NOTTER

Videos

Loading the player ...

- Offer Profile

- Innovation, quality and

reliability are the foundations on which our traditional family company was

built. Since its inception in 1960, we have continued to write new chapters

in the history of tabletting tools and successfully established the “NOTTER

TABLETTING TOOLS” brand within the pharmaceuticals and foodstuffs industry.

A key factor in the success of our tabletting tools is their consistent precision and exceptional service life. These two features made them stand out from the very beginning, and these core values now have an increasingly important role to play given the current trend towards ever-increasing production volumes and cost minimisation.

Product Portfolio

Tabletting Tools

- Consistent precision and long service life are the

hallmarks of modern tabletting tools. NOTTER has offered the same high

quality for over 50 years and is proud to be the world’s leading

manufacturer of standard to high-end tools for all common tablet presses.

ECO Tool Line- Engineered for products with normal wear behaviour and standard pressing forces

- Normal service life

- Available for Euro B, D

- Possible coatings: PLASMACHROM®

- End-to-end testing to ensure conformity with requisite parameters – simple inclusion of data in dispatch certificate

- Made in Germany

- Engineered for high-volume manufacturing, including abrasive and challenging products

- Capable of achieving very high pressing forces

- Above-average service life

- Materials tailored to specific application

- Specially adapted coatings

- Available for all tool types

- Full measurements and documentation in dispatch certificate, including detailed dimensions relating to shaft, diameter, functional size, overall length, head height and diameter, as well as tip diameter

Single Tip and Snap-Tab Tools

- In contrast to more conventional solutions, NOTTER tabletting tools are designed to deliver superior precision at all times. It is this level of consistency that provides the basis for efficient operations and end-products of exceptional quality. Our patented Snap-Tab® tool is the perfect choice for tablets with designated breaklines.

Creative Tools

- Creative tools by NOTTER are designed to deliver the

ultimate in uniqueness. Whether coffee beans, miniature bears or toy cars –

almost anything is possible with a little imagination.

Feel free to get in touch with NOTTER for further inspiration. We are able to simulate your customised tablet shapes on the basis of lifelike 3D renderings, as well as calculating the precise weight, volume and surface structure of the product by means of state-of-the-art CAD software.

Multi-Tip and Pelleting Tools

- The superior quality of NOTTER TABLETTING TOOLS is

particularly important for Multi-Tip and Pelleting Tools. Designed to the

highest quality standards, NOTTER precision tools will always deliver the

perfect performance. Owing to their consistent operational length and exact

pressing dimensions, our multi-tip and pelleting tools are capable of

producing perfectly uniform tablets even during high-speed processing.

Mono-Multi-Tip Tools

NOTTER Mono-Multi-Tip Tools are manufactured from a single piece of steel. Compared to composite multi-tip tools, these mono tools – due to our innovative production concept – can be operated at very high speeds. Thus, they are capable of achieving impressive throughput volumes, while maintaining consistent dosage precision and tablet weights. In addition they are as easy to set up as standard moulding tools and can be cleaned in accordance with GMP guidelines.

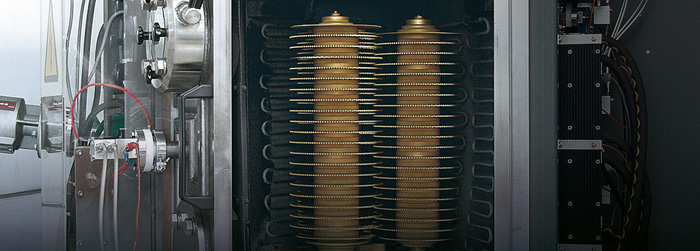

Tool Coating

- Besides hardness, break resistance and corrosion

resistance of the base material, the surface coating plays an important role

in optimising and reducing wear, and sticking and picking tendencies.

At our coating center we have focused our research and development efforts mainly on these two areas. As a result, today we are well equipped with a variety of unique, micro-fine and almost non-porous surface finish coatings. These coatings increase lifetime, reduce wear and enable the surface separation of tablets made from difficult, sticking prone powders.

NOTTER – Production

- Carefully selected raw materials, exceptionally fine-tuned and adaptable production processes and a continuous high level of competence at all manufacturing steps provide NOTTER TABLETTING TOOLS with inherent precision and consistent first class quality.

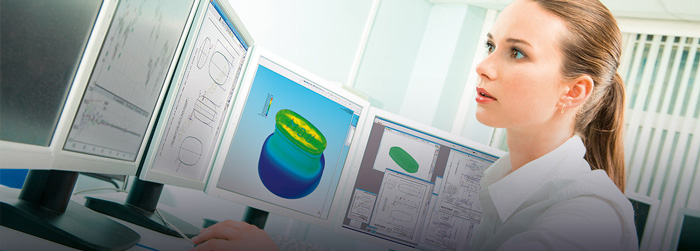

2D/3D VISUALIZATION

- Exact simulation of weight

- Volume and surface

- 3D CAD and Rapid prototyped Models

- Finite Element Calculations (FEM)

- Extensive experience

MATERIAL SELECTION

- Steel Material specifically developed for NOTTER

- Many different alloys and heat treatment dependent structures

- Adapted toughness

- Wear resistance and breaking strength

- Corrosion resistance

EMBOSSING

- Perfectly embossed surfaces by using preformed blanks

- Total precision (Accuracy< 2/100 mm), particularly in the area of engraving

HEAT TREATMENT

- Individual recipes adapted for materials and applications

- Processcontrolled heating and cooling phases

- Core temperature monitoring accurate to 1°C

- Repeatable and tested hardness and toughness

- Resulting in high breaking strength and wear resistance

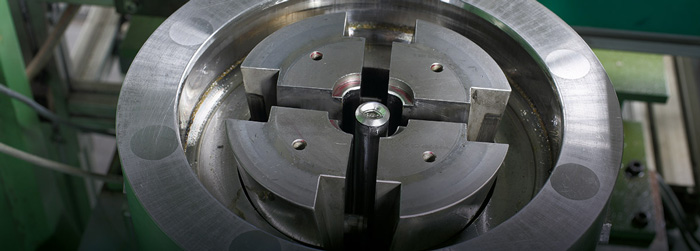

GRINDING

- Grinding of head, shaft and tip provides precise geometry and a perfect surface finish

- High operational reliability and longevity

- Optimized NOTTER head shape geometries available for use with standard shaped cams

COATING

- Plasma high vacuum coating producing a micro-fine surface finish

- Proprietary coating systems developed in house

- Reduction of effects such as sticking, picking and wear

POLISHING

- Manual finish, Trimming of engravings and small spaces

- Reduction of sticking and picking

- Functional optimisation for perfect Tablet quality

Tool-Management

NOTTER – Tool-Management

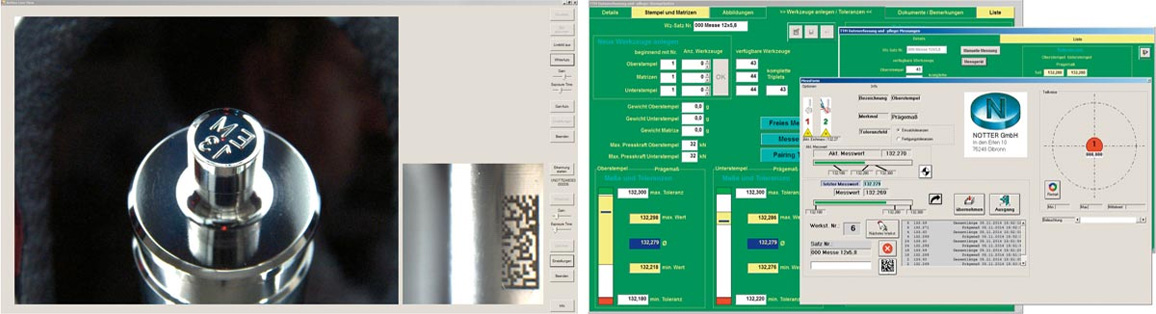

- TTS (Tabletting Tool Scanner) by Notter is a pioneering

laser measurement system to determine the exact dimensions of functional

length and overall length of the tool in a single step. TTS allows you to

speed-up the measurement process dramatically. Only one third of the time of

a manual analysis is required. At the same time Tabletting Tool Manager (TTM)

– a high-performance analysis and administrative software integrated within

the system – provides other business-critical information, such as total

usage, downtime, repairs, etc. associated with the specific tool. In

addition, TTM is a full resource management system and includes e.g.

Tabletpresses, Turrets and Compression suits.

Furthermore, the Assembly function included in Tabletting Tool Manager can be used to compile recommendation lists for the regular deployment of all existing tools targeting for uniform wear. The integrated pairing function can be used to minimise force variation in production.

Sophisticated tool analysis- Check for application requirements of the tools

- Analysis of the current status of the tools

- Data collection: e.g. Number of compressions, repair and failures

- Assessment and corrective action