Raylase

Videos

Loading the player ...

- Offer Profile

- RAYLASE develops advanced modular components and deflection units for the control of laser beam. Maintaining high product quality standards is a priority at RAYLASE. All products are shipped to customers only after extensive tests.

Product Portfolio

2-AXIS DEFLECTION UNITS

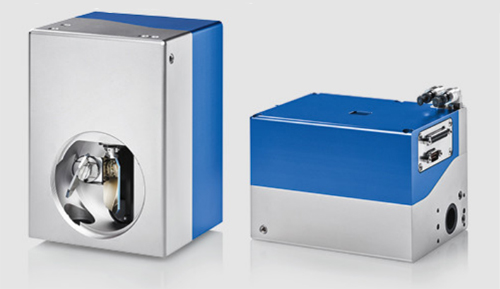

MINISCAN II

-

The MINISCAN II is the new generation of scan heads with compact design and the performance optimized to achieve 50% less drift values.

The MINISCAN II is available for various wavelengths in 7, 10, 14, 20 mm apertures.

FEATURES- Very low drift

- Extreme compact design

- Robust and dust proof for industrial conditions

- Insensitive to external temperature conditions

- Available apertures (mm): 7, 10, 14, 20

SUPERSCAN IIE

-

SUPERSCAN IIE is the perfect deflection unit for demanding laser applications. The “enhanced” option offers a 50% better long-term drift performance.

SUPERSCAN IIE is available for various wavelengths in 7, 10, 12, 15, 20, 30 mm apertures.

FEATURES- Lowest drift values through twin-shell design

- Laser power capabilities up to 5 kW

- Improved drift values with enhanced model

- Minimal drift with Water tempering option

- Available apertures (mm):

- 7, 10, 12, 15, 20, 30

SUPERSCAN III

-

SUPERSCAN III offers full digital control electronics. This allows real time monitoring of mirror position, mirror speed and temperature.

SUPERSCAN III is available for various wavelengths in 10, 15, 20, 30 mm apertures.FEATURES

- Full digital control electronics

- Real time monitoring of mirror position, mirror speed and temperature

- RAYLASE 18-Bit interface

- Pyrometer optional available (for 30 mm apertures)

- Available apertures (mm):

- 10, 15, 20, 30

SUPERSCAN IV

-

SUPERSCAN IV offers full digital control electronics. These ensure high speed especially for Marking-and-processing-On-The-Fly (MOTF) applications.

SUPERSCAN IV is available for various wavelengths in 15, 20, and 30 mm aperture.

FEATURES- Control via SL2-100 protocol 20 bit or XY2-100 protocol 16 bit

- Greatly reduced power loss and minimal heat development thanks to digital PWM output stages

- Dynamic responses and high speeds for maximum productivity, especially in MOTF applications

- Wide range of mirror substrates and coatings for diverse applications

- Available apertures (mm): 15, 20, 30

SUPERSCAN V

-

The digital feedback control electronics inside the SUPERSCAN V provides excellent dynamics monitoring continuously the position of the mirrors as well as their speed and temperature.

SUPERSCAN V is available for various wavelengths in 15 mm and 30 mm apertures.FEATURES

- Positioning of the laser with 20 bit resolution with the SL2-100 protocol

- Minimal drift and extremely low noise thanks to digital encoder technology

- Extreme acceleration and precise laser guidance for sharp corners and edges

- Recording and diagnosis of all properties

- Available aperture (mm): 15, 30

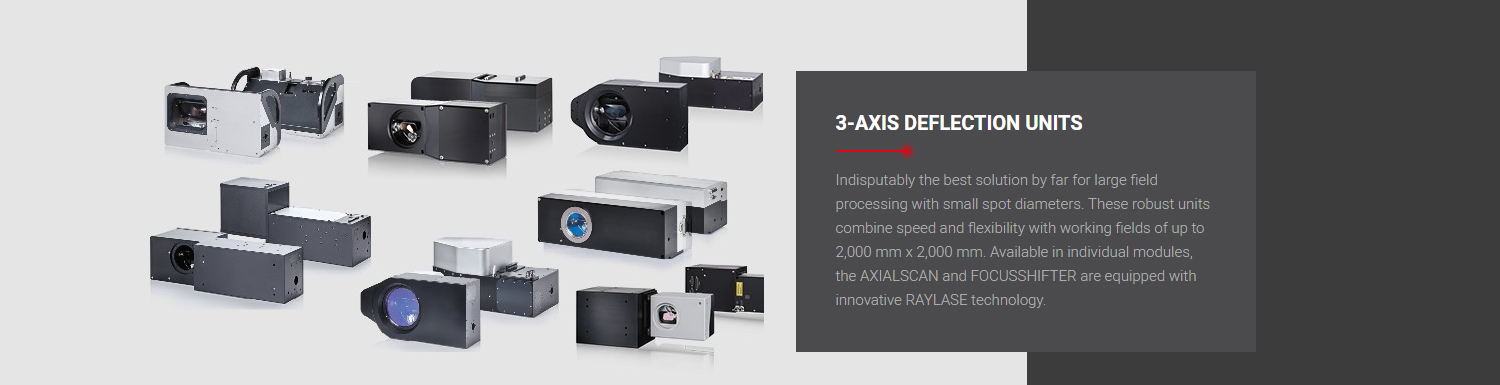

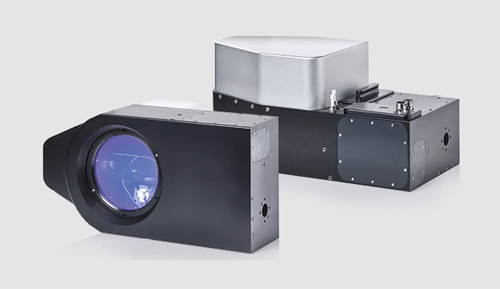

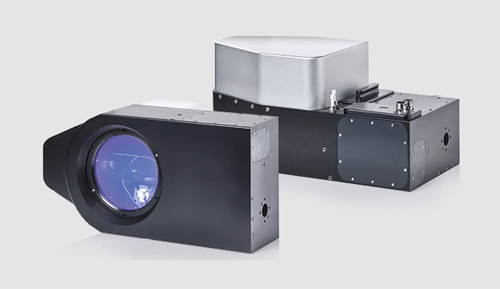

3-AXIS DEFLECTION UNITS

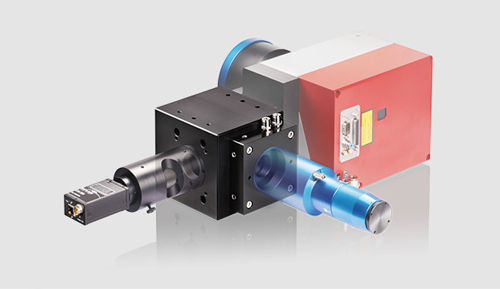

AXIALSCAN-12

-

The AXIALSCAN-12 offers a focus range in Z-direction of more than 200 mm for a 300 mm x 300 mm field. The RAYLASE twin shell design reduces thermal effects allowing low drift values.

Variable field sizes from 120 mm x 120 mm to 600 mm x 600 mmFEATURES

- Process 3D forms, planar, inclined and curved surfaces

- Offers highest focus range in Z-direction

- Smallest spot diameter and high mark quality

- Digital control via control card

- Typical field sizes (mm x mm): 120 x 120, 180 x 180, 300 x 300, 400 x 400, 500 x 500, 600 x 600

AXIALSCAN-20/-30

-

The AXIALSCAN-20/-30 deflection units offer very small spot diameters at large field sizes, flexibility, high scanning speeds, long term stability and low drift values.

Variable field sizes from 100 mm x 100 mm to 1,800 mm x 1,800 mm.FEATURES

- For wide working fields with small spot size and 3D-applications

- For laser power of up to 2.5 kW

- High speed Z-axis with double motor option

- Available options: Motorized, high power, high speed, low drift

- Variable field sizes (mm x mm): 100 x 100 up to 1,800 x 1,800

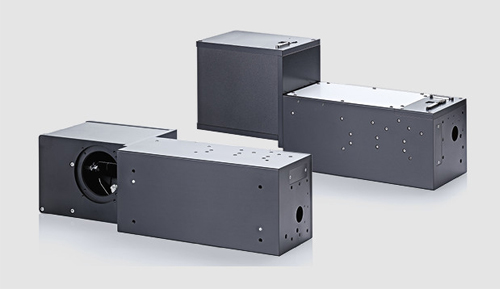

AXIALSCAN-30 DIGITAL II

-

The AXIALSCAN-30 DIGITAL II deflection units offer very small spot diameters at large field sizes.

Variable field sizes from 100 mm x 100 mm to 1,800 mm x 1,800 mm.FEATURES

- For large areas with small spot sizes and 3D applications

- Control via SL2-100 protocol 20 bit or XY2-100 protocol 16 bit

- Digitally controlled high-speed Z axis

- Greatly reduced power loss and minimal heat development thanks to digital PWM output stages

- Variable processing fields (mm x mm): 100 x 100 to 1,800 x 1,800

AXIALSCAN-30 DIGITAL II HP

-

The AXIALSCAN-30 DIGITAL II HP deflection units for large working areas with small spot sizes for laser power up to 4 kW.

Variable field sizes from 200 mm x 200 mm to 1,200 mm x 1,200 mmFEATURES

- For large areas with small spot sizes and 3D applications

- For laser power up to 4 kW

- Control via SL2-100 protocol 20 bit or XY2-100 protocol 16 bit

- Digitally controlled high-speed Z-axis

- Optimized long-term drift for highly challenging process quality

AXIALSCAN-50

-

The AXIALSCAN-50 DIGITAL series 3-axis deflection units with digital servo circuitry enhances dynamic performance and quality with a range of diagnosis possibilities.

Variable field sizes from 300 mm x 300 mm to 1,200 mm x 1,200 mm.FEATURES

- Smallest spot in the market

- High processing speed as a result of the patented twin motor drive

- For laser power of up to 1.5 kW

- Easily changeable lens set

- Variable field sizes (mm x mm): 300 x 300 to 1,200 x 1,200

AXIALSCAN 50 DIGITAL

-

The AXIALSCAN-50 DIGITAL series 3-axis deflection units with digital servo

circuitry enhances dynamic performance and quality with a range of diagnosis

possibilities.

Variable field sizes from 300 mm x 300 mm to 1,200 mm x 1,200 mm.FEATURES

- For high power applications up to 5 kW

- Digital high speed Z-axis

- High processing speed as a result of the patented twin motor drive

- Optional available: pilot laser function

- Variable field sizes (mm x mm): 300 x 300 to 1,200 x 1,200

AXIALSCAN-50 DIGITAL II

-

The with cutting-edge digital control electronics 3-axis deflection units of the AXIALSCAN-50 DIGITAL II series offer not only the smallest spot diameters with large processing areas, but also flexibility, long-term stability and exceptionally low drift values.

Variable field sizes from 300 mm x 300 mm to 1,000 mm x 1,000 mm.FEATURES

- For applications at up to 5 kW laser power (*at 50% capacity utilization (10,600 nm))

- Control via SL2-100 protocol 20 bit or RL3-100 protocol 20 bit and XY2-100 protocol 16 bit

- Digitally controlled high-speed Z-axis

- Optimized long-term drift performance for the highest process quality

- Optional: Pilot laser function

AXIALSCAN-70

-

The AXIALSCAN-70 offers extremely fine spot sizes in working areas up to 2,000 mm x 2,000 mm. The AXIALSCAN-70 is well equipped for high power applications of up to 2.5 kW.

Variable field sizes from 300 mm x 300 mm to 2,000 mm x 2,000 mm.FEATURES

- Robust industrial design

- Manual or motorized working field adjustments

- Extremely fine spots in various working areas

- Easily changeable lens sets (300 mm to 1,000 mm; 1,000 mm to 2,000 mm)

- Variable field sizes (mm): 300 x 300 up to 2,000 x 2,000

FOCUSSHIFTER

-

The FOCUSSHIFTER deflection units provide tiny spot diameters with flexible focusing range in Z-direction. The modular, compact, robust and pre-aligned design (CE) makes integration easy. The field sizes are determined by the f-theta objective used. The FOCUSSHIFTER is available for various wavelengths and in 15 mm aperture.

FEATURES

- Variable, easy to adjust focus range in Z-direction

- Modular and compact design for easy integration

- Excellent price-performance ratio

- Available aperture (mm): 15

FOCUSSHIFTER DIGITAL II

-

Thanks to its modular, pre-adjusted, compact and robust design, the FOCUSSHIFTER DIGITAL II is perfect for easy and cost-effective integration into specialized applications. The FOCUSSHIFTER DIGITAL II is available for various wavelengths and in 10 mm and 15 mm aperture.

FEATURES

- For easy, variable adjustment of focal height relative to the workpiece surface

- Control via SL2-100 protocol 20 bit or XY2-100 protocol

- Digitally controlled high-speed Z-axis

- Greatly reduced power loss and minimal heat develop-ment thanks to digital PWM output stages

- Available apertures (mm): 10, 15

FOCUSSHIFTER-CS

-

The FOCUSSHIFTER-CS deflection units provide tiny spot diameters with flexible focusing range in Z-direction. The modular, compact, robust, and pre-aligned design (CE) makes integration easy.

The FOCUSSHIFTER-CS is available for various wavelengths and in 10, 14 and 15 mm apertures.FEATURES

- Variable, easy to adjust focus range in Z-direction

- Modular and compact design for easy integration

- Perfect for 3D-processing

- Digital trigger via SP-ICE-1 PCIe PRO und SP-ICE-3 control card

- Available apertures (mm): 10, 14, 15

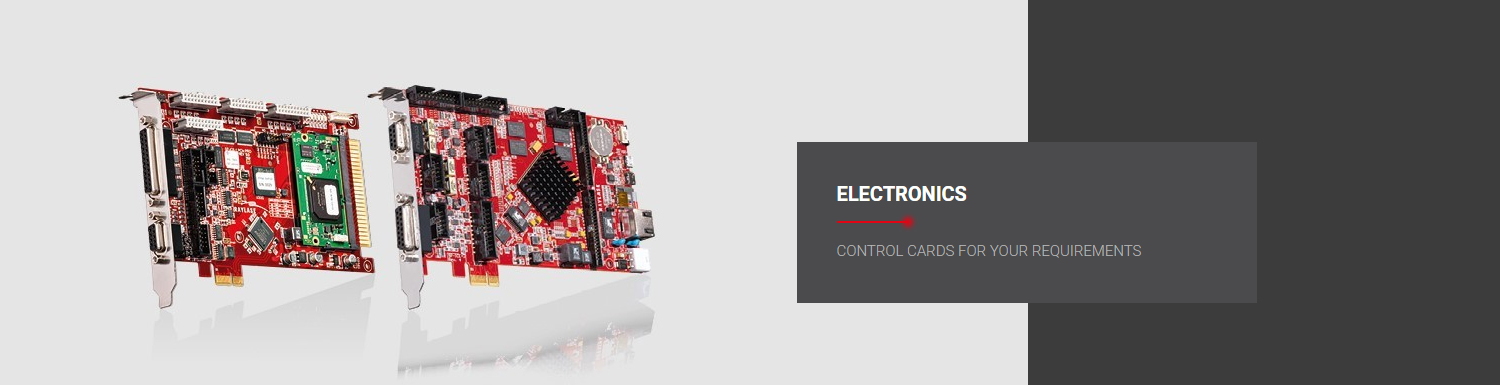

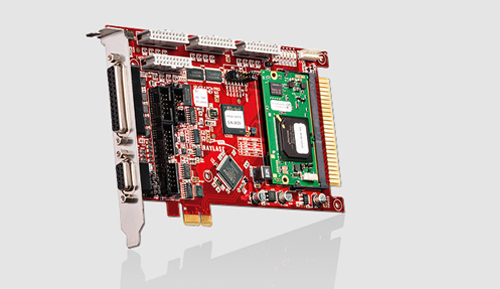

ELECTRONICS

- RAYLASE incorporates industry-leading know-how and R&D to deliver precise state of the art electronics focused on satisfying customers' application requirements. In addition to innovative electronic components built into the deflection units and power control devices, the RAYLASE electronics portfolio consists of intelligent control cards to drive the deflection units. These also function as an interface between software and mechanical systems with the capacity to control external machines.

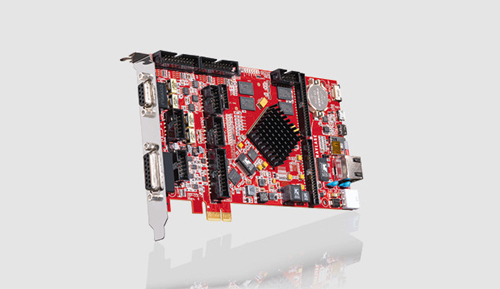

SP-ICE-1 PCIE PRO

-

FEATURES

- Micro SD Card with 4 GB memory on-board

- Master-slave and master-master operation

- Marking-and-processing-On-The-Fly (MOTF) as an option

- Interface XY2-100 enhanced with feedback channel

- Interface: PCIe

SP-ICE-3

-

FEATURES

- Controls 2-, 3-, 4- and 5-axis deflection units and all common laser sources

- Speed- and position-dependent laser control

- Extended Marking-and-processing-On-The-Fly functionality (MOTF)

- Can be used as external control card via Gigabit Ethernet

- Support of RL3-100 protocol

WELDMARK® 3

-

YOUR BENEFITS

weldMARK® 3 stands out due to its full 3D-processing functionality. This enables customers to leverage the full performance of their 3-axis deflection units, such as the RAYLASE product lines AXIALSCAN and FOCUSSHIFTER. weldMARK® 3 provides additional functionality for a range of 3D laser processes, such as deep engraving, laser drilling and laser cutting. weldMARK® 3 is easy to use for advanced 3D processes like trepanning or glass cutting. The weldMARK® 3 software suite supports RAYLASE control cards SP-ICE-1 PCIe PRO and SP-ICE-3. For 2-axis deflection units weldMARK® 3 offers new features like “Inline Parameter Switching”. This feature allows for varying laser parameters along the processing path. 2-axis deflection units also benefit from the new “Spot-offset” feature. This helps improving the marking quality especially of small objects by adjusting the spot-position to the contour. SOLUTIONS

AM-MODULE NEXT GEN

-

YOUR BENEFITS

The AM-MODULE NEXT GEN for fibre-coupled lasers features homogeneous power density and exceptionally low drift values. It enables ultradynamic, rapid processing with flexible spot diameters. Full digital, model-based control is ensured with absolute precision. up to 4 modules can be operated simultaneously over one construction field. Direct connection of a photodiode or pyrometer for process control is also possible.

FEATURES

HIGH POWER WELDING MODULE

-

TYPICAL APPLICATIONS

Welding battery cell covers is a typical application for the HP welding module, as is welding cell contact surfaces made of aluminum or copper plates in order to electrically connect the individual cells to a battery block. The module is also a perfect solution for welding steel plates using the “remote welding” method, mounted on axis gantries or robot arms. In addition to the deflection unit with 30 mm aperture, deflection units with 20 mm aperture are available for plastics welding.

FEATURES- 3 deflection unit types available: “Economical", “High speed”, “Full digital high precision”

- Fiber collimator for all standard fibers and beam parameter products

- On-Axis camera and/or sensors for monitoring weld seam parameters and protective glass monitoring

- Wide range of mirror substrates and coatings for diverse applications

- Laser power up to 6 kW (8 kW, 75 % duty cycle)

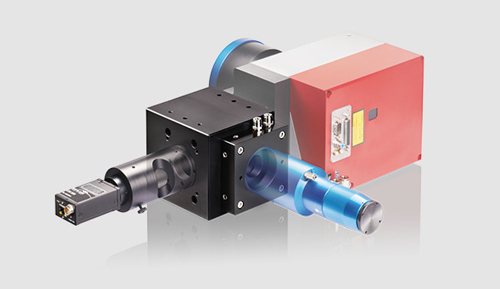

ULTRA-HIGH-SPEED SCANNER

-

YOUR BENEFITS

The highly innovative, revolutionary ULTRA-HIGH-SPEED SCANNER (UHSS) opens up new application areas for ultra-short pulse lasers at unprecedentedly high speeds. RAYLASE has achieved these high deflection speeds for the UHSS by combining an extremely precise polygon with two high-stability galvanometer scanners. One scanner takes care of corrections for the fast axis of the polygon and the other scanner provides the line off-set as well as corrections for the second axis. The polygon scanner provides extraordinarily high speed along its scan path. The RAYLASE UHSS is the only system that enables companies to scan their usual work areas ultra-fast and very precisely, reducing production time and costs significantly.

FEATURES- Suitable for ultra-short pulse lasers

- Extremely low drift level

- Perfect for applications requiring a high degree of filling

- Available apertures (mm): 15

MACHINE VISION CONTROL

-

MACHINE VISION CONTROL

- Automatic localization of workpieces

- Adaptation of the laser process to the part position and rotation

- Immediate quality inspection during and after the process

RAYLASE Machine Vision Control (MVC) enhances laser processes by the valuable possibilities of modern Machine Vision Control. A well-adjusted system of industrial cameras, lenses, optical adapters, illuminations and intelligent image processing software simplify the development of industrial laser processes, reduces system costs and allow for the advanced control, monitoring and in-line quality inspection. The Machine Vision Control solution is capable to automatically recognize the position and rotation of a workpiece by recurring patterns or fiducials. In the design phase, these reference points can be taught to the system fast and intuitively. RAYLASE MVC adapts the parameters of the laser process to the actual workpiece position even when it is continuously advancing on a conveyor belt. Right after the process, the same system verifies the success of the laser process.

APPLICATIONS- Marking and perforation of surfaces and packages, also in Marking-and-processing-On-The-Fly (MOTF) applications

- Micro structuring and nano structuring

- Surface treatment

- Cutting, fine cutting, drilling and welding with laser beam power levels of up to 6 kW (On-Axis) or any power level (Off-Axis)

- Additive manufacturing / 3D-printing

- Processing of plastics, fabrics, glass, food products, carbon fiber composites, metals and diamonds

- Process monitoring and optical quality inspection of workpieces

ON-AXIS CAMERA APPLICATION

-

YOUR BENEFITS

High-precision laser process monitoring thanks to inherent drift compensation

Thanks to a special dichroic element inside the deflection unit, the camera can be coupled into the optical path of the laser beam. This setup allows for the precise localization of the workpiece and the adjustment of the laser process, even at very short working distances. This renders high efforts in mechanical fixtures for the accurate positioning of parts redundant. Since laser beam and camera share the same optical path, this setup inherently compensates for the drift in the laser beam deflection and ensures especially high accuracy in the localization of workpieces as well as in the quality inspection of the process results.- All working distances, also at fΘ < 163 mm

- High-precision (< 10 µm)

- Inherent drift compensation

- Recognizes fiducials in the laser field and within a narrow frame strip

- Laser beam power up to 6 kW

- Different refraction indices for different wavelengths of the laser and the visual light are compensated in X-Y plane

OFF-AXIS CAMERA APPLICATION

-

Large area laser process monitoring and MOTF processing

While On-Axis process monitoring offers many benefits, for some application scenarios the classic Off-Axis integration of industrial cameras is still appropriate. When parts shall be processed during constant conveyance, e.g. on a belt, Off-Axis cameras allow the early localization of the part and its speed in order to start and adapt the laser process accordingly. This scenario is also referred to as Marking-and-processing-On-The-Fly (MOTF).

Furthermore, at large processing fields, where precision requirements are less critical, this approach to utilize modern Machine Vision technology is the right choice for the optimization of laser processes and assurance of high product quality.

FEATURES- Integrated workpiece localization and quality inspection for working distances from 150 mm, i.e. fΘ ≥ 163 mm

- Large working field sizes feasible

- Marking-and-processing-On-The-Fly (MOTF) available

- Geometric calibration of cameras and laser field require

- No inherent drift compensation

CAMERA ADAPTER

-

YOUR BENEFITS

Used in combination with our On-Axis camera lenses, the RAYLASE CAMERA ADAPTER allows digital cameras to be connected, enabling the “On-Axis” observation of workpieces via the mirrors in the deflection unit. The active process can be observed and detected “online”, while the process result can be observed and detected "offline”. Additional sensors can be adapted as an alternative or extra option.

FEATURES- Compatible with all RAYLASE 2-axis systems with 7 mm to 20 mm apertures

- Collimator mount sets for all standard collimators

- On-Axis camera with lenses for process positioning and monitoring

- Different laser and observation wavelengths

- Input aperture: 20 mm, laser power up to 500 W

CAMERA ADAPTER HP

-

YOUR BENEFITS

Used in combination with our On-Axis camera lenses, the RAYLASE Camera Adapter HP allows digital cameras to be connected, enabling the “On-Axis” observation of workpieces via the mirrors in the deflection unit. The active process can be observed and detected “online”, while the process result can be observed and detected “offline”. Additional sensors can be adapted as an alternative or extra option.

FEATURES- Compatible with all RAYLASE 2-axis systems with 20 mm (L) and 30 mm apertures

- Water-cooled fiber collimator connection for all standard collimators

- On-axis camera and/or sensors for position monitoring or monitoring of weld seam parameters

- Different laser and observation wavelengths

- Input aperture: 30 mm; Laser power up to 6 kW (8 kW/75 % duty cycle)

APPLICATIONS

-

Laser material processing has many applications where RAYLASE solutions are often used. At this point we would like to present some of the most common applications.

RAYLASE solutions can be used in many other industries. If your industry is not mentioned here as an example, please do not hesitate to contact us. We explore with you the benefits that can be derived from RAYLASE solutions for your industry.

Our deflection units are used in applications where a focused laser beam needs to be directed onto a workpiece. The possible applications of such laser processing can hardly be fully enumerated. In cooperation with our customers, our R&D department is constantly developing products for new applications. Typical applications for our deflection units include, for example...

MARKING AND ENGRAVING

-

Laser technology has become the state of the art in many areas of production. The laser is suitable for markings on virtually all materials and shapes.

RAYLASE is the market leader in solutions for marking curved, slanted or unusual surfaces.

These systems off the following advantages when marking:

Consistently high spot quality on the component

No mechanical object displacement necessary

Maximum productivity

Differentiate your systems from the competition

ITO-PATTERNING

-

ITO-patterning of glass is used for example in the high-end display and touch-screen technology. For this patterning work, laser technology with RAYLASE solutions is ideal.

RAYLASE offers highly precise components with which absolute invisible structuring of transparent ITO-coatings can be realized.

LASER CUTTING

-

With a laser narrow kerfs can be achieved and thus parts are precision cut. Laser cutting is ideal for metallic materials as well as for plastics, textiles, glass and ceramics.

A special form of laser cutting is the laser scribing, as it is for example used in the packaging industry for “easy opening”. RAYLASE solutions offer short focus diameters to obtain ideal results in laser cutting.

RAYLASE solutions for laser cutting give you almost unlimited cutting paths. Particularly noteworthy are the RAYLASE solutions to make three-dimensional cuts, for example, in the processing of glass.

FLEXIBLE 2.5D DEEP ENGRAVING

-

RAYLASE offers a variety of solutions for flexible processing in depth. These range from the texturing on tools by deep engraving to in-glass marking.

RAYLASE solutions consist of hardware and software to perform the tasks of flexible deep processing precisely with lasers. In particular, our new software weldMARK® 3 provides further functionality for a variety of 3D-laser machining processes. For example, for deep engraving, laser drilling, laser cutting. weldMARK® 3 offers optimized machining processes such as trepanning or optimized cutting tools works.

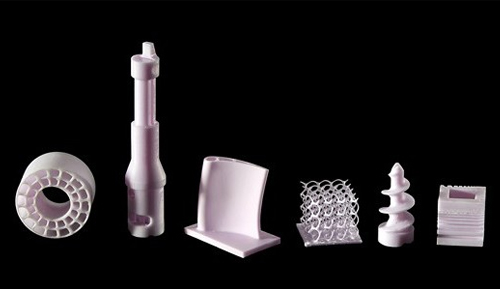

3D-PRINT CERAMIC COMPONENTS (LCM)

- Solution for 3D-print of ceramic components.

INDUSTRIES

-

RAYLASE solutions for material processing with lasers are used in many industries.

Here we describe some of the common applications in various industries.

RAYLASE solutions can be used in many other industries. If your industry is not mentioned here as an example, please do not hesitate to contact us. We explore with you the benefits that can be derived from RAYLASE solutions for your industry.

PACKAGING INDUSTRY

-

High demands are made from trading on the packaging industry. Packaging should present the product appealingly, ensure high-quality storage and be easy to open.

In addition, the packaging must take over tasks in the distribution chain from producer to consumer. This can be for example the protection during transportation and storage, the maturity control and ensuring easy preparation and processing for consumption.

The process with the laser allows the weakening of targeted individual layers of packaging, for example, as perforation. Likewise, by means of laser technology, tiny perforations, which helps to create a defined atmosphere within the package is introduced. In all these applications in the packaging industry solutions from RAYLASE help.

The processing of packaging films is usually on large rolls at very high speeds of several hundred meters per minute. These requirements are a perfect match for RAYLASE Marking-and-processing-On-The-Fly solutions.

TEXTILE INDUSTRY

-

RAYLASE solutions offer advantages in the textile industry through high flexibility and precision. Some laser applications in the textile industry are:

- Cutting and structuring of fabrics in the clothing industry

- Processing of decorative textiles

- Cutting of special fabrics - such as airbags

- Bleaching fabrics – e.g. used look for jeans

RAYLASE solutions offer particular advantages due to large field sizes for the textile industry. The 3-axis deflection unit AXIALSCAN-50 and AXIALSCAN-70 offer here the largest processing fields with the smallest spot Diameters.

AUTOMOTIVE INDUSTRY

-

RAYLASE offers a variety of solutions for the automotive industry:

- Marking of components

- 3D Day-and-Night design

- Laser cutting of components and metal foils

- Welding

RAYLASE offers solutions to help you achieve optimal results in the automotive industry:- 3-axis deflection units for working on 3D-surfaces

- 3-axis deflection units for optimal spot diameter in the working field

- 2-axis deflection units for welding applications up to 5 kW

ELECTRONICS INDUSTRY

-

RAYLASE solutions help for many applications in the electronics industry:

- Marking of electronic components

- Depanelization

- Via-hole drilling

- ITO-patterning of glass surfaces

- Laser Direct Structuring

- Backlight-Illumination of flat panels

RAYLASE is market leader in solutions for marking of curved, slanted or uneven surfaces.

These systems provide you the following benefits when marking electronic components:- Consistently high mark precision on the component

- No mechanical object displacement necessary

- Maximum productivity

- Differentiate your systems from the competition