- Offer Profile

Quality made in Germany

For many years PHOTON ENERGY GmbH has been established as a reliable partner for industry and science. The globally acting company focusses on laser marking systems and OEM laser sources for industrial laser materials processing. The individual requirements of our customers are our number one priority. Therefore you can count on our tailor-made solutions and comprehensive support.

Our high quality standards ensure a leading position as supplier of very reliable high power laser sources and systems for a wide range of applications. PHOTON ENERGY GmbH is ISO 9001:2015 certified.

Laser marking systems and OEM laser sources for industrial laser materials processing

- Our product range covers laser sources, laser sources

including beam delivery as well as complete laser marking systems.

The laser sources are pulsed diode pumped solid state lasers (DPSSL) providing pulse widths in the ns or ps range and are particularly designed for micromachining applications. These OEM components are easy to integrate in larger system environments and are especially developed for system integrators.

Our OEM marking systems provide you with a complete and independent solution. The marking systems include a laser source, beam adaptation and delivery, galvo scanner as well as the required software to control the system. The different modules are specially matched and form a stable mechanical unit that is ideal for integration in assembly lines or special machines. The OEM markers can be controlled with our proprietary PHOTONmark software.

The laser marking systems feature a laser class-1 housing and provide a complete solution as a fully equipped work station for end customers, plug-and-play.

Due to our high level of vertical integration we can provide you with capacity and flexibility at all three product lines.

Providing outstanding quality is our number one priority: PHOTON ENERGY is ISO 9001:2015 certified since 2003. ps laser sources

- CEPHEUS is a compact ultrafast laser. The pulse width

of this modelocked diode pumped solid state laser are typically below 15 ps.

These ultrafast laser pulses induce nonlinear multi-photon absorption

processes which to a large extent make the processing independent from laser

wavelength. That means that nearly all materials, even those being

transparent at the laser wavelength, can be processed. A further advantage

of ultrafast laser pulses is the fact that ablation is not based on heat

effects like with nanosecond lasers. It´s a so called “cold ablation” which

makes the CEPHEUS picosecond laser a perfect choice for all kinds of

processes where deterioration of the work piece due to heat induced melting,

deformation or discoloration are not acceptable.

Pulse energies in the microjoule range provide a comparably small material ablation per pulse and therefore significantly increase the precision of the process compared to nanosecond lasers

Prior to its delivery every CEPHEUS laser passes a comprehensive final test.

Robustness and reliability are ensured by a special endurance test which is part of the final check procedure.

The endurance test comprises:- Long term test for minimum 48 hours with temperature fluctuations of +/- 5 degree

- Test against electrical discharge with Tesla coil (a few tens kV)

- Vibration and mechanical shock test (see video)

Ultrashortpulse laser CEPHEUS

- Thus, CEPHEUS lasers are the right choice wherever

ns-lasers can’t meet the required precision standards.

CEPHEUS is designed for various applications. The laser is able to generate high pulse energies of up to 300 μJ which is needed for applications like precision hole drilling. CEPHEUS can also work at high repetition rates making it the right choice for fast processing. Because of this variability the available laser power can be applied efficiently, thus optimizing the process in terms of quality and speed.

The technical concept of the CEPHEUS laser system allows operating it in a burst mode regime. That means that instead of a single laser pulse a set of pulses within a short period can be generated. All critical parameters can be well adjusted to your process requirements providing optimum flexibility.

CEPHEUS can be easily integrated into your system because of its very compact design and air-cooling. The unique optical concept as well as its robust opto-mechanical design provide excellent stability, making it a perfect choice for shift operation in industry.

ns laser sources

-

AQUILA lasers are diode pumped solid state lasers (DPSSL). They are pulsed lasers with their pulses being in the ns range and provide an average output power of up to 200 W.

Because of these properties AQUILA lasers are well suited for materials processing. Possible applications cover drilling, cutting, engraving and marking of metals, plastics, ceramics or glass.

The lasers are designed as OEM-devices which are easy to integrate and are characterized by their reliability and robustness. Their laser parameters can be easily adjusted on a wide scale which makes the lasers particularly flexible. Without any hardware changes it is for example possible with the same system to perform both annealing marking or engraving on metal, two processes that require significantly different laser parameter settings.

Because of their high average output power of up to 200 W, AQUILA lasers are ideal for processing large areas or volumes that simultaneously require short cycle times. AQUILA

-

AQUILA lasers are diode pumped solid state lasers (DPSSL). They are pulsed lasers with their pulses being in the ns range and provide an average output power of up to 200 W.

Because of these properties AQUILA lasers are well suited for materials processing. Possible applications cover drilling, cutting, engraving and marking of metals, plastics, ceramics or glass.

The lasers are designed as OEM-devices which are easy to integrate and are characterized by their reliability and robustness. Their laser parameters can be easily adjusted on a wide scale which makes the lasers particularly flexible. Without any hardware changes it is for example possible with the same system to perform both annealing marking or engraving on metal, two processes that require significantly different laser parameter settings.

Because of their high average output power of up to 200 W, AQUILA lasers are ideal for processing large areas or volumes that simultaneously require short cycle times.

Laser marking systems

-

PHOTON ENERGY´s solutions are made for customers who are looking for a complete and ready-to-use laser marking system. The machines stand out due to their flexibility as well as their intuitive handling. Our marking systems can either be used as stand-alone-device or be integrated into automation solutions.

MISTRAL

-

The laser marking system MISTRAL was introduced in 1997 in Munich at the LASER World of Photonics trade fair. Because of its groundbreaking compact design it pioneered the era of compact laser marking systems.

Since that time we continuously adjusted and improved the technology used for the MISTRAL systems, today making it more precise than ever. Optional fittings include a camera system as well as a rotary axis.MISTRAL can either be used as a stand-alone-unit or be implemented into production lines. For that purpose, the upper marking cabinet can be separated from the supply unit. MISTRAL itself meets all requirements of a Class I laser.

Depending on the field of application, our integrated OEM-markers offer various possibilities to equip a MISTRAL with the best fitting laser source for your particular demand. FIBER lasers are suited for fast processing with considerable material removal or large marking areas.

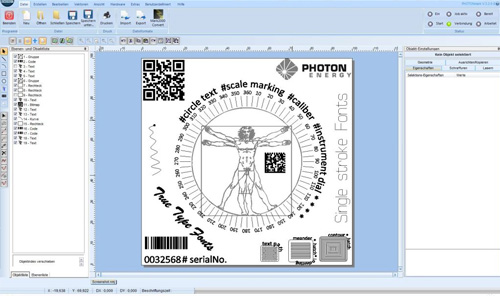

PHOTONmark, our proprietary software for marking applications is included with the MISTRAL system.

WORKSTATION

-

WORKSTATION is a universal laser processing cabinet for various marking and structuring applications up to 2.5D. It can be equipped with our ns-laser-sources AQUILA or FIBER or our ultrafast laser system CEPHEUS. It comes with a software-controlled z-axis. Additional options include a rotation axis or an X-Y-table. The large semiautomatic door and the z-axis vertical stroke of 300 mm enable markings of large and bulky objects.

The aluminum profile based design is extremely stable and can be operated while sitting or standing in front of the system. The WORKSTATION is designed as a stand-alone unit and can easily be transferred to another location due to its robust construction.

The WORKSTATION meets all requirements of a class I laser device.

The WORKSTATION is delivered with our proprietary software for marking applications, PHOTONmark.

WORKSTATION L

-

The WORKSTATION L is a very compact and flexible laser system. It features a large marking area of 500 x 500 x 500 mm³ and can be equipped with all of our beam sources. The system satisfies the highest standards regarding quality and performance. The semi-automatic door and adjustable display-mount allow for an ergonomic workplace.

The WORKSTATION L can be extended with options like a rotary table for all-round machining or a rotary tilting unit. Additionally an autofocus or our camera system „CamVision“ with its different packages can be integrated which in many cases facilitates the processing.

The machine is delivered with our in-house development PHOTONmark. This laser control software offers a user-friendly easy-to-understand layout which can be used to realize every marking-scenario one can imagine.

The WORKSTATION L meets all requirements of a class 1 laser device.

WORKSTATION XXL

- The WORKSTATION XXL can be armed with all of our laser

sources, which includes our ultra short pulse lasers with a mean output

power of up to 50W. This opens up a wide range of possible applications:

from PERMAblack markings for the medical industry to deep markings for

mechanical engineering.

It comes with a software-controlled z-axis. Additional options include a rotation axis or an x-y-table. The aluminum profile based design is extremely stable and can be operated while sitting or standing in front of the system. The very wide, fully-automatic door and the scope of the z-axis of ca 300mm allow for ergonomic loading of large or bulky objects.

The WORKSTATION XXL meets all requirements of a class I laser device, it is delivered with our intuitive software for marking applications, PHOTONmark.

OEM laser markers

-

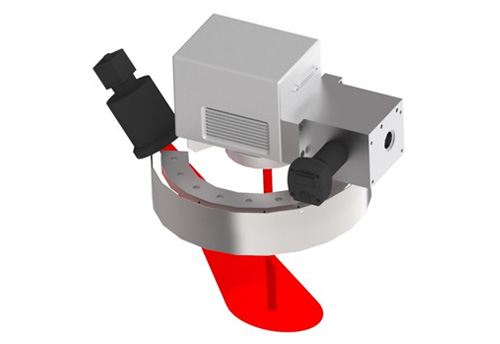

Our OEM marking systems provide you with a complete and independent solution.

Examples for the use of our OEM markers are PHOTON ENERGY’s marking cabinets MISTRAL and WORKSTATION. The OEM markers can be controlled with our proprietary PHOTONmark software

The marking systems include a laser source, beam adaptation and delivery, galvo scanner as well as the required software to control the system. The different modules are specially matched and form a stable mechanical unit that is ideal for integration in assembly lines or special machines.

AQUILA Mark

- AQUILA Mark is designed for marking at high process

speed, enabling you to work large quantities in short cycles. Even larger

marking areas can be labeled. Furthermore this laser can produce deep

engravings with excellent precision on materials like steel as well as on

non-ferrous metals.

The AQUILA-Mark line was developed for use under extreme conditions and is therefore especially robust. Due to their high average power (120 or 200 Watts) AQUILA lasers are especially suited for various applications in the field of materials processing. The lasers are ideal for tasks which require the work on large areas or volumes in a short amount of time.

AQUILA lasers are diode pumped solid state lasers (DPSSLs). In comparison to lamp pumped lasers they stand out due to their ideal combination of beam quality, pulse repetition frequency and pulse energy. Additionally they provide the ability to vary the laser parameters on a wide scale.

Of course the laser is protected against optical back reflections.

AQUILA Mark is delivered in combination with our proprietary software package PHOTONmark.

FIBER Mark

- FIBER Mark is designed for marking at high process speed,

enabling you to work large quantities in short cycles. Even larger marking

areas can be labeled.

Furthermore this laser can produce deep engravings with excellent precision on materials like steel as well as on non-ferrous metals. The FIBER especially shows its advantages at marking annealing colors on steal. For even quicker applications, the 50W- version suits the best.

The FIBER-Mark line was developed for use under extreme conditions and is therefore especially robust. Due to their power (20 or 50 Watts) FIBER lasers are especially suited for various applications in the field of materials processing.

The compact processing head is easy to integrate in assembly lines or workstations. Due to the high efficiency the connection line is very low.

Of course the laser is protected against optical back reflections.

FIBER Mark is delivered in combination with our proprietary software package PHOTONmark.

CEPHEUS Mark

- This OEM laser system is a powerful, yet very compact and

robust marking system.

Its extremely short pulses (typically <15 picoseconds), very limited material ablation per laser pulse and the possibility of “cold processing” make CEPHEUSMark the ideal laser marking system for delicate, highly precise structures on sensitive materials (like wafer-thin films).

These ultrafast laser pulses induce nonlinear multi-photon absorption processes which to a large extent make the processing independent from laser wavelength. This means that almost all materials, even the ones like glass that are typically transparent to these wavelengths can be processed with our ps-lasers.

Because this processing technique does not rely on heat effects like with nanosecond lasers, meaning there is no deterioration of the work piece due to heat induced melting, deformation or discoloration it can be used for a variety of applications that wouldn’t have been possible with conventional lasers.

Customized solutions

Customized solutions and contract manufacturing

- You need a tailored solution for your application? Let´s

talk!

Our experienced development team has the expertise to design customized solutions in the fields of optics, mechanics, electronics and software. Our laser sources are adapted to your particular requirements. In our application lab we determine the optimum optical design and the best fitting application parameters for you.

Software

Camera solutions

- Our different camera options facilitate the positioning of markings with the CAD-editor. This can be done manually as well as automatically.

Graphical intuitive user interface

- Our PHOTONmark laser control offers you a user friendly, easy to understand layout and can be used to realize any kind of marking application.

Integrated CAD-Editor

- Part of the program is also a CAD-editor which makes it easy to generate and modify logos and other graphics.

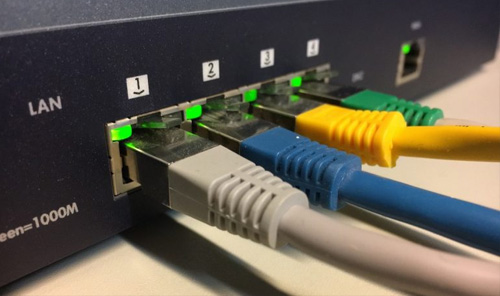

Interface for automation

- Our marking systems can be integrated into your manufacturing process using a multitude of interfaces.

Material data base

- Our software facilitates the marking process by providing you with a set of laser parameters for your application.

Data interchange

- Extensive possibilities for data interchange enable the connection to a SAP-environment as well as the integration into a UDI compliant production.

Camera Options

- The classical way of positioning the marking on a

workpiece is a redlight frame or a marking simulated by a laser pointer.

These techniques remain sufficient for many applications.

If the user wants to see the exact position of the marking on the workpiece, there’s no better solution than a camera system.

PHOTON ENERGY’s different camera solutions enable fast and exact markings. The range of possibilities reaches from simple positioning help (MAP) to fully automatic positioning on a μm-scale with our SMART option.

Functions - MAP Marking by Augmented Positioning

- MAP generates pictures of the marking area by using

different available camera systems (CamVision or CamVisionPro). Our image

correction algorithm adjusts those pictures and displays them in our laser

software PHOTONmark.

The marking can be placed on the picture which equals placing it directly on the workpiece. This ensures placing the marking exactly where you want it.

Functions - SMART Simple Marking by Augmented Reality Targeting

- The function package SMART is available for the

CamVisionPro and CamVisionCombi versions. With this solution it is possible

to integrate Pre- and Post-processes into the procedure.

An assistant intuitively introduces the Shape-Detection capabilities of our system.

The camera systems - CamVision

- The most simple method of depicting the marking field in the laser software is CamVision. The camera looks onto the marking field sideways at an angle. The picture is adjusted for the angle and then displayed to the user. With MAP and drag-and-drop all elements that you wish to mark can be placed on the picture. The marking result is visible before the marking process even started. This system makes it easier to set up the laser process and minimizes rejects.

The camera systems - CamVisionPro

- High-precision positioning is possible with CamVisionPro.

The camera looks onto the marking field through the scanner unit and focal lens. To achieve a maximum of precision the pictures are adjusted by the most advanced image correction algorithms.

The size of each individual picture is smaller with this method, but a larger image can be produced by merging those pictures to a larger grid.

The camera systems - CamVisionCombi

- Combining CamVision and CamVisionPro delivers a maximum

of flexibility and precision.

The lateral camera generates a complete picture of the marking area. Finding parts on the workpiece that are of interest for the marking process is easy that way. This region of interest (ROI) can then be looked at with CamVisionPro which delivers high-resolution pictures. This means that filigree areas can be examined without having to screen all of the marking field. This equals significant savings in process time.

Applications

- Depending on target material and characteristics of the laser source various effects may be realized. No matter if you process metal, ceramics, glass or plastics, for nearly any material we can provide the appropriate laser system.

Metal

Engraving

- All metals can be engraved with the lasers offered in the product range of PHOTON ENERGY. In this respect, the good beam quality and short pulse durations are particularly useful, especially for the engraving of non-ferrous and precious metals.

Black marking PERMAblack

- A saturated black color of the metallic surface can be achieved by using our ultrashort pulse lasers with our proprietary PERMAblack marking process. In contrast to annealing colors, the markings created with this laser have a deep black appearance that is independent of the viewing angle.

Annealing colors

- Annealing makes use of the structural change that occurs on steel and titan at high temperatures. A well-known example of annealing colors are stainless steel exhaust pipe parts, which turn dark at high operating temperatures. With the laser, this effect can be achieved even on a very small area thanks to its high thermal impact.

Cutting

- The cutting of metals is possible if a sufficient laser power is available and if it is ensured that the released material can leave the incision area. This can be achieved by configuring a fixed laser beam with high-velocity auxiliary gas.

Material removal

- Corrosion protection layers made of plastic materials that are applied on a metallic substrate can be removed with a high-power laser. The excellent removal performance and a homogenous beam profile ensure high removal rates. The metallic substrate is not damaged in the process and remains available for further processing (e.g. via adhesive bonding or galvanic methods).

Plastics

Carbonization

- Many types of plastic react to the laser by producing carbonization effects, which can be used to achieve a dark coloration. This ensures a very good contrast in light-colored plastics. The important parameter for this effect is the absorption of laser light by the material. This is why it may be beneficial to use a green-light laser for some plastic types.

Engraving

- Engravings with material removal are particularly suited for thermosetting plastics. A good legibility is achieved due to the reflection contrast of the engraving.

Foaming

- In certain plastic compositions the plastic foams when exposed to laser light. This changes the color, for example from black all the way to white or a soft brownish color. This ensures an excellent color contrast. Since this type of labeling can be performed with very low power, the method can be used for high-velocity applications.

Material removal

- An outstanding contrast can be achieved by removing the upper layer in coated plastic parts. Material combinations whose top layer interacts more strongly with the laser light than the substrate material are particularly suited for this method.

Ceramics

- Ceramics are materials characterized by high abrasion resistance and hardness. Processing these components requires laser sources providing excellent beam quality. This also facilitates marking with character heights of less than 0.5 mm.

Engraving

- Almost all ceramics can be engraved with our lasers. Both the good beam-quality as well as the ultrashort pulses of our lasers enable stress-free processing with no heat-induced effects.

Color change

- Depending on the material composition, a color change can be realized on a variety of different ceramics.

Glass

Surface marking

- Appropriate laser parameters for marking of glass depend strongly on the particular glass type used. Standard sheet glass or lead glass and many types of optical glasses are well processed using our CEPHEUS laser.

Inner glass marking

- With our lasers, marking very close to the surface is possible without damaging the surface. This can be realized at high process speeds, which makes our product highly competitive.

Cutting

- Laser cutting of glass has many advantages compared with conventional cutting methods. Laser glass cutting is contactless, almost debris-free, zero-gap processing. In many cases glass parts cut with lasers don’t require post-processing.

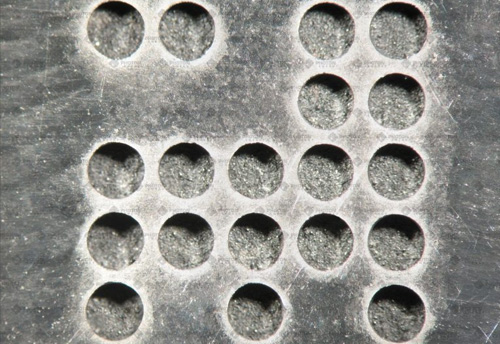

Micromachining

- Many industrial applications rely on laser micro

machining solutions. Compared to conventional technologies lasers enable

faster speed and more precise results while at the same time offering a

lower cost of ownership. Both our short pulse and ultrashort pulse laser

sources can be used for such operations.

Micromachining refers to the processing of materials on very small scales. These techniques can be used for processes like precise drilling, cutting, structuring or micro marking of various materials. Our lasers are for instance used in applications like UDI-compliant, autoclavable markings of stainless steel or drilling in glass for lab-on-a-chip applications.

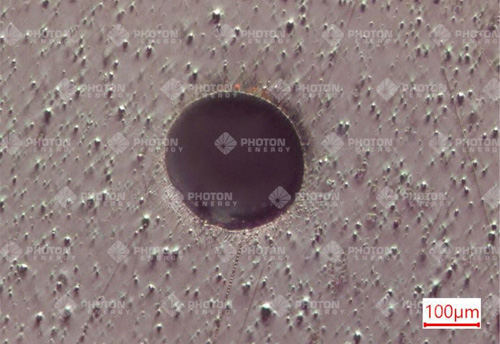

Drilling

- Creating micro holes plays an increasingly significant role in many industries. Applications include drilling on metal, polymers and glass.

Processing within glass

- This includes cutting of displayglass for smartphones as well as drilling in glass for lab-on-a-chip applications.

Structuring

- PHOTON ENERGY particularly concentrated on investigating the process steps required for the fabrication of displays and thin film photovoltaic cells.

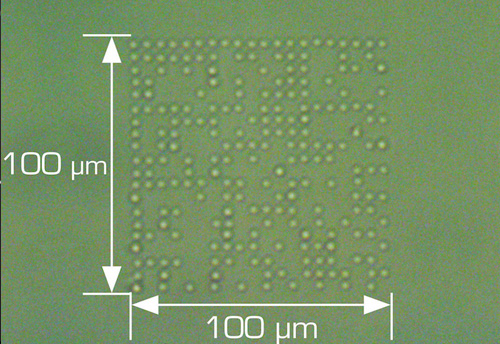

Micromarking

- Since the deposited heat of the ps-laser is very little,

small markings without heat affected zones are achievable. This can for

instance be applied on a wafer-target material. Laser treatment with

ultra-short-pulse lasers like the CEPHEUS is a so-called “cold ablation”

process.

Medical

- Medical technology at PHOTON ENERGY

With over 25 years of experience in the field, our medical department is one of our key assets. PHOTON ENERGY offers solutions for a wide variety of medical applications including autoclavable markings on stainless steel, aluminium workpieces or implants. Our systems can easily be integrated into a UDI-compliant production.

Certified processes for the medical industry

As a certified manufacturer of medical laser systems, we are well acquainted with the special requirements of the medical industry. Consequently, we implemented the so called Good Manufacturing Practices, to ensure that our work adheres to the highest quality standards. Our medical-team will be at your side throughout every step of your project and provide you with valuable support.

Medical devices

- PHOTON ENERGY uses its PERMAblack-technology to mark surgical instruments. Compared to the technique typically used by our competitors, our disruptive approach distinguishes itself through significant advantages.

Implants

- Lasers are used in the production of various implants like hip sockets today. The marking process with lasers has many benefits

UDI-markings on medical products

- PHOTON ENERGY has developed an add-on to PHOTONmark that

allows to seamlessly integrate our marking systems into the udi-process