JENOPTIK laser machines

Videos

Loading the player ...

- Offer Profile

- Jenoptik laser technology

delivers impressive accuracy and performance.

Laser technology delivers impressive accuracy

Jenoptik manufactures products and applications across the entire value chain for your laser material processing– from individual components to complex laser systems.

In the laser technology field, we specialize in high-quality semiconductor lasers and reliable diode lasers. The latter are available either as modules or systems. We also produce innovative solid-state lasers such as disk and fiber lasers. Thanks to the broad range of our product portfolio, we have the right products for you for the pulse width range from cw to fs.

Product Portfolio

Lasers for Precise and Efficient Material Processing

-

Our laser machines process polymers and metals extremely precisely, efficiently and safely, allowing you to optimize and automate your production processes. The units can be easily integrated into existing systems. You can even try out different laser beam sources and machines in our application centers to help ensure that the product precisely meets your requirements.

The energy-efficient and environmentally-friendly exhaust cleaning systems from Jenoptik remove pollutants without any residue, thereby helping to protect your sensitive production facilities and your employees.

With our lasers and laser technology, you can process the most diverse materials with ultimate precision while saving energy. High-precision laser applications: Process materials efficiently

-

Jenoptik provides versatile laser processes that help you to optimize your processing tasks, applications and production processes.

Jenoptik experts will help you to find the best processes for your laser application in production, allowing you to process different materials such as metals, plastics, semiconductors, textiles and leather efficiently and cost-effectively. We offer highly developed laser beam sources such as diode, solid-state and fiber lasers, as well as laser machines tailored to the relevant process. These are ideal for a range of different industries — from the automotive industry to sciences.

You can test all the laser beam sources offered by Jenoptik in our application laboratory. These include various diode, solid-state and fiber lasers. The practical tests will help you determine which laser is best suited to your specific needs.

Our customer application center also gives you the opportunity to use all of our series production systems in a targeted manner — tested on your own products under real conditions. You can choose from 15 different laser systems and machines, and will be assisted and advised by our highly qualified engineers. The application centers give you the opportunity to develop your production processes in a sustainable manner. Your feedback will also help us to continuously improve our own products.

Invisible and functionally reliable predetermined breaking points thanks to precise laser perforation

-

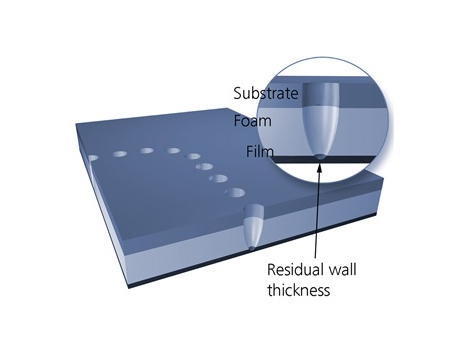

The patented laser perforation process from Jenoptik enables you to integrate precise, functionally reliable and invisible predetermined breaking points in plastic components in just one process step.

The sensor-based Jenoptik laser perforation process meets the highest demands in terms of safety and aesthetics, allowing you to process plastic components in a fast and controlled manner. In just one step, for example, you can create predetermined breaking points in vehicle airbag covers that are invisible to passengers. The specially developed sensor technology from Jenoptik is so precise that you can precisely retain predetermined residual wall thicknesses. At the same time, the process ensures that the highest safety standards are met. Each individual processing point is monitored during the laser perforation process and compared against the corresponding parameter values. All data can be reliably archived in a traceability system.

Unlike mechanical processes, laser perforation is completely non-contact. The non-wearing laser beam tool does not induce any mechanical stresses on the material. The process is also particularly clean and does not require any subsequent reworking because any dust generated is immediately extracted and cleaned. You can set the type, distances and contour of the holes according to your requirements — specific to the material you are currently processing. The process is therefore perfectly suited to the perforation of predetermined breaking points in plastics, textiles or leather.

Benefits- Flexible: Exact and invisible predetermined breaking points in a wide range of materials thanks to precise sensor technology.

- Economic: Process multi-layered materials in just one process step.

- Non-wearing: Non-contact processing minimizes maintenance and spare parts costs.

- Variable: Increased flexibility in terms of component design.

- Safe: Monitored and traceable process for safety-related components.

- Automotive industry: Predetermined breaking points for airbag covers in the vehicle trim.

Precise laser cutting of 3D plastic and metal components

-

The non-contact laser cutting system from Jenoptik provides a quick way to process metals and plastics. The non-wear process from Jenoptik guarantees low maintenance costs.

With the laser technology from Jenoptik, you can cut metals and plastics efficiently and flexibly in a process that is gentle to the material, delivering the best-possible laser cutting results. You can tailor the energy applied precisely to the machining process in question, preventing the material from warping or overheating and saving you time and money.

Metal Laser Cutting

Process metal quickly and extremely precisely with the highly developed robot and beam guidance technology from Jenoptik. Laser technology allows you to reach complex 3D components even in hard-to-reach places. Set-up time is significantly reduced as just one tool can be used for all tasks. After the laser cutting process, the components do not need to be cleaned because the laser process works without any additional cutting equipment.

Plastic Laser Cutting

Laser technology provides an energy-efficient way to cut plastics and creates exceptionally precise edges. The process is non-contact, which protects the material and prevents both tool wear and damage to your 3D component. High-performance exhaust air purification systems also extract the smoke, ensuring a clean machining process.

Benefits- Flexible: Complex 3D components can be laser cut easily at any point.

- Efficient: Extremely dynamic and fast.

- Precise: Achieves precise cutting results.

- Non-wearing: Non-contact process for minimal maintenance and spare parts costs.

- Rapid set-up times: Use one tool for all tasks.

- Clean: Extract smoke with high-performance exhaust air purification systems.

Fields of Application- Automotive industry: Laser cutting of metal and plastic 3D components.

- Household technology: Laser cutting of housings and plastic components.

Precise and extremely strong welding of plastics with energy-efficient laser welding

-

Laser welding allows you to join plastic parts with an extremely strong bond. The process is non-contact and vibration-free, which helps protect the material.

With laser welding, you can join plastic parts quickly and precisely while saving energy, creating strong and durable weld seams that do not leave a visible mark. This means that plastic welding using laser technology also meets the highest aesthetic demands.

The process is completely non-contact and vibration-free, and the energy input is precisely metered, which means the joined components are subjected to minimal thermal and mechanical loads. At the same time, laser welding is a particularly clean process. Processing does not create any emissions, has no flash and does not cause any burr formation.

Benefits- Metered: Precisely control energy input during laser welding.

- Non-contact and vibration-free: Minimizes mechanical and thermal loads.

- Efficient: Minimal operating costs compared to competing technologies.

- Extremely durable: Hermetically sealed weld ensures highest quality.

- Controlled: Monitor the weld seam online.

- Environmentally friendly: Clean process means no emissions.

Fields of Application- Automotive industry: Laser welding of pumps and filters, injectors, controllers, deployment channels for airbags, mounts for parking sensors and other components on bumpers.

- Electronics and household goods industry: Laser welding of displays, valves, pumps, sensor housings.

- Medical technology: Laser welding of blood glucose monitors, catheters, dialysis machines.

Efficient material processing thanks to efficient laser machines from Jenoptik

-

Jenoptik laser machines do not damage the material, are extremely precise and deliver maximum quality, allowing you to optimize your production processes.

Cut, weld and perforate a range of materials using efficient and cost-effective laser machines from Jenoptik. The process is completely non-contact, and you can set a precisely defined energy input, helping to protect the workpiece and tool and preventing damage and wear. The highly developed laser technology also prevents the material from overheating and warping, which minimizes reworking time and saves costs.

Jenoptik is one of the world’s leading manufacturers of laser machines and laser systems for material processing. We develop and build efficient laser machines for your specific production requirements, helping you to realize new manufacturing opportunities. Your process requirements, production environments and specific goals are our benchmark. We configure and optimize our modular standard platforms in close cooperation with you to deliver a tailored solution — because progress needs a base of excellence.

Benefits of Jenoptik Laser Machines- Non-damaging: The laser machines use a non-contact and non-wearing process.

- Precise: Precise results thanks to sensor-guided laser technology.

- Controlled: User-defined energy input, helping to minimize thermal load.

- Economic: Minimal operating costs thanks to short processing times and optimized processes.

- Tailored: Laser machines optimized in line with your specific production processes.

Fields of Application- Automotive industry: Perforation of predetermined breaking points for airbag covers, and 3D laser processing (welding and cutting) of plastic and metal components.

- Household technology: Laser cutting and welding of housings and plastic components.

- Electronics and household goods industry: Laser welding of displays, valves, pumps, sensor housings.

- Medical technology: Laser welding of blood glucose monitors, catheters, dialysis machines.

JENOPTIK-VOTAN® A series: Laser Scoring for Fail-Safe Breaking Points in Airbag Covers.

-

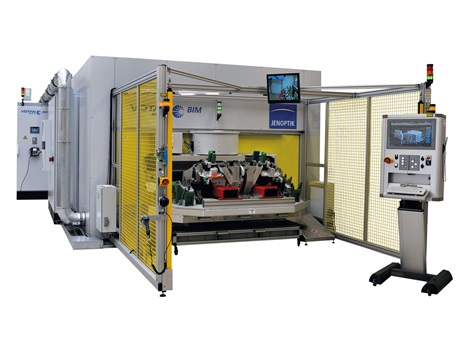

The patented laser scoring process from Jenoptik for airbag covers opens up completely new design possibilities in vehicle design. Use the series of JENOPTIK-VOTAN® A to perforate automotive parts in a precise way without damaging the material.

Laser Perforation Machine for functionally reliable predetermined breaking points in airbag covers

The procedure developed by Jenoptik for the laser scoring of airbag covers opens up completely new options for vehicle design. All products in the JENOPTIK-VOTAN® A series also work in a completely non-contact and wear-free manner. The leading procedure for laser scoring therefore combines the highest aesthetic demands with safety and efficiency.

In the patented procedure for laser scoring, a laser creates a series of blind holes on the reverse of the material. This means that a weakening line is created along the contour of the airbag flap. Vehicle passengers will not notice the integrated breaking point. However, if a situation arises when the airbag needs to trigger, then the material rips open at the weakened point.

Benefits- Unique: No other principle controls the process quality directly in the part.

- Economical: Handle multi-layered materials in just one process step.

- Fail-safe: Exact remaining wall thicknesses thanks to sensor-controlled laser technology.

- Flexible: Variably adjust contour and tensile strength of the breaking point.

- Non-contact: The processing is wear-free and preserves material.

Fields of Application- Automotive industry: Laser scoring of breaking points for passenger, side, thorax, and knee airbags in dashboards and interior trim panels.

JENOPTIK-VOTAN® BIM Laser Cutting System: High-Precision 3D Cutting of Metal and Plastic Parts

-

With the laser cutting system from Jenoptik, you can process 3D components at high speeds according to your exact specifications.

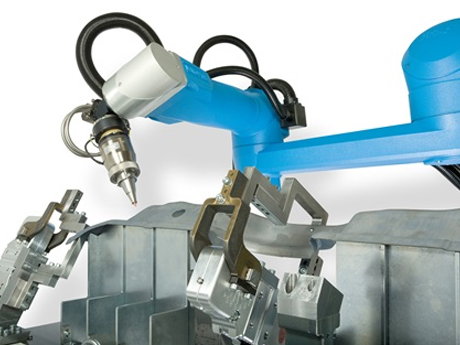

The JENOPTIK-VOTAN® BIM laser cutting system is ideal for 3D laser cutting of metals and plastics. The innovative robot technology processes complex components— quickly, effectively and precisely. It sets new standards, particularly in the metal industry.

Our mirror system inside the lightweight robot guides the light onto the cutting head. The individual mirrors are actively cooled, and precisely guide the beam through all axes. There is no need for a moving light guide cable, which makes the laser cutting system very streamline and lightweight. The cutting head has plenty of room, and is therefore very mobile, allowing access even to places that are hard to reach.

The laser cutting system is the ideal tool for processing 3D components. Even with the extremely short cycle times, the contours are cut incredibly precisely. The high cutting and adjustment speed significantly accelerates the process. The system is dynamic and can be perfectly tailored to the component.

Thanks to the modular structure of the core components, the laser cutting system can be effortlessly integrated into your system. The compact system design ensures that both commissioning and service costs are kept to a minimum. You will receive a reliable laser system that is already used successfully by over 200 companies in the automotive industry. We would be happy to develop a machine specifically tailored to your needs verified in our advanced application center.

Benefits- Extremely fast: The laser processes 3D components at top speed.

- Precise: The laser cutting system precisely follows the contour and ensures maximum accessibility to the workpiece.

- Powerful: Laser power of up to 4 kW possible.

- Energy-efficient: Based on our reliable fiber laser technology and CO2 laser technology.

- Cost-effective: Minimal operating costs and service costs.

- Reliable: Over 200 laser processing systems currently used successfully in automotive manufacturing.

Fields of Application- Automotive industry: 3D laser processing of plastic and metal components.

JENOPTIK-VOTAN® W Laser Welding System for Efficient Plastic Welding

-

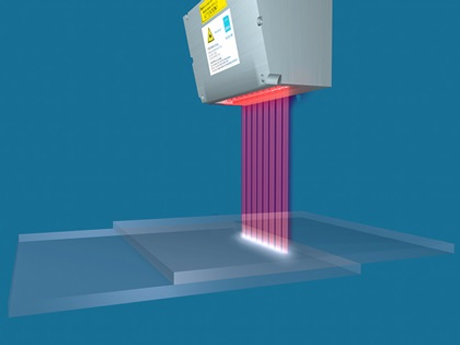

Using energy-efficient diode technology, the JENOPTIK-VOTAN® W laser welding system is fast and reliable, and can join plastics without damaging the material or leaving a visible mark.

The JENOPTIK-VOTAN® W is a powerful laser welding system that joins plastics efficiently, quickly and reliably using free-radiating diode technology. The process joins components with minimal thermal or mechanical load and without leaving any marks on the components. The weld seams are very strong and reproducible.

At the heart of every JENOPTIK-VOTAN® W laser welding system is the free-radiating diode technology. Jenoptik has developed the diode laser line that can be switched on and off section by section specifically for large components. It consists of eight diode laser submounts in a compact housing, and creates a consistent line with a total length of around 100 mm. Each of these submounts can be switched on or off individually depending on the contour you want to weld.

If several diode laser lines are arranged as an overall line (diode nest), components of almost all sizes can be joined very productively in just one run. The laser welding process is therefore extremely productive and saves operating costs. The laser welding system is already used successfully in industry.

Benefits of the Laser Welding System- Non-contact and vibration-free: Weld parts without mechanical or thermal loads.

- Highly robust: Hermetically sealed weld seams with an inherent strength of around 90percent.

- Clean: No emissions, no flash and no burr formation.

- Non-damaging and aesthetic: Reduced wall thicknesses in joined components.

- Economic: Highly efficient process with minimal operating costs, and very flexible in the event of plant changes.

- Monitored: Thermal monitoring of the welding process.

Fields of Application- Automotive industry: Laser welding of plastic parts.

- Household goods industry: Laser welding of displays and housings.

- Medical technology: Laser welding of blood glucose monitors, catheters, dialysis machines.

- Consumer electronics: Reliable joining of plastic components.

Process automation solutions for automotive manufacturers and suppliers

-

Product and process portfolio for automation solutions.

Jenoptik is a full-service turnkey provider of automation solutions and application products – starting from individual production machines to the complex automated production line.- Welding Systems (Resistance, Mig, Tig, Projection and Laser)

- Fastening Systems (Rivets, Clinch Nuts, Adhesive)

- Material Handling (Robotic and Hard Automation)

- Transfer Devices and Systems

- Fixtures

- End of Arm Tooling (EOAT)

- Positioner

Benefits- Solutions Base Engineering with Global experience

- Flexible manufacturing experience and methods

- Conventional Turnkey Systems or on customer floor

Fields of Application- Line integration

- Customization of manufacturing

- Increase of automation levels

Material Handling Automation

-

Jenoptik has experience with many types of metal joining systems. These systems range from high speed robotic weld lines to low volume manual body shops.

- Resistance Weld Systems

- Mig and Tig Welding Systems

- Remote Fiber Laser Welding Systems

- Riveting and Toggle Lock Systems

- Fastener Welding Systems

- Adhesive Bonding Systems

- Hot Stamping Systems

- Vision Integration Systems

Jenoptik can deliver specialized flexible solutions for many types of material handling requirements.

- Robotic Handling Systems

- Automated Positioners

- Specialized Conveyors

- Seventh Axis Integration

- LCA’s (Low Cost Accumulation)

- Specialized “End Of Arm Tooling”

- Overhead assists

Automated Production

-

The following list represents types of automation solutions that Jenoptik has experience with.

- Body in White Spot Welding

- Body Sides

- Under Body

- Floor Pans

- Roof and Sun Roof

- Fenders

- Truck Box and Box Sides

- Structural Items

- Engine Cradles

- “A”-Arms

- Frames

- Rails (Frame)

- Laser Welding

- Door Halo’s

- Bumper Brackets

- Tailored Blanks

- Hot Stamping

- “C” – Pillars

- “A” – Pillars

- Custom Robot End Effectors

- Fastener Systems

- Projection Nut and Stud Cells

- Rivet Systems

- Clinching Systems

- Press Lock Systems

- Closures