (DIN 650): 7 x 18 x 125

- Load max. (uniform distribution) (kg): 2.722

- Travels

- X-Axis (mm): 1.625

- Y-Axis (mm): 864

- Z-Axis (mm): 762

- Spindle

- Spindle Taper (DIN 69871 A): SK40 / SK50

- Spindle Speed max. (rpm): 12.000 (SK40) / 8.000 (SK50)

- Spindle Power (kW): 18 (SK40) / 22 (SK50)

- Spindle Torque max. (Nm): 239 (SK40) / 353 (SK50)

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 18 / 18 / 13.5

- Automatic Tool Changer

- Number of stations: 30 / 40 / 96 (SK40) // 32 (SK50)

- Tool diameter max. (mm): 80 / 76 / 95 (SK40) // 125 (SK50)

- Tool length max. (mm): 300 / 300 / 280 (SK40) // 300 (SK50)

- Tool weight max. (kg): 7 (SK40) / 15 (SK50)

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 6.338 x 4.496 x 3.335

- Machine weight (kg): 14.600 / 15.000 / 15.500 (SK40) // 14.600 (SK50)

- Content coolant tank (l): 836

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

VMX 84 i - 3-Axis-Machining Centers

-

Premium components and meticulous manufacturing extend the machine's service life.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 127 - 887

- Table working surface W x D (mm): 2.185 x 865

- T-Slots (DIN 650): 7 x 18 H8 x 125

- Load max. (uniform distribution) (kg): 2.270

- Travels

- X-Axis (mm): 2.135

- Y-Axis (mm): 865

- Z-Axis (mm): 762

- Spindle

- Spindle Taper (DIN 69871 A): SK40 / SK50

- Spindle Speed max. (rpm): 12.000 (SK40) / 8.000 (SK50)

- Spindle Power (kW): 18 (SK40) / 22 (SK50)

- Spindle Torque max. (Nm): 239 (SK40) / 353 (SK50)

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 18 / 18 / 13.5

- Automatic Tool Changer

- Number of stations: 40 (SK40) / 32 (SK50)

- Tool diameter max. (mm): 75 (SK40) / 125 (SK50)

- Tool length max. (mm): 300

- Tool weight max. (kg): 7 (SK40) / 15 (SK50)

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 7.574 x 4.450 x 3.310

- Machine weight (kg): 17.000

- Content coolant tank (l): 867

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

VMX 6030 i - 3-Axis-Machining Centers

-

High performance for any machining application

- FACTS AND FIGURES

- Travels

- X-Axis travel (mm): 1.524

- Y-Axis travel (mm): 762

- Z-Axis travel (mm): 610

- Table

- Spindle nose – table (mm): 101 - 711

- Table working surface W x D (mm): 1.680 x 762

- T-Slots (DIN 650): 7 x 18 H8 x 100

- Load max. (uniform distribution) (kg): 2.000

- Spindle

- Spindle Taper (DIN 69871 A): SK40 / SK50

- Spindle Speed max. SK40 (rpm): 12.000

- Spindle Speed max. SK50 (rpm): 8.000

- Spindle Power (kW): 18 (SK40) / 22 (SK50)

- Spindle Torque max. SK40 (Nm): 239

- Spindle Torque max. SK50 (Nm): 353

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 32 / 32 / 24

- Cutting Feedrate X-Axis / Y-Axis / Z-Axis (m/min): 32 / 32 / 24

- Automatic Tool Changer

- Number of stations: 40 (SK40) // 30 (SK50)

- Tool diameter max. (mm): 75 (SK40) // 120 (SK50)

- Tool length max. (mm): 300

- Tool weight max. (kg): 7 (SK40) / 15 (SK50)

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 5.606 x 4.085 x 3.345

- Machine weight (kg): 11.450 (SK40) / 11.700 (SK50)

- Scraper type chip conveyor: Standard

- Travels

- FACTS AND FIGURES

3-AXIS-MACHINING CENTERS - High Speed

- Premium components and expert design.

VMX 10 HSi Plus - 3-Axis-Machining Centers

-

The plus in display and technical features optimizes ease of use and efficiency.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 102 - 610

- Table working surface W x D (mm): 762 x 406

- T-Slots (DIN 650): 3 x 18 x 100

- Load max. (uniform distribution) (kg): 1500

- Travels

- X-Axis (mm): 661

- Y-Axis (mm): 407

- Z-Axis (mm): 508

- Spindle

- Spindle Taper (DIN 69893): BT-30

- Spindle Speed max. (rpm): 20.000 / 30.000

- Spindle Power (30min Rating) (kW): 9

- Spindle Torque (30min Rating) (Nm): 5 / 3

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 28 / 28 / 28

- Automatic Tool Changer

- Number of stations: 20

- Tool diameter max. (mm): 80

- Tool length max. (mm): 250

- Tool weight max. (kg): 3

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 3.204 x 3.395 x 2.564

- Machine weight (kg): 3.150

- Content coolant tank (l): 107

- Chip auger: Standard

- Table

- FACTS AND FIGURES

VMX 24 HSi - 3-Axis-Machining Centers

-

Built to withstand the rigors of high speed machining.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 152 - 762

- Table working surface W x D (mm): 760 x 510

- T-Slots (DIN 650): 5 x 18 H8 x 100

- Load max. (uniform distribution) (kg): 1.500

- Travels

- X-Axis (mm): 610

- Y-Axis (mm): 508

- Z-Axis (mm): 610

- Spindle

- Spindle Taper (DIN 69893): HSK63A

- Spindle Speed max. (rpm): 20.000

- Spindle Power (kW): 35

- Spindle Torque max. (Nm): 119

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 45 / 45 / 40

- Automatic Tool Changer

- Number of stations: 30

- Tool diameter max. (mm): 80

- Tool length max. (mm): 300

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 3.930 x 4.041 x 2.773

- Machine weight (kg): 4.900

- Content coolant tank (l): 367

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

VMX 30 HSi - 3-Axis-Machining Centers

-

Built for speed, accuracy and repeatibility.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 152 - 762

- Table working surface W x D (mm): 1.020 x 510

- T-Slots (DIN 650): 5 x 18 x 100

- Load max. (uniform distribution) (kg): 1500

- Travels

- X-Axis (mm): 762

- Y-Axis (mm): 508

- Z-Axis (mm): 610

- Spindle

- Spindle Taper (DIN 69893): HSK63A

- Spindle Speed max. (rpm): 20.000

- Spindle Power (kW): 35

- Spindle Torque max. (Nm): 119

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 45 / 45 / 40

- Automatic Tool Changer

- Number of stations: 30 / 40

- Tool diameter max. (mm): 80 / 76

- Tool length max. (mm): 300

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 3.940 x 4.042 x 2.773

- Machine weight (kg): 5.000

- Content coolant tank (l): 367

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

VMX 42 HSi - 3-Axis-Machining Centers

-

Ideal high-speed machining for mold making

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 152 - 762

- Table working surface W x D (mm): 1.270 x 610

- T-Slots (DIN 650): 5 x 18 x 100

- Load max. (uniform distribution) (kg): 1.750

- Travels

- X-Axis (mm): 1.067

- Y-Axis (mm): 610

- Z-Axis (mm): 610

- Spindle

- Spindle Taper (DIN 69893): HSK63A

- Spindle Speed max. (rpm): 20.000

- Spindle Power (kW): 35

- Spindle Torque max. (Nm): 119

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 45 / 45 / 40

- Automatic Tool Changer

- Number of stations: 40

- Tool diameter max. (mm): 75

- Tool length max. (mm): 300

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 4.600 x 3.718 x 2.982

- Machine weight (kg): 7.100

- Content coolant tank (l): 484

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

5-AXIS-MACHINING CENTERS

-

Full support of 5-sided simultaneous machining

A rigid machine that is fully compatible with all CAD/CAM packages for simultaneous 5-axis machining forms a minimum requirement for complex simultaneous 5-axis parts. Hurco has all that and more. We have control features that optimize CAM programs to reduce file size, improve surface finish, and reduce cycle time. You will also appreciate the fast processing speed and generous 2 GB RAM. 5-AXIS-MACHINING CENTERS - Swivel Head and Rotary Table

- Swivel head/ Rotary table machine designed for high mix manufacturing.

VMX 42 SRTi - 5-Axis-Machining Centers

-

Swivel head/ rotary machine designed for high mix manufacturing.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 9 - 619

- Working Surface / Rotary-Diameter (mm): 1.270 x 610 / 600

- T-Slots (DIN 650): 5 x 18 x 100

- Tableload max. / Rotaryload (uniform distribution) (kg): 1.360 / 500

- Travels

- X-Axis (mm): 1.067

- Y-Axis (mm): 610

- Z-Axis (mm): 610

- B-Axis (°): +/- 90

- C-Axis (°): 360

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 12.000 / opt. 16.000

- Spindle Power (kW): 36,5

- Spindle Torque max. (Nm): 118

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 38 / 38 / 32

- Rapid traverse B-Axis / C-Axis (rpm): 50 / 100

- Automatic Tool Changer

- Number of stations: 40

- Tool diameter max. (mm): 75

- Tool length max. (mm): 250

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 4.954 x 3.767 x 3.187

- Machine weight (kg): 8.400

- Content coolant tank (l): 314

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

VMX 60 SRTi - 5-Axis-Machining Centers

-

Huge travels and swivel head/ Rotary design for high-mix manufacturing.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 12 - 622

- Working Surface / Rotary-Diameter (mm): 1.680 x 660 / 600

- T-Slots (DIN 650): 6 x 18 x 100

- Load max. (uniform distribution) (kg): 1.360 / 500

- Travels

- X-Axis (mm): 1.524

- Y-Axis (mm): 660

- Z-Axis (mm): 610

- B-Axis (°): +/-90

- C-Axis (°): 360

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 12.000 / opt. 16.000

- Spindle Power (kW): 36,5

- Spindle Torque max. (Nm): 118

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 32 / 32 / 24

- Rapid traverse B-Axis / C-Axis (rpm): 50 / 100

- Automatic Tool Changer

- Number of stations: 40

- Tool diameter max. (mm): 75

- Tool length max. (mm): 250

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 5.662 x 3.921 x 3.298

- Machine weight (kg): 10.900

- Content coolant tank (l): 848

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

5-AXIS-MACHINING CENTERS - Integrated Trunnion Table

- Power, speed and unbeatable value - the ideal machine for medium-sized parts.

VM 10 Ui Plus - 5-Axis-Machining Centers

-

Power, speed and unbeatable value - the ideal machine for small-sized 5-axis-parts.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 36 - 519

- Faceplate- / Partdiameter max. (mm): 198 / 320

- T-Slots (DIN 650): 6 x 10

- Tableload max. / Rotaryload (uniform distribution) (kg): 150

- Travels

- X-Axis (mm): 533

- Y-Axis (mm): 406

- Z-Axis (mm): 483

- A-Axis (°): +30 / -110

- C-Axis (°): 360

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 12.000

- Spindle Power (kW): 11

- Spindle Torque max. (Nm): 61

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 28 / 28 / 28

- Rapid traverse A-Axis / C-Axis (rpm): 25 / 25

- Automatic Tool Changer

- Number of stations: 24

- Tool diameter max. (mm): 80

- Tool length max. (mm): 250

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 3.264 x 3.379 x 2.714

- Machine weight (kg): 2.850

- Content coolant tank (l): 108

- Chip auger: Standard

- Table

- FACTS AND FIGURES

VMX 30 Ui - 5-Axis-Machining Centers

-

Power, speed and unbeatable value - the ideal machine for medium-sized 5-axis parts.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 90 - 610

- Faceplate- / Partdiameter max. (mm): 250 / 435

- T-Slots (DIN 650): 6 x 12

- Load max. (uniform distribution) (kg): 200

- Travels

- X-Axis (mm): 760

- Y-Axis (mm): 510

- Z-Axis (mm): 520

- A-Axis (°): +30 / -110

- C-Axis (°): 360

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 12.000

- Spindle Power (kW): 13.4

- Spindle Torque max. (Nm): 215

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 38 / 38 / 32

- Rapid traverse A-Axis / C-Axis (rpm): 25 / 25

- Automatic Tool Changer

- Number of stations: 40

- Tool diameter max. (mm): 76

- Tool length max. (mm): 300

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 3.940 x 4.041 x 2.864

- Machine weight (kg): 5.500

- Content coolant tank (l): 265

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

VMX 30 UDi - 5-Axis-Machining Centers

-

Power, speed and unbeatable value - the ideal machine for medium-sized 5-axis parts.

- FACTS AND FIGURES

- Travels

- X-Axis travel (mm): 762

- Y-Axis travel (mm): 508

- Z-Axis travel (mm): 520

- A-Axis travel (°): +30 / -110

- C-Axis travel (°): 360

- Table

- Spindle nose – table (mm): 90 - 610

- Faceplate- / Partdiameter max. (mm): 248 / 435

- T-Slots (DIN 650): 6 x 12

- Load max. (uniform distribution) (kg): 200

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 15.000

- Spindle Power (kW): 15

- Spindle Torque max. (Nm): 95.5

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 38 / 38 / 32

- Rapid traverse A-Axis / C-Axis (rpm): 25 / 25

- Automatic Tool Changer

- Number of stations: 40

- Tool diameter max. (mm): 76

- Tool length max. (mm): 300

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 3.940 x 4.058 x 3.166

- Machine weight (kg): 5.500

- Content coolant tank (l): 367

- Scraper type chip conveyor: Standard

- Travels

- FACTS AND FIGURES

VMX 42 Ui - 5-Axis-Machining Centers

-

5-axis workhorse packed with industry leading technologies.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 90 - 610

- Faceplate- / Partdiameter max. (mm): 398 / 535

- T-Slots (DIN 650): 6 x 14

- Load max. (uniform distribution) (kg): 250

- Travels

- X-Axis (mm): 1.067

- Y-Axis (mm): 610

- Z-Axis (mm): 520

- A-Axis (°): +30 / -110

- C-Axis (°): 360

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 12.000

- Spindle Power (kW): 18

- Spindle Torque max. (Nm): 239

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 38 / 38 / 32

- Rapid traverse A-Axis / C-Axis (rpm): 25 / 25

- Automatic Tool Changer

- Number of stations: 40

- Tool diameter max. (mm): 75

- Tool length max. (mm): 300

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 4.600 x 3.718 x 3.111

- Machine weight (kg): 7.200

- Content coolant tank (l): 510

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

VC 500 i - 5-Axis-Machining Centers

-

Trunnion table 5-axis makes 5-sided machining easy.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 150 - 550

- Faceplate- / Partdiameter max. (mm): 500 / 625

- T-Slots (DIN 650): 5 x 14 x 100

- Load max. (uniform distribution) (kg): 250

- Travels

- X-Axis (mm): 520

- Y-Axis (mm): 450

- Z-Axis (mm): 400

- B-Axis (°): +110 / -110

- C-Axis (°): 360

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 12.000

- Spindle Power (kW): 13

- Spindle Torque max. (Nm): 82

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 28 / 28 / 28

- Rapid traverse B-Axis / C-Axis (rpm): 25 / 25

- Automatic Tool Changer

- Number of stations: 30 / 40

- Tool diameter max. (mm): 80 / 75

- Tool length max. (mm): 250

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 4.592 x 3.604 x 2.955

- Machine weight (kg): 8.400

- Content coolant tank (l): 320

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

VMX42 UDi - 5-Axis-Machining Centers

-

- FACTS AND FIGURES

- Travels

- X-Axis travel (mm): 1.067

- Y-Axis travel (mm): 610

- Z-Axis travel (mm): 520

- A-Axis travel (°): +30 / -110

- C-Axis travel (°): 360

- Table

- Spindle nose – table (mm): 63 - 583

- Faceplate- / Partdiameter max. (mm): 398 / 535

- T-Slots (DIN 650): 6 x 14mm x 60°

- Load max. (uniform distribution) (kg): 250

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 15.000

- Spindle Power (kW): 15

- Spindle Torque max. (Nm): 96

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 45 / 45 / 40

- Rapid traverse A-Axis / C-Axis (rpm): 25 / 25

- Automatic Tool Changer

- Number of stations: 40 / 60

- Tool diameter max. (mm): 75

- Tool length max. (mm): 300

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 4.578 x 3.719 x 3.237

- Machine weight (kg): 7.200

- Content coolant tank (l): 510

- Scraper type chip conveyor: Standard

- Travels

- FACTS AND FIGURES

VCX 600 i XP - 5-Axis-Machining Centers

-

Trunnion table 5-axis makes 5-sided machning easy

- FACTS AND FIGURES

- Travels

- X-Axis travel (mm): 820

- Y-Axis travel (mm): 550

- Z-Axis travel (mm): 500

- B-Axis travel (°): -110 / +110

- C-Axis travel (°): 360

- Spindle

- Spindle Taper (DIN 69871 A): SK-40

- Spindle Speed max. (rpm): 12000

- Spindle Power (S6) (kW): 16

- Spindle Torque (S6) (Nm): 102

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 36 / 36 / 36

- Rapid traverse B-Axis (rpm): 50

- Rapid traverse B-Axis / C-Axis (rpm): 100

- Cutting Feedrate X-Axis / Y-Axis / Z-Axis (m/min): 36 / 36 / 36

- Axis Thrust X-Axis / Y-Axis / Z-Axis (kN): 22.4 / 22.4 / 22.4

- Automatic Tool Changer

- Number of stations: 40

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 4,482 / 4,635 / 3,217

- Machine weight (kg): 10,000

- Travels

- FACTS AND FIGURES

5-AXIS-MACHINING CENTERS - Swivel Head

- Huge travels with swivel head and optional Rotary A-axis or C-axis.

VMX 42 SWi - 5-Axis-Machining Centers

-

4-axis swivel head machine with optional rotary a-axis or C-axis-available.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 152 - 762

- Table working surface W x D (mm): 1,270 x 610

- T-Slots (DIN 650): 5 x 18 x 100

- Load max. (uniform distribution) (kg): 1,360

- Travels

- X-Axis (mm): 1,067

- Y-Axis (mm): 610

- Z-Axis (mm): 610

- B-Axis (°): +/- 90

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 12,000 / opt. 16,000

- Spindle Power (kW): 36.5

- Spindle Torque max. (Nm): 118

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 38 / 38 / 32

- Rapid traverse B-Axis (rpm): 50

- Automatic Tool Changer

- Number of stations: 40

- Tool diameter max. (mm): 76

- Tool length max. (mm): 250

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 4,598 x 3,713 x 3,149

- Machine weight (kg): 7,130

- Content coolant tank (l): 340

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

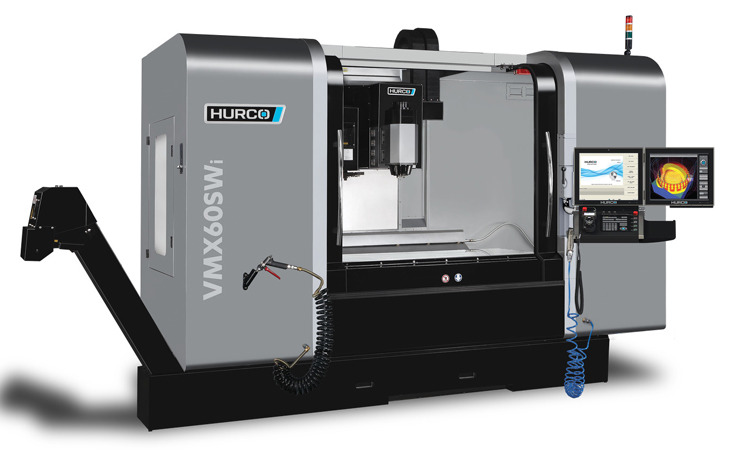

VMX 60 SWi - 5-Axis-Machining Centers

-

Huge travels with swivel head and optinal rotary A-axis or C-axis.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 102 - 711

- Table working surface W x D (mm): 1,680 x 660

- T-Slots (DIN 650): 6 x 18 x 100

- Load max. (uniform distribution) (kg): 2,000

- Travels

- X-Axis (mm): 1,524

- Y-Axis (mm): 660

- Z-Axis (mm): 610

- B-Axis (°): +/- 90

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 12,000 / opt. 16,000

- Spindle Power (kW): 36.5

- Spindle Torque max. (Nm): 120

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 32 / 32 / 24

- Rapid traverse B-Axis (rpm): 90

- Cutting Feedrate X-Axis / Y-Axis / Z-Axis (m/min): 32 / 32 / 24

- Axis Thrust X-Axis / Y-Axis / Z-Axis (kN): 22.7 / 22.7 / 35.3

- Automatic Tool Changer

- Number of stations: 40 / 60

- Tool diameter max. (mm): 75

- Tool length max. (mm): 250

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 5,606 x 3,930 x 3,378

- Machine weight (kg): 9,900

- Content coolant tank (l): 848

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

VMX 84 SWi - 5-Axis-Machining Centers

-

Huge travels with swivel head and optional A-axis or C-axis.

- FACTS AND FIGURES

- Travels

- X-Axis travel (mm): 2,134

- Y-Axis travel (mm): 864

- Z-Axis travel (mm): 762

- B-Axis travel (°): +/- 90

- Table

- Spindle nose – table (mm): 127 - 889

- Table working surface W x D (mm): 2,184 x 865

- T-Slots (DIN 650): 7 x 18 x 125

- Load max. (uniform distribution) (kg): 2,268

- Spindle

- Spindle Taper (DIN 69871 A): SK40

- Spindle Speed max. (rpm): 12,000

- Spindle Power (kW): 36.5

- Spindle Torque max. (Nm): 120

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 18 / 18 / 13.5

- Rapid traverse B-Axis (rpm): 50

- Automatic Tool Changer

- Number of stations: 40 / -

- Tool diameter max. (mm): 76

- Tool length max. (mm): 250

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 7,557 / 4,501 / 3,163

- Machine weight (kg): 16,750

- Content coolant tank (l): 1,046

- Scraper type chip conveyor: Standard

- Travels

- FACTS AND FIGURES

PORTAL MACHINING CENTERS

Double-Column 3-Axis-Machining-Centers

- Premium components and expert design.

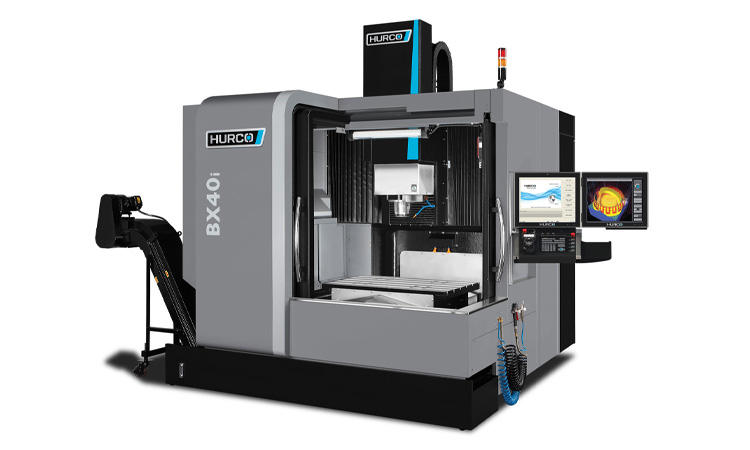

BX 40 i - Double-Column 3-Axis-Machining-Centers

-

High speed and accuracy for tight tolerances.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 178 - 678

- Table working surface W x D (mm): 1,050 x 700

- T-Slots (DIN 650): 6 x 18 H8 x 125

- Load max. (uniform distribution) (kg): 1,000

- Travels

- X-Axis (mm): 1,020

- Y-Axis (mm): 700

- Z-Axis (mm): 500

- Spindle

- Spindle Taper (DIN 69893): HSK63A

- Spindle Speed max. (rpm): 20,000

- Spindle Power (kW): 35

- Spindle Torque max. (Nm): 119

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 36 / 36 / 36

- Automatic Tool Changer

- Number of stations: 30 / 50

- Tool diameter max. (mm): 75

- Tool length max. (mm): 300

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 4,048 x 3,485 x 3,144

- Machine weight (kg): 9,100

- Content coolant tank (l): 647

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

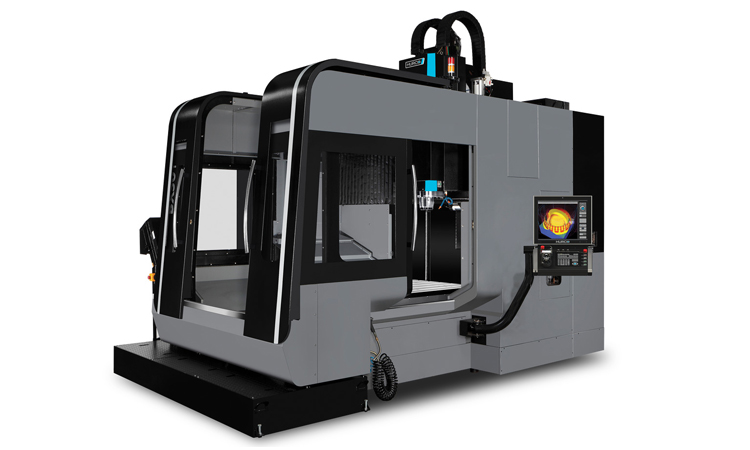

BX 50 i - Double-Column 3-Axis-Machining-Centers

-

Stability combines with exceptional accuracy and outstandidng surface finish capabilities.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 200 - 780

- Table working surface W x D (mm): 1,360 x 960

- T-Slots (DIN 650): 6 x 22 x 160

- Load max. (uniform distribution) (kg): 2,000

- Travels

- X-Axis (mm): 1,250

- Y-Axis (mm): 950

- Z-Axis (mm): 580

- Spindle

- Spindle Taper (DIN 69893): HSK63A

- Spindle Speed max. (rpm): 20,000

- Spindle Power (kW): 35

- Spindle Torque max. (Nm): 119

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 36 / 36 / 36

- Automatic Tool Changer

- Number of stations: 30 / 50

- Tool diameter max. (mm): 80 / 75

- Tool length max. (mm): 300

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 4,344 x 4,096 x 2,929

- Table

- FACTS AND FIGURES

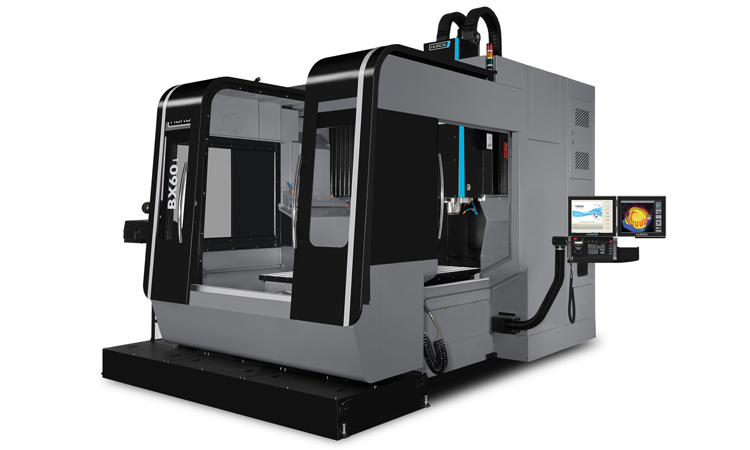

BX 60 i - Double-Column 3-Axis-Machining-Centers

-

Stability combines with exceptional accuracy and outstandidng surface finish capabilities.

- FACTS AND FIGURES

- Table

- Spindle nose – table (mm): 180 - 880

- Table working surface W x D (mm): 1,900 x 1,300

- T-Slots (DIN 650): 8 x 22 x 160

- Load max. (uniform distribution) (kg): 6,000

- Travels

- X-Axis (mm): 1,600

- Y-Axis (mm): 1,300

- Z-Axis (mm): 700

- Spindle

- Spindle Taper (DIN 69893): HSK 63A

- Spindle Speed max. (rpm): 20,000

- Spindle Power (kW): 35

- Spindle Torque max. (Nm): 119

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 36 / 36 / 36

- Automatic Tool Changer

- Number of stations: 30 / 50

- Tool diameter max. (mm): 80 / 75

- Tool length max. (mm): 300

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 5,398 x 5,256 x 3,800

- Machine weight (kg): 20,000

- Table

- FACTS AND FIGURES

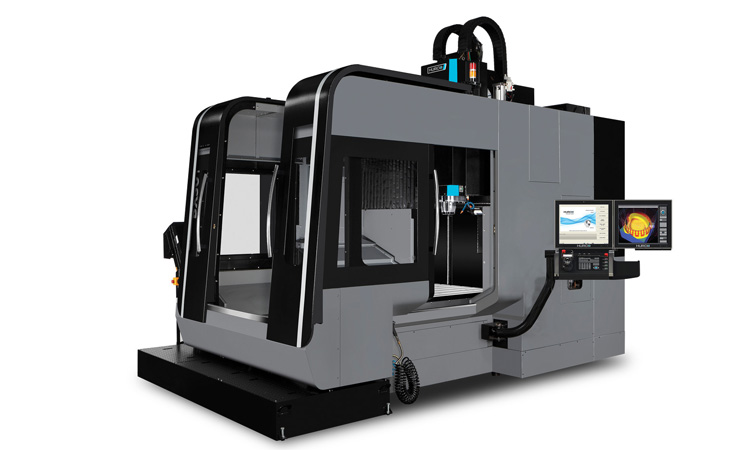

BX 50 Ti - Double-Column 3-Axis-Machining-Centers

-

Stability - combined with accuracy and high surface quality

- FACTS AND FIGURES

- Travels

- X-Axis travel (mm): 1,350

- Y-Axis travel (mm): 950

- Z-Axis travel (mm): 600

- Table

- Spindle nose – table (mm): 180 - 780

- Table working surface W x D (mm): 1,500 x 960

- T-Slots (DIN 650): 6 x 22 x 160

- Load max. (uniform distribution) (kg): 2,500

- Spindle

- Spindle Taper (DIN 69871 A): SK 50

- Spindle Speed max. (rpm): 10,000

- Spindle Power (kW): 26

- Spindle Torque max. (Nm): 336

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 36 / 36 / 36

- Automatic Tool Changer

- Number of stations: 40

- Tool diameter max. (mm): 125

- Adjacent sides empty (mm): 220

- Tool length max. (mm): 300

- Tool weight max. (kg): 15

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 4,640 x 5,244 x 3,561

- Machine weight (kg): 13,000

- Content coolant tank (l): 790

- Travels

- FACTS AND FIGURES

CNC 5-AXIS PORTAL MACHINING CENTERS

- Flexible yet high-performance milling - that's what our portal machining centers with rotary swivel table or 2-axis fork head make possible.

BX 40 Ui

-

The Hurco BX40Ui CNC - machining center in portal design with rotating swivel table is the perfect combination of performance and flexibility.

- FACTS AND FIGURES

- Travels

- X-Axis travel (mm): 950

- Y-Axis travel (mm): 550

- Z-Axis travel (mm): 500

- B-Axis travel (°): -30 / +110

- C-Axis travel (°): 360

- Table

- Faceplate- / Partdiameter max. (mm): 348 / 535

- T-Slots (DIN 650): 6 x 14mm x 60°

- Load max. (uniform distribution) (kg): 250

- Spindle

- Spindle Taper (DIN 69893): HSK 63-A

- Spindle Speed max. (rpm): 18,000

- Spindle Power (kW): 35

- Spindle Torque max. (Nm): 119

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 36 / 36 / 36

- Rapid traverse B-Axis / C-Axis (rpm): 25 / 25

- Automatic Tool Changer

- Number of stations: 30 / 50

- Tool diameter max. (mm): 76

- Tool length max. (mm): 300

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 4,187 / 3,705 / 2,885

- Machine weight (kg): 9,400

- Content coolant tank (l): 557

- Scraper type chip conveyor: Standard

- Travels

- FACTS AND FIGURES

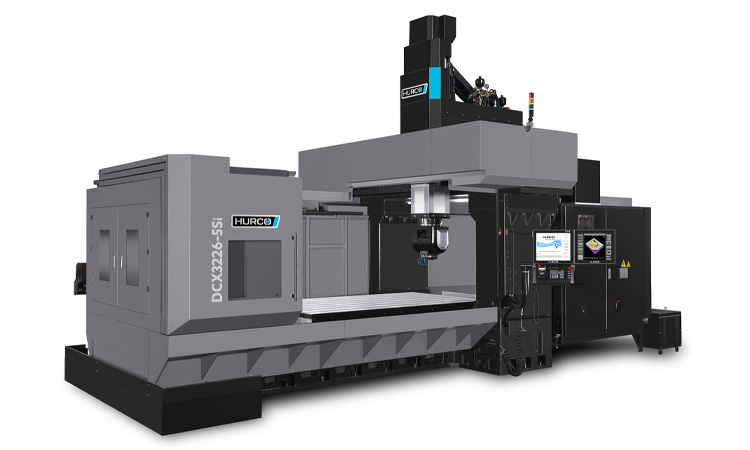

DCX 32-5 Si

-

Vertical 5-axis gantry machining center

- FACTS AND FIGURES

- Travels

- X-Axis travel (mm): 3,200

- Y-Axis travel (mm): 2,100

- Z-Axis travel (mm): 900

- B-Axis travel (°): +100 / -110

- C-Axis travel (°): ±360

- Table

- Spindle nose – table (mm): 66 - 966

- Table working surface W x D (mm): 3000 x 1700

- T-Slots (DIN 650): 7 x 22 H8 x 220

- Load max. (uniform distribution) (kg): 11,000

- Spindle

- Spindle Taper: HSK63-A

- Spindle Speed max. (rpm): 18,000

- Spindle Power (kW): 63

- Spindle Torque max. (Nm): 106

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 15 / 15 / 10

- Rapid traverse B-Axis / C-Axis (rpm): 120 / 80

- Cutting Feedrate X-Axis / Y-Axis / Z-Axis (m/min): 10 / 10 / 10

- Axis Thrust X-Axis / Y-Axis / Z-Axis (kN): 61 / 41.5 / 40.6

- Automatic Tool Changer

- Number of stations: 40 / 60

- Tool diameter max. (mm): 76

- Tool length max. (mm): 300

- Tool weight max. (kg): 7

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 9,982 x 6815 x 5250

- Machine weight (kg): 37,700

- Content coolant tank (l): 1,470

- Scraper type chip conveyor: Standard

- Chip auger: Standard

- Travels

- FACTS AND FIGURES

DCX 3226 HT-5 Si

-

Vertical 5-axis gantry machining center

- FACTS AND FIGURES

- Travels

- X-Axis travel (mm): 3,200

- Y-Axis travel (mm): 2,450

- Z-Axis travel (mm): 1,100

- B-Axis travel (°): ±110

- C-Axis travel (°): ±360

- Table

- Spindle nose – table (mm): 201 - 1,301

- Table working surface W x D (mm): 3,000 x 2,100

- T-Slots (DIN 650): 9 x 22mm x 220mm

- Load max. (uniform distribution) (kg): 14,000

- Spindle

- Spindle Taper (DIN 69893): HSK-A100

- Spindle Speed max. (rpm): 12,000

- Spindle Power (S6 - 40%) (kW): 53

- Spindle Torque (S6 - 40%) (Nm): 253

- Max Tool Length (mm): 300

- Max Tool Diameter (mm): 240

- Max Tool Weight (kg): 30

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis (m/min): 15 / 15 / 10

- Cutting Feedrate X-Axis / Y-Axis / Z-Axis (m/min): 15 / 15 / 10

- Automatic Tool Changer

- Number of stations: 40 / 60

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 10,382 / 7,165 / 6,263

- Travels

- FACTS AND FIGURES

HORIZONTAL MACHINING CENTERS & HORIZONTAL BORING MILLS FROM HURCO

4-AXIS MACHINING CENTERS AND HORIZONTAL BORING MILLS DIRECT FROM THE MANUFACTURER. FOR PERFECTION ALL ALONG THE AXIS.

HURCO's horizontal machining centers and horizontal boring mills are unrivaled in performance, speed and are the ideal machines for 4-axis horizontal machining of workpieces. We have been a machine tool manufacturer since 1968. As a result, we know exactly how different the manufacturing requirements for CNC milling machines can be. With our horizontal machining centers and horizontal boring mills, your workpieces will meet every requirement for maximum precision.

HORIZONTAL CNC BORING MILLS Our horizontal 4-axis boring mills impress with their efficiency, accuracy and high productivity. The stable cast iron construction of the machine ensures high rigidity and stability of the linear guides in all axes. The B axis can be used as a full NC axis for machining particularly complex workpieces. Depending on the model, our horizontal boring mills can withstand table loads of between 4,000 and 10,000 kg, have a spindle speed of 1,500 to 2,500 rpm with a spindle power of 30 kW, and a 60- or 90-fold tool changer. In addition, each boring mill has individual unique selling points. Our HBMX 80 i horizontal boring mill, for example, is particularly space-saving despite its size, as it has a small footprint.

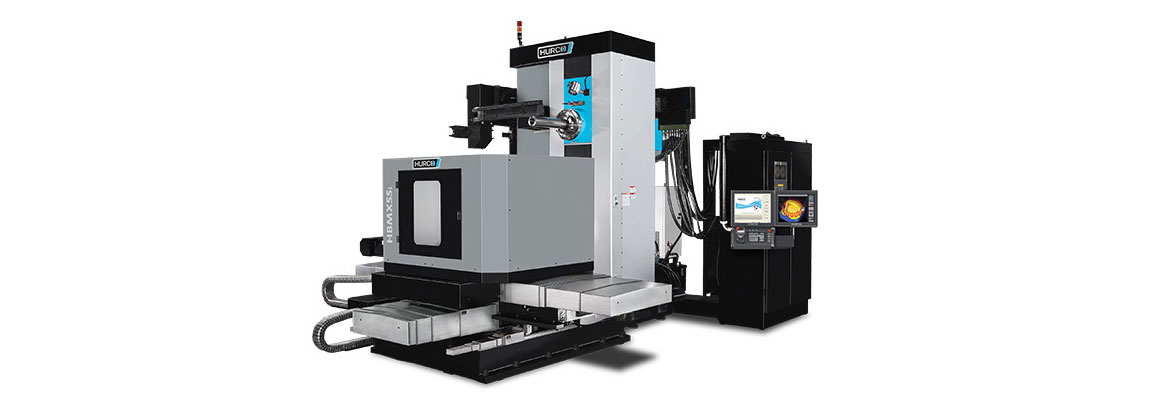

HBMX 55i

-

Efficiency and precision at the highest technical level

- FACTS AND FIGURES

- Table

- Spindle nose - table center (mm): 0 - 1,555

- Table working surface W x D (mm): 1,120 x 1,250

- T-Slots (DIN 650): 7 x 24 x 160

- Load max. (uniform distribution) (kg): 4,000

- Travels

- X-Axis (mm): 1,400

- Y-Axis (mm): 1,390

- Z-Axis (mm): 1,100

- W-Axis (mm): 500

- Spindle

- Spindle Taper (DIN 69871 A): SK50

- Spindle Speed max., gear range 1 / 2 (1/min): 454 / 2,500

- Spindle Power (S6 / S1) (kW): 30 / 22

- Spindle Torque max., gear range 1 / 2 (Nm): 1,500 / 412

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis / W-Axis (m/min): 10 / 10 / 10 / 4

- Rapid traverse B-Axis (rpm): 1

- Automatic Tool Changer

- Number of stations: 60

- Tool diameter max. (mm): 120

- Tool length max. (mm): 400

- Tool weight max. (kg): 25

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 5,597 x 5,272 x 3,370

- Machine weight (kg): 19,500

- Content coolant tank (l): 500

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

HBMX 80i

- FACTS AND FIGURES

- Table

- Spindle nose - table center (mm): 130 - 2,280

- Table working surface W x D (mm): 1,440 x 1,600

- T-Slots (DIN 650): 9 x 24 x 160

- Load max. (uniform distribution) (kg): 6,300

- Travels

- X-Axis (mm): 2,000

- Y-Axis (mm): 1,780

- Z-Axis (mm): 1,650

- W-Axis (mm): 500

- Spindle

- Spindle Taper (DIN 69871 A): SK50

- Spindle Speed max., gear range 1 / 2 (1/min): 454 / 2,500

- Spindle Power (S6) (kW): 30

- Spindle Torque max., gear range 1 / 2 (Nm): 1,500 / 412

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis / W-Axis (m/min): 10 / 10 / 10 / 4

- Rapid traverse B-Axis (rpm): 1

- Automatic Tool Changer

- Number of stations: 60 / 90

- Tool diameter max. (mm): 120

- Tool length max. (mm): 400

- Tool weight max. (kg): 25

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 6,711 x 5,781 x 3,765

- Machine weight (kg): 23,500

- Content coolant tank (l): 500

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

HBMX 120i

- FACTS AND FIGURES

- Table

- Spindle nose - table center (mm): 130 - 2,280

- Table working surface W x D (mm): 1,440 x 1,600

- T-Slots (DIN 650): 9 x 24 x 160

- Load max. (uniform distribution) (kg): 6,300

- Travels

- X-Axis (mm): 3,000

- Y-Axis (mm): 1,780

- Z-Axis (mm): 1,650

- W-Axis (mm): 500

- Spindle

- Spindle Taper (DIN 69871 A): SK50

- Spindle Speed max., gear range 1 / 2 (1/min): 454 / 2,500

- Spindle Power (kW): 30

- Spindle Torque max., gear range 1 / 2 (Nm): 1,500 / 412

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis / W-Axis (m/min): 10 / 10 / 10 / 4

- Rapid traverse B-Axis (rpm): 1

- Automatic Tool Changer

- Number of stations: 60 / 90

- Tool diameter max. (mm): 120

- Tool length max. (mm): 400

- Tool weight max. (kg): 25

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 6,729 x 6,711 x 3,765

- Machine weight (kg): 26,000

- Content coolant tank (l): 500

- Scraper type chip conveyor: Standard

- Table

- FACTS AND FIGURES

TURNING CENTERS

Universal Turning Centers

- Power and Speed - the ideal machines for turning medium sized parts.

TM 6 i - Universal Turning Centers

-

Tiny footprint for a powerful slant-bed lathe.

- FACTS AND FIGURES

- Travels

- X-Axis (mm): 168

- Z-Axis (mm): 356

- Machine Capacity

- Turning diameter max. (mm): 215

- Swing over bed diameter (mm): 405

- Swing over cross slide diameter (mm): 240

- Spindle

- Spindle Speed max. (1/min): 6,000

- Spindle Torque max. (Nm): 114

- Chuck diameter (mm): 169

- Spindle Power max. (kW): 13

- Draw Tube Diameter (mm): 45

- Feedrates

- Rapid traverse X-Axis / Z-Axis (m/min): 30 / 30

- Turret

- Type: VDI 20

- Stations: 12

- Boring Bar Diameter max. (mm): 32

- Tool Shank Width (mm): 19

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 3,916 x 2,525 x 2,144

- Machine weight (kg): 3,250

- Travels

- FACTS AND FIGURES

TM 8 i - Universal Turning Centers

-

Short run versatility on a slant-bed lathe.

- FACTS AND FIGURES

- Travels

- X-Axis (mm): 203

- Z-Axis (mm): 550

- Machine Capacity

- Turning diameter max. (mm): 256

- Swing over bed diameter (mm): 525

- Swing over cross slide diameter (mm): 300

- Spindle

- Spindle Speed max. (1/min): 4,000

- Spindle Torque max. (Nm): 221

- Chuck diameter (mm): 210

- Spindle Power max. (kW): 23

- Draw Tube Diameter (mm): 64.5

- Feedrates

- Rapid traverse X-Axis / Z-Axis (m/min): 30 / 30

- Turret

- Type: VDI 30

- Stations: 12

- Boring Bar Diameter max. (mm): 32

- Tool Shank Width (mm): 19

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 4,489 x 2,729 x 2,193

- Machine weight (kg): 4,050

- Travels

- FACTS AND FIGURES

TM 10 i - Universal Turning Centers

-

The perfect combination of size and functionality.

- FACTS AND FIGURES

- Travels

- X-Axis (mm): 250

- Z-Axis (mm): 790

- Machine Capacity

- Turning diameter max. (mm): 304

- Swing over bed diameter (mm): 582

- Swing over cross slide diameter (mm): 402

- Spindle

- Spindle Speed max. (1/min): 3,000

- Spindle Torque max. (Nm): 351

- Chuck diameter (mm): 260

- Spindle Power max. (kW): 22

- Draw Tube Diameter (mm): 81

- Feedrates

- Rapid traverse X-Axis / Z-Axis (m/min): 30 / 30

- Turret

- Type: VDI 40

- Stations: 12

- Boring Bar Diameter max. (mm): 40

- Tool Shank Width (mm): 25

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 5,032 x 2,854 x 2,233

- Machine weight (kg): 5,050

- Travels

- FACTS AND FIGURES

TM 12 i - Universal Turning Centers

-

Specifically created to withstand the rigors of heavy cuts.

- FACTS AND FIGURES

- Travels

- X-Axis (mm): 305

- Z-Axis (mm): 1,016

- Machine Capacity

- Turning diameter max. (mm): 395

- Swing over bed diameter (mm): 680

- Swing over cross slide diameter (mm): 510

- Spindle

- Spindle Speed max. (1/min): 2,800

- Spindle Torque max. (Nm): 605

- Chuck diameter (mm): 305

- Spindle Power max. (kW): 55

- Draw Tube Diameter (mm): 104

- Feedrates

- Rapid traverse X-Axis / Z-Axis (m/min): 30 / 30

- Turret

- Type: VDI 40

- Stations: 12

- Boring Bar Diameter max. (mm): 40

- Tool Shank Width (mm): 25

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 6,227 x 3,225 x 2,305

- Machine weight (kg): 7,500

- Travels

- FACTS AND FIGURES

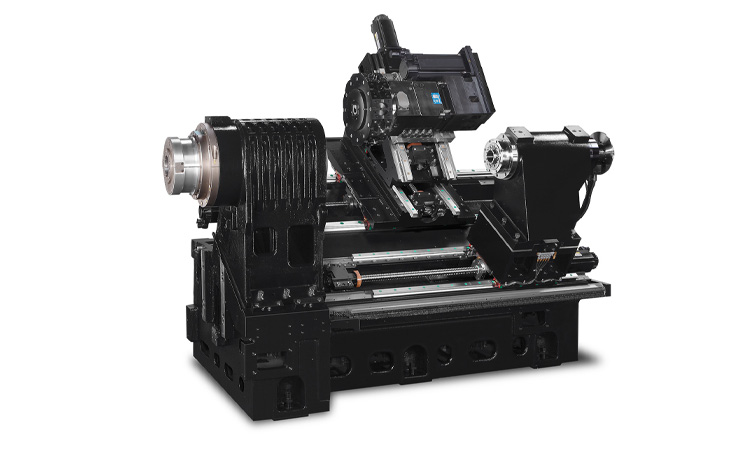

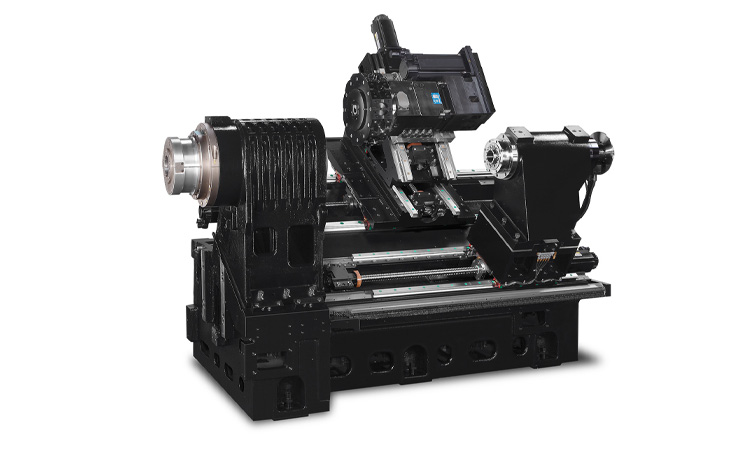

Multi-Axis

-

Open source interface - our basis for your individual automation solution Automation makes life easier - this also applies to CNC machining and the metal and plastics processing industry. To maximize the efficiency of your production and get the most out of your CNC machines, we support you in automating your HURCO machine - for even faster performance, satisfied customers and higher sales.

HURCO machines can be connected to almost all robotics and automation solutions for CNC machine tools via an open source interface. We advise you on the way to individual automation and work closely with renowned suppliers to combine all the advantages of automation in a customized implementation for your production: AMF, BMO, Erowa, , FMB, Indunorm, Kösters Maschinenbau, Lang Technik, Pro Cobots, Robojob, Universal Robots, Zero Clamp and many more. With our team of application engineering employees, experienced machining specialists are available to advise you on the introduction of CNC automation and support you in the digitalization of your manufacturing processes.

TM 8 Mi - Multi-Axis

-

Robust, reliable machine with long service life.

- FACTS AND FIGURES

- Travels

- X-Axis travel (mm): 198

- Z-Axis travel (mm): 550

- Machine Capacity

- Turning diameter max. (mm): 256

- Swing over bed diameter (mm): 525

- Swing over cross slide diameter (mm): 300

- Spindle

- Spindle Speed max. (1/min): 4,000

- Spindle Torque max. (Nm): 264

- Chuck diameter (mm): 210

- Spindle Power max. (kW): 23

- Draw Tube Diameter (mm): 64.5

- Live Tools

- Spindle Speed max. (rpm): 6,000

- Spindle Power (kW): 5

- Spindle Torque max. (Nm): 29

- Feedrates

- Rapid traverse X-Axis / Z-Axis (m/min): 30

- Turret

- Type: VDI 30 / DIN 1809

- Stations: 12

- Boring Bar Diameter max. (mm): 32

- Tool Shank Width (mm): 19 x 19

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 4,466 x 2,812 x 2,192

- Machine weight (kg): 4,400

- Travels

- FACTS AND FIGURES

TM 10 Mi - Multi-Axis

-

Save time-turn and mill on one machine.

- FACTS AND FIGURES

- Travels

- X-Axis travel (mm): 250

- Z-Axis travel (mm): 790

- Machine Capacity

- Turning diameter max. (mm): 295

- Swing over bed diameter (mm): 582

- Swing over cross slide diameter (mm): 402

- Spindle

- Spindle Speed max. (1/min): 3,000

- Spindle Torque max. (Nm): 520

- Chuck diameter (mm): 254

- Spindle Power max. (kW): 40

- Draw Tube Diameter (mm): 81

- Live Tools

- Spindle Speed max. (rpm): 5,000

- Spindle Power (kW): 7.4

- Spindle Torque max. (Nm): 47

- Feedrates

- Rapid traverse X-Axis / Z-Axis (m/min): 30 / 30

- Turret

- Type: VDI 40 - DIN 1809

- Stations: 12

- Boring Bar Diameter max. (mm): 40

- Tool Shank Width (mm): 25 x 25

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 5,008 x 2,910 x 2,233

- Machine weight (kg): 5,450

- Travels

- FACTS AND FIGURES

TM 12 Mi - Multi-Axis

-

Large inclined bed lathe with driven tool.

- FACTS AND FIGURES

- Travels

- X-Axis travel (mm): 305

- Z-Axis travel (mm): 1,016

- Machine Capacity

- Turning diameter max. (mm): 360

- Max. swing over bed (mm): 680

- Swing over cross slide diameter (mm): 510

- Spindle

- Spindle Speed max. (1/min): 2,800

- Spindle Torque max. (Nm): 744

- Chuck diameter (mm): 315

- Spindle Power max. (kW): 40

- Draw Tube Diameter (mm): 104

- Live Tools

- Spindle Speed max. (rpm): 4,000

- Spindle Power (kW): 10

- Spindle Torque max. (Nm): 64

- Feedrates

- Rapid traverse X-Axis / Z-Axis (m/min): 30 / 30

- Turret

- Type: VDI 50 / DIN 1809

- Stations: 12

- Boring Bar Diameter max. (mm): 50

- Tool Shank Width (mm): 32

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 6,227 x 3,225 x 2,305

- Machine weight (kg): 7,500

- Travels

- FACTS AND FIGURES

TMX 8 MYi - Multi-Axis

-

Powerful productivity in alive tooling turning center.

- FACTS AND FIGURES

- Travels

- X-Axis (mm): 285

- Y-Axis (mm): +/- 55

- Z-Axis (mm): 560

- W-Axis (mm): 640

- Machine Capacity

- Turning diameter max. (mm): 336

- Max. swing over bed (mm): 508

- Spindle

- Spindle Speed max. (1/min): 4,500

- Spindle Torque (S6 / S1) (Nm): 239 / 164

- Chuck diameter (mm): 210

- Spindle Power (S6 / S1) (kW): 25 / 17.2

- Draw Tube Diameter (mm): 64.5

- Live Tools

- Spindle Speed max. (rpm): 5,000

- Spindle Power (kW): 6.3

- Spindle Torque max. (Nm): 28

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis / W-Axis (m/min): 24 / 12 / 30 / 30

- Turret

- Type: VDI 40 / DIN 1809

- Stations: 12

- Boring Bar Diameter max. (mm): 40

- Tool Shank Width (mm): 25

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 5,519 x 3,296 x 2,552

- Machine weight (kg): 7,500

- Travels

- FACTS AND FIGURES

TMX 10 MYi - Multi-Axis

-

Mill turn machining with live tools.

- FACTS AND FIGURES

- Travels

- X-Axis (mm): 305

- Y-Axis (mm): +/- 55

- Z-Axis (mm): 670

- W-Axis (mm): 740

- Machine Capacity

- Turning diameter max. (mm): 375

- Max. swing over bed (mm): 560

- Spindle

- Spindle Speed max. (1/min): 3,500

- Spindle Torque (S6 / S1) (Nm): 267 / 229

- Chuck diameter (mm): 260

- Spindle Power (S6 / S1) (kW): 28 / 24

- Draw Tube Diameter (mm): 78

- Live Tools

- Spindle Speed max. (rpm): 5,000

- Spindle Power (kW): 6.3

- Spindle Torque max. (Nm): 28

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis / W-Axis (m/min): 24 / 12 / 30 / 30

- Turret

- Type: VDI 40 / DIN 1809

- Stations: 12

- Boring Bar Diameter max. (mm): 40

- Tool Shank Width (mm): 25

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 5,523 x 3,052 x 2,552

- Machine weight (kg): 7,700

- Travels

- FACTS AND FIGURES

TMX 8 MYSi - Multi-Axis

-

Complete machining with sub spindle.

- FACTS AND FIGURES

- Travels

- X-Axis (mm): 286

- Y-Axis (mm): +/- 55

- Z-Axis (mm): 560

- W-Axis (mm): 640

- Machine Capacity

- Turning diameter max. (mm): 336

- Max. swing over bed (mm): 508

- Spindle

- Spindle Speed max. (1/min): 4,500

- Spindle Torque (S6 / S1) (Nm): 239 / 164

- Chuck diameter (mm): 203

- Spindle Power (S6 / S1) (kW): 25 / 17.2

- Draw Tube Diameter (mm): 64.5

- Subspindle

- Speeds (1/min): 6,000

- Torque (S6 / S1) (Nm): 102 / 75

- Power (S6 / S1) (kW): 15 / 11

- Live Tools

- Spindle Speed max. (rpm): 5,000

- Spindle Power (kW): 6.3

- Spindle Torque max. (Nm): 28

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis / W-Axis (m/min): 24 / 12 / 30 / 30

- Turret

- Type: VDI 40 / DIN 1809

- Stations: 12

- Boring Bar Diameter max. (mm): 40

- Tool Shank Width (mm): 25

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 5,519 x 3,296 x 2,552

- Machine weight (kg): 7,500

- Travels

- FACTS AND FIGURES

TMX 10 MYSi - Multi-Axis

-

Built for speed and repeatibility.

- FACTS AND FIGURES

- Travels

- X-Axis (mm): 305

- Y-Axis (mm): +/- 55

- Z-Axis (mm): 670

- W-Axis (mm): 740

- Machine Capacity

- Turning diameter max. (mm): 375

- Max. swing over bed (mm): 560

- Spindle

- Spindle Speed max. (1/min): 3,500

- Spindle Torque (S6 / S1) (Nm): 267 / 229

- Chuck diameter (mm): 254

- Spindle Power (S6 / S1) (kW): 28 / 24

- Draw Tube Diameter (mm): 78

- Subspindle

- Speeds (1/min): 6,000

- Torque (S6 / S1) (Nm): 102 / 75

- Power (S6 / S1) (kW): 15 / 11

- Live Tools

- Spindle Speed max. (rpm): 5,000

- Spindle Power (kW): 6.3

- Spindle Torque max. (Nm): 28

- Feedrates

- Rapid traverse X-Axis / Y-Axis / Z-Axis / W-Axis (m/min): 24 / 12 / 30 / 30

- Turret

- Type: VDI 40 / DIN 1809

- Stations: 12

- Boring Bar Diameter max. (mm): 40

- Tool Shank Width (mm): 25

- Further details

- Floor space required (mm) (doors open, incl. control and chip conveyor): 5,523 x 3,052 x 2,552

- Machine weight (kg): 7,700

- Travels

- FACTS AND FIGURES

PROCOBOTS® – THE AUTOMATION SOLUTION FOR REAL DOERS

-

THE AUTOMATION SOLUTION FROM HURCO®: THE PROCOBOTS® ROBOTIC ARM.

Efficiency through automation

Automation in CNC machines aims to increase productivity, shorten loading times, reduce the error rate and thus improve overall efficiency. In this context, automatic loading processes by robots enable personnel capacities to be used more efficiently, for example to prepare new production orders while the current order is being processed automatically.

PROCOBOTS®

-

Advantages of the ProCobot® robotic arm

- The HURCO® Automation Job Manager software is fully integrated into the CNC control system of the HURCO® machines. We have developed the control software so that programming is not done on the robot, but directly on the control system via the HURCO® Automation Job Manager software. This makes your automated CNC lathe or mill with CNC robot arm super smart and super fast ready for use.

- The ProCobots® robot is an attractive solution to the current skills shortage.

- By using the robot, more revenue can be generated with the same amount of personnel.

- Due to the extended machine running times, the ProCobots® can potentially generate €120,000* in turnover.Benefit from the advantages of our ProCobots® automation solution. We support you in automating your CNC machining center for smart manufacturing in no time!

HURCO® CNC CONTROL MAX®5

-

HURCO® CNC control increase profitability - fastest from design to finished part.

Highly profitable and highly precise at the same time - the powerful MAX® 5 CNC control from HURCO® makes it possible. Together with the WINMAX® control software, it forms the CNC control system with the greatest flexibility in the industry for every need in your production - whether you work with CNC turning centers, vertical machining centres or horizontal boring mills. Thanks to HURCO's MAX® 5, you can operate your machines more intuitively than ever before and optimise the use of your expertise and resources. Every function of the control system offers benefits that can be measured in terms of increased productivity. With the MAX® 5 from HURCO®, you get the best out of your machines and increase the profitability of your company in the long term.

Your advantages at a glance

- Accelerates progress from drawing board to machined part

- Quickest user learning curves

- Fastest programming

- Ergonomic design

HURCO® CNC CONTROL MAX®5

-

SPECIAL FEATURES OF THE MAX® 5 CONTROL

- Adjustable keyboard tilt angle

- Solvent-resistant keyboard constructed in ABS polycarbonate

- Extractable keyboard with trackball

- Rotary override knobs in brushed stainless steel

- Two USB ports

- Height-adjustable console for ergonomically correct user convenience

- Removable electronic handwheel including LCD display

SIMPLY SMARTER MILLING WITH THE HURCO® CNC SYSTEM

-

High-quality hardware meets intuitive CNC software with customized options

At HURCO®, we have specialized in developing and manufacturing CNC machining centers for every need for more than 50 years - from cost-saving 3-axis entry-level models to machines for machining highly complex workpieces on 5 axes.

As a manufacturer of CNC machining centers with many years of know-how, we know exactly what the requirements are in machining materials such as milling. Standard solutions are often not sufficient to meet individual requirements in the multitude of machining industries. For this reason, we have developed our own CNC control system: the MAX® 5 control system with WinMax® software. This CNC control system is perfectly matched to your HURCO® machine tool and allows you to get the most out of your production.

The CNC control system from HURCO® combines powerful hardware with user-friendly WinMax® software and optional features. One highlight is Solid Model Import - a convenient function for importing DXF and STEP files that allows you to flexibly adapt your unit of HURCO® machine and control to the conditions in your plant.

Our benefits and services for your CNC machining at a glance

- User-friendly operation. Perfection can be so simple - thanks to intuitive plain-text dialog programming, you set the control precisely according to your requirements.

- Minimal time required. The control system can be learned and operated without any programming knowledge at all and supports your employees optimally with short, clear programs for machining workpieces in the shortest possible time.

- Individual configuration. Choose from a wide range of software features (e.g. Solid Model Import) specifically for your needs, so that your CNC control system from HURCO® fits you exactly.

- High profitability. You'll master even the most demanding part production and higher capacity utilization of your operation in no time.

- Measurable productivity. CNC software features are proven to increase your capacity.

- Improve employee satisfaction. Automate part handling and free up operators for more complex tasks.