TROTEC Laser

Videos

Loading the player ...

- Offer Profile

- Trotec was formed in 1997 from a research branch of Trodat and has since then become a world leader in the field of laser technology. As part of the Trodat Trotec Group, Trotec develops, manufactures and markets laser systems for marking, cutting and engraving, as well as engraving materials. Trotec sets new standards, serves customers in more than 90 countries and has more than 500 employees.

Product Portfolio

Laser Engravers

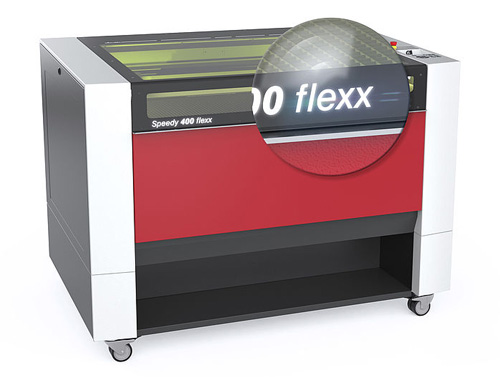

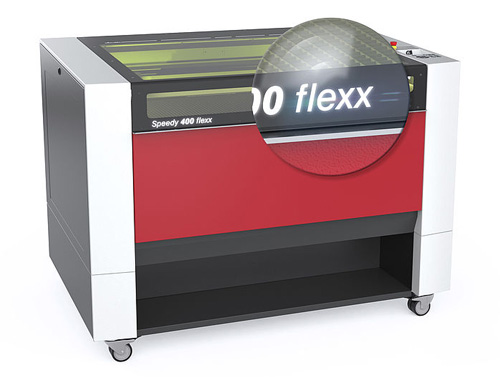

Speedy Series

-

The Speedy is the ideal laser engraving machine - whether you start your business or want to speed up production. Highest quality components ensure minimal maintenance requirements. The patented InPack TechnologyTM provides the highest laser lifetime in the market. The Speedy laser engraver is 100% designed and manufactured in Austria.

Fastest laser engraving machines on the market

Trotec builds the fastest laser engraving machines in the market. Time is money - the minutes spent per laser job are crucial for your business. Increase your production efficiency by processing at maximum speed of 3.55 m/sec and 5g.

Technical data

Laser type: CO₂, Fiber or Flexx laser

Work area: 610 x 305 up to 1016 x 610 mm

Max. workpiece height: 125 - 305 mm

Laser power: 12 - 250 watts / 20 watts MOPA

Benefits of the Speedy laser engravers

Fastest laser engraving machine on the market

- Productivity

by Design

Time is money - the time per laser job is crucial for the success of your business. Increase your production capacity with an engraving speed of 4.2 m/s and 5 g and a laser power of up to 250 watts. Thanks to the OptiMotion™ motion control, cutting jobs are up to six times faster than comparable laser machines on the market.

The patented CeramiCore® laser source technology convinces with reliability, engraving quality and longevity. Thanks to the InPack Technology™, all sensitive components of the laser engraving machine, such as lenses, mirrors or motors, are protected against dust. This results in higher productivity and lower operating costs for you.

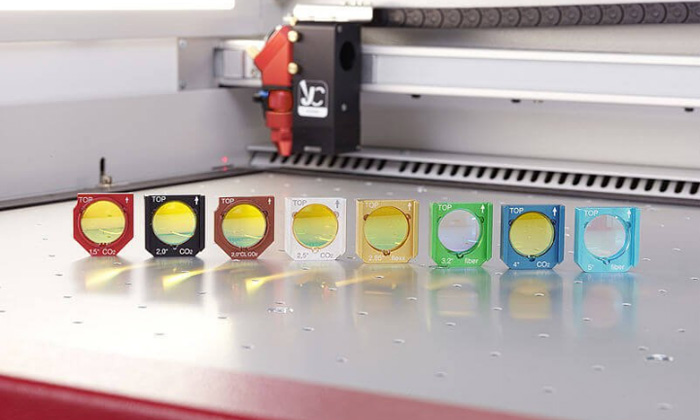

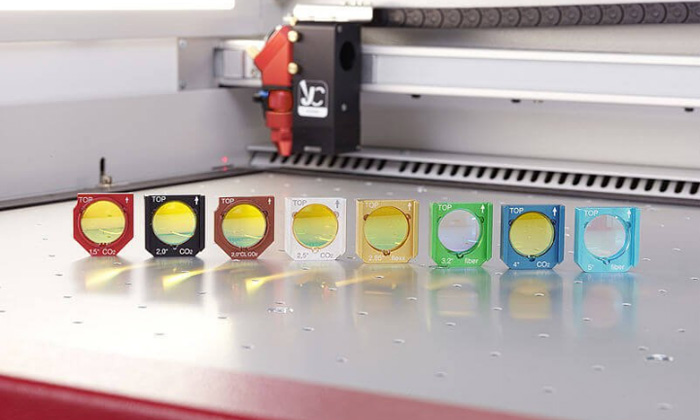

Endless application options thanks to CO2 and fiber lasers in one machine

- Flexibility

by Design

Every conceivable CO2 laser application, as well as an annealing or a metal engraving, can be realized in no time. The MOPA fiber laser offers even more possibilities for laser marking metals and plastics. The special feature of the patented Flexx Technology™: Depending on the material, the two laser sources are activated alternately – in one job, without manual changing of the laser tube, lens or focus.

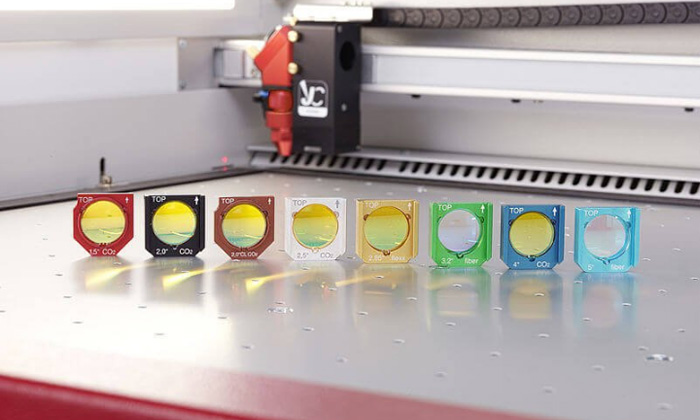

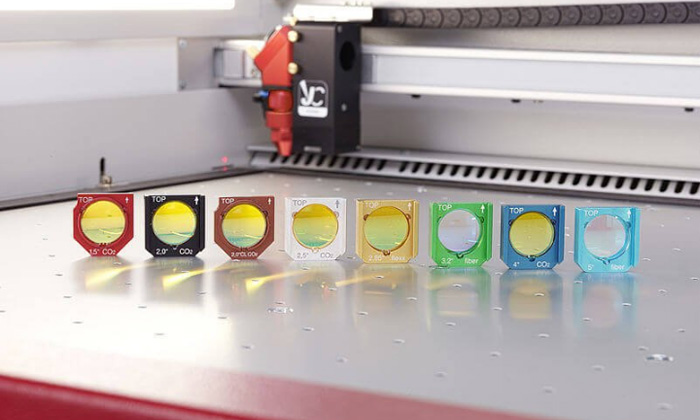

The multi-functional table concept allows the ideal table to be selected and easily switched depending on your application. This ensures the highest processing quality and productivity. Use the modular concept and choose different lenses or other options such as the pass-through or rotary engraving attachment.

Intuitive laser software and easy operation

- Usability by Design

Speedy laser engraving machines are equipped with the most powerful JobControl® laser software. Work in your usual graphics program and simply send your jobs to the laser using a printer driver. Equipped with a variety of options, the software is suitable for both beginners and experienced engravers.

Atmos exhaust systems and Speedy laser engravers create a perfectly matched system, providing a clean and safe complete solution that guarantees easy operation.

Automated focusing at the touch of a button thanks to the patented SonarTechnology™. With the dynamic status display and 100% view of the work area, the status of the laser and processing progress can be seen directly on the machine, thus avoiding unnecessary downtime. Thanks to the ergonomic access, the processing table and materials can be inserted quickly and easily, without straining your back.

Laser Cutters

SP Series

-

The SP Series is the right choice for large format CO₂ laser cutting machines. The highly efficient flatbed laser plotters are ideal for demanding cutting applications in plastics, wood, textiles and many more. The SP Series laser cutters are 100% developed and manufactured in Austria.

Technical data

Laser type: CO₂ laser

Work area: 1245 x 710 up to 3250 x 3210 mm

Max. workpiece height: 50 - 112 mm

Laser power: 40 - 400 watts

Benefits of the SP Series laser cutters

SP laser cutters: Highest level of productivity and user friendliness

- Trotec CO2 laser cutters are designed for fast and

precise processing of large-format materials. Highest laser cutting speed,

the four-sides access and Tandem Assist ensure maximum productivity. Use the

entire work area, with no downtime. Due to high RIP and CAD compatibility

seamless integration of the laser cutter into your workflow is possible.

Accessibility of the working area from all four sides

The working area of the SP3000 and SP2000 laser cutter is designed for large-format materials and high-volume production, and can be easily accessed from all four sides. This allows for fast and ergonomic loading and unloading, even during processing.

Highest level of cutting quality with every application

- Trotec developed an unique, multifunctional table concept for the series of SP laser cutting machines. The ideal table for every application can be selected and replaced easily and quickly. Additional functions for outstanding cutting quality include an exhaust system located directly at the work head, a sectioned exhaust system at the processing table, as well as the option of digital regulation of the compressed air.

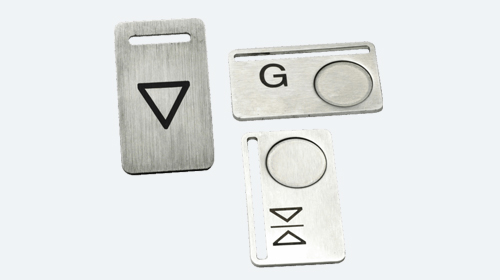

Marking Lasers

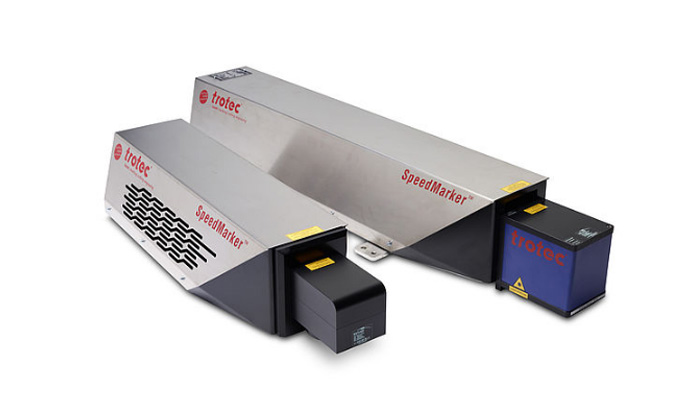

SpeedMarker

-

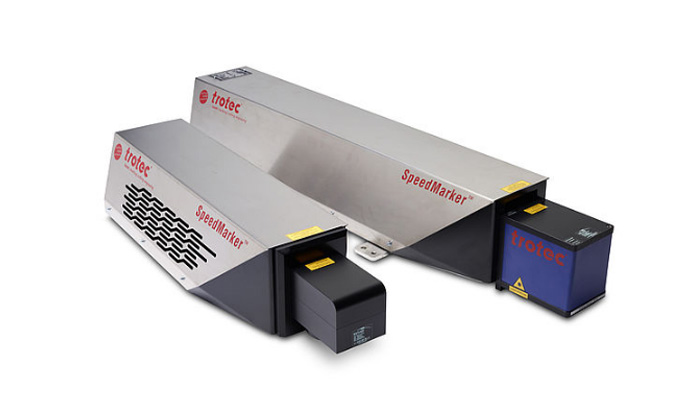

SpeedMarker - High-speed laser marking for industrial applications.

The SpeedMarker galvo laser markers are developed for efficient laser marking of metals and plastics along the industrial production chain. They offer the perfect combination of intelligent software with highest quality hardware. The SpeedMarker laser marking machines are 100% designed and manufactured in Austria and Germany.

Technical data

Laser type: CO₂ or Fiber laser

Max. work area: 190 x 190 up to 1300 x 450 mm

Max. workpiece height: 250 - 764 mm

Laser power: 10 - 50 watts / 20 + 100 watts MOPA

Benefits of the SpeedMarker Galvo Laser Marking Machines

Modular product portfolio

Our galvo lasers are available in different sizes with various configurations to meet individual requirements. Additionally, a broad range of options to customize your laser marking system is available.

Intelligent laser marking software

The SpeedMark software provides program modules for typical laser marking processes. From simple direct input to fully automated workflows, everything is possible - with no need for any special programming knowledge.

Reliability in demanding environments

Thanks to their thoughtful and robust design our laser markers guarantee absolute reliability and precision even in demanding environments. The galvo laser head is practically maintenance free.

ProMarker

-

ProMarker - high speed marking as easy as printing.

The ProMarker laser marking machine offers easy high speed laser marking. It has been designed for marking metal and plastic parts, such as promotional articles, gifts and dataplates. With its printer driver you can operate the laser from your usual graphics software. The ProMarker laser marker is 100% designed and manufactured in Austria.

Technical data

Laser type: Fiber laser

Work area: 180 x 180 mm

Max. workpiece height: 250 - 531 mm

Laser power: 10 - 20 watts

Benefits of the ProMarker Laser Marker

High-speed laser marking

The ProMarker laser marker has been developed for marking large quantities of small- to medium-sized parts. The laser marking machine is able to mark pens, usb-sticks or dataplates in only a few seconds.

As easy as printing

The pre-installed laser software acts like a printer driver and works with all graphics, CAD and label printing software. There is no need to learn a new software program: use your usual graphics software to create a design and send it to the laser using the print command. No converting or data import necessary, just print. All of the settings can be easily adjusted in the print window. The material database contains a wide range of materials and allows you to add your own. Save frequently recurring jobs in a job queue.

Low costs of maintenance

The built-in fiber laser head is practically maintenance free and absolutely reliable. The energy consumption of the laser markers is very low. Costs for consumables, spare parts or laser machine maintenance do not incur.

Business Solution Laser Machines

Paper cutting laser GS

-

Laser system for high-speed laser cutting and high volume paper finishing

Added value for printed materials: Achieve higher profit margins by using laser finishing. Whether business cards, brochures, packaging or labels – use of laser cutting or engraving increases the quality and selling prices of these products. By engraving of logos, individual laser cutting of names and ultra-sophisticated ornaments you set yourself apart from the competition.

Expand your range of services with a laser system

The GS series enables you to create products that would be impossible without a laser system. Expand your range with additional services such as register-accurate contour cutting, finest geometries of engraving or perforation of printed materials. Short runs thus become highly profitable.- High return on investment even with short runs

- Extremely delicate cuts and engravings on paper

Laser type: Galvo CO₂ laser

Work area: 19.6 x 19.6 inch

Laser power: 100 watt, super-pulsed

Laserati DT

-

Specially developed for rubber stamp engraving

The Trotec Laserati is a particularly powerful CO2 laser engraving machine that was specially developed for rubber stamp engraving. During the process, up to 4 DIN A4 laser rubber plates are clamped on a roller and are held in place by a vacuum. Thanks to its special design, this laser machine will engrave an A4 laser rubber page in approximately 20 minutes (engraving depth 1.1 mm). The drum works virtually without wear and tear while delivering an excellent engraving quality.

The benefits of our laser machine- Minimum ongoing maintenance

- Low production times

- High production volumes

- Maximum quality at the same time

Dimensions: 1420 x 850 x 1420 mm / 56" x 34" x 56"

Working area: 840 x 300 mm / 33,1" x 11,7"

Laser type: Sealed-off CO2 laser

Available laser power: 105-220 Watt

Electrical connection: single phase 230V/ 50-60 Hz

SpeedCutter Twin - Stent Laser Cutting System

-

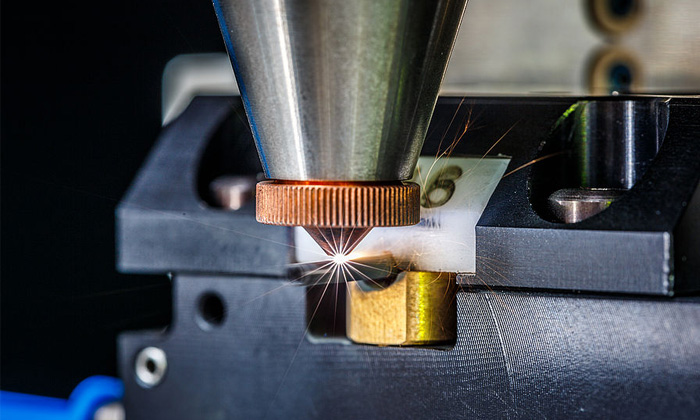

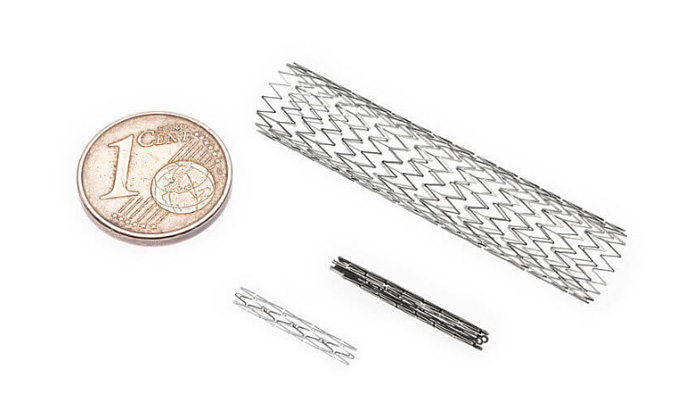

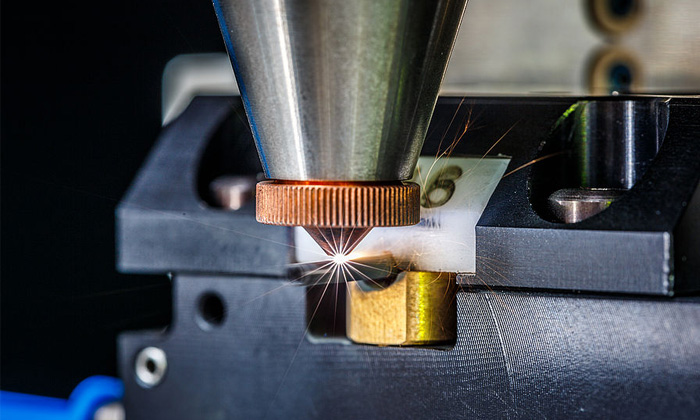

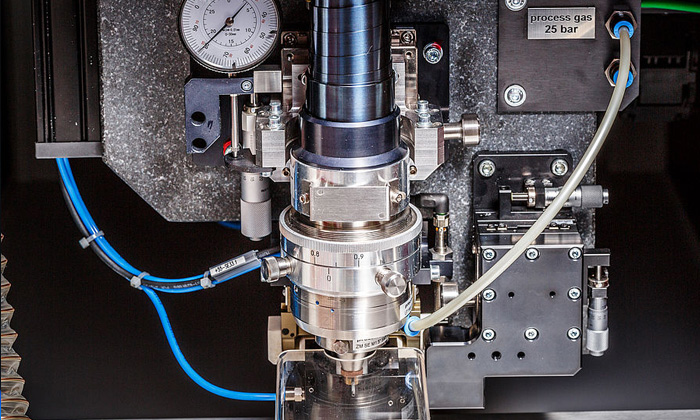

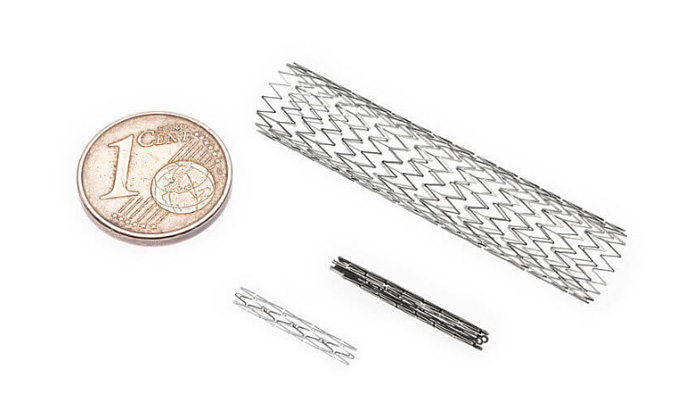

Precision for stent manufacturing

Stent production requires maximum precision. Precision, which only a laser device can provide for cutting tasks. In developing the Speedcutter Twin Trotec has created a unique tool that has revolutionized the manufacture of this kind of implant.

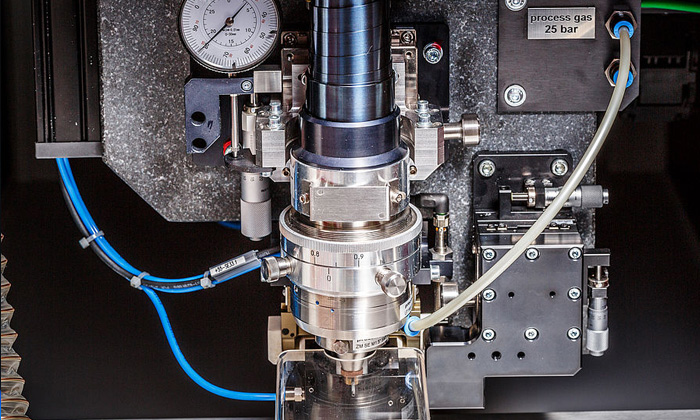

Parallel and automated

As a single laser system for the production of stents the Speedcutter Twin is equipped with two identical air-cooled laser fiber sources capable of cutting two stents simultaneously. Furthermore, lasers distinguish themselves through their absolute reliability with minimal maintenance. The space-saving system is equipped with an innovative automatic loading system that holds the tube being fed in perfectly in focus.

Solid construction for continuous operation

The rugged granite construction of the machine ensures absolute rigidity and therefore greatest repeatability. Consequently, the system can be operated fully automated and produce stents 24 hours a day - a huge economic advantage for the operator, offered by no other system. With the included and already pre-tested and installed intuitive software new geometry settings and stent designs can be created and implemented within a very short period of time. Flexibility for both the manufacturer and customer.

Technical Data

System: Welded steel frame

Fiber laser source: 1065 ± 5 nm; nominal power: 100 – 400 W; cooling system: air cooled (400 W water cooled);

Femtosecond laser: Nominal power 4 – 25 W; pulse width: 400 – 1.000 fs; frequency: 100 – 1.000 kHz

Cutting optics: Lengths of focus: ca. 80 mm; gas pressure: max. 25 bar

OEM marking laser for system integrators

-

Galvo marking laser for integration into existing systems

Specifically for system integrators, Trotec offers the Galvo OEM laser in addition to laser systems. Depending on your requirements and application, you can choose between fiber and CO2 laser sources.

SpeedMarker FL - marking laser for continuous operation in the industrial environment

The SpeedMarker FL (fiber laser) from Trotec can be integrated into existing systems. It is particularly suitable for long-term use - even under the toughest conditions.

ProMarker OEM – laser marking as easy as printing

Alternatively to the SpeedMarker FL, the ProMarker OEM complements the portfolio of Galvo OEM fiber lasers. Unlike the SpeedMarker FL, the ProMarker OEM is controlled by the DirectMark laser software - this works like a printer driver. You can then work using your usual graphics programs and then send the print file to the laser. No previous knowledge is required for the application of the DirectMark printer driver - simply plug & play.

SpeedMarker CL - the high-speed laser for high demands

The SpeedMarker CL (CO2 laser) is characterized by maximum speed and a laser power up to 200 W. With the integrated Galvo laser technology, perfect engravings and cuts can be produced on materials such as wood, paper, plastic, leather, textiles or laminates. The SpeedMarker CL can be easily integrated into existing systems and thus optimally adapts to the requirements of the operation. In addition, the optional third axis gives you maximum precision, even with large working surfaces.

Custom Built Laser Systems

-

Particularly for industry applications Trotec offers individual custom built machines: Standard laser workstations upgraded with modules such as feeders or conveyors as well as fully or semi-automated systems. Our systems are as versatile as your business is varied.

When designing a custom built system, the proven and robust laser workstations usually form the basis, which is expanded by the addition of different modules, such as feeders or sorters. Entirely new systems can also be developed, which always have Trotec's galvo laser technology at their core.

Custom-built SpeedMarker 1300 with palette feeding for marking heavy parts

-

Easy loading of heavy parts with a crane

Trotec experts developed the system to meet the need of a particular customer who needed an easy way to load heavy parts onto a Class 2 laser. The custom laser machine includes palette feeding and an automatically closing side partition so that heavy parts can be easily loaded and unloaded on a palette and then transported into the laser workstation. A coordinated identification and a 3-axis-system (x-, y- and z-axis) enable the laser to make precise markings exactly where they are needed. Additionally, lighter parts can be easily loaded and unloaded via front door.

Laser marking long parts with SpeedMarker 300 and modified substructure

-

Laser marking of pipes and profiles with the SpeedMarker 300

For labeling of long bar stock of extruded aluminum and steel at one end, a Trotec SpeedMarker 300 lettering laser was modified and provided with a support for the parts. The substructure was designed so that the machine corresponds to Laser Class 1 or Laser Class 2 (with laser pointer).

Thus, rails, pipes, and profiles with lengths from 100 to 4000 mm can be laser-marked. Smaller single parts or small batches of other components can be inserted directly into the labeling chamber. The laser marking station can also be used portably, further increasing the flexibility of the laser system. The labeling program is started using a code on a working document, and the variable labeling content is transferred via an ERP database connection to the laser software.

Customized SpeedMarker 700 for laser lettering of long or oversized parts

-

SpeedMarker 700 with parts support for oversized parts

The SpeedMarker 700 laser workstation can also be adapted for laser marking long parts. Long parts can be inserted into an automated feeder. The parts are then moved into the labeling chamber, marked and moved on a conveyor belt. To ensure laser safety, the supply and discharge openings are closed with a cover.

The advantage of this variation is the positioning in the labeling chamber, since it allows labeling not only at one end of the part, but at any position of the component. Alternatively, the system can be designed so that the feeders on both sides can be alternately loaded to increase throughput.

Extrawide workstation

-

SpeedMarker laser marking system with extra-wide casing

In some cases, it is necessary to design an even wider casing for the laser system in order to be able to mark broad and heavy parts.

The system in the picture on the left was designed for the marking rifles, which must be labeled in accordance with specific legal requirements regarding traceability and authorisation. In order to enable the insertion as well as the positioning of these long firearms, the casing was widened accordingly and equipped with a displaceable X- and Z-axis.

SpeedMarker 1300 with numerical controlled exchange tables

-

Loading and laser marking at the same time

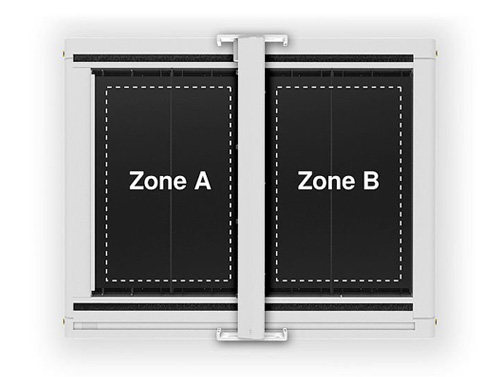

Because the cycle times had to be very short, Trotec designed a custom-built laser system with two moving exchange tables that alternate to allow work pieces to be unloaded and loaded and marked at the same time. In addition, the two y-tables can move parallel when large work pieces need to be laser marked.

The base of this custom-built laser machine is the SpeedMarker 1300. Automation experts adapted the 1300 to include with the exchange tables so that the output could be doubled. With added modules the SpeedMarker quickly and easily became a custom-built laser solution.

SpeedMarker 700 with storage system, seperating unit and tapping point for laser marking ball bearings

-

Fully automated laser marking for components

Trotec developed a fully automated laser workstation with table magazine, separating unit and conveyor belt for the marking of ball bearings. With the laser software SpeedMark, the ball bearings can be marked with production data, country of origin, type identification or the name of the producer. All the relevant data can be directly processed from the customers SAP system. This fast and automated safety class laser marking process enables users to achieve short cycle and setup times.

The ball bearings are loaded to the maintenance-free fibre laser with a separating unit and conveyor belt. As the system is fully covered, the parts can be marked at high speed while laser safety class 2 is guaranteed. The marked bearings are then transported to a storage bin with the conveyor belt where they can be collected and unloaded. Even larger parts or different materials can be marked by using the front housing. The multi-functional laser software SpeedMark is easy to use and can be handled by all employees.

SpeedMarker 300 with Exchange drawer for laser marking type plates

-

Laser solution for efficient type plate labeling

SpeedMarker 300 as desk station with exchange drawer for fast loading and unloading of type plates during laser marking. Different templates for correct loading of different type plates, protection cover for marking of other components.

Individual program surface by advanced scripting: user has individualized user surface Programmed integration of ERP data used to laser mark the type plates with the correct dynamic data such as type code, serial number, but also fluid quantity, pressure, temperature, power, to name a few.

Automated laser workstation for marking of spiral drills

-

Fully automated workstation with conveyor belt

Since spiral drills and other precision tools are produced in very large quantities, the marking process has to be very fast too – ideally in just a few seconds. With a custom-tailored laser workstation all the requirements can be met, and the spiral drills can be marked in two seconds. The high-speed laser marking also has many other advantages such as extremely high and stable quality or highest reliability by using maintenance-free fiber lasers. With the SpeedMark software, it is also possible to mark variable data such as production date and serial numbers – in the form of texts or codes.

Laser marking systems for industrial applications with selective shielding

-

Laser marking of large or bulky parts

While manyworkpieces (smaller pieces in particular) are marked within the confines of protective laser housings with manual or automatic parts feeds, very large or heavy items have different requirements. They can be made of a number of different materials, such as stainless steel or coated metals, and include castings as well as large plastic components or ceramics.The problem is always determining how to enclose these parts into protective housings and how to best align them for marking with the laser. The effort required to set up marking process in plants with these requirements is considerable. Laser markings are often very expensive to produce with these solutions. A single area of selective shielding over the marking area can be a good alternative to large protective housings with automatic laser positioning. Only the area between the beam exit on the lens and the marking surface is protected by means of a protective dome or lens barrel. A sealing lip prevents possible beam exits from the workpiece surface.

Laser workstation SpeedMarker 1300 with loading cart for laser marking high parts

-

Laser marking high parts

Trotec developed a custom workstation for a unique customer requirement. The customer was a printing company in need of a solution for laser marking rotary die cutters and other tool steel cylinders with heights of up to 600 mm. The solution needed to be able to mark the front-end of the cylinders as well as offer the possibility to engrave smaller pieces.

Before working with Trotec, the customer had been using a micro-percussion marking machine for this application, which did not provide the same versatility or efficiency as laser marking. Trotec's custom solution was built using a SpeedMarker 1300 as starting point. A loading cart was added to provide space for the large cylinders. Using the custom laser workstation, the customer can load cylinders with a length of up to 1200 mm, and push them into the laser with the help of the loading cart. A supporting table makes it possible to adapt to the different sizes of the cylinders. The lift gate to load and unload the machine can be opened manually or programmed to open automatically. When the lift gate is closed, the laser marking station can be used in laser protection class 1.

Applications

Acrylic laser cutting

-

Laser cutters for acrylic, plexiglas, TroGlass, Perspex and PMMA

Acrylic (PMMA) is ideal for laser processing projects such as illuminated advertisements, signage, point of sales displays and more. Without any additional post-processing, the laser cuts result in shiny, flame polished edges. Panels up to 25 mm thick can be cut efficiently and cost-effectively. Acrylic can be engraved to create a matted finish with the CO2 laser, or marked to create a color change with the fiber laser.

Suitable materials for laser cutting and engraving- Plexiglas®

- Altuglas®

- Acrylite®

- TroGlass

- Madre Perla®

- Plazit®

- Perspex®

- Quinn®

- Oroglas®

- Plaskolite®

Anodized Aluminum

-

Lasers are a great way to create engravings and markings on anodized aluminum. Depending on the color of the layer, a CO2 laser produces great contrast and a nice, bright engraving, and a fiber laser is a highly effective way to mark anodized aluminum. The MOPA laser can also be used for markings in different shades of gray up to a rich black. The surface is not stripped in the process. The result is comparable to the annealing marking on steel. Used on natural anodized aluminum, in particular, a MOPA laser creates a clearly legible, high-quality marking, that can be applied to smartphones and other items.

Suitable materials for laser engraving and laser marking include:- Anodized aluminum

- Natural anodized aluminum

- Anodized layers in all colors

- Depending on the requirements and application, anodized aluminum can be engraved or marked.

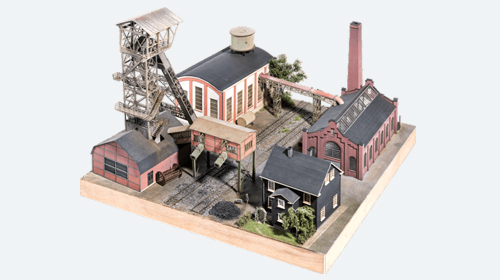

Architectural Models

-

Laser Cutting of Architectural Models and Model Railways

Laser applications in model making

Laser technology in model making - always an advantage

For laser cutting and laser engraving architectural models a wide range of materials are used: textiles, synthetic materials, wood, veneer, MDF, PMMA, cardboard, paper, foam, polystrene, foils and films, acrylic, plastics, and many more.

Arts & Crafts

-

Decorating jewelery and utensils with laser engraving

Attention to detail and individuality characterize your products. With a Trotec laser, virtually any design can be engraved faithfully onto a wide variety of materials. Lettering, ornaments, logos, images, and even photos: Trotec lasers are as easy to use as printers are, and decorate your artwork in no time.

Suitable materials for laser processing- TroGlass, Acrylic and Plexiglas®

- Wood

- Felt

- Textiles

- Paper

- Wax

- Glass

- Stone

- Cardboard

- Ceramic

- Carble

- Leather

- Base metals

- Plastics

- Stainless steel

Automotive parts

-

Laser marking automotive parts

For automotive components made from plastics and metal

In the automotive industry, complete clarity and traceability of safety-related components must be ensured. Optimal readability of Data Matrix codes or other alphanumeric labels is a prerequisite for this application. Laser systems are an ideal tool to be able to reliably and quickly apply these codes and other contents to almost all materials that are used in the automotive industry while achieving a high-quality finish.

Materials suitable for laser marking- Steel

- Steel alloys

- Aluminum

- Aluminum alloys

- Coated metals

- Plastics, such as polyamides, PP, ABS, etc.

- Composites

- Natural fibers

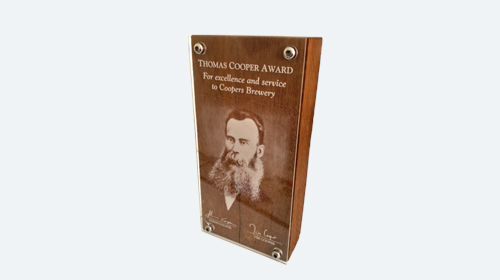

Awards and trophies

-

Laser engraving awards and trophies

Personalise awards, trophies, prizes or cases quickly and easily with Trotec laser engraving machines. Virtually any design including text, logos, images or photos can be engraved with the laser on a wide variety of materials and surface finishes in great detail. Impress clients with your own designs made of acrylic, cuts made with a Trotec laser produce a clear edge without the need for additional processing.

Materials suitable for laser engraving- Acrylic and Plexiglas®

- Acrylic films

- Wood

- Glass

- Rubber

- Marble

- Leather

- Metals

- Plastics

- Textiles

Ball bearing

-

Ball bearing marking with a laser

Tremendous forces act on ball and roller bearings. Laser marking is ideal for the creation of identification labels as they are extremely resistant to heat and mechanical stress. Even under the toughest conditions, laser markings on stainless steel, hardened and coated metals, plastics and ceramics remain permanently legible. They are used in production codes, lettering, logos or dimensions.

Materials suitable for laser marking- Stainless steel

- Hardened metals

- Coated metals

- Ceramic

Barcodes and serial numbers

-

Laser marking with barcodes and serial numbers

Line and 2D codes, like serial numbers, are already used in most industries, such as (e.g. the automotive industry, medical technology, or electronics industry), in order to make products or individual parts traceable. The codes (mostly data matrix or bar codes) contain information regarding the parts properties, production data, batch numbers and much more. Such component marking must be readable in a simple manner and partially also electronically and have a lasting durability. Here, laser marking proves to be a flexible and universal tool for a wide variety of materials, shapes and sizes as well as the processing of dynamic and changing data. Parts are laser-marked at the highest speed and absolute precision, while wear is minimal.

Suitable materials for laser processing

Components, parts or products of all types of metals e.g.- stainless steel, alloyed steels

- aluminum, anodized aluminum

- titanium, titanium alloys

- brass

- copper, other precious metals

- coated metals

and plastics e.g.- PA, PC, PE, PET, PMMA

- silicone or many other plastics

Depending on requirements, metals and plastics can either be laser marked or laser engraved.

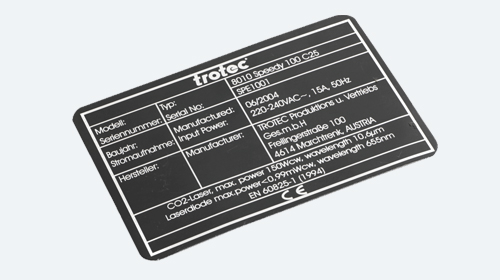

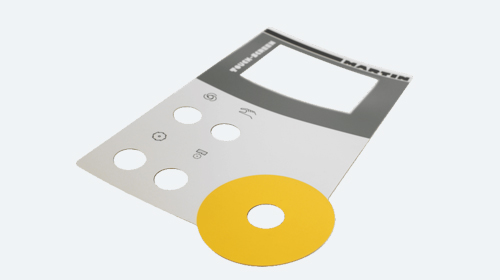

Dataplates

-

Laser Marking Dataplates

and Industrial Tags

Be flexible

A marking laser is the ideal tool for engraving nameplates. Whether you need to install signs for legal reasons or simply require functional labels, a laser allows you to label self-adhesive materials, plastics and metals. It is equally suitable for standard sizes as well as unusual shapes or sizes.

Materials suitable for laser engraving- Plastics

- Laminates

- Acrylic plates

- Coated metals, e.g. anodized aluminum

- Stainless steel

- and many more

Delrin

-

Delrin laser engraving

Delrin is used for the production of embossing presses. Embossing presses are used by notaries, companies, engineers and government agencies to add relief embossings, in addition to a signature, in order to protect quality documents from being copied fraudulently. Furthermore, an elegant embossing adds a personal touch to stationery and invitations. Whether it is a logo, home address or something creative, there is no limit to the number of possible applications.

What is Delrin?

Delrin is a trade name for the material group polyacetal (POM). This material is highly suitable for laser cutting or engraving because it can easily be removed by the laser beam.

Digital printing

-

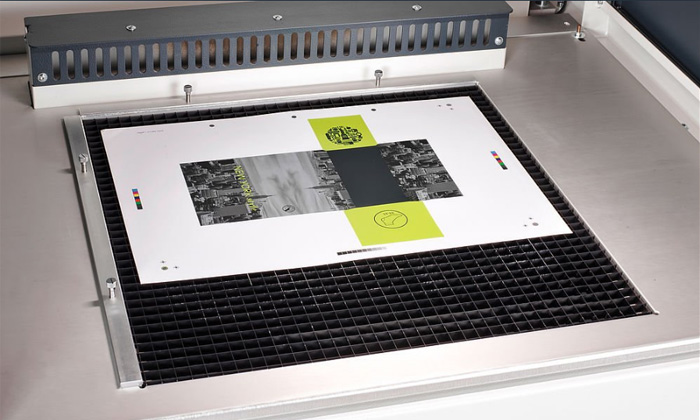

Laser cutting and laser engraving in digital printing

Producing printed products (such as flyers, brochures or invitation cards) has evolved from fine craftsmanship to industrial production. While offset printing is used for large order volumes, digital printing has become the norm at many print shops and copy shops because it can be used for small and medium-sized print runs (up to approx. 5,000 pages per order). The advantage is that no static printing form is used, making it possible to print each sheet differently. Combined with a laser system, digital printing presents many new possibilities for paper finishing, giving print service providers opportunities to create new business areas with high-quality products, making even small print runs profitable.

Suitable materials for laser processing

Materials that can be printed by digital printing:- mainly paper (paper finishing in all possible formats and strengths)

- acrylics

- plastics

- MDF

Electronic components

-

Electronics and semiconductor industry

Products in the electronics and semiconductor industry are mostly mass-market products that are produced fully automatically in large numbers. Many parts, such as SMD components, are very small and need to be labeled with a lot of information. For this purpose small, complex 2D Data Matrix codes are used, which must be easily and permanently legible. Due to these requirements, the electronics industry has already made laser marking a standard procedure. Galvo laser systems allow for a trouble-free, quick, fully or semi-automated labeling process.

Materials suitable for laser engraving- Plastics: Laser marking by means of foaming or color change

- Metals: Marking by means of annealing

FabLabs & Universities

-

Laser cutting for FabLabs, Maker Spaces, schools and universities

In FabLabs, Maker Spaces, universities or schools, Trotec laser machines are used for model making, industrial design, prototype construction, in research, and in many other DIY projects. The amazing and inspiring designs that laser technology offers are also ideal for product development in start-ups and small businesses.

Materials suitable for laser processing:- acrylic

- film

- wood

- cardboard

- plastic

- MDF

- paper

- plastic

- PMMA

- polystyrene

- foam

- textiles and much more

In digital production many different materials are used -- from cardboard, paper, MDF, wood to acrylic. Textiles, plastics, polystyrene or film can also be processed with great results. In addition, it is not necessary to consider the diameter of the tool. Depending on the lens used, the laser beam is about 0.1 mm wide. Therefore almost any geometry can be cut using the laser.

Films and Foils

-

Laser Cutting Plastic Foils and Films

The laser beam allows for controlled fusing of the foils and films and produces clear and sealed cutting edges. With the laser, you can cut even the smallest radii precisely and produce simple geometries at record speed. During laser cutting, no pressure is exerted on the foils or films by a tool, the entire process is contact-less and consequently, the end product will turn out perfect.

Another plus: As opposed to working with a punch or a knife, laser cutting of the foil or film will not result in chipping of paint from the end product.

The benefits of a laser cutting machine: Faster than a cutting plotter, more precise than punching dies, and more economical for small series up to 1,000 pieces.

Foam & Filter

-

Laser Cutting Foam & Filter Mats

Foams made of polyester (PES), polyethylene (PE) or polyurethane (PUR) or Neopren® are well suited for laser cutting, laser engraving and laser marking. Foam is used for suitcase inserts or padding, and for seals. Apart from these, laser cut foam is also used for artistic applications, such as souvenirs or photo frames, for example.

Film materials suitable for laser cutting:- Polyester (PES)

- Polyethylene (PE)

- Polyurethane (PUR)

- Neopren®

Glass

-

Glass laser engraving

You can create beautiful laser engraving and laser etching on glass items using a Trotec laser engraving machine. Laser etched glass produces a fascinating matte effect. Very fine contours and details can be etched into glass as photos, lettering or logos, e.g. on wine glasses, Champagne flutes, beer glasses, bottles, mirror or window glass. Personalized gifts for parties or corporate events are memorable and make laser-engraved glass unique.

Types of glass suitable for processing with a glass engraving laser- Container glass

- Cast glass

- Pressed glass

- Float glass

- Sheet glass

- Crystal glass

- Mirror glass

- Window glass

- Mirrors Conical and round glasses

- Drinking glasses, wine glasses

- Bottles

Jewelry

-

Laser engraving and laser marking of jewelry

Traditional crafts, modern tools

Jewelry today is manufactured using a broad range of materials; however the most common materials are noble metals and alloys. Traditionally, the industry used engravings (produced mechanically) mostly to personalize the gold inlay on expensive pieces or to add a meaningful inscriptions to them. Jewelers today also use laser engraving to produce unique and creative jewelry designs.

A creative tool for a creative industry

Laser engraving is a more efficient alternative for producing creative designs. Whether used to create classical styles, to engrave rings, to add a special inscription to a watch, or to decorate a necklace or to personalize a bracelet - a laser engraver offers you the opportunity to work on countless shapes and materials. Functional markings, patterns, textures, personalization, even photo-engravings can be produced using a laser engraving machine, making it ideal for a creative industry.

Laminates

-

Laser engraving laminates

What are laminates?

Laminates are 2- or 3-ply plastics. They are made of a core layer of modified acrylic which has been coated with a thin top layer. The engraving process reveals the color of the core material.

Laminate sheets are especially popular for laser engraving as they are well suited for both interior and exterior applications and available in many colors with different effects. Laminates are often used for signage such as dataplates, signboards, nameplates or industrial markings.

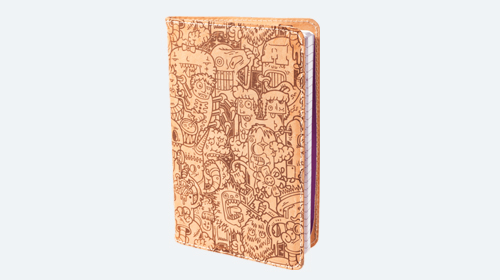

Leather

-

Laser engraving and cutting leather

With a customized laser engraving machine, you can easily give leather a quality finish. With a Trotec laser, leather is engraved quickly and easily for purses, wallets, bracelets, belts, shoes and more.

Leather types suitable for laser engraving- Natural leather

- Suede leather

- Napped leather

- Nubuck leather

- Synthetic leather

- Alcantara leather

Machine Construction

-

Laser Marking in Mechanical Engineering

Guaranteed traceability

Trotec laser machines are used in every stage of the industrial production process. Especially when it comes to guaranteeing traceability laser marking is perfect, as laser labelling creates permanent and resistant marks which can withstand mechanical stress and harsh weather condistions. Suitable for all forms on almost any material, a laser marking tool can mark a range of components.

Intelligent software for optimal process integration

Thanks to Trotec's pre-installed intelligent software solutions you can also easily generate your own serial numbers, dates, part numbers or date codes and use them to cost-efficiently mark different components and workpieces. This guarantees high quality for your end products and negates the requirement for outsourcing to external contractors. You can also easily produce your own identification or other data plates and thus save time and money! Trotec's laser software packages guarantee smooth process integration and full flexibility.

Machining technology

-

Laser marking tools

Flexibility in many dimensions

Turning, drilling and milling tools are subject to heavy stress. The markings on these precision tools must also be able to withstand these stresses. Laser markings offer some decisive advantages over other methods, such as etching or stamping:

Consistent quality and readability of the markings with absolute durability, depending on the process choice without changing the workpiece properties

Clean processing methods without consumables

Flexibility in many dimensions (marking content, component or tool shapes, material)

Low cost per marking for individual items or mass production

Materials suitable for laser marking- Hardened metals

- Tool steel

- High-speed steel (HSS)

- Titanium

- Alloys

- Boron steel

- Coated metals

Medical technology

-

UDI or "Unique Device Identification" is based on ISO compliant standard codes, which must be specified on medical products for traceability requirements. By scanning the code, you can obtain information such as the manufacturer's name, item reference or expiration date. This allows error-free documentation and helps ensure patient safety.

Laser markings are resistant to acids, cleaners or bodily fluids. As the surface structure remains unchanged, depending on the labeling process, surgical instruments can be kept clean and sterile easily. Even if implants remain inside the body for a long time, no materials from the label can detach themselves and harm the patient."

Materials suitable for laser marking- Titanium and titanium alloys

- Stainless steel

- High-alloy steel

- Coated metals

- Ceramic

- Plastics (e.g. PEEK for implants)

Metal

-

Laser Marking and Engraving Metals

Laser marking and laser engraving are extremely accurate and clean ways to process metal. Etching and engraving with the laser are contact-free processes, so the surface is not damaged. For bare, uncoated metals, a fiber laser is used for best results. Typical applications for laser marking of metals include product labeling and coding in the electronics industry (mobile phones, tables, etc), tool construction, and medical technology. Trotec offers a wide range of fiber laser systems to accommodate any number of applications.

Many types of metal can be laser marked, including:- Stainless steel

- hardened metals

- alloy steels

- high-speed steels

- aluminum

- anodized aluminum

- titanium, titanium alloys

- hard metals

- brass

- copper

- precious metals

- coated metals

Metals can be engraved or marked, depending on your application.

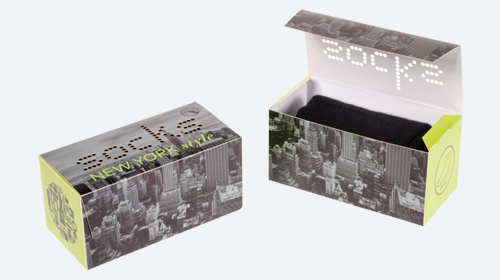

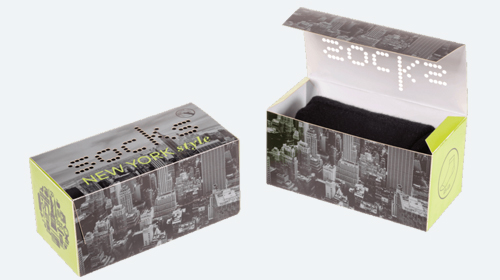

Packaging Design

-

Laser Cutting of Paper & Plastics in Packaging Design

Flexible from prototype construction to small series

From prototype construction to small series, the laser is the flexible tool for packaging design. Laser cutting machines from Trotec impress users in the packaging industry thanks to their detail, speed and flexibility.

One laser cutter for many materials

Laser cutting, perforating, grooving or carving makes you flexible with regard to the shape and the selected material. Your packaging will thus be more than just a punched cardboard box. Whether paper, plastics, cardboard, corrugated cardboard or packaging films - Trotec laser cutting machines are suited for a wide range of materials.

Paper

-

Laser cutting and laser engraving paper & cardboard

Laser cutting and laser engraving open up unlimited possibilities for paper finishing. When you process paper with a laser, you can enhance greeting cards, book covers or gift wrap with a unique, individual engraving or a delicate laser-cut pattern. Lasers can also perforate paper, which opens up even more design possibilities. Whether you are creating logos, photos or ornaments for personalization, you always get impressively accurate engravings and highly precise cutting edges with a laser.

Types of paper suitable for laser engraving and cutting:- fine paper

- art paper

- uncoated paper

- handmade paper

- cardboard

- card

- corrugated cardboard

With a Trotec CO2 laser cutter, you can laser cut and engrave paper.

Plastics

-

Laser marking and engraving plastics

Plastics can be marked or engraved with lasers in a variety of ways. With a fiber laser, you can mark many different commercially used plastics, such as polycarbonate, ABS, polyamide, and many more with a permanent, quick, high-quality finish. Thanks to the low set-up times and flexibility a marking laser offers, you can mark even small batch sizes economically.

Plastic types

suitable for laser engraving- Polyamide (PA)

- Polycarbonate (PC)

- Polyethylene (PE)

- Polypropylene (PP)

- Polyoxymethylene (POM)

- Polyarylsulfone (PSU, PPSU)

- Poly ether ketone (PEEK)

- Acrylonitrile butadiene styrene copolymer (ABS)

- Polyimide PI

- Polystyrene PS

- Polymethylmetacrylate PMMA

- Polyester (PES)

- Polyethylene terephthalate PET

- Silicone

Promotional products

-

Laser engraving promotional items

Make a lasting impression on your customers with personalized, laser engraved promotional materials. With a Trotec laser device, you will own a universal tool that allows you to design advertising gifts that are individual and useful at the same time. Whether key chains, glasses, ball pens, USB sticks, or Zippo® lighters, personalized promotional products are easily created with a Trotec laser system.

Refine wood, acrylic, textiles or glass with a CO2 laser. Using a fiber laser, you can quite easily label and mark metals (stainless steel, natural aluminum…) or plastics (polycarbonate, polyamide…). With a laser machine of the flexx series, use both laser sources in one system to become even more independent in terms of material. This allows you to work much more efficiently, faster and more cost-effectively with a Trotec laser engraving machine than this was possible before with advertising printing.

Materials suitable for laser engraving- Paper and cardboard

- Wood

- Acrylic

- Textiles

- Glass

- Metal, e.g. aluminum

- Plastics, e.g. polycarbonate, polyamide

- Rubber

Rubber

-

Engraving rubber with a laser

The laser can be used to engrave texts in the smallest fonts, logos with fine details or even pictures directly into the rubber. With a Trotec laser system, you can create stamps in an efficient, inexpensive, simple and environmentally-friendly way with the highest precision to produce clean, detailed, quality imprints without chemicals.

Rubber types suitable for laser engraving- Laser rubber

- Natural rubber

- Synthetic rubber

- Microporous laser foam

- Oil resistant laser rubber

- Silicone rubber

- Foam rubber

- Odorless rubber

Rubber Stamps

-

Laser Engraving Rubber Stamps

Rubber stamp manufacturing with laser engravers

Laser engraving machines for rubber stamp manufacture play a crucial role in the area of rubber stamp engraving. Largely automated processes reduce production times significantly and increase productivity of text plate engraving.

Save time when laser engraving rubber stamps

With laser engraving machines from Trotec, you can manufacture rubber stamps within just a few minutes and also streamline series manufacture considerably. The Trotec JobControl software and the rubber stamp embossing program JobCreator provide comprehensive support for the process. These programs ensure easy and time-saving production of rubber stamps.

Signage

-

For signage for indoor and outdoor use

Laser engrave practically any design onto plaques; from filigree motifs to complex designs, our lasers can do it all! Trotec laser engraving machines are particularly suitable for processing a wide variety of materials for series productions or single pieces. Quickly and cost-effectively create signage for indoor and outdoor use or offer additional services like individual "dog tag" engravings.

Materials suitable for signage engraving- Laminates

- Acrylic

- Anodized aluminum

- Plastic

- Paper

- Stone

- Glass

- Wood

- Textile

- Stainless steel

Signs & Displays

-

Laser cutting for

signage & displays

Laser finishing provides you the capabilities to create exceptional shapes for POS/pop-up displays, illuminated advertising or advertising signs, making your end product more sophisticated and higher quality. The creative "finishing" with a laser cutting machine transforms a printed acrylic sheet or wooden board into a finished product with a higher value. From simple rectangular advertising signs to complex contours and markings, anything is possible with Trotec laser cutting machines.

Materials suitable for laser processing

Rigid materials:- acrylic

- foam

- polystyrene

- wood

- MDF

- plywood

- veneer

- plexiglass

Flexible materials:- card

- corrugated cardboard

- polyester film

- polycarbonate film

- textiles

- cotton

- canvas

- carpet

- polyester

Smartphones & Laptops

-

Customized laser engraving of

smartphones and laptops

With a Trotec laser engraving machine, text, images and logos can be applied quickly and easily to electronic products or mobile phone covers. Personalized, high quality laser engravings not only upgrade the product itself, they also protect it from being mistaken for a similar item. Thanks to permanent markings, electronic devices can be easily identified if lost or stolen.

Materials suitable for laser marking- Plastics, e.g. acrylic / Plexiglass

- Wood

- Textiles

- Leather

- Metals, e.g. anodized aluminum

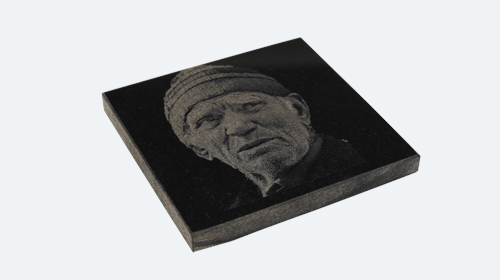

Stone

-

Stone laser engraving

Carving on stone, granite or marble offers incredible possibilities. Your personal message "written in stone" is a suitable gift for many occasions. Even detailed photos and graphics are possible with a Trotec laser. Laser engraving on stone is performed with a CO₂ laser and is similar to a kind of "matting" of the material.

Stone types suitable for laser engraving- Granite

- Marble

- Slate

- Basalt

- Marble

- Salt crystals

- Pebbles

- Stone tiles

- Natural stone

- Ceramic, porcelain

Textiles

-

Laser cutting and engraving textiles

With a Trotec laser, you can quickly and easily laser cut a variety of textiles to size. Materials can be also be given a high-quality finish with a tactile effect. Whether you use it to engrave felt or to cut extravagant shapes out of polyester, lasers offer you incredible design possibilities. Synthetic substances react very well during processing, the laser beam fuses edges on polyester and prevents fraying.

Textile types suitable for laser processing- Cotton

- Felt

- Silk

- Linen

- Lace

- Polyester

- Fleece

- Softshell

- Jeans

- Alcantara

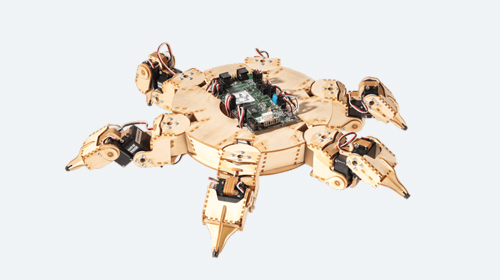

Toys

-

Laser cut and engrave toys

Laser cut delicate parts for construction sets, puzzles or craft supplies for toys, or personalize wooden toys with logos, names or sayings with laser engraving. Trotec laser engraving machines are particularly suitable for processing a wide range of materials, whether the job includes serial production or individual pieces.

Materials suitable for laser processing- wood

- plywood

- MDF

- plastics

- acrylic

- textiles

- felt

- polyester

Watches

-

Laser marking of watch parts

Functional laser marking for part identification and traceability as well as engravings for design purposes are indispensable in the watch industry. While one engraved mechanically or etched in the past, more and more laser machines are now being used for marking tasks. Part numbers, serial numbers and/or charge labeling, as well as data matrix codes, but also decorative markings such as logos and graphics, are applied to watch parts, e.g. clockwork components, oscillation weights, bezels, crowns, housings, watch case backs or dials by means of laser marking. The advantage of the laser here is clearly the high precision so that even the smallest and filigree laser markings can be carried out efficiently, quickly and with high precision on wristwatches.

Suitable materials for laser engraving and laser marking- stainless steel

- titanium

- ceramics

- brass

- gold and other precious metals

- leather (for the wristbands with wristwatches)

- silicone and elastomers for seals

- sapphire glass

Wood

-

Laser cutting and engraving wood

With Trotec laser equipment, you can cut and engrave toys, arts, crafts, souvenirs, Christmas jewelry, gift items, architectural models and inlays. When laser processing wood, the focus is often on personal customization options. Trotec lasers can process a variety of wood types to create the look you like and can cut thicknesses up to 20 mm.

Wood types suitable for laser processing- MDF

- HDF

- Multiplex

- Plywood

- Chipboard

- Natural wood, real wood

- Precious woods

- Solid wood, solid timber

- Cork

- Veneers

Fashion

-

Refine textiles and accessories with a laser

Lasers are gaining in popularity among fashion designers. Whether engraving velvet or making fancy shape cuts, virtually any design can be processed with the laser. With faster processing speeds for individual graphic designs, each piece can be unique even in series production. Laser cutting single-layer textiles is more productive than cutting with a knife or scissors. Lasering textiles also melts the cutting edges with synthetic materials. The results are clean, perfectly sealed edges. In addition to textiles and leather, other materials such as wood, acrylic, stone or paper can be perfectly processed with the laser.

Laser materials for the fashion industry- Fel

- Viscose

- Lenzing Modal®

- Tencel®

- Lace

- Polyester

- Polyamide material

- Fleece

- Softshell

- Cotton

- Silk

- Linen

- Denim

- Alcantara

- EVA (ethylene vinyl acetate)

- Leather

- Fluffy materials (e.g. teddy bear materials, artificial fur)

- Laserflexx

- Acrylic

- Wood

- Stone

- Paper

Natural Branding

-

Laser marking of fruits and vegetables as natural branding

More and more foods are being laser marked. Especially in the organic food sector, natural branding – the direct labeling of fruits and vegetables – is becoming increasingly important, for example, to distinguish organic foods from conventional fruits and vegetables. In addition, laser marking replaces environmentally damaging plastic packaging or stickers. In addition, food labeling or natural branding offers the possibility of applying logos or personalized labels.

Foods that are suitable for laser marking- (organic) fruits, such as apples, bananas, pineapples, etc.

- (organic) vegetables, such as cucumbers, squash, potatoes, etc.

- baked goods (bread)

- meats and sausages

- many other types of foods