- Offer Profile

-

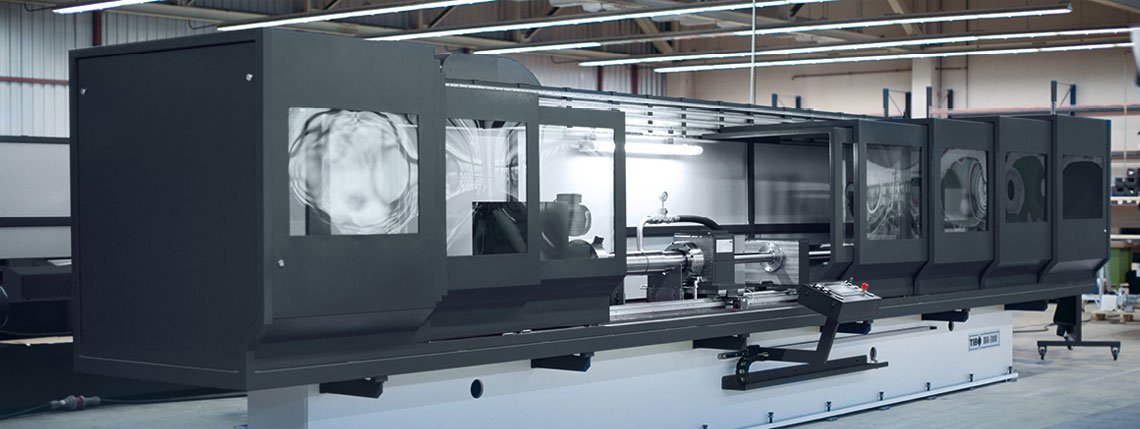

Experience Tibo – deep hole drilling machines for highly specific applications

As one of the leading suppliers of single-spindle or multi-spindle deep hole drilling machines the TIBO Tiefbohrtechnik GmbH provides sophisticated solutions for sophisticated tasks. The excellence of Tibo deep hole drilling machines is recognized in a wide range of branches throughout the world including hydraulics, pneumatics, aerospace, renewable energies and medical technologies.

Tibo Deep Hole Drilling Machines

-

Gundrilling machines, cross table machines and BTA deep hole drilling machines made from modular system components.

Deep hole drilling is defined as "a metal-cutting" machining process for making boreholes in which the ratio of drilling depth to drilling diameter is normally 10:1 or more". A method that requires a lot of technical know-how, high-quality tools and maximum precision.

As one of the world's leading manufacturers of deep hole drilling machines, Tibo supplies high-precision solutions that have been proven many times over for drilling tasks involving diameters of 2 mm to 400 mm and drilling depths up to 12,000 mm, realised in a modular machine concept consisting of high-quality, perfectly harmonised system components.

Depending on the diameter and depth, this involves using various methods that Tibo has continuously perfected in ongoing development work: Gundrilling and BTA deep hole drilling. Both methods allow highly precise and fast deep hole drilling in a wide variety of materials from aluminium and stainless steel to super-alloys in aerospace engineering. The Tibo modular system

-

Modular and flexible.

The Tibo modular system is as simple as it is ingenious, and offers almost limitless configuration possibilities – from the universal standard machine to part-specific special solutions. Individually adapted to your deep hole drilling requirements, this means that we can always offer you an optimum machine configuration that does exactly what's demanded of it with maximum efficiency.

Continuous further improvements to our product range and the use of proven components result in much simpler handling, less complex setting-up and extended machining possibilities.An overview of the Tibo modular system

1st Module: Machine bed

The solid basis of every Tibo deep hole drilling machine is our machine bed, which is available in many standard sizes including linear guides and various base plates onto which the other drilling units are mounted. This ensures extreme precision down to the 1/1000 mm.

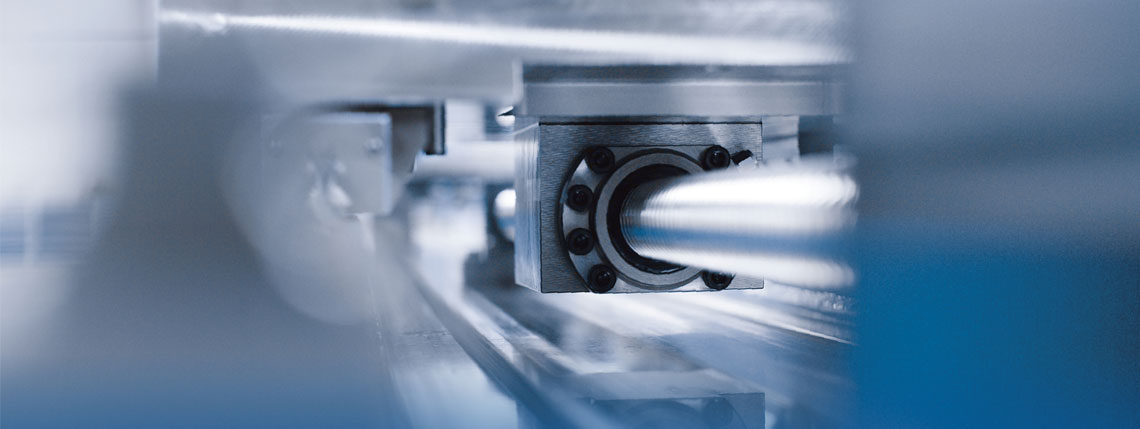

2nd Module: Drill spindle

The drill spindles are mounted onto the linear guides and base plates – between one and six spindles that are fitted with the drive to match depending on the drilling task. Spindle drives with switchable gears are also available for large machines.

3rd Module: Tailstock or second drill spindle

Fixed or counter-rotating tailstocks can be fitted, depending on the customer's requirements and the task. Alternatively, a second spindle component can also be configured to drill simultaneously from two sides with up to twelve spindles in total.

4th Module: Drill bush holder carriage (ELB) or coolant pressure head BOZA (BTA)

he optionally movable drill bush carriage or the coolant pressure head (BOZA) is attached, depending on the drilling method. The drill bush holder with a clamping cone used in gundrilling (ELB) guides and centres the drill and takes up the coolant and drilling chips that are removed from the bore hole. The coolant pressure head (BOZA) is used in the BTA method. It guides the drill tube and at the same time presses the deep drilling oil with high pressure along the drill to the drill's tip. In the process, the Tibo modular system also allows a combination of gundrilling and BTA methods on one machine.

5th Module: Chip removal and coolant system

The drilling chips are fed to the chip discharge via the chip conveyor (optionally: chip basket), while the drilling oil is first filtered, cooled if necessary and finally fed back into the coolant oil tank. A combination with a centrifuge is also optionally available.

6th Module: Steady rests and vibration dampers

The required number of tool steady rests (gundrilling method), vibration dampers (BTA method) and workpiece steady rests (all methods) is used depending on the length of the workpiece. Here, the modular Tibo system also allows quick and simple changing of the steady rests – giving you an inestimable advantage over the competition when frequently changing machining tasks are involved.

7th Module: Control

Tibo deep hole drilling machines are equipped with state-ofthe-art automation technology. Our intuitive touch based user interface enable efficient parametrisation and supervision of our drilling processes. Essentials features such as work peace memory, user account control and remote access capabilities are always included. The movable control panel gives you unrestricted access to all machine components.

8th Module: Safety doors / light barriers

Tibo deep hole drilling machines conform to the European Machinery Directive 2006/42/EC and are equipped with light barriers in combination with a safety fence. Machine enclosures are available as an option

Gundrilling machines (ELB method)

-

- Solid drilling to Ø 40 mm

- Drilling depths to 4,500 mm*

Tibo gundrilling machines are ideally suited to deep hole drilling tasks with smaller drilling diameters of 2 mm to 40 mm.

A characteristic of the gundrilling method is that the coolant is introduced through channels inside the tool shaft. It is removed together with the drilling chips via a V-shaped slot (beading) along the tool. Our unique machine concept with high-quality, harmonised system components enables deep hole drilling operations to be performed down to a drilling depth of 4,500 mm or more – with maximum precision and at high speed.spindles 1 2 3 4 6 E10 2 - 10 2 - 10 2 -10 2 -10 2 - 10 E15 2 -15 2 -15 2 - 15 2 -15 2 - 15 E25 3 - 25 3 - 25 3 - 25 3 - 25 E30 5 -30 5 -30 5 -30 E40 5 - 40 5 - 40

The modular system enables every gundrilling machine to be individually adapted to the user's needs: At the same time, systems with between one and six spindles can be realised as standard. Additionally, assembly as a TWIN UNIT is possible for machining particularly large quantities, involving drilling with up to twelve spindles simultaneously from two sides. There is also optional provision for shutting down individual drilling spindles, if for example different batch sizes are often machined.

Every deep hole drilling machine can also be configured with automatic loading and unloading, making it ideal for economical series production. The modular design and extensive optional accessories allow additional machining methods such as reaming for example. Proven components and state-of-the-art tools guarantee highly precise drilling results.

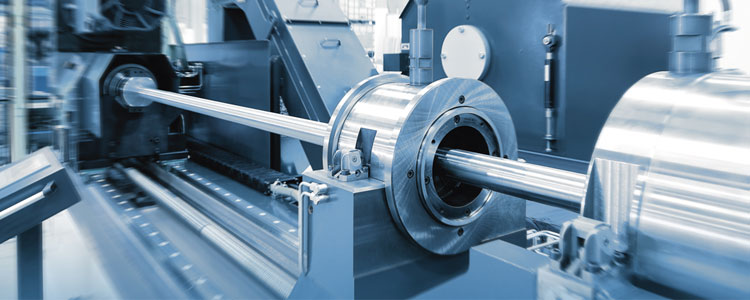

BTA deep hole drilling machines

-

- Solid drilling to Ø 250 mm

- Counter-boring to Ø 400 mm

- Drill depths to 12,000 mm*

BTA deep hole drilling machines from Tibo provide the optimum method for larger drill diameters of 18 mm to 250 mm solid drilling (up to 400 mm counter-boring) and drill depths of up to 12,000 mm.

With the BTA method, the coolant is introduced and removed and the chips are transported away in exactly the opposite way to the gundrilling method: Thanks to the larger diameter of the BTA drill, here it is possible to reliably and continuously remove the chips through the tool's interior. The coolant on the other hand is introduced from the outside and under pressure through the annular gap between the bore hole and the drill by means of a coolant pressure head (BOZA).System BTA B80 B125 B160 B250 Drilling Ø mm 10 - 80 25 - 125 25 -160 50 -250 Counter-drilling Ø max. mm 100 200 250 400 Drill depth max. mm 4.500 12.000 12.000 12.000 Workpiece Ø max. mm 630 630 630 825 Torque Nm 600 at n=140 -¹ 2.000 at n=180-¹ 5.390 at n=90-¹ 7.500 at n=90-¹

A variant of this is the ejector drilling method in which the deep drilling oil is supplied through an annular chamber between the drill tube and an internal tube. The cooling lubricant exits at the side of the drilling head, flows around it and flows back with the chips in the internal tube. At the same time, some of the cooling lubricant is supplied into the internal tube via a ring nozzle. The resulting vacuum at the chip mouth allows the return flow (ejector effect).

Tibo BTA deep hole drilling machines are also available as single-spindle or multi-spindle versions. By selecting different gearboxes and depending on the drilling task, different drive variants can be realized, thus always achieve optimum cutting performance.

The modular design and extensive optional accessories allow additional machining methods such as skiving and roller burnishing, pull boring und bottle boring. Proven components and state-of-the-art tools guarantee highly precise drilling results.

Customized machines

- In addition to the well-known modular deep hole drilling machines Tibo develops, designs and manufactures customized solutions for deep hole drilling and related methods. Customized machines made by Tibo are used in almost all industries.

According to your specifications we are developing a customized solution for you. Wherever possible we are using components out of our modular system for competitive solutions.

We accompany you from the first idea through conceptual design, development, assembly, installation until start up. During operation our specialist are supporting you with service and maintenance worldwide.

Due to the number of customized solutions we built over the years like rifling machines, machines with integrated milling capability, for eccentric holes with rotating table and cross slides we are capable of finding the perfect solution for you.

In addition we are offering solutions for integrated loading and unloading systems based on robots or gantry systems, cleaning and deburring units. The complete periphery like exhaust systems, chip breakers or chip centrifuges is always part of the solution.

With our experience, know-how and team of experts we can offer you an innovative and tailor-made solution.

Modular expandability: tailstock or other cachine components.

Used machines

- We are offering complete Services around used machines:

- Training

- competent support from Tibo Headquarter

- Service and support at your site

- Spare parts and additional equipment

Control unit

- All of our deep hole drilling machines have intuitive control technology for maximum process reliability and control. Via touch panel, the machine operator obtains all the important process parameters at a glance and can, if necessary, also perform optimisations during ongoing operation.

Depending on the drilling task, the chip breakage is individually programmable and thereby guarantees maximum process reliability, low tool wear and maximum efficiency. If a fault occurs, the system remembers the drill’s current position and can return to it again precisely and quickly after the fault is remedied.

The system also has a high-performance drilling data memory in which repeat applications can be stored and recalled at your fingertips. This means the machine is set up and ready for the new drilling task within a very short time. Temporarily shutting down individual spindles is also possible as an option.

Another important advantage of the control concepts implemented by Tibo is its remote capability. This allows the machine data to be saved and edited on a PC. It also permits genuine remote access for maintenance purposes for example. If the customer wishes and if necessary, Tibo staff can also access the machine to check the control process parameters and optimise them if required. Service, accessories and spare parts

- High process reliability using original parts

The modular design of our deep hole drilling machines guarantees the long-term compatibility and availability of all accessories and spare parts. An extensive stock and logistics programme guarantees quick delivery.

We offer custom tailed packages for accessories and spare parts.- Spindle blocks

- Drilling units

- Drills Drill bushes

- Drill bush holders

- Clamping cones

- Coolant pressure heads

- Deep drilling oil etc.

Areas of use

- Deep hole drilling solutions for every requirement.

Whether it's the oil and gas industry or renewable energies, hydraulics and pneumatics, automotive, aeronautical – wherever highly precise and durable deep hole drilling machines are needed, Tibo can provide optimum custom solutions.

Oil and gas

- Whether it's drill collars, drillpipes or submersible pumps – Tibo deep hole drilling machines will allow high-precision drilling operations with minimal runout in alloys typical for the application such as nickel steels, and come with additional features specially developed for the task, for example chip breakage monitoring for reliable cutting which is integrated as standard.

Machine type for this area:- Gundrilling machines

- BTA deep hole drilling machines

Medical technology

- Medical implants such as bone nails, medullary nails, bone screws or stents, most of which are made of titanium or stainless steel alloys, require maximum-precision deep hole drilling with minimum runout. Parts with very thin walls are exactly those that present a real challenge, but that can also be brilliantly and reliably overcome with Tibo deep hole drilling

machines.

Machine type for this area:- Gundrilling machines

Automotive and vehicle construction

- Camshafts, crankshafts, transmission shafts, drive shafts, flanged shafts, injection nozzle bodies, fuel rails, valves, con-rods or piston pins – there's hardly any other industry in which so many deep hole drilling applications are encountered. This is in addition to large quantities and maximum output in the shortest possible time. Tibo deep hole drilling machines deliver solutions here that are as precise as they are efficient: Consequently, when through-holes are present – for example in camshafts and common rails – it is also possible to drill simultaneously from two sides. All over the world, our customers rely here on deep hole drilling machines that have been specially developed for this task with designs that incorporate up to 12 spindles – including fully automated part handling by, for example, synchronized chains, overhead gantries and robot loading. This allows cycle times that are almost 50 per cent quicker!

Machine type for this area:- Gundrilling machines

- BTA deep hole drilling machines

Aerospace

- Components such as landing gear, turbine shafts and refuelling pipes, often made of titanium, tempered steels or special alloys such as Inconel, require extremely precise drilling. The material-saving construction processes that are normal in aircraft production also often require deep hole drilling contours for this, with different hole diameters as the drilling depth increases. Tibo deep hole drilling machines of the BTA series are used for this, which are able to produce all desired internal contours through what is known as bottle boring.

Machine type for this area:- BTA deep hole drilling machines

Hydraulics and pneumatic components

- In earth-moving machines such as dump trucks and dredgers, hydraulic and pneumatic cylinder tubes must work reliably over long periods and under the most difficult conditions. Precise dimensional accuracy and top surface quality on the cylinder tubes are therefore absolutely essential. Besides making precise deep bores in cylinder tubes, Tibo deep hole drilling machines are also suitable for skiving and roller burnishing the drilled tubes (also in double or triple combinations). Automated loading and unloading equipment, as well as automated tool-changing devices, make our BTA series deep hole drilling machines the ideal solution for economical and precise series production.

Machine type for this area:- BTA deep hole drilling machines

Semi-finished products

- Camshafts, crankshafts, transmission shafts, drive shafts, flanged shafts, injection nozzle bodies, fuel rails, valves, con-rods or piston pins – there's hardly any other industry in which so many deep hole drilling applications are encountered. This is in addition to large quantities and maximum output in the shortest possible time. Tibo deep hole drilling machines deliver solutions here that are as precise as they are efficient: Consequently, when through-holes are present – for example in camshafts and common rails – it is also possible to drill simultaneously from two sides. All over the world, our customers rely here on deep hole drilling machines that have been specially developed for this task with designs that incorporate up to 12 spindles – including fully automated part handling by, for example, synchronized chains, overhead gantries and robot loading. This allows cycle times that are almost 50 per cent quicker!

Machine type for this area:- Gundrilling machines

- BTA deep hole drilling machines

Renewable energies

- Typical deep hole drilling applications in the field of renewable energies are turbine shafts or rotors for wind power systems. With regard to component dimensions, there is a need here for customised, high-precision deep hole drilling solutions. Thanks to the varied combination possibilities, our modular system allows the right solutions to be found here for any application.

Machine type for this area:- Gundrilling machines

- BTA deep hole drilling machines

Die and mould making

- At the manufacturing of moulds, mould frames and also mould inserts for the die and mould industry, cooling holes are already very important and will play a major role in the future. Typical, these cooling holes are deeper than 40 x diameter, therefore, using a standard milling center will not be successful to reach the drilling depth. Tibo convinces with a new development of the cross table series KTE with a deep hole drilling depth up to 1.000 mm, maximum cutting capacity, process stability through customized pressure and power monitoring, performance, stability, high-precision and minimal run out.

Machine type for this area:- Cross table machines