- Offer Profile

- Panasonic Connect Europe is dedicated to serving the business world and our goal is to "connect" our customers’ operations to a better future. By connecting our specialised hardware with the latest technologies and using the knowledge and expertise cultivated in our deep history of manufacturing to provide advanced services, we create value for our customers and provide solutions to their challenges whilst building together a more sustainable future.

Robot & Welding Solutions

-

European-wide support and partner network

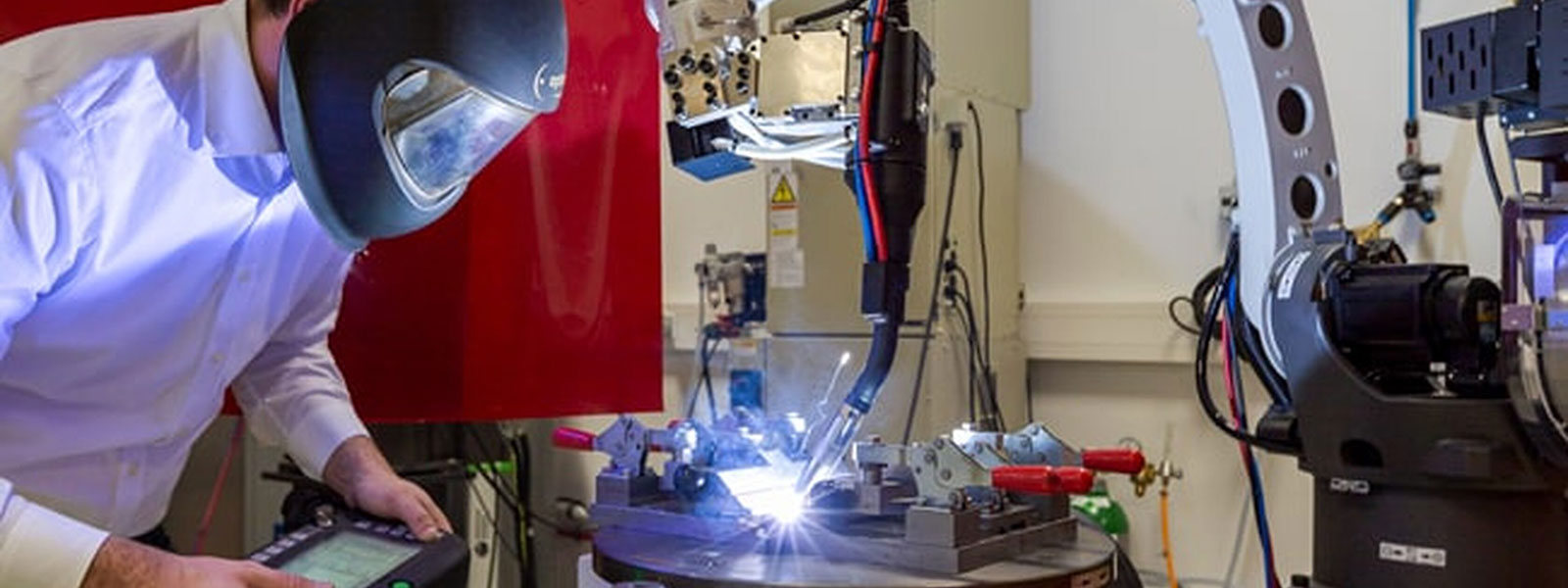

Since 1957, Panasonic has been at the forefront of welding technology, making significant strides in MIG/MAG/TIG and robotic welding. Panasonic Robot & Welding Europe serves as the provider for welding products, solutions, and services across Europe. Based in Neuss near Düsseldorf, our headquarters features a comprehensive training room and a state-of-the-art welding test area, establishing it as a center of excellence for robotic and welding systems.

With an extensive European-wide support and partner network, we ensure that our products and services are readily available in almost every European country. This robust network provides several benefits, including localized support, faster response times, and a deeper understanding of regional market needs, enhancing customer satisfaction and operational efficiency

Our mission is to support the entire industry with 'All From One Manufacturer' solutions in the field of welding. Panasonic Robot & Welding offers turnkey, complete automated welding systems, including robots, power sources, and torches. Our integrated solutions eliminate interface issues, ensuring seamless performance for various industrial welding tasks. Whether serving the general industry or the automotive sector, we deliver optimal solutions tailored to specific production requirements.

TAWERS - The Arc Welding Robot System

-

Robot and controller combined with welding power source and servo wire feeder in one unit.

Fusion of robots, robot controller, power source and servo wire feed together in one unit: Faster, better and worldwide unique. Everything from one manufacturer. The idea behind TAWERS is based on the “fusion technology” contained in TAWERS, whereby the robot controller is fused with the welding power source controller. All control parameters such as data processing and programming sequences for the welding power source, the wire feed and the robot are combined on a 64-bit CPU PCB. This technology enables up to 250 times faster communication, eliminating virtually any delay in information flow between the individual components.

The result is unique and allows many special functions to increase the quality and productivity of TAWERS, e.g. SP-MAG, lift start and lift end, automatic wire distance control, welding data monitoring, collision detection etc.

TAWERS WG3

-

Robot Controller with Power Source 350A

Optimum welding processes are achieved by utilising an integrated inverter power source within the robot controller, ensuring complete synergy within the common control system.

This ensures that the established benefits and advantages of the existing TAWERS Fusion Technology are also now available for use for the range of MIG, MAG and DC TIG welding process.

Key features:

- MAXIMUM FLEXIBILITY OF WELDING PROCESSES

- HIGH PROCESSING SPEED

- REDUCTION OF PRODUCTION COSTS

- OPTIMUM ACCESSIBILITY THANKS TO THE SLIM CONSTRUCTION

- FAST AND EFFICIENT

TAWERS WGH3

-

Robot Controller with Power Source 450A

Optimum welding processes are achieved by utilising an integrated inverter power source within the robot controller, ensuring complete synergy within the common control system.

This ensures that the established benefits and advantages of the existing TAWERS Fusion Technology are also now available for use with WGH3.

Key features:

- MAXIMUM FLEXIBILITY OF WELDING PROCESSES

- HIGH PROCESSING SPEED

- REDUCTION OF PRODUCTION COSTS

- OPTIMUM ACCESSIBILITY THANKS TO THE SLIM CONSTRUCTION

- FAST AND EFFICIENT

TAWERS WG4

-

The New Generation

Optimum welding processes are achieved by utilising an integrated inverter power source within the robot controller, ensuring complete synergy within the common control system.

- Improvement in manipulator controlperformance

- Teach Pendant touch panel adopted

- Improved maintainability

- IoT industry standard I/F adoption

- Compliance with international standards for functional safety

Key features:

- Highly accurate and efficient welding experience

- Easier to use with touch panel and 3D display

- For manufacturing where everything is connected

- Cables arranged on the back to save space

Industrial robots

-

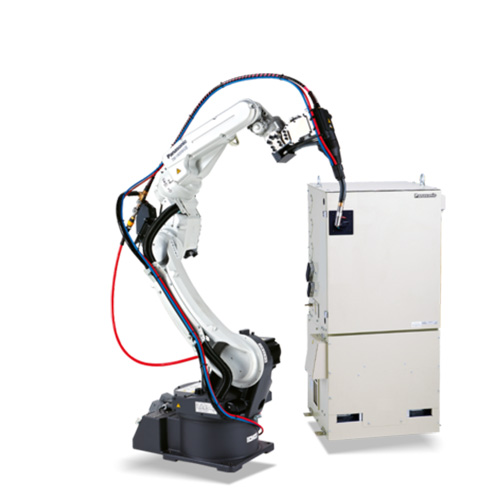

Industrial welding and handling robots with a wide range of robotic application. Available as G3/G4 version with full digital communication to our power sources or with TAWERS technology.

Panasonic provides industrial welding and handling robots with a wide range of robotic application.

All robots are available as G3/G4 Version with full digital communication to our Panasonic power sources or with TAWERS technology. One advantage of TAWERS systems is the fusion of power source, controller, wire feeder servo motor and robot which share one CPU and are able to communicate very quickly.

TM series

-

Panasonic presents the TM Welding Robot Series, this being the all new and unique generation of robots.

Customers have the possibility to decide freely whether to use an externally or internally mounted torch cable to match requirements of their applications.

Additionally the robot series benefit from a highly rigid arm structure and an improved and efficient servo motor, which provides an enhanced harmonious movement for the positioning of the welding torch.

With an all new high resolution encoder working in combination with the highly rigid arm, the TM robots provide improved path accuracy. Through this the TM robot fits optimally the requirements of a flexible and efficient welding process.

TL series

-

The new developed TL Robot series by Panasonic has the opportunity to work in a 2 meter working area for wide and maximum reachable welding procedures.

With the efficient and rapid mechanical system this robot is the fastest robot on the market. Compared to former products the speed of the major axis is adjusted to its maximum.

An integrated wire feeder and an optional usable wire guiding are only two outstanding advantages of the new Panasonic robot model.

The new torch design allows an optimal adjustment of the welding torch according to the installed TCP-properties. Through this an improved path accuracy and therefore an optimal welding result can be achieved.

TS series

- Specifications:

External cable management system

External torch cable and wire

(+) Big and therefore good wire curvature

(-) Large interior due to cable weight and movement

Through-arm cable management system

Torch cable and wire through the hollow shaft

(+) Small interior due to outside lying cables

(-) Problematic wire managementKey features:

- 841 and 971mm

- payload: 8kg

- maximum motion speed: 540°/s (average of all axes)

- supports two cable management systems

- various installation types (floor/ceiling/wall)

Welding Cells

- Panasonic PerformArc Robotic Welding Cells provide a modular concept developed using standard, reliable Panasonic components. These systems offer turnkey, cost-efficient, and universally usable welding solutions. Key benefits include enhanced precision, increased productivity, and improved safety through automation of welding processes. With easy settings managed by a single teach pendant for both the robot and power source and reduced running costs thanks to needing only one Panasonic technician for training and maintenance, these systems ensure consistent weld quality, lower labor costs, and minimized downtime. Advanced features like open standards provide flexible, efficient, and reliable solutions for various industrial applications.

PERFORMARC TT Series

-

The Panasonic standard cell is also available in the following specifications:

- PERFORMARC TT

- PERFORMARC TT-2PD-250 (with 2 external axes PanaDice)

- PERFORMARC TT-2PD-500 (with 2 external axes PanaDice)

- PERFORMARC TT-2DK-300 (with 2 tilt and turn positioners)

- PERFORMARC TT-2DK-500 (with 2 tilt and turn positioners)

PERFORMARC ET Series

-

The Panasonic standard cell is available in the following specifications:

- PERFORMARC ET

- PERFORMARC ET-XL (large work envelope)

- PERFORMARC ET-XXL (extra-large work envelope)

- PERFORMARC ET-2PD (with 2 external axes PanaDice)

- PERFORMARC ET-2PD-XL (with 2 external axes PanaDice and large work envelope)

- PERFORMARC ET-2DK-250 (with 2 tilt and turn positioners)

- PERFORMARC ET-2DK-500 (with 2 tilt and turn positioners)

PERFORMARC H-Frame Series

-

The system design allows for the coverage of a wide range of different sized work components by utilizing twin workstation manipulation.

The cell comprises of the latest technically advanced Panasonic robot and welding components seamlessly integration into a system configuration for simple user-friendly control.

The torsion-free base frame design ensures accurate position location of the robot and work piece manipulation providing the capability to pick up and move the total system without any need of programming correction.

PERFORMARC MT Series

-

The Panasonic standard cell is also available in the following specifications:

- PERFORMARC MT

- PERFORMARC MT-XL (large work envelope)

- PERFORMARC MT-XXL (extra-large work envelope)

PERFORMARC FW Series

-

The Panasonic standard cell is also available in the following specifications:

Scope and benefit of this concept

- Serial and prototype production

- Medium to high automation level

- Ideal for long and „flat“ parts

- Big Working range

- Big part supply/ loading area

- eachable with fork-lift or cranes

The Panasonic standard cell is available in the following specifications: (other dimensions on request)

- PERFORMARC FW-3PD (with 3 external axes, turn positioners)

- PERFORMARC FW-3PD-XXL (with 3 external axes, turn positioners)

Accessories & Software

- Together with a Panasonic robot, our tried and tested positioners and servomotors guarantee accurate positioning and rapid reorientation for efficient production. Additionally, thanks to software solutions, robot programs can be created and edited offline.

Welding torches

-

Just weld it!

Do you want to avoid interface problems?

Then, our modular robot welding torches are the solution. True to our principle “everything from one manufacturer” - from the contact tip to the total solution.

Peripherals Positioner

- 250 -1000 kg Tilt-Positioners

more than 1000kg possible upon request

Panasonic RJC-Series positioners are built to move in harmony with robots and are designed for maximum flexibility to meet the needs of your applications.

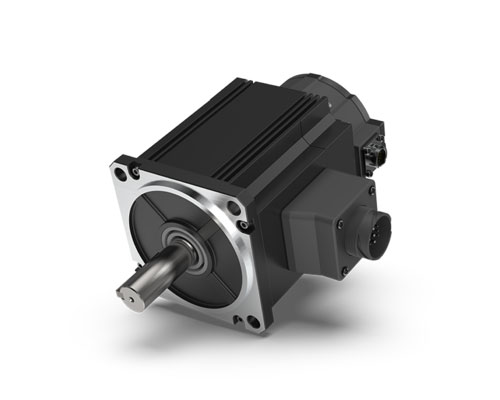

AC servo motors

-

With the help of AC Servo Motors the functionality of positioners can be increased and furthermore additional applications are possible.

A flexible solution from Panasonic! The AC-Servo Motors are free programmable and help improve synchronism with robots, enables smoother movement, and enhances productivity.

- Used in conjunction with the Robot G3 control system

- Motor sizes between 100w and 5,5 KW

- Cable lengths up to 30m in length

- Harmonizer and synchronous motion with robot possible .

- Programmed from GUI Teach pendent

Integrated Welding Network Box IWNB

-

Productivity improvement

• Availability and cycle time analysis function.

• Support improvement of availability by visualizing error status.