- Offer Profile

- PRIMINER MACHINE TOOLS was founded by a global team which had been working in the field of CNC machine tools manufacturing for more than 15 years.

We have office in Germany and Taiwan,and we have manufacturing plant in China and Indonesia. In this way we can keep ourself to have the up- to-date technology and turn it into our products.

CNC Vertical Machining Center

Mini Center

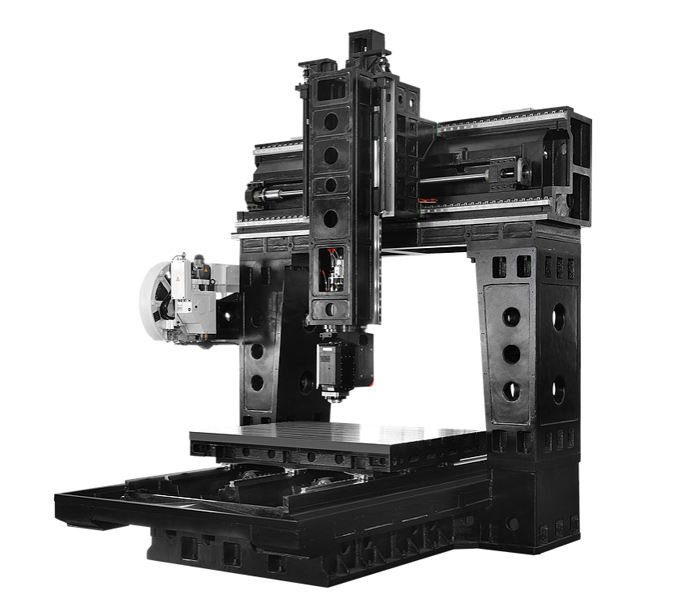

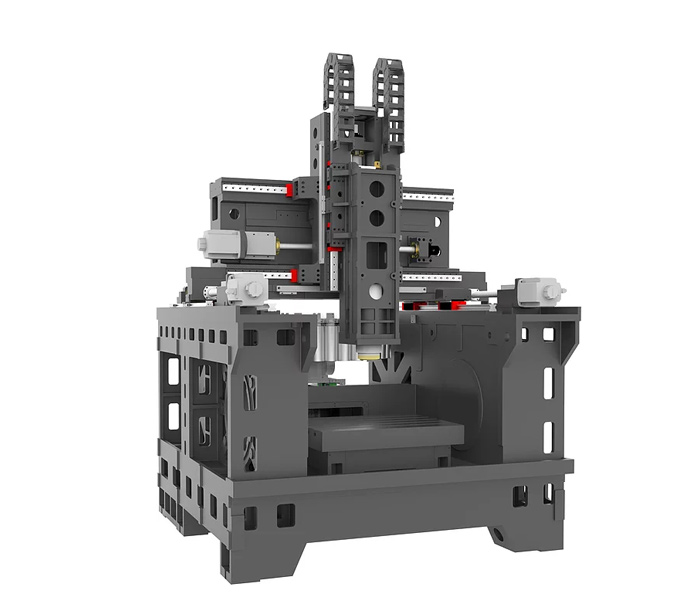

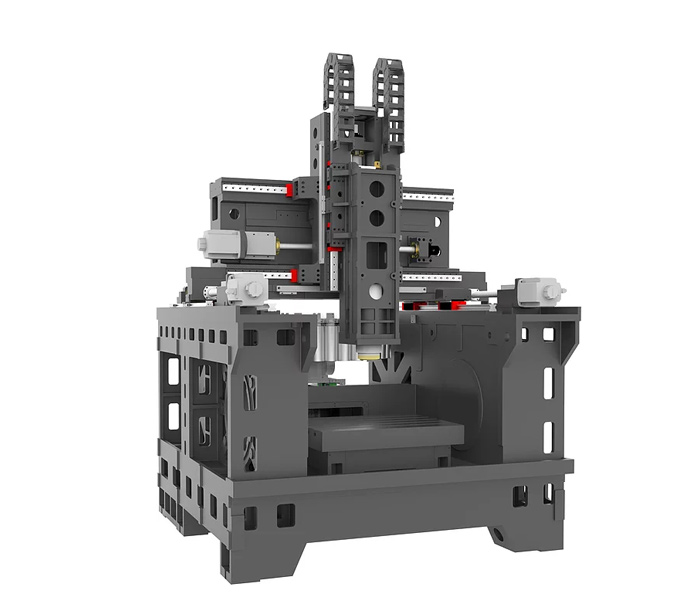

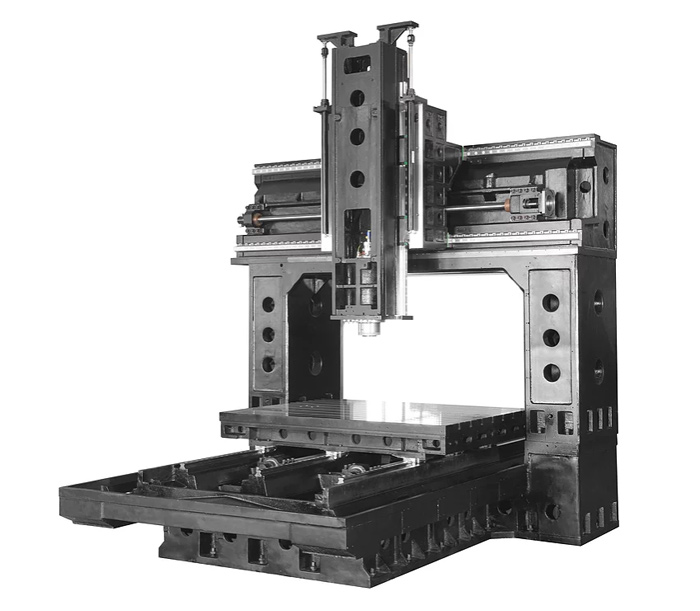

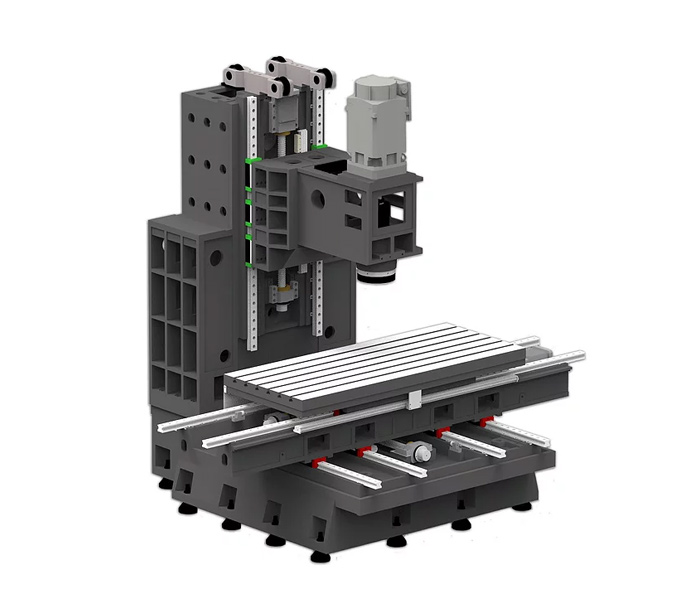

MINI CENTER

-

Mini Center - The entry into the world of milling

What is a CNC Mini Center? The term CNC stands for "Computer Numerical Control."

The definition of CNC machining explains that it is a subtractive manufacturing process that typically uses computerized controls and machine tools to remove layers of material from a stock piece - known as a blank or workpiece - and produce a custom part.In simpler terms, our CNC Mini Center is a machine tool - one of the smallest in the world. It performs all the functions of a "big" machine tool. Only the weight of the workpiece, which is limited to 200 kilograms - due to the "small size" of the machine.

The Mini Center scores as a fully integrated CNC machining center with an excellent price-performance ratio. We install the same top-level components in this series as in all other PRIMINER series.

We make no compromises here!- Travel (x/y/z): 500/300/400 mm

- Table size: 650×300 mm

- Max. load: 200 kg

- Cast iron is tempered for stress relief to ensure structural stability without deformation

- C3 class ballscrews ensure the highest accuracy and durability

- Pretension on all axis minimizes thermal distortion

5-Axes Gantry Machining Center

5-Axes Gantry Machining Center GT18-5X

-

Specifications

- Full enclosed splash guard

- Motor spindle HSK A63 24000 min-1

- 60 pockets chain type tool changer

- Chip conveyor (two screw type and one chain type)

- Air-conditioned electrical cabinet

- High precision spindle water cooler

- Rigid tapping

- Ethernet, CF card and USB interface

- Automatic lubrication system

- Coolant system

- Linear scale

- Oil separator

- Air blast during cutting

- LED working lamp

- End of program light

- Electronic handwheel (MPG)

- Tool box

- Leveling bolts and blots

- Coolant gun

- Air gun

- User Manual

Options

- CTS Coolant through spindle + ATS

- Oil cooled ballscrew

- Workpiece probe

- Tool probe

High Speed Gantry Type Machining Center

U500

-

Specifications

- Full enclosed splash guard

- Motor spindle HSK A63 20.000 min-1

- 24 pockets umbrella tool changer

- Chain type chip conveyor

- Linear scale

- Air-conditioned electrical cabinet

- High precision spindle water cooler

- Rigid tapping

- Ethernet ,CF card and USB interface

- Automatic lubrication system

- Coolant system

- Oil separator

- Air blast during cutting

- LED working lamp

- End of program light

- Electronic handwheel(MPG)

- Tool box

- Leveling bolts and blots

- Coolant gun

- Air gun

- User Manual

Options

- Motor spindle HSK E40 30.000 min-1 with 40 pockets chain type tool changer

- CTS Coolant through spindle + ATS

- Oil cooled ballscrew

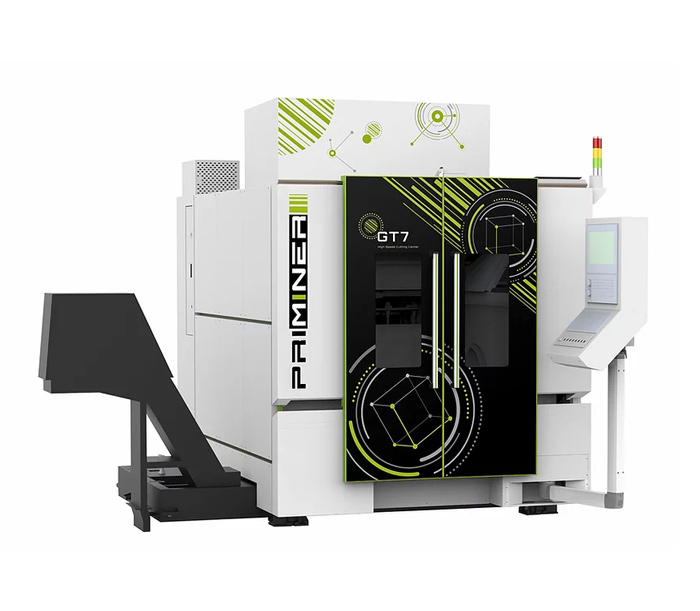

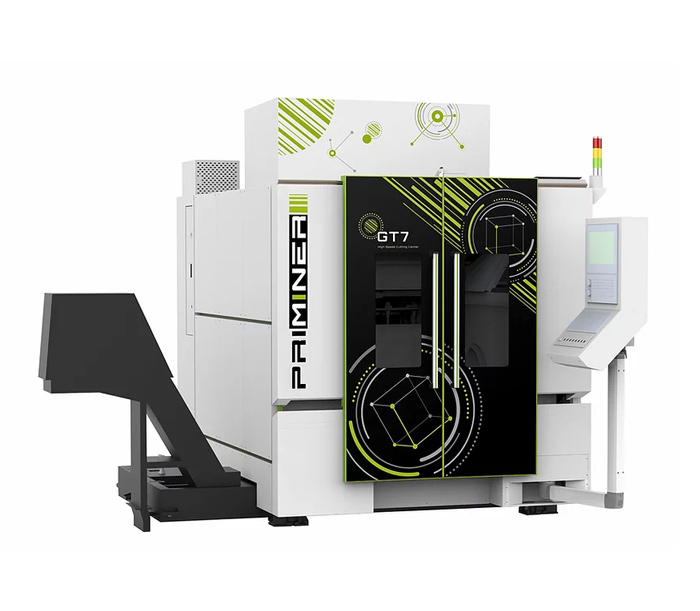

GT7

-

Specifications

- Full enclosed splash guard

- Motor spindle HSK E50 36.000 min-1

- 24 pockets umbrella tool changer

- Chain type chip conveyor

- Linear scale

- Air-conditioned electrical cabinet

- High precision spindle water cooler

- Rigid tapping

- Ethernet, CF card and USB interface

- Automatic lubrication system

- Coolant system

- Oil separator

- Air blast during cutting

- LED working lamp

- End of program light

- Electronic handwheel (MPG)

- Tool box

- Leveling bolts and blots

- Coolant gun

- Air gun

- User Manual

Options

- HSK E40 30.000 min-1 with 40 pockets umbrella tool changer

- HSK A63 20.000 min-1 with 24 umbrella tool changer

- CTS Coolant through spindle + ATS

- Oil cooled ballscrew

- Workpiece probe

- Tool probe

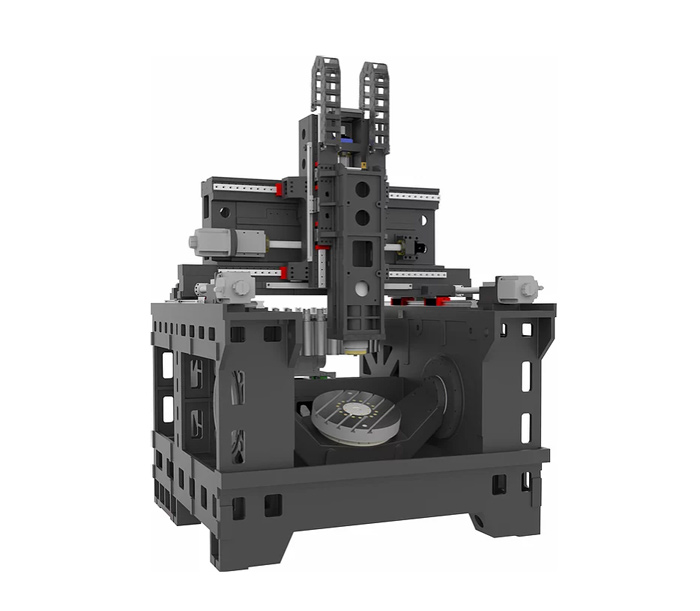

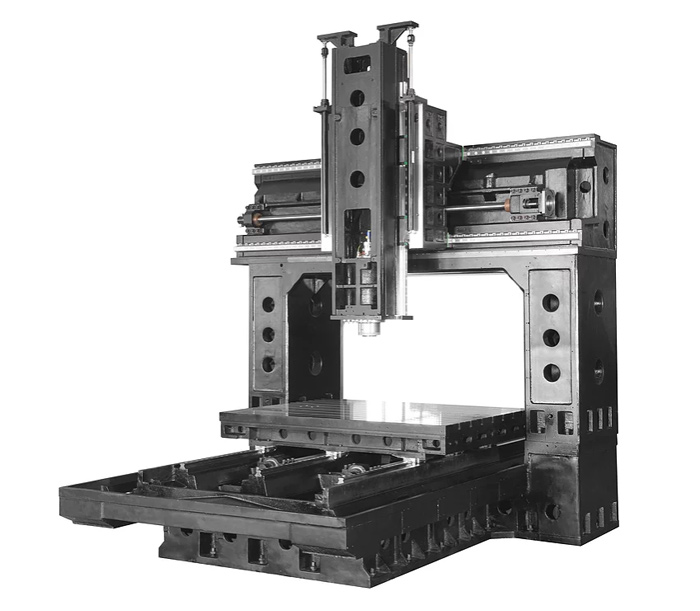

High Speed Double Column Center

V1613HS • V2013HS

-

- Cast iron is tempered for stress relief to ensure structural stability without deformation

- C3 class ballscrews ensures the highest accuracy and durability

- Pre-tension on all axes minimizes thermal distortion

- Roller type linear guideway, which offers supper high rigidity and loading capacity

Standard configuration

- Fully enclosed splash guard

- Air-conditioned electrical cabinet

- Rigid tapping

- Ethernet, CF card and USB interface

- Automatic lubrication system

- Coolant system

- Spindle cooling system

- LED working lamp

- End of program light

- Electronic handwheel (MPG)

- Tool box

- Leveling bolts and blots

- Coolant gun

- Air gun

- User Manual

Optional configuration

- Direct drive spindle 15.000 min-1

- Motor spindle 20.000 min-1, HSK A63

- 32 pocket arm tool changer

- Chip conveyor (two screw type and one chain type)

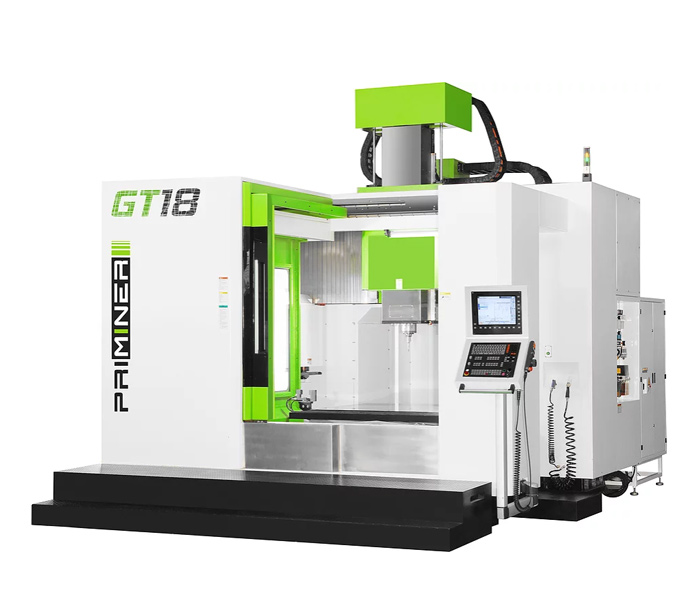

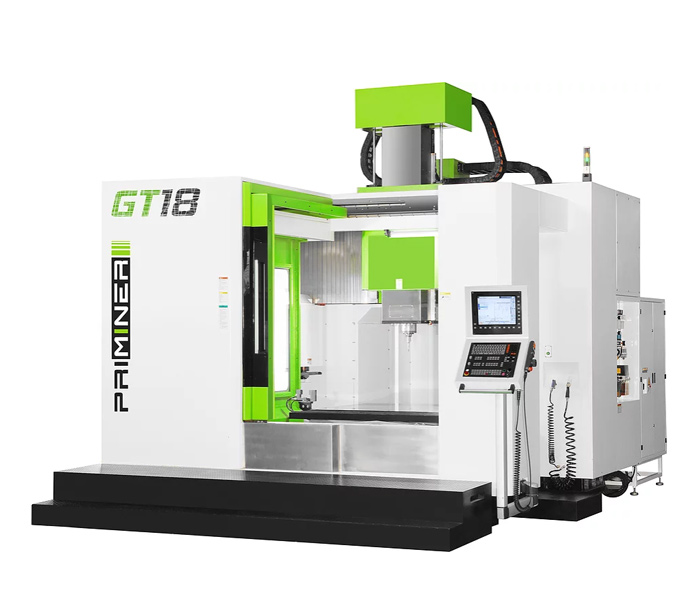

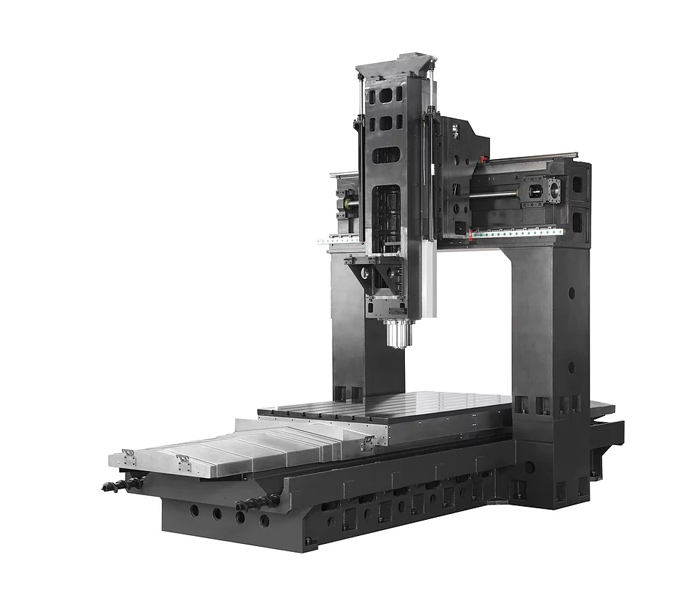

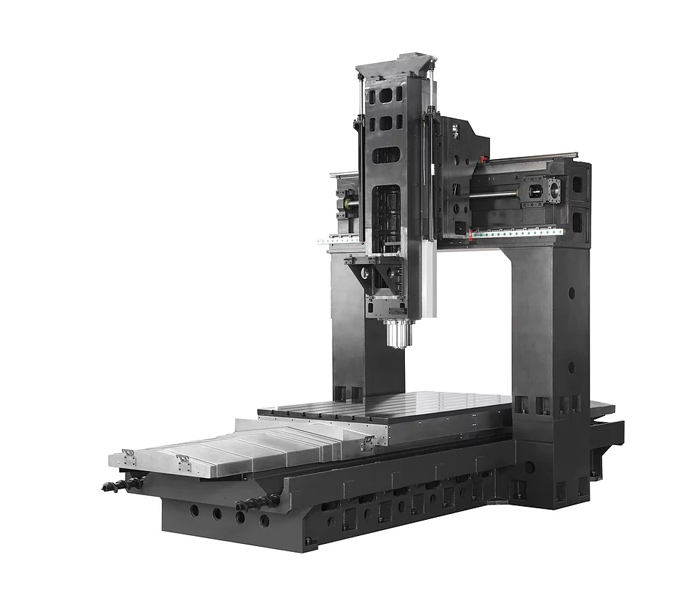

GT18

-

Standard configuration

- Full enclosed splash guard Motor spindle HSK A63 24.0000 min-1

- 60 pockets chain type tool changer

- Chip conveyor (two screw type and one chain type)

- Air-conditioned electrical cabinet

- High precision spindle water cooler

- Rigid tapping

- Ethernet, CF card and USB interface

- Automatic lubrication system

- Coolant system

- Linear scale

- Oil separator

- Air blast during cutting

- LED working lamp

- End of program light

- Electronic handwheel (MPG)

- Tool box

- Leveling bolts and blots

- Coolant gun

- Air gun

- User Manual

Optional configuration

- Motor spindle HSK A100, 12000 min-1

- CTS Coolant through spindle + ATS

- Oil cooled ballscrew

- Workpiece probe

- Tool probe

Ultra High Performance VF Series

VF760

-

Advanced design with reinforced body structure through FEM analysis, VF series offers superb cutting performance and reduced vibration to meet the highest machining demand. Extra wide machine column and base design ensure the high rigidity during high speed movement.

- Cast iron is tempered for stress relief to ensure structural stability without deformation

- C3 class ballscrews ensure the highest accuracy and durability

- Pretension on all axis minimizes thermal distortion

Standard configuration

- Fully enclosed splash guard

- Direct drive spindle 12.000 min-1

- Spindle cooling system

- 24 pocket arm tool changer

- Air-conditioned electrical cabinet

- Rigid tapping

- Ethernet, CF card and USB interface

- Automatic lubrication system

- Coolant system

- Oil separator

- LED working lamp

- End of program light

- Electronic handwheel (MPG)

- Tool box

- Leveling bolts and blocks

- Coolant gun

- Air gun

- Air blast during cutting

- Chain type chip conveyor

- User Manual

Optional configuration

- CTS coolant through spindle + ATS

- Motor spindle 20.000 min-1, HSK A63

- 4th axis

- 4/5th axis

- Workpiece probe

- Tool probe

- Linear encoder

VF900 • VF1100 • VF1300 • VF1500

-

Advanced design with reinforced body structure through FEM analysis, VF series offers superb cutting performance and reduced vibration to meet the highest machining demand. Extra wide machine column and base design ensure the high rigidity during high speed movement.

- Extra wide column to increase to connection surface with the crossbeam to avoid vibration during cutting

- All axes are moved by high quality precision gear box to ensure high torque and rigidity during movement (V3317 on all axes and V3025 / V4025 on X axis)

- Roller type linear guideway, which offers super high rigidity and loading capacity

- Hydraulic balancing system on Z-axis

Standard configuration

- Fully enclosed splash guard

- Direct drive spindle 12.000 min-1

- 24 pocket arm tool changer

- Two screw type and one chain type (VF 1100, VF1300, VF1500)

- Chain type chip conveyor (VF900)

- Spindle cooling system

- Air-conditioned electrical cabinet

- Motor mounting block cooling circuit (VF1100, VF1300, VF1500w)

- Rigid tapping

- Ethernet, CF card and USB interface

- Automatic lubrication system

- Coolant system

- Oil separator

- LED working lamp

- End of program light

- Electronic handwheel (MPG)

- Tool box

- Leveling bolts and blocks

- Coolant gun

- Air gun

- Air blast during cutting

- User Manual

Optional configuration

- Direct drive spindle 10.000 min-1, BBT50 (VF1100, VF1300, VF1500)

- Direct drive spindle 15.000 min-1, BBT40

- Motor spindle 18.000 min-1, HSK A63

- CTS coolant through spindle + ATS

- Oil cooled ballscrew

- Linear encoder

- 4th axis

- 4/5th axis

- Workpiece probe

- Tool probe

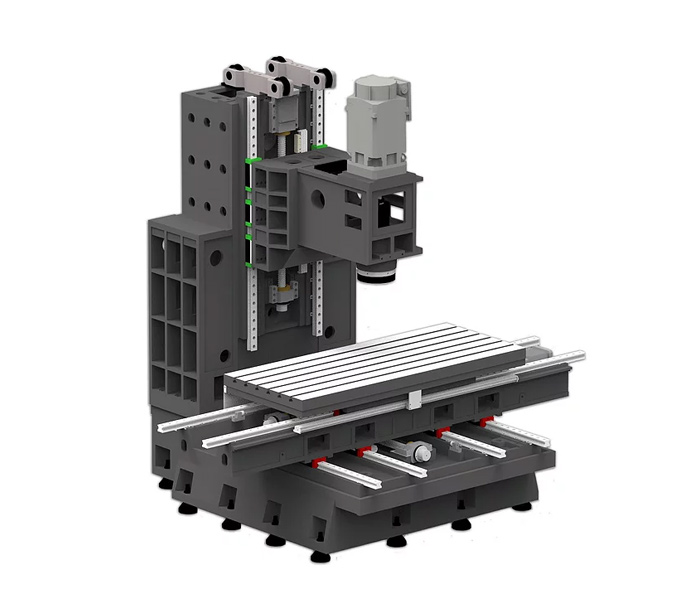

Delta Center

V10L

-

- Cast iron is tempered for stress relief to ensure

- structural stability without deformation

- Pre-tension on all axes minimizes thermal distortion

- C3 class ballscrews ensures the highest accuracy and durability

Standard configuration

- Fully enclosed splash guard

- Belt drive spindle 10.000 min-1

- 24 pocket arm tool changer

- Air-conditioned electrical cabinet

- Rigid tapping

- Ethernet, CF card and USB interface

- Automatic lubrication system

- Coolant system

- Oil separator

- LED working lamp

- End of program light

- Electronic handwheel (MPG)

- Tool box

- Leveling bolts and blocks

- Coolant gun

- Air gun

- Chip flushing system

- User Manual

Optional configuration

- Spindle speed 12.000 min-1, direct drive

- Spindle cooling system

- CTS Coolant through spindle + ATS

- Chain type chip conveyor

- 4th axis

- 4/5th axis

- Workpiece probe

- Tool probe

V6L

-

- Training

- Tool room workshop

- Metal parts machining

- Mold making, R&D

- Cast iron is tempered for stress relief to ensure machine stability without deformation

- C3 class ballscrews ensures the highest accuracy and durability

- Pre-tension on all axes minimizes thermal distortion

Standard configuration

- Fully enclosed splash guard

- Belt drive spindle 10.000 min-1

- 20 pocket arm tool changer

- Heat exchanger for electrical cabinet

- Rigid tapping

- Ethernet CF card and USB interface

- Automatic lubrication system

- Coolant system

- Oil separator

- LED working lamp

- End of program light

- Electronic handwheel (MPG)

- Tool box

- Leveling bolts and blocks

- Coolant gun

- Air gun

- Chip flushing system

- User Manual

Optional configuration

- Spindle speed 12.000 min-1, direct drive

- Spindle cooling system

- CTS Coolant through spindle + ATS

- 4th axis

- Workpiece probe

- Tool probe

Alpha Center

V13L • V15L

-

- Cast iron is tempered for stress relief to ensure structural stability without deformation

- C3 class ballscrews ensures the highest accuracy and durability

- Pre-tension on all axis minimizes thermal distortion

Standard configuration

- Fully enclosed splash guard

- Belt drive spindle 10.000 min-1

- 24 pocket arm tool changer

- Air-conditioned electrical cabinet

- Rigid tapping

- Ethernet, CF card and USB interface

- Automatic lubrication system

- Coolant system

- Oil separator

- LED working lamp

- End of program light

- Electronic handwheel (MPG)

- Tool box

- Leveling bolts and blocks

- Coolant gun

- Air gun

- Air blast during cutting

- User Manual

Optional configuration

- Belt drive spindle 6.000 mm-1 BT50

- Spindle speed 12.000 min-1, direct drive

- Spindle cooling system

- CTS Coolant through spindle + ATS

- Chain type chip conveyor

- 4th axis

- 4/5th axis

- Workpiece probe

- Tool probe

V9L • V11L

-

- Cast iron is tempered for stress relief to ensure structural stability without deformation

- C3 class ballscrews ensures the highest accuracy and durability

- Pre-tension on all axis minimizes thermal distortion

Standard configuration

- Fully enclosed splash guard

- Belt drive spindle 10.000 min-1

- 24 pocket arm tool changer

- Air-conditioned for electrical cabinet

- Rigid tapping

- Ethernet, CF card and USB interface

- Automatic lubrication system

- Coolant system

- Oil separator

- LED working lamp

- End of program light

- Electronic handwheel (MPG)

- Tool box

- Leveling bolts and blocks

- Coolant gun

- Air gun

- Chip flushing system

- User Manual

Optional configuration

- Spindle speed 12.000 min-1, direct drive

- Spindle cooling system

- CTS Coolant through spindle + ATS

- Chain type chip conveyor

- 4th axis

- 4/5th axis

- Workpiece probe

- Tool probe

V7L

-

Standard configuration

- Fully enclosed splash guard

- Belt drive spindle 10.000 min-1

- 24 pocket arm tool changer

- Air-conditioned electrical cabinet

- Rigid tapping

- Ethernet CF card and USB interface

- Automatic lubrication system

- Coolant system

- Oil separator

- LED working lamp

- End of program light

- Electronic handwheel (MPG)

- Tool box

- Leveling bolts and blocks

- Coolant gun

- Air gun

- Chip flushing system

- User Manual

Optional configuration

- Spindle speed 12.000 min-1, direct drive

- Spindle cooling system

- CTS Coolant through spindle + ATS

- Workpiece probe

- Chain type chip conveyor

- 4th axis

- 4/5th axis

- Tool probe

Double Column Center

V2518 • V3018 • V3025 • V4025

-

- Extra wide column to increase to connection surface with the crossbeam to avoid vibration during cutting

- All axes are moved by high quality precision gear box to ensure high torque and rigidity during movement (V3317 on all axes and V3025 / V4025 on X axis)

- Roller type linear guideway, which offers super high rigidity and loading capacity

- Hydraulic balancing system on Z axis

Standard configuration

- Half enclosed splash guard

- Air-conditioned electrical cabinet

- Rigid tapping

- Ethernet, CF card and USB interface

- Automatic lubrication system

- Coolant system

- Spindle cooling system

- LED working lamp

- End of program light

- Electronic handwheel (MPG)

- Tool box

- Leveling bolts and blocks

- Coolant gun

- Air gun

- User Manual

Optionales Zubehör

- 24 pocket arm tool changer

- Chip conveyor (two screw type and one chain type)

- Gear box

V2013

-

Standard configuration

- Fully enclosed splash guard

- Air-conditioned electrical cabinet

- Rigid tapping

- Ethernet, CF card and USB interface

- Automatic lubrication system

- Coolant system

- Spindle cooling system

- LED working lamp

- End of program light

- Electronic handwheel (MPG)

- Tool box

- Leveling bolts and blocks

- Coolant gun

- Air gun

- User Manual

Optional configuration

- Gear box

- 24 pockets arm tool changer

- 40 pockets chain tool changer

- Chip conveyor (two screw type and one chain type)