- Offer Profile

-

THE SYSTEM

A CONSTRUCTION KIT THAT CONVINCES!

The Hirt-Line system can be the basis of a successful production. The basis for the system in turn is its individual components.To give customers the opportunity to go their own way in designing and implementing their systems, Hirt-Line makes all components and their data available here individually. Hirt-Line has made all its elements available online for quick and easy ordering.

HIGH PRESSURE COOLING LUBRICANT LINE SYSTEMS MADE OF STAINLESS STEEL

-

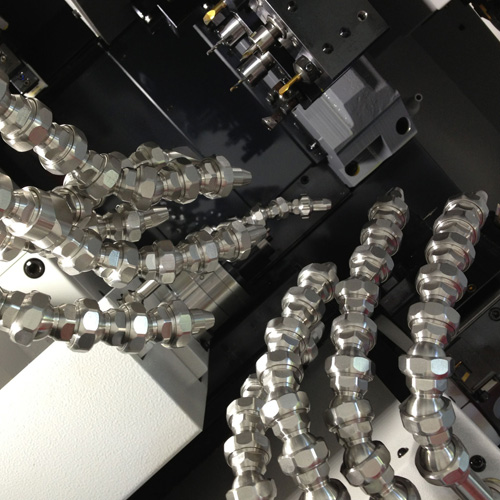

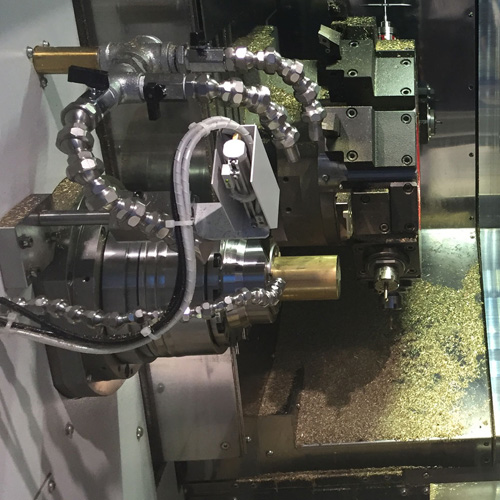

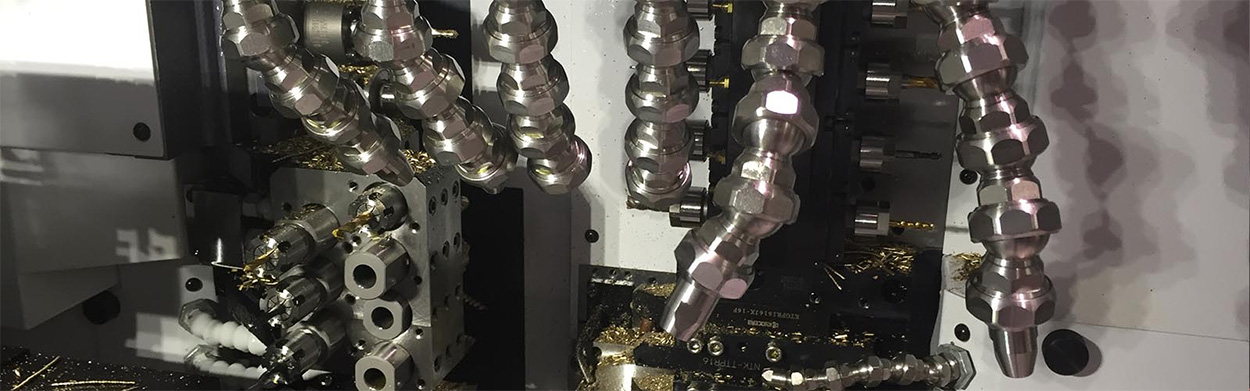

INDIVIDUAL & FLEXIBLE

Our articulated hose system can be expanded as required, is stainless and offers a long service life. The individual parts are precision-made and insensitive to heat and chemical substances. Can be easily screwed together, adjusted, extended and shortened by hand. Neither coolant pressure nor machine vibrations can change the position. Pressure resistance over 100 bar. Can be used on machine tools and production lines.

Hirt-Line coolant hoses fit on lathes, milling machines, grinding machines, sawing machines, filling machines,

are ideally suited for emulsions, cooling and cutting oils, chemical substances and can be used for air cooling.

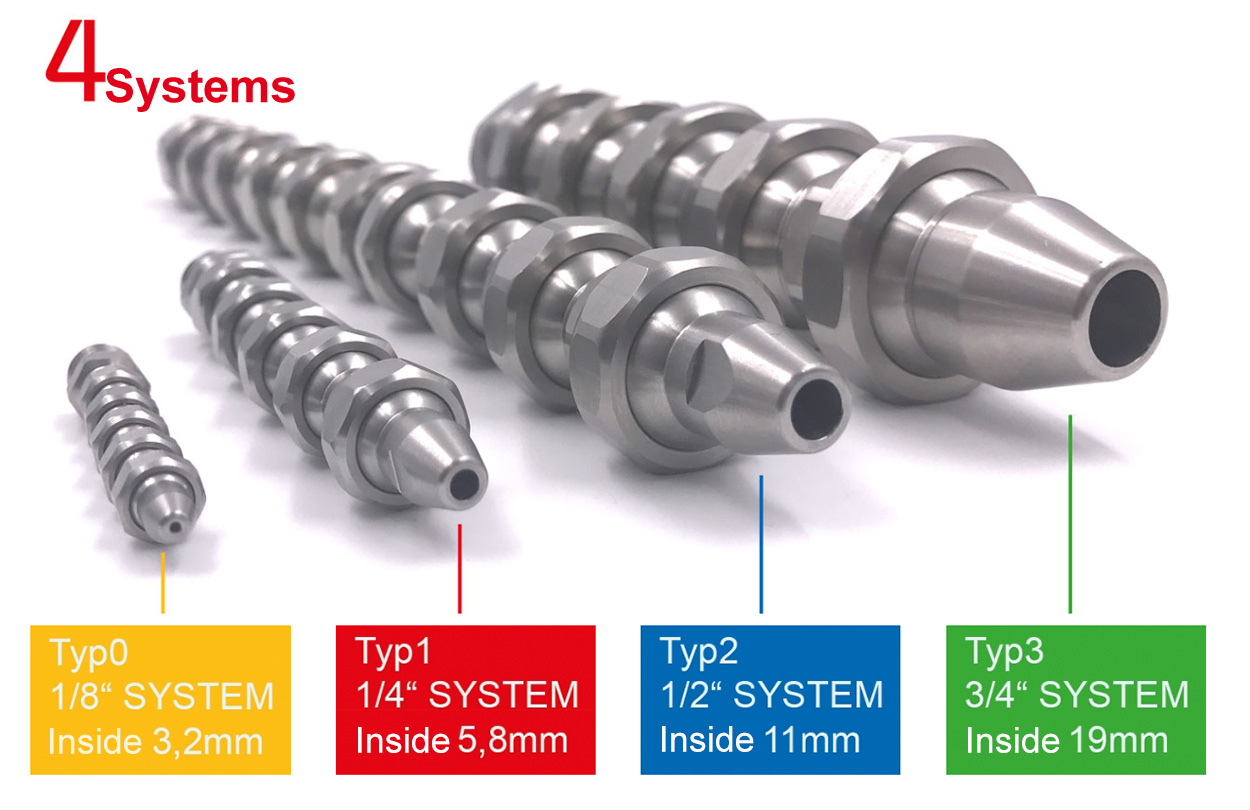

4 sytems, 4 different sizes

-

- Beam can be set and fixed with pinpoint accuracy (screwable)

- Resistant to high temperatures, chemical substances, chips, pressure and vibrations

- Corrosion resistant material 1.4305 (on request in V4A)

- Wear-resistant

- Pressure stable over 100 bar

- 4 system sizes, all compatible with each other

- Long service life

- Can be used directly on the tool (AGW connection)

- Versatile in combination

- Sophisticated and effective range

- Applicable in the food industry

- Mounting brackets for each machine

- Basic sets in every system

THE SYSTEM

-

A CONSTRUCTION KIT THAT CONVINCES!

The Hirt-Line system can be the basis of a successful production. The basis for the system in turn is its individual components.

To give customers the opportunity to go their own way in designing and implementing their systems, Hirt-Line makes all components and their data available here individually. Hirt-Line has made all its elements available online for quick and easy ordering.

4 SYSTEM SIZES mutually compatible

- Type0 | 1/8" | passage 3,2mm | thread M8x0,75

Type1 | 1/4" | passage 5,8mm | thread M14x1

Type2 | 1/2" | passage 11.0mm | thread M24x1.25

Type 3 | 3/4" | passage 19.0mm | thread M34x1.25

MACHINE ADAPTER

- Besides the standard pipe threads G 1/8", G 1/4", G 3/8", G 1/2", G3/4", G1" as well as metric M5x0.8 over M14x1.0 to M20x1.5, we also offer conical threads and ball head adapters with the dimensions Ø10mm Ø12mm Ø14mm Ø15mm, plus various special adapters. On request you will receive your special connection adapter!

BASIC ELEMENTS

- 3.2mm, 5.8mm, 11.0mm and 19.0mm inner diameters measure the basic elements of the Hirt-Line System. The multitude of different standard lengths from 9.3mm over 100mm up to 1000mm make an exact adjustment and fixing of the cooling beam at the desired position possible. And thus ensure effective and simple adjustment. Other lengths are possible on special order.

ANGLE ELEMENTS

- The Hirt-Line system offers many different angle elements in every system size, whether type0, type1, type2, or type3, we have the right ones like e.g. elbows 90°, multiple connections, T- and Y-pieces. Due to the large selection, we ensure the greatest possible flexibility of the system. Special fittings on request!

NOSES

-

The nozzles made of a material 1.4305 (V2A) are insensitive to heat and available from Ø1.0 mm, over Ø10.0 mm up to Ø19.0 mm passage. Our numerous flat nozzles with different slot widths leave nothing to be desired, whether for washing or cooling as well as flat and round grinding. In addition there are some special nozzles either with several holes or mini-slots - all of them are optimized for perfect cooling.

ACCESSORIES

- The Hirt-Line accessories consist of suitable products such as quick-release couplings, knurled nuts or sealing caps, as well as reductions to combine the individual systems with each other. We also offer suitable external articles such as ball valves and open-end wrenches. With this assortment you can also ensure an optimal and stable coolant supply for the future, especially for individual applications.

PRODUCT OVERVIEW HIRT-LINE ARTICULATED HOSES

HIRT-LINE TYP0 (1/8") SYSTEM

-

The new Type0 system is quick to install, easy to set up on the appropriate tool and includes a wide range of matching nozzles from Ø1.0 mm to Ø3.0 mm and even nozzles with multiple outlets. A wide range of machine adapters from M5x0.8 to M10x1.5 to ball adapters Ø10.0 mm and of course again various

Basic and angular elements give the user the necessary flexibility and Variability in the processing of your products.

TECHNICAL DATA:

- Size Type0 (1/8")

- Passage 3.2 mm

- Pressure resistant up to 80 bar

- Operating range -30°C to +60°C

- Optional ES system up to +300°C (available on request)

- Thread (elements) M8x0.75

- Material 1.4305 (V2A) | Optional 1.4404 (V4A)

HIRT-LINE TYP1 (1/4") SYSTEM

-

The Type 1 system for all machine applications in the range up to max. ±170l/min With round nozzles sizes from Ø1.6 mm to Ø5.0 mm and a variety of flat nozzles and nozzles with several holes, this system is a standard for every machine. The wide range of machine adapters from M8x1.0, M14x1.5 and G3/8" to various

Ball adapter Ø14.0 mm and of course again basic and angle elements guarantee for a smooth installation.

TECHNICAL DATA:- Size Type1 (1/4")

- Passage 5,8 mm

- Pressure resistant over 100 bar

- Operating range -30°C to +60°C

- Optional ES system up to +300°C (available on request)

- Thread (elements) M14x1

- Material 1.4305 (V2A) | Optional 1.4404 (V4A)

HIRT-LINE TYP2 (1/2") SYSTEM

-

With the Type 2 system you can optimize your machine process by ±12%. Take advantage of the variety of the nozzle range and adapt the cooling to your needs. Whether flat nozzles, round nozzles

or nozzles with several outlets, for grinding, turning, milling or air cooling, you will find the appropriate elements here. The type 2 basic elements and machine adapters provide

for a round assortment, which offers you the security to avoid tool wear and tear and guarantee stable cooling.

TECHNICAL DATA:- Size Type1 (1/2")

- Passage 11 mm

- Pressure resistant over 100 bar

- Operating range -30°C to +60°C

- Optional ES system up to +300°C (available on request)

- Thread (elements) M24x1.25

- Material 1.4305 (V2A) | Optional 1.4404 (V4A)

HIRT-LINE TYP3 (3/4") SYSTEM

-

The Type 3 or also called 3/4" system promises the right stability for your machines in addition to the proven and reliable quality. The passage with Ø19mm brings the necessary liter capacity (over 200l/min) precisely and stable (up to 60 bar) from the pump to the tool. Suitable in this system there are 22 different nozzles, from simple round nozzles from Ø12mm, Ø15mm and Ø19mm up to the largest flat nozzle 101mm x 2mm which are also optimized for the grinding process. All nozzles are manufactured in a high precision and are easily exchangeable for any application. With the two adapters 3-AD-34-PT (3/4") and3-AD-10-PT (1"), it is an easy to install this system on any to install the machine. As usual there are different basic and Angle elements which allow the system to be flexible and adaptable to wishes to configure. Optionally a ball valve and further accessories can be purchased.

TECHNICAL DATA:

- Size Type 3 (3/4")

- Passage 19.0 mm

- Pressure resistant up to 100 bar

- Operating range -30°C to +60°C

- Optional ES system up to +300°C (available on request)

- Thread (elements) M34x1.25

- Material 1.4305 (V2A) | Optional 1.4404 (V4A)

PRODUCT OVERVIEW HIRT-LINE SUPPLEMENTS

VARIOJET (VJ14) AUTOMATIC COOLANT NOZZLE

-

Hirt-Line VarioJET VJ14 suitable for type 1 system diffuser size 3,2mm

- Maximum twisting angle 35° infinitely variable

- Connection thread coolant G1/4" W-LAN with WPA2 encryption

- Configurable via web browser (PC, tablet, smartphone) Connection 230V AC

- Power consumption 50W

- Dimensions: 85mm x 70mm x 100mm

- Material 1.4305 V2A

- Operating range -10°C - +60°C

- Cooling water pressure up to max. 20bar (optionally up to 80 bar)

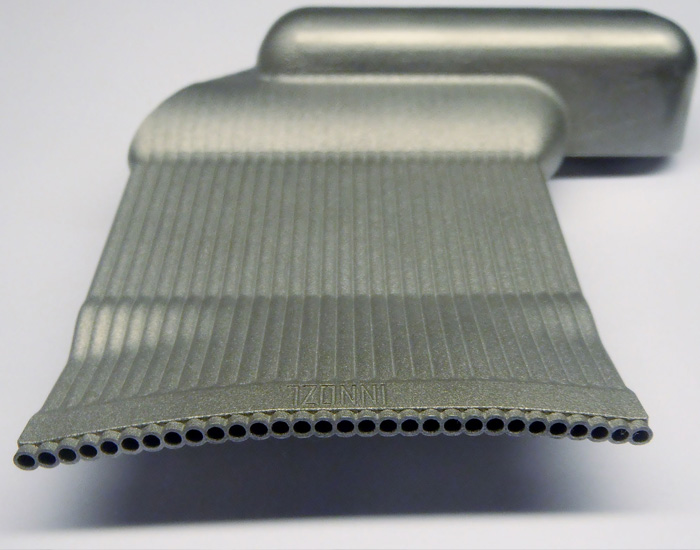

INNOZL 3D SPECIAL NOZZLES CD-LINE

-

The 3D printed INNOZL™ CD line consists of one or more nozzles designed for a specific application. Modern analysis software offers the possibility to go through the engineering process relatively quickly, with the know-how being to achieve the same cooling speed everywhere. The production technology 3D printing supports a fast and flexible production.

Advantages:

- The cooling actually comes into the contact zone

- The danger of grinding burn is reduced to a minimum

- Greater production output

- Lower the absorbed spindle power

- Longer service life of the grinding wheel

- Great reduction of general refrigerant operating costs through:

- Reduced energy consumption

- Lower coolant consumption

- Smaller cooling units

- Optimal design space

- Flow analysis for optimal internal flow

Result:

- Better price / performance ratio

- Longer life of your products

- Voltage reduction in your parts

- Quality Improvement

INNOZL 3D PRINTED NOZZLES MADE OF TITANIUM STL-LINE

-

Advantages:

Designed to maintain a constant coolant speed across the entire nozzle width. Due to the compact design, the coolant reaches even tight contact zones to cool to the point.Features:

- The danger of grinding burn is reduced to a minimum

- Greater production output

- Less spindle power

- Less tension in your products

- Longer service life of the grinding wheel

- Great reduction in general refrigerant operating costs

- Smaller cooling units

PROFESSIONAL MIXING UNIT (TAFAN 5000) FILLING STATION FOR MACHINE TOOLS

-

The professional filling station Tafan-5000 is perfectly suited to fill machine tools of all

Way to fill professionally and quickly. With our professional mixer Tafan-5000

the preparation of machine emulsion and the filling of the equipment can be done in one operation. Due to the self-priming (vacuum), the cooling lubricant concentrate is easily sucked in and mixed with the tap water

is mixed into the emulsion. The automatic nozzle prevents overflowing on the machine.Important notes:

The machine works according to the Venturi principle, i.e. the values on the scale

are only a guideline, but depend strongly on the water pressure, the oil level of the concentrate in the barrel and the length of the outlet hose,

therefore always check and adjust the desired concentration using a refractometer.

COLD AIR NOZZLE (HL6910.15) WITH VA ARTICULATED HOSE

-

By using cooled air, the temperature in the cutting area is reduced, allowing higher cutting speeds and tool life to be achieved. Modern coatings can only exploit all the advantages of this type of cooling, as damage to the cutting edge from thermal shock is avoided.

In addition, the very light chips produced during copy milling are also removed from deep recesses or cavities with the aid of the cold air nozzle. The principle of the cold air nozzle is based on the operating principle of vortex tubes. Ordinary compressed air is divided into a cold and a hot air stream. Without additional energy supply by current or moving parts the cold air nozzle can achieve a cooling capacity of up to 733 W or temperatures of approx. -40 °C and only requires operating compressed air of approx. 6 bar. A water separator or a maintenance unit should be connected upstream. A control valve in the hot air outlet controls the temperatures and flows.