- Offer Profile

-

CNC high-performance Machining Centers

High rigidity, thermal stability and dynamic characterize the CNC portal milling machines from Takumi. The post processing efforts is significantly reduced.

Machining Center

Vertical Machining Centers

-

Takumi Machining Centers of the VC series are focussed on parts manufacturing as well as mold & die production.

V 12

-

Solid and precise at the same time - that's the TAKUMI V 12 for vertical machining of medium-sized components in tool, mold and machine construction. The compact machine tool, which has a table clamping area of 1,250 x 650 mm, a maximum table load of 1,200 kg and a 24-position tool changer with double gripper, is also suitable for roughing and pre-roughing operations.

- Belt-driven spindle or gear-driven spindle up to 12,000 rpm

- Pretensioned ballscrews for all axes to prevent thermal deformation

- Spindle cooler

- User-friendly, ergonomic access for loading

- Optional: Gear-driven spindle torque up to 640 Nm (S1)

V 15

-

The compact V 15 milling machine is the ideal choice for your operation if you are looking for a space-saving and cost-effective all-round CNC solution for machining medium-sized workpieces in tool and mold making. With up to 8,000 rpm (revolutions per minute), the integrated spindle, which can be either a belt or gear spindle, enables high-performance milling and the highly productive production of small batches.

- Belt-driven spindle or gear-driven spindle up to 12,000 rpm

- Pretensioned ballscrews for all axes to prevent thermal deformation

- Spindle cooler

- User-friendly, ergonomic access for loading

- Optional: Gear-driven spindle torque up to 640 Nm (S1)

V 18

-

The V 18 machining center is perfectly suited for high-performance vertical machining of medium-sized workpieces as well as for roughing and pre-roughing operations in tool and mold making. With its particularly large traverse paths (1,800 mm x-travel, 850 mm y-travel, 750 mm z-travel), a table clamping surface of 1,900 x 850 mm and a table load of up to 2,000 kg, the vertical machining center remains maximally stable even with workpieces of greater weight. Because the V 18 can be equipped with either a belt-driven or a gear-driven spindle, the machine is suitable for a wide variety of vertical applications in tool, mold and machine construction.

- Belt-driven spindle or gear-driven spindle up to 12,000 rpm

- Pretensioned ballscrews for all axes to prevent thermal deformation

- Spindle cooler

- User-friendly, ergonomic access for loading

- Optional: Gear-driven spindle torque up to 640 Nm (S1)

VC 0852

-

The TAKUMI VC 0852 cross table machining center delivers reliable precision with universal application range. The machine is the ideal solution for your production if you want to machine small workpieces with maximum accuracy. With a table clamping area of 1,000 length and 520 mm width, and travels of 860 mm on the X-axis, 520 mm on the Y-axis, and 610 mm on the Z-axis, the VC 0852 is the most compact CNC machining center in the TAKUMI VC series and performs big despite its space-saving size. With a weight of 5,250 kg, the milling machine weighs in at a level that ensures high stability despite its compact size.

- Direct-drive spindle up to 15,000 rpm

- Spindle cooler

- User-friendly, ergonomic access for loading

VC 1052

-

The VC 1052 machine from our portfolio of vertical 3-axis CNC machining centers is a cost-optimized investment that will help you get the maximum performance from your production. Thanks to its stable yet compact design, the milling machine has a small footprint, making it ideal for store floor operation and shop floor programming.

- Direct-drive spindle up to 15,000 rpm

- Spindle cooler

- User-friendly, ergonomic access for loading

VC 1200

-

The TAKUMI VC 1200 machining center is a space- and cost-efficient machine for machining smaller workpieces, for example in tool and die making. Requiring only a small footprint, the milling machine is perfect for store floor applications and shop floor programming.

- Direct-drive spindle up to 15,000 rpm

- Spindle cooler

- User-friendly, ergonomic access for loading

VC 1000

-

Versatile, universal and highly flexible - that is the TAKUMI VC 1000 cross table machining center with 3 axes (X-path with 1,067 mm length, Y-path and Z-path with 610 mm length each). The highly robust CNC machine offers high-precision machining with a universal range of applications and an optimal price-performance ratio. This makes the VC 1000 the ideal machining center for CNC production with maximum demands on precision and efficiency.

- Direct-drive spindle up to 15,000 rpm

- Spindle cooler

- User-friendly, ergonomic access for loading

VC1500

-

Travels and Table

X-Axis (mm): 1.524

Y-Axis (mm): 762

Z-Axis (mm): 610

Highly Rigid Portal Machining Centers

- The stable and rigid portal design ensures high torsional rigidity on all axes. The automatic compensation of temperature fluctuations enables machining with long running times and, moreover, high precision. With the 3-axis gantry machining centers, CN machining of large workpieces with high component weights as well as small part machining of micro molds is possible. In all cases, the quality of the surfaces is very high due to the mechanical accuracy and temperature resistance of the machining centers.

H 6

-

With the H 6, minimum space requirement meets maximum precision and productivity. The machining center is a universal and dynamic high-speed portal milling machine for machining small workpieces.

- Motor spindles rated for up to 36,000 rpm

- User-friendly, ergonomic access for loading

- Stable and rigid bridge-type design concept featuring excellent resistance to high temperatures

- Absolute direct measuring systems

- System to offset thermal spindle expansion

- Spindle cooling system

- Internal coolant supply through the spindle (30 bar ICF, optionally 70 bar)

H 10

-

The machine that makes your entry into HSC milling possible with the ideal price-performance ratio - the H 10 CNC machining center takes up little floor space and is still powerful. The portal machining center is suitable for the production of small workpieces.

- Motor spindles rated for up to 36,000 rpm

- User-friendly, ergonomic access for loading

- Stable and rigid bridge-type design concept featuring excellent resistance to high temperatures

- Absolute direct measuring systems

- System to offset thermal spindle expansion

- Spindle cooling system

- Internal coolant supply through the spindle (30 bar ICF, optionally 70 bar)

H 12 E

-

The H 12 E machining center combines stable performance with precise dynamics. With a table clamping area of 1,360 x 960 mm, it is the ideal choice for space-saving CNC machining of medium-sized workpieces and highly dynamic applications in tool and mold making. As standard, the portal machining center already comes with everything you need for precise milling. In addition, you can optimally adapt the machine to your requirements with individual configuration options.

- Ideal for crane loading

- High rigidity and dynamic response for perfect milling results

- User-friendly, ergonomic access for loading

- Stable and rigid bridge-type design concept featuring excellent resistance to high temperatures

- Absolute direct measuring systems

- System to offset thermal spindle expansion

- Spindle cooling system

- Internal coolant supply through the spindle (30 bar ICF, optionally 70 bar)

H 16

-

The TAKUMI H 16 is the ideal machine tool for CNC machining of medium-sized workpieces - compactly built and highly efficient. The stable and rigid gantry construction made of robust cast iron ensures optimum temperature resistance and maximum precision along the traverse paths. Additional temperature compensation is provided by the temperature-dependent compensation of spindle growth.

- Ideal for crane loading

- High rigidity and dynamic response for perfect milling results

- User-friendly, ergonomic access for loading

- Stable and rigid bridge-type design concept featuring excellent resistance to high temperatures

- Absolute direct measuring systems

- System to offset thermal spindle expansion

- Spindle cooling system

- Internal coolant supply through the spindle (30 bar ICF, optionally 70 bar)

H 22 S

-

With a table load of up to 8,000 kg, the H 22 S machining center is the perfect machine for machining heavy and large workpieces on 3 axes. Among our load-bearing models for CNC heavyweights, it has the smallest clamping surface and the shortest travels on the X-axis and Y-axis respectively. In terms of precision and performance, it nevertheless keeps up uncompromisingly with its even larger machine brothers H 22 T, H 32 S and H 32 T.

- Optimized for large and heavy workpiece

- Simple machine loading thanks to machine doors that open wide

- Stable and rigid bridge-type design concept featuring excellent resistance to high temperatures

- Absolute direct measuring systems

- System to offset thermal spindle expansion

- Spindle cooling system

- Internal coolant supply through the spindle (30 bar ICF, optionally 70 bar)

- Spindle cooler

H 22 T

-

Your manufacturing needs determine our machine design: TAKUMI delivers the right table size for every workpiece - regardless of size and weight. For us, striving for perfection means configuring the perfect machine for your part requirements.

- Optimized for large and heavy workpieces

- Simple machine loading thanks to machine doors that open wide

- Stable and rigid bridge-type design concept featuring excellent resistance to high temperatures

- Absolute direct measuring systems

- System to offset thermal spindle expansion

- Spindle cooling system

- Internal coolant supply through the spindle (30 bar ICF, optionally 70 bar)

- Spindle cooler

H 32 S

-

The H 32 S is the ideal milling machine for machining large and heavy workpieces. With its generous travels (3,200 mm X-axis, 1,600 mm Y-axis, 800 mm Z-axis), a possible table load of 8,500 kg and a stable gantry design, the machine remains maximally stable even when milling large parts. The CNC machine's performance is completed by a spindle with speeds of up to 15,000 rpm.

- Optimized for large and heavy workpieces

- Simple machine loading thanks to machine doors that open wide

- Stable and rigid bridge-type design concept featuring excellent resistance to high temperatures

- Absolute direct measuring system

- System to offset thermal spindle expansio

- Spindle cooling system

- Internal coolant supply through the spindle (30 bar ICF, optionally 70 bar

- Spindle cooler

H 32 T

-

The H 32 T is a high-performance machine for machining large and heavy workpieces. With travels of 3,200 mm on the X-axis, 2,200 mm on the Y-axis and 800 mm on the Z-axis, a table clamping area of 3,320 x 2,100 mm and 8,500 kg maximum table load, it is one of the heftier milling machines in the H series. Thanks to its sturdy gantry design and standard integrated accessories to increase thermal resistance (including spindle cooler, thermal spindle expansion compensation system, absolute direct travel measuring systems in all axes), the machine is not only extremely stable, but also capable of extremely precise milling.

- Optimized for large and heavy workpiece

- Simple machine loading thanks to machine doors that open wide

- Stable and rigid bridge-type design concept featuring excellent resistance to high temperatures

- Absolute direct measuring systems

- System to offset thermal spindle expansion

- Spindle cooling system

- Internal coolant supply through the spindle (30 bar ICF, optionally 70 bar)

- Spindle cooler

H 42 S

-

Your manufacturing needs determine our machine design: TAKUMI delivers the right table size for every workpiece - regardless of size and weight. For us, striving for perfection means configuring the perfect machine for your part requirements.

- Optimized for large and heavy workpieces

- Simple machine loading thanks to machine doors that open wide

- Stable and rigid bridge-type design concept featuring excellent resistance to high temperatures

- Absolute direct measuring systems

- System to offset thermal spindle expansion

- Spindle cooling system

- Internal coolant supply through the spindle (30 bar ICF, optionally 70 bar)

- Spindle cooler

H 42 S

-

Your manufacturing needs determine our machine design: TAKUMI delivers the right table size for every workpiece - regardless of size and weight. For us, striving for perfection means configuring the perfect machine for your part requirements.

- Optimized for large and heavy workpieces

- Simple machine loading thanks to machine doors that open wide

- Stable and rigid bridge-type design concept featuring excellent resistance to high temperatures

- Absolute direct measuring systems

- System to offset thermal spindle expansion

- Spindle cooling system

- Internal coolant supply through the spindle (30 bar ICF, optionally 70 bar)

- Spindle cooler

H 52 S

-

Your manufacturing needs determine our machine design: TAKUMI delivers the right table size for every workpiece - regardless of size and weight. For us, striving for perfection means configuring the perfect machine for your part requirements.

- Optimized for large and heavy workpieces

- Simple machine loading thanks to machine doors that open wide

- Stable and rigid bridge-type design concept featuring excellent resistance to high temperatures

- Absolute direct measuring systems

- System to offset thermal spindle expansion

- Spindle cooling system

- Internal coolant supply through the spindle (30 bar ICF, optionally 70 bar)

- Spindle cooler

5-axis-Machining Centers

-

Takumi Machining Centers of the U-Series are designed for the 5-axis and 5-axis simulteanous machining.

UC 250

-

The UC 250 is the perfect machining center for your cost-saving CNC entry into the machining of small components. With its minimal footprint and large work envelope, the machine opens up a wide range of possibilities for 5-axis machining in small spaces. The compact design houses a powerful BigPlus spindle with SK 40 tool holder, which has speeds of 15,000 rpm and offers 14 kW of power. The machine's wide-opening doors provide the best accessibility and enable user-friendly loading and unloading.

- Inline spindle with up to 15,000 rpm

- Preloaded recirculating ball screws in all axes against thermal deformation

- Spindle cooler

- User-friendly ergonomic loading and unloading through wide-opening machine doors

- Direct path measuring systems in all axes

- 5-axis simultaneous capability

- Optional: IKZ up to 70 bar (standard: 30 bar)

- Small footprint, large working area"

UC 320

-

The UC 320 is a space- and cost-saving entry into working with CNC milling machines. The compact, 5-axis simultaneous-capable cross table machining center with low space requirements and large working area is perfectly suited for machining small workpieces. It comes standard with everything you need for maximum precision, stability and a high surface quality - and can be adapted exactly to the requirements of your CNC production with optional accessories.

- Inline spindle with up to 15,000 rpm

- Preloaded recirculating ball screws in all axes against thermal deformation

- Spindle cooler

- User-friendly ergonomic loading and unloading through wide-opening machine doors

- Direct path measuring systems in all axes

- 5-axis simultaneous capability

- Optional: IKZ up to 70 bar (standard: 30 bar)

- Small footprint, large working area

U 400

-

With its size and price-performance ratio, the U 400 is the ideal entry-level machine for the production of small workpieces in tool and mold making. Thanks to its gantry design, the machine is designed for versatile requirements and enables precise machining of complex contours. The powerful spindle with speeds of up to 24,000 rpm ensures high productivity. Temperature resistance with maximum performance is ensured by the preloaded ball screw in all axes, the spindle cooler and the automatic compensation of spindle growth.

- Motor spindle with up to 24,000 rpm

- Ideal for crane loading

- Preloaded recirculating ball screw in all axes against thermal deformation

- Spindle cooler

- Stable and rigid gantry construction with high temperature resistance

- User-friendly ergonomic loading and unloading due to wide opening machine doors

- Direct path measuring systems in all axes

- High rigidity and dynamics for precise milling results"

U 600

-

The U 600 is the perfect machining center for 5-axis production of small or medium-sized workpieces with a focus on tool and mold making. Thanks to its gantry design, the machine is optimally designed for your company's diverse production scenarios and combines a small footprint with great productivity - the powerful spindle with SK 40 or optional HSK63 tool holder and direct drive manages 15,000 or 24,000 rpm. In addition to the high rigidity and dynamics, the machine is characterized by high stability and resistance to thermal deformation, which is ensured by a preloaded ball screw in all axes and a spindle cooler.

- Motor spindle with up to 24,000 rpm

- Ideal for crane loading

- Preloaded recirculating ball screw in all axes against thermal deformation

- Spindle cooler

- Stable and rigid gantry construction with high temperature resistance

- User-friendly ergonomic loading and unloading due to wide opening machine doors

- Direct path measuring systems in all axes

- High rigidity and dynamics for precise milling results"

U 800

-

Are you looking for a machine for machining large workpieces that is cost-, time- and space-efficient at the same time? Then the U 800 is the machine of your choice. The machining center can withstand a table load of up to 1,200 kg. Thanks to its gantry design and swivel bridge, the U 800 operates with high precision and stability. The powerful inline or motorized spindle achieves speeds of up to 15,000 or 20,000 rpm. The machine's performance is perfected by its extensive standard equipment.

- Inline or motorized spindle with up to 15,000 or 20,000 rpm respectively.

- Ideal for crane loading

- Preloaded recirculating ball screws in all axes against thermal deformation

- Spindle cooler

- User-friendly ergonomic loading and unloading through wide-opening machine doors

- Direct path measuring systems in all axes

- High rigidity and dynamics for precise milling results

- Stable gantry design for high temperature resistance and rigidity

UB 3222

-

The UB 3222 is an extremely sturdy machine for machining very large and heavy workpieces.The machining center is characterized by its highly rigid design with a large table clamping surface, which ensures reliable cutting and precise milling results even with a maximum table load of 8,500 kg.Thanks to the 5-axis fork head, the 5-axis simulatan option and large traverse paths (3,200 mm x-travel, 2,250 mm y-travel, 1,200 mm z-travel), even complex workpieces are no problem for the machine.

- Motor spindle with up to 18,000 rpm

- Ideal for crane loading

- Preloaded recirculating ball screws in all axes against thermal deformation

- Spindle cooler

- User-friendly ergonomic loading and unloading through wide-opening machine doors

- Direct path measuring systems in all axes

- High rigidity and dynamics for precise milling results

- Stable and rigid gantry construction with high temperature resistance

Dynamic Graphite Machining Centers

- The TAKUMI G-series machines are specially developed and designed for graphite machining. The completely enclosed machining chamber incl. graphite extraction system ensures modern, highly particle-resistant graphite machining.

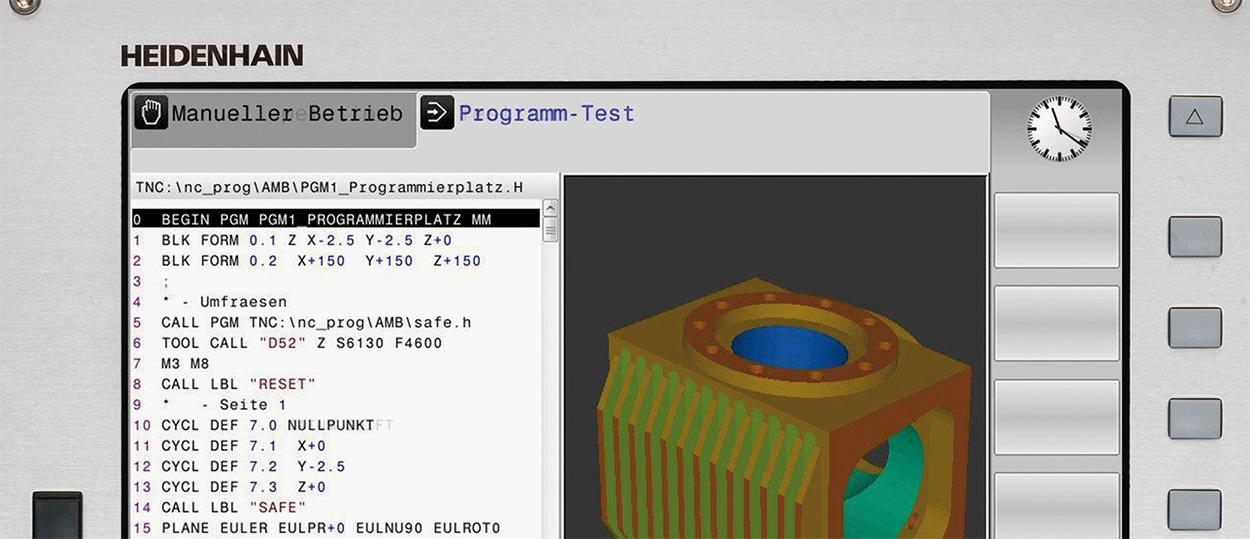

All G-series milling machines are equipped with the latest version of the Heidenhain TNC 640 CNC control, which is particularly user-friendly thanks to dialog and ISO NC programming. The programming method typical of Heidenhain enables outstanding results with the finest contours. The modern control technology is an effective tool with which the graphite milling machine precisely meets even high machining requirements and ensures maximum process reliability even when CNC milling complex graphite parts. Faulty contours are thus a thing of the past. G 1000

-

The G 1000 is the ideal CNC machine for your production if you are looking for a steadfast solution for graphite machining with an optimal price-performance ratio. The machining center is equipped with first-class components as standard and can also be expanded with numerous additional options - for the production of workpieces with the finest contours specifically according to the requirements of your production.

- Completely enclosed machining area incl. extraction for modern graphite machining.

- High form and dimensional accuracy due to compact gantry design

- Comprehensive basic equipment for a first-class price/performance ratio

- Stable and rigid gantry construction with high temperature resistance

- Absolute direct travel measuring system

- System for compensation of thermal spindle expansion

- Cooling system for the ball screw - 25,000 min-1, HSK-E50, motor spindle Graphite extraction system"

Control

-

Heidenhain Control TNC 640

The trust of our customers in our CNC technology and our equipment is very important to us.

Our CNC specialists are continuously trained and further trained on the Heidenhain control.

Our Takumi portal machining centers are equipped with the latest version of the Heidenhain control TNC 640:

- Versatile path control with up to five controlled axes and a controlled spindle

- workshop-oriented programmability with graphic support

- many practical cycles

- user-friendly operating concept

The interplay of Takumi CNC machining centers and the Heidenhain control guarantee an optimal, performance-oriented interplay of technology, machine and people in the entrepreneurial sense of our customers.