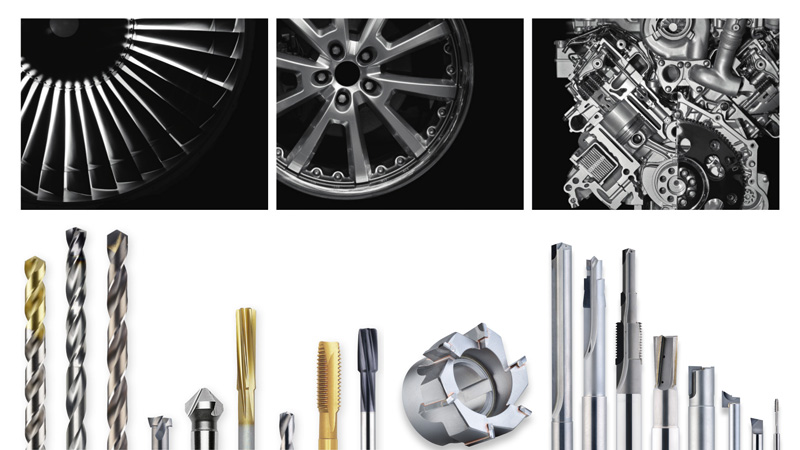

- Offer Profile

- With over 75 years of experience in the production of precision tools in solid carbide, cobalt alloy and powder alloy high-speed steel, Werkö Ltd. is one of Europe's most competent providers in the fields of drilling, reaming and threading.

ALUBLUE & ALUBLACK

- High performance end mills for aluminium processing

BLUE & BLACKLINE

-

Our BlueLine offers the perfection of a high-performance tool combined with a very good price-performance-ratio.It is suitable for various materials.

Our BlackLine ensures you highest perfection in high-performance field for your serial production. It guarantees optimum results in a wide range of applications.

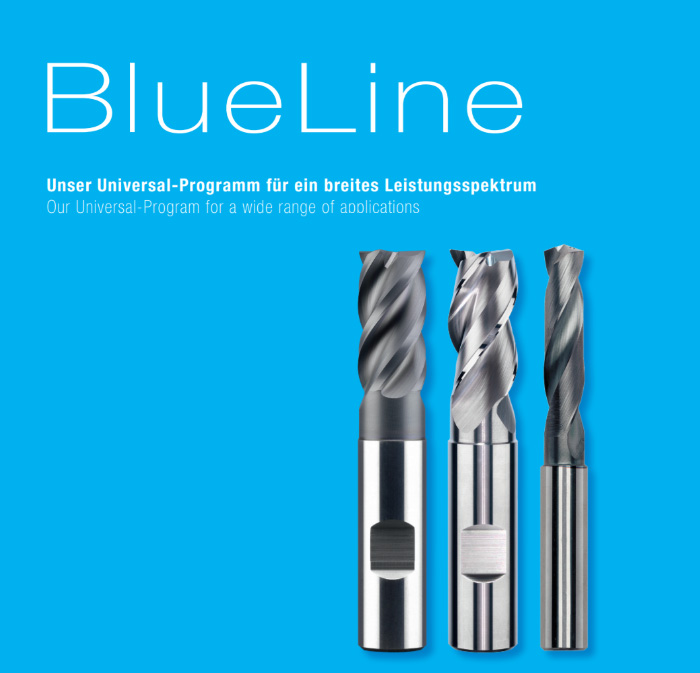

BLUE LINE

-

The BlueLine-Series offers the perfection of a high-performance tool combined with a very good price-performance-ratio. These tools - manufactured in our plant in Thuringia, Germany - convince by their unique design.

The BlueLine stands for highly economical universal application in a wide range of materials.

BLACK LINE

-

The BlackLine-Series ensures you highest perfection in highperformance field for your serial production. It guarantees excellent process-reliability. Economic viability and workpiece quality are the main focus of these tools manfactured in our plant in Thuringia, Germany. All BlackLine products are suject to a special finish and a defined cutting edge rounding which ensure longer tool life and improved surface of the workpiece. Especially developed new geometries, together with state-of-the art coatings result in best material removal rates, smallest cutting forces and minimized machine load.

The BlackLine stands for High-Perfomance-Tools which increase your productivity in a broad range of applications.

BLUE LINE

Solid Carbide End Mills: Blue Line 502153 BL

-

Application/Design

- Universal end mill for the general purpose use in non alloyed and alloyed steels, stainless steels and also special alloys

- Ultra fine grain • Very good cutting performance at high feed rates and cutting speeds

- Shank design according to DIN 6535, Form HB

Characteristics

- Unequal helix with 38 and 41 degrees

- Unequal pitch of cutting-edges

- TiAlN coating

- Longer tool life at good surface quality

Solid Carbide End Mills: AluBlue 502254

-

Application/Design

- Solid Carbide End Mill for the machining of aluminium, plastics and non-ferrous metals

- Ultra fine grain • Very good cutting performance at high feed rates and cutting speeds

- Polished flutes for an excellent chip removal

- Shank design according to DIN 6535, Form HB

Characteristics

- Polished flutes

- Unequal helix

- Longer tool life at good surface quality

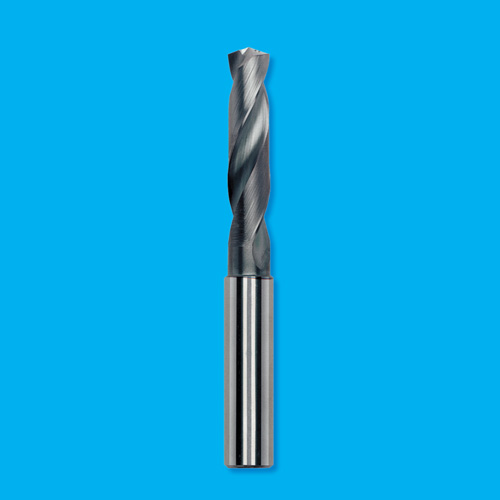

Solid Carbide Drills: BlueLine WK 300 328653BL

-

Application/Design

- High-performance twist drill for Steels up to 1.300 N/mm2

- Good positioning and formation of short chips

- With high accuracy of dimension and alignment • Ultra fine grain

Characteristics

- Shank design according to DIN 6535, Form HA

- Point angle 140°

- TiAlN coating

- KK = With internal cooling

BLACK LINE

Solid Carbide End Mills: BlackLine 502155 BK

-

Application/Design

- High-performance end mill for non alloyed and alloyed steels, stainless steels, high alloyed steels and hardened steels up to 55 HRC

- Ultra fine grain

- Suitable for roughing- and finishing- application

- Optimum cutting results at higher feed rates and cutting speeds

- Maximum smoothness in the processing without vibration and soar up

- Shank design acc. DIN 6535, Form HB

Characteristics

- unequal helix with 38 and 41 degrees • Unequal pitch of cutting-edges

- OERLIKON BALZERS BALINIT® ALNOVA coating

- Defined cutting edge rounding ensures stable cutting edge and for longer tool life

- Surface treatment leads to optimal chip removal

- Improved surface finish at workpiece

Solid Carbide End Mills: AluBlack 502256

-

Application/Design

- Solid Carbide High-Performance End Mill for machining of aluminium, plastics and nonferrous metals

- Ultra fine grain • Optimum cutting results at high feed rates and cutting speeds

- Maximum smoothness in the processing without vibration and soar up

- Shank design according DIN 6535, Form HB

Characteristics

- High performance coating for machining of aluminium

- Unequal helix • Follow-up treatment of the flutes for optimal chip removal

- Improved surface finish at workpiece

Solid Carbide End Mills: BlackLine WK 500KK 328453 BK

-

Application/Design

- High-performance twist drill for Steels up to 1.300 N/ mm2

- Good postioning and formation of short chips

- With high accuracy of dimension and alignment

- Ultra fine grain • Polished flutes

- Defined edge rounding

Characteristics

- Shank acc. DIN 6535 HA • Point angle 140 °

- OERLIKON BALZERS BALINIT® LATUMA coating

- With internal cooling

SPECIAL TOOLS

-

WE DEVELOP SOLUTIONS FOR YOU

OUR SERVICES

We react quickly and flexibly to your enquiries and wishes. We have the necessary performance, technology and resources to solve your problem. We design, optimise and manufacture your tools to increase productivity. We secure potential savings by adapting technologies.

REGRINDING AND REPAIR SERVICE

Not only do we regrind, we rework. Your VHM and HSS tools will be regrinded with the original manufacturer's grinding and thus guarantee the usual service life and process reliability. Short delivery times - high quality. Depending on the technical condition of the tools, we decide whether to erode, regrind or re-equip them.

PKD PRECISION TOOLS

PCD - stands for polycrystalline diamond, a synthetically produced, extremely hard, intergrown mass of diamond particles. Depending on the respective application, it is often no longer the tool that determines the application data, but the performance.

of the machine tool. This makes PCD tools particularly suitable for complex steps and contour tools in order to perform several operations in one operation. This saves tools and tool change times. In addition, a high alignment accuracy in the workpiece can be achieved through multi-stage operation. The exceptionally high wear resistance of the very hard diamond cutting material significantly increases the service life of the tools. With high-precision, low-balance rotary tools

very high cutting speeds and feed rates are possible.SPECIAL TOOLS MADE OF VHM

- Various HM grades

- Defined edge rounding

- Polished grooves

- Various coatings (application-specific, from different coating partners)

- Special lengths up to 30xd

- Finishing and roughing cutters

- Various shaft designs

- Straight or spiral grooved

- Step drills

- Brazed special tools, e.g. shank made of HSS / cutting material made of VHM

SAND-CORE-DRILLS

-

Especially for metal-foundries we offer SAND-CORE-DRILLS for the preparation of ventilation-holes. In recent years we specialized in preparation of ventilation-holes in sand-cores, in order to provide high-performance tools. SAND-CORE-DRILLS

-

Especially for metal-foundries we offer SAND-CORE-DRILLS for the preparation of ventilation-holes. In recent years we specialized in preparation of ventilation-holes in sandcores, in order to provide highperformance tools. At highest level, we provide you with these individual carbide-tipped tools – with best performance regarding accuracy, process-reliability and tool-life.

- Diameter ranges from Ø 2,5mm - Ø 20,00 mm (expandable up to Ø 40mm)

- Total-length possible up to 1000mm

- Also available in solid-carbide

- Different shank-types

SN-TOP

-

Our new tool in our product family DIN 338 the SN-top with TiN-coated head. A universal, very stable HSS drill bit for all standard applications. Split-Point permits very good positioning and reduces feed and torque. TiN-coating provides longer tool life or increased cutting-speed.

- Our new tool in our product family DIN 338 – the “SN-top” with TiN-coated head.

- A universal, very stable HSS drill bit for all standard applications.

- Split-Point permits very good positioning and reduces feed and torque. TiN-coating provides longer tool life or increased cutting-speed.

- For materials up to 1000/mm2 - cast steel, grey cast iron, malleable iron, sintered iron, German silver and graphite.

MAIN CATALOGUE

- More than 75 years of experience! In Königsee, highly skilled workers of WERKÖ GmbH produce high-precision, modern cutting tools for standard- and customized applications. Our solutions are a contribution to ensuring manufacturing processes and improving efficiency. High availability of tools ex stock and service level agreements provide outstanding availability of all products.