- Offer Profile

- In 2011 two young innovators

with a passion for AI-driven software and robots decided to combine those

technologies to solve problems in an industry badly in need of innovation.

They chose fulfillment.

3 technologies are fundamentally changing the nature of how things work: Artificial Intelligence, Machine learning and Robotics. Greyorange combiness all 3 to shape the future of fulfillment in real time.

Fullfillment Operating System Overview

-

Welcome to the age of immediacy

Your fulfillment operation is already feeling the impact

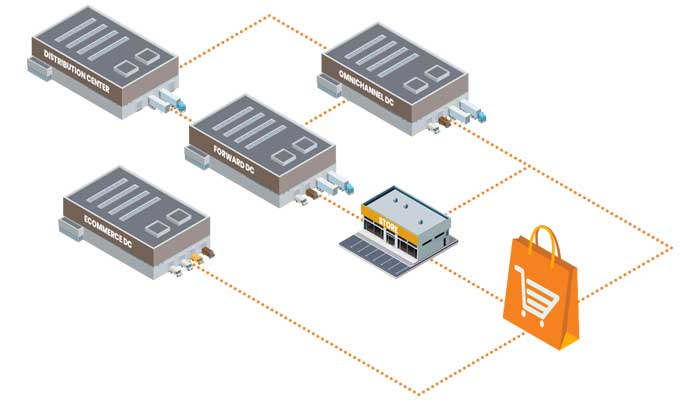

In addition to customer-driven choices in the thousands, multiple channels and destinations, unlimited buyers and hundreds of form factors, now you must execute on all of it in time windows never before imagined.

Buyers, whether a business replenishing retail inventory or a consumer receiving doorstep delivery—increasingly view next day/same day—even multi-hour delivery–beyond a preferred choice…to them it’s fast becoming an expected standard.It’s time for a modern approach to fulfillment

Delivering satisfaction to today’s savvy buyers requires deeper, smarter, faster technology.

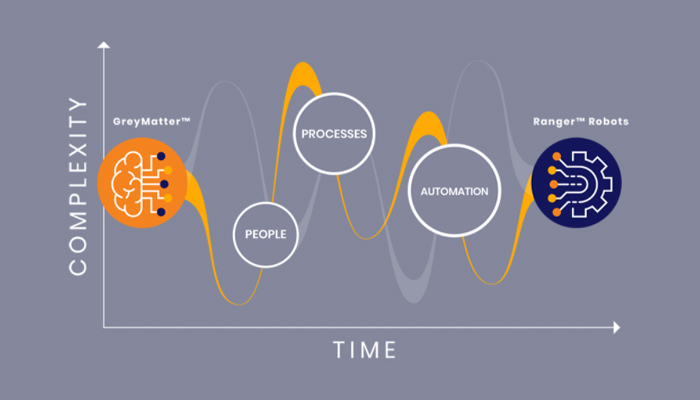

The GreyMatter™ Fulfillment Operating System uses advanced fulfillment science to instantaneously evaluate order data and compose best decisions in real time to efficiently orchestrate people, processes and robots. The result is a fast, agile and precisely tuned operation equipped to perpetually meet the what-when-where expectations of the market you serve.

The GreyMatter™ FOS rapidly responds to real time exceptions and events, prescribes actions, and orchestrates integrated and frictionless performance across every node

of your operation. GreyMatter™ AI Software

-

GREYMATTER™

The always-solving Fulfillment Operating System engineered for modern commerceAlways solving, always ready

The GreyMatter fulfillment operating system continuously solves to drive optimal decisions, efficient orchestration and rapid execution across the entire fulfillment operation–so you’re ready in real time for whatever the market has in store.

GreyMatter FOS: The always-solving Fulfillment Operating

-

Because GreyMatter automatically grows smarter, your fulfillment process continuously gets better

GreyMatter is the only fulfillment solution designed to deliver progressive performance with every execution cycle.As advanced Ai seamlessly integrates software, smart robots and people—the system instantaneously models best decisions to drive optimal workflows and execution using machine learning and adaptive learning.

GreyMatter perpetually stores high performing outcomes, factors and resources calibration of ‘what works best’.

As every new scenario, with its level of character and complexity is instantaneously assessed in real time, high outcome formula histories are called up, tested, applied, rejected or fluidly calibrated for best fit and highest probable accuracy, efficiency and speed.

This dynamic knowledge base of data-driven information and best case workflows accelerates and optimizes every future decision and scenario to deliver perpetually improving fulfillment operations.

Ranger™ Robot Series

-

The Ranger™ series of intelligent fulfillment robots

Ranger robots are developed in integration with GreyMatter AI software to flexibly respond, intelligently adapt and mobilize faster, frictionless fulfillment.

Maximum life™ robotics

Built to Last and Learn

The Ranger series of intelligent robots are built together with our GreyMatter AI-driven software to form the GreyOrange Fulfillment Operating System. A real-time feedback loop between GreyMatter and Ranger robots continuously shapes decisions and performance.

Unlike robots that operate as system attachments, Ranger robots incorporate GreyMatter intelligence as a learning layer that guides them to adapt to real-time events happening within the distribution center and externally as orders fluctuate and you adjust your fulfillment priorities.Maximum-life robotics outperform add-on robots across 3 key dimensions

Performance & Efficiency

- Higher performance per unit of power consumed, longer running time per charge

- Powerful processing & intelligence capabilities at the bot level, including selfcorrecting paths & recovery

- Able to learn new capabilities for future-fluid adaptation with each new software release

Safety & Compliance- Compliance with local and global safety standards and workplace regulations protects worker & asset safety and maximizes uptime

- Human-robot interaction contemplated in operational design to protect safety while accelerating productivity

- Compliance-certified design tested by leading 3rd -party labs

Lower Total Cost Over Time

- Long life span built-in through durable components and adaptive learning to protect investment payback

- Standardized platform design supports reusable parts while global spare part availability commitments protect long-life utilization

- Built-in adaptability reduces the need to replace robots to accommodate evolutions in your business, enabling your initial robot investment to apply against longer time horizons

Always-solving intelligence

-

Always-solving intelligence optimizes performance in peak periods and every day

Real-time data flow between GreyMatter and Ranger robots feeds always-solving algorithms to calculate and recalibrate each next-best decision, whether you’re prioritizing to deliver peak demand fulfillment or managing every-day fulfillment payoffs and tradeoffs.

Together, GreyMatter and Ranger Robots Are the Brains and Muscle of the GreyOrange Fulfillment Operating SystemRanger robots communicate with each other and with GreyMatter to continuously recalculate and orchestrate fulfillment priorities and inventory movement patterns based on real-time factors. As order promise dates, inventory positions, store replenishment requests, available workers and robots, actual fulfillment pace and time remaining in dispatch windows fluctuate, the system adapts to ensure you meet your top priorities and Service Level Agreements.

Ranger™ GTP Decision-driven science robotic

-

Goods-to-Person System

In today’s age of immediacy, the buyer is at the wheel. Meeting their rising expectations for choice and speed is the real world challenge facing fulfillment. At GreyOrange we recognize speed-to-fulfill is at the heart of accelerating overall ‘click-to door’ time and the satisfaction it delivers—a challenge that can’t be met with fixed infrastructure and rigid automation built for a previous era.

Improves speed & accuracy- Faster, error-free order fulfillment,

- decreases order-to-pick time,

- increases number of orders picked per person

- Reduces order fulfillment time,

- increases inventory efficiency,

- decreases days-on-hand stock

- Improves job satisfaction by reducing operational inefficiencies, errors and training time

- Simplifies warehouse processes and seamlessly adapts to customer business workflows and inventory types

From fixed, rigid and slow to Mobile, smart and fastRanger™ GTP is an advanced autonomous mobile robot that uses robotic goods-to-person technology for automated put-away, inventory storage, replenishment and order picking in fulfillment and distribution centers.

Developed in concert with GreyMatter™ AI software and purpose-engineered for speed and versatility, Ranger GTP continuously data-shares with GreyMatter while working in collaborative performance with other robots and the human workforce.

The Ranger GTP automation system adapts seamlessly to changing inventory profiles, demand patterns and peaks.

Modular system architecture ensures bi-directional scalability to increase storage volume or fulfillment throughput independently, by adding more storage racks or robots, as needed.

From reducing travel time by 5x that of human workers, to reconfiguring mobile stock units (MSUs), and working in tandem with other GTPs and Ranger Pick, the result is fluid, dynamic optimization.

Ranger™ IL

-

Automating and streamlining DC interzone mobility

Automating and Streamlining DC Interzone Transport

The Ranger IL (Intralogistics) robot is an intelligent, versatile Autonomous Mobile Robot (AMR) engineered to move a diverse range of inventory payloads – on pallets, racks, cages or trolleys – among zones in a warehouse. By automating material transportation, distribution centers can optimize productivity, focus workers on higher-value activities, and schedule deliveries more effectively to reduce material bottlenecks.Simple, ready-to-run implementation and the ability to adapt workflows in real time to accommodate shifts in delivery volumes or orders enable Ranger IL to generate a rapid return-on-investment through increased productivity, reduced material damage and saved time, cost and labor.

- Rapid, ready-to-run implementation

Ready-to-run means Ranger IL delivers near immediate value in time, cost and accuracy. - Seamless travel across DC interzones

Engineered to traverse warehouse inter zones carrying a diverse variety of payloads - Flexibility to adapt in real time as orders vary

Workflows can be adjusted in real time through dynamic integration with GreyMatter™ - Mobile spatial navigation reduces accidents

Ranger IL operates in accident-free collaboration with other robots, automated infrastructure, people and inventory.

Less time, less labor, Higher safety for people and materials

GreyMatter intelligence assesses DC performance in real time and orchestrates how and when Ranger IL transports inventory among zones, dynamically adjusting to protect SLAs, avoid bottlenecks, heighten throughput and protect the safety of people and materials.

Ranger IL uses advanced Simultaneous Localization and Mapping (SLAM) navigation along with GreyMatter mobile-spatial intelligence to operate in accident-free collaboration with other robots, automated infrastructure, people and inventory. The robot’s patented vertical motion Lift Deck™ enables it to handle additional forklift tasks and greatly reduce pallet and trolley damage through smooth vertical storing.

- Rapid, ready-to-run implementation

Ranger™ MoveSmart

-

Flexible, scalable fleets convey & sort packages or inventory from receiving through dispatch without bottlenecks or rigidity

Scale and locate conveying and sorting robots as demand requires

Modern fulfillment can’t afford the restrictions of rigid sortation systems you need to size today based on predictions for the shape and pace of your business years in the future. Once locked-in, these systems can’t flexibly adapt and scale with demand patterns and business changes.

Ranger MOBILE SORT can augment or even replace rigid systems to deliver scalable and portable conveying and sorting as you need it, where you need it, especially when handling peaks. Capable of operating in footprints where rigid systems won’t fit, Ranger MOBILE SORT helps you optimize current facilities, plus can easily relocate to other facilities as you grow.

Mobile & Portable- Free range of motion extends reach and versatility

- Component-based design configures to any work pattern requirement

- Real time agility enables seamless adjustment

- Scalability to shift up and down with fluctuating demand

FUTURE FLUID DESIGN PROTECTS YOUR PERFORMANCE & INVESTMENT

Modular units and footprint adaptability enable you to deploy Ranger MOBILE SORT to handle numerous applications across retail and logistics operations. The AI-enabled system easily scales up or down with demand for investment-friendly performance.

RANGER™ PICK

-

A reliable workforce assistant that teams with Ranger GTP to accelerate Pick-to-Pack performance

Unique, versatile 'from-rack' picking expands options for workforce-assisted or autonomous order fulfillment

Sophisticated machine vision algorithms enable best-in-class SKU identification while single- and dual-arm options broaden range of merchandise ready for robot-enabled fulfillment- Enables 24/7 Autonomous Order Fulfillment

- Eliminates Pilferage And Picking Errors

- Lowers Cost Per Shipment

RANGER PICK

OUTPERFORMS OTHER PICKING SOLUTIONS- Collaboratively works with human teams or autonomously 7/24/365

- A reliable workforce assistant that teams with Ranger GTP to accelerate Pick-to-Pack throughput

- Unique from-rack picking versatility expands use across merchandise far beyond standard downward picking arms

- Sophisticated machine vision algorithm enables highly accurate identification of more than 100,000 SKUs

- Machine learning continuously refines and optimizes how Ranger PICK grasps and moves different SKU variations to speed performance across sizes, shapes, rigidities, surface finishes and other characteristics

- Automated barcode scanning validates items picked and continuously updates the GreyOrange Fulfillment Operating System.

- Available in Single Arm and Dual Arm configurations

- Patented two-arm system expands picking volume and versatility

HIGH YIELD FULFILLMENT

- HIGH YIELD FULFILLMENT

IS THE MISSION:

Performance, profitability & promises kept

Competing in the age of immediacy means meeting customer expectations and your margins simultaneously - at unprecedented levels of complexity and speed.

What if you could always make a high yield decision at any time, at every node of your fulfillment operation?

Considering:- Order promises to customers across all channels

- Labor constraints

- Order Placement time horizons & fulfillment windows

- Inventory positions

- Replenishment promises to stores

A tall order not possible without the most advanced fulfillment science, technology and engineering. HIGH YIELD FULFILLMENT

- Fortunately, it's an order GreyOrange has filled.

HIGH YIELD FULFILLMENT IS HERE

Because GreyOrange FOS orchestrates seamless, real time integration of GreyMatter AI software and intelligent Ranger robots, the result is always-solving, 360º awareness and algorithmic calibration of every next best decision. For business, that translates to higher yield performance, higher yield economics and higher yield customer satisfaction.

Real time data and instantaneous modeling inform GreyOrange FOS continuously, facilitating uninterrupted throughput no matter how volatile the order flow.

As the FOS system flexibly prescribes actions, Ranger robots efficiently act– autonomously and in collaboration with human workforce– as all nodes across the fulfillment operation are automatically orchestrated to keep inventory in motion, at pace with demand.

AWAREhouse

- FROM WAREHOUSE TO AWAREHOUSE

The thinking DC for modern commerce

The GreyOrange Fulfillment Operating System (GreyOrange FOS) orchestrates and optimizes data, resources and processes to sync in continuous real time, linking operational awareness across every node of DC fulfillment.

THIS IS THE AWAREHOUSE AT WORK.

In the world of modern commerce, nothing short of integrated operational awareness can meet the uncompromising new thresholds of accuracy, speed and satisfaction demanded by business and buyers.

Anticipate. Activate. Automate.

The AWAREhouse does it all. Always aware, always solving 7/24/365 technology automatically identifies, calculates and executes next best decisions for highest yield outcomes in continuous real time across every node of fulfillment.

Predict. Prescribe. Perform.

Because modern commerce is always changing, the AWAREhouse is always solving. Integrated awareness accelerates real time solutioning to exceptions and unpredictable events, without loss of velocity, volume or value. THE AWAREHOUSE

- ALWAYS AWARE, ALWAYS SOLVING

THE AWAREHOUSE: HIGH YIELD FULFILLMENT IS THE MISSION.

Find out more about how you can transform your warehouse into an AWAREhouse to prosper in the age of immediacy.

The GreyOrange fulfillment operating system is THE ORCHESTRATOR.

The dynamic master framework that integrates and manages GreyMatter software + Ranger robots for cooperative system awareness, speed, agility, accuracy, dynamic workforce optimization and best workflows for high yield fulfillment results.

Greymatter is THE BRAIN.

Always-solving Intelligence correlates, calculates and executes every next best decision to orchestrate and optimize inventory in motion with the flow of the floor.

Ranger robots are THE MUSCLE.

The Ranger™ Series of advanced, Maximum-Life™ fulfillment robots intelligently perform, flexibly adapt and last & learn for an extended, durable lifetime. Task-designed for goods-to-person, movement, picking, consolidating, packing and sorting for dispatch: Ranger GTP, Ranger GTP XL, Ranger Pick and Ranger Mobile Sorter operate in combination with GreyMatter and your human workforce.

Inventory in motion is the CIRCULATORY SYSTEM.

Inventory in motion is the healthy vital sign of the awarehouse–animated by deeper data, dynamic decisions and demand-driven delivery.

The GreyOrange Difference

- THE DEEPTHINK™ DISTRIBUTION ADVANTAGE:

Deeper data, dynamic decisions and demand-driven delivery

THE NEW RULES OF MODERN COMMERCE

Today’s buyer-driven commerce demands faster, smarter, more satisfying fulfillment than ever before, squeezing businesses between the promises they must make for loyalty and the profits they must make for economic viability.

That challenge just became steeper with next day/same day/multi-hour delivery moving beyond a preferred option to an expected standard.

The GreyOrange Fulfillment Operating System (FOS) is powered by applied AI science, mobile-spatial logic and purpose-built integration of people + software + robots to drive high yield outcomes for performance, profits and promises kept.

A Higher Bar for Modern Fulfillment

It’s time for distribution centers to break free from traditional cost center confines to become strategic enablers of growth, employee empowerment and customer satisfaction. Equipped with data insights and process capabilities that extend beyond standard throughput and cost-focused Key Performance Indicators (KPIs), companies can measure broader strategic impacts of modern fulfillment.

Store satisfaction with distribution center service

DCs focused only on “within the four walls” metrics lose sight of the meaningful impact their actions have on store employees and performance. Understanding that DCs, stores and customers are in a cooperative system demands broader thinking. The GreyOrange FOS enables DCs to deliver replenishment orders timed and packed according to each store’s preference for efficient receipt-to-shelf processing, avoiding the extra store labor time and cost that results from imprecise replenishment practices.

DC employee empowerment, job satisfaction and career commitment

Giving fulfillment employees the opportunity to work with and manage advanced technology, including teams of robots, helps companies attract and retain high-performing workers. Jobs evolve into careers that deliver continuous learning and skill expansion. Employees admire their companies as modern innovators that equip them with smart technology. The GreyMatter Command Center gives workers insight to real-time inventory flow-on-the-floor, and a perspective of their role in the DCs overall performance, a view not previously available.

Topline growth, online customer reorders, store shopper satisfaction

Deeper insights into omnichannel metrics and the ability to orchestrate consumer and store orders in real time elevates the DC’s role in driving top-line performance. DC managers can begin measuring their impact on business metrics such as order rates and revenue from the highest value ecommerce customers or shopper satisfaction with store inventory availability.

GreyOrange is leading the new era of DEEPTHINK™ DISTRIBUTION

The pace of modern commerce demands modern thinking and modern technology. That’s why the GreyOrange Fulfillment Operating System combines AI-driven software and intelligent robots that work together, continuously communicating to make each other smarter. By observing real time orders and the flow of the floor – and using that data to inform always-solving algorithms that calculate each moment’s best decision – the GO System is ushering in a new era of distribution based on deeper thinking. Deeper data, dynamic decisions, and demand-driven delivery enable you to fulfill the future in real time. NEW RULES REQUIRE A NEW SOLUTION

- In addition to solving the variability, form factor intricacy and velocity of immediate commerce, fulfillment operations must also open up their processes to factor in expanded distribution ecosystems of every type in closer reach of buyers. From retail store replenishment, forward DCs, urban pickup centers, dark fulfillment centers, to fulfilling thousands of e-commerce ‘markets of one’–your fulfillment operation must satisfy the market’s ‘immediate commerce’ mindset.

As the transformation continues, more businesses are learning that solutions built for simpler times cannot measure up to the complexity of immediate commerce.

At GreyOrange, we recognize measuring up requires a higher level of advanced technology to power a modern approach to fulfillment.

Deepthink™ Distribution: the GreyOrange difference

ADVANCED FULFILLMENT SCIENCE FOR MODERN COMMERCE

GreyOrange is leading the new era of Deepthink distribution—advanced AI decision science, machine learning and real time analytics that contemplate, correlate, and drive deeper data, dynamic decisions and demand-driven delivery to meet the challenges of modern commerce.

Deepthink technology activates the GreyOrange Fullfilment Operating System (FOS) with 360° awareness and holistic real time orchestration through the integrated performance of GreyMatter AI software and Ranger intelligent robots.

Advanced algorithmics enable the GO System to automatically analyze and instantaneously model data, performance and events to optimize and execute every next best decision in real time—orchestrating directives and workstreams between people, robots, and processes while also factoring in ecosystems beyond the walls of the warehouse.

ALWAYS AWARE, ALWAYS SOLVING

The GreyOrange FOS continuously solves and logs progressively improved results at every node of your operation. We call it high yield fulfillment. In the fierce landscape of modern commerce, anything less can compromise your service level agreements, financial goals and competitive position.