- Offer Profile

- The roots of Harmonic Drive SE can be traced back to the invention of the strain wave gear by Walton Musser in 1955. Originally designed for space applications, the outstanding characteristics of this gear principle – including zero backlash, compactness and high reduction in one stage – quickly gained acceptance in other industries. Since 1970, Harmonic Drive has been the leading manufacturer of precision gears and is your first point of contact worldwide when it comes to highly developed drive solutions.

Harmonic Drive® Gears

- Harmonic Drive® Gears consist of three individual components – Circular Spline, Flexspline and Wave Generator. Gear component sets extremely compact design ensures installation in applications with the most demanding space requirements. Gears with output bearing ease integration by combining the precise component sets with high capacity tilt resistant output bearings.

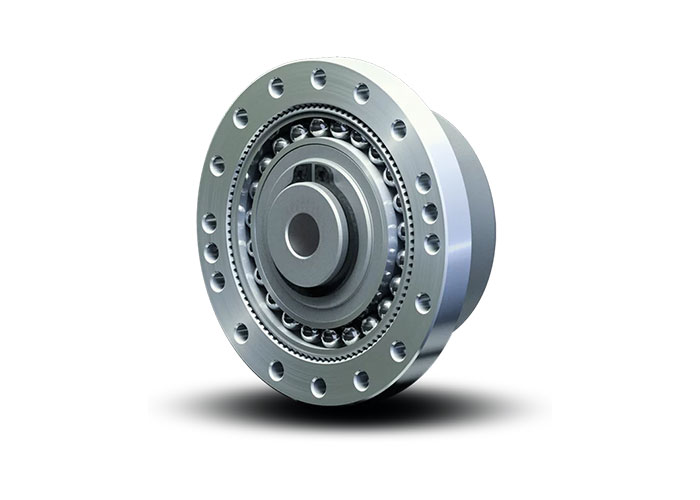

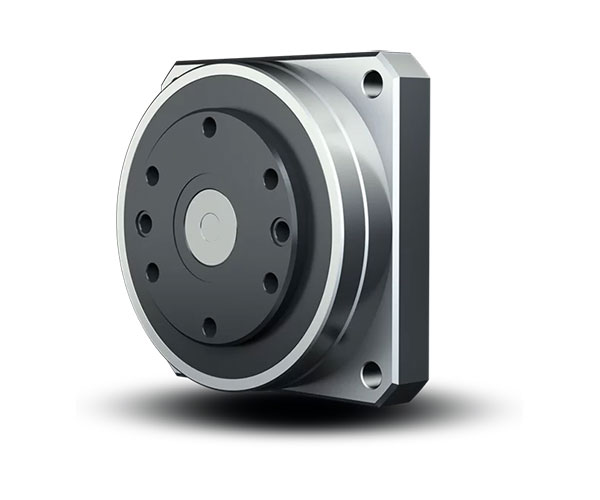

CSG-2A

-

Highest Torque Capacity and Lifelong Precision

- Maximum Torque: 7 … 6175 Nm

- Ø Hollow Shaft: -

- Sizes: 14 … 65

- Ratio: 50 … 160

CPL-2A

The Lightweight Gear with Large Hollow Shaft

- Maximum Torque: 9 … 372 Nm

- Ø Hollow Shaft: 13.5 … 36.0 mm

- Sizes: 14 … 32

- Ratio: 30 … 160

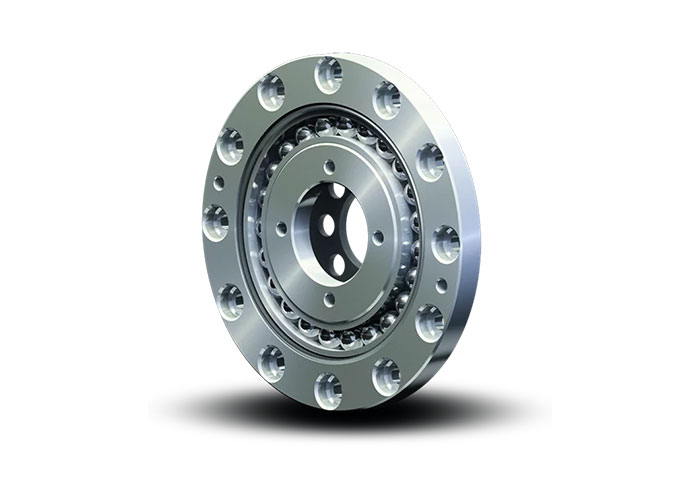

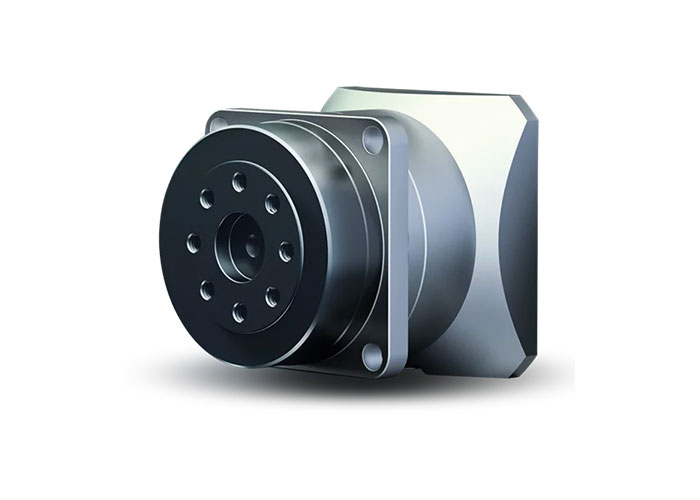

CSD-2A

-

Compact, Lightweight and Precise

- Maximum Torque: 12 … 823 Nm

- Ø Hollow Shaft: 11.0 … 50.0 mm

- Sizes: 14 … 50

- Ratio: 50 … 160

SHG-2A

-

High Overload Capacity and Service Life

- Maximum Torque: 7 … 6175 Nm

- Ø Hollow Shaft: -

- Sizes: 14 … 65

- Ratio: 50 … 160

Gears with output bearing

- Harmonic Drive® Gear with output bearing combines the precise gear component set with a torsional resistant cross roller or four point bearing to support high loads.

CSG-2UH

-

Highest Torque Capacity and Lifelong Precision

- Maximum Torque: 7 … 6175 Nm

- Tilting Moment: 41 … 1175 Nm

- Sizes: 14 … 65

- Ratio: 50 … 160

- Ø Hollow Shaft: -

CSF-ULW

Outstanding Low Weight Combined with a Short Design

- Maximum Torque: 1.8 … 92 Nm

- Tilting Moment: 2.9 … 18.9 Nm

- Sizes: 8 … 20

- Ratio: 30 … 160

- Ø Hollow Shaft: 3 … 19 mm

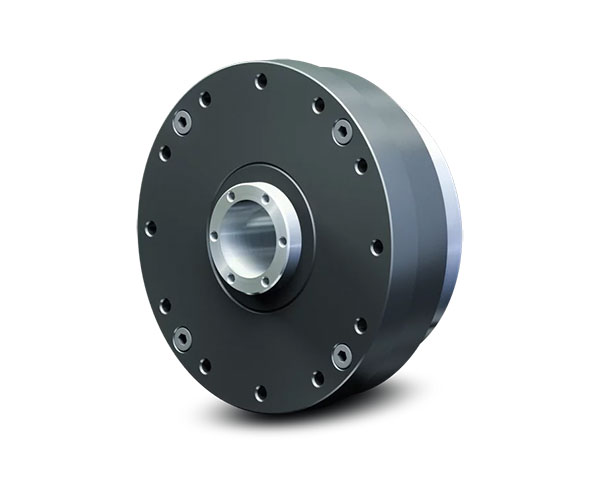

CPU-M

-

Motor Mounting Gear with Reinforced Output Bearing

- Maximum Torque: 9 … 1840 Nm

- Tilting Moment: 73 … 2222 Nm

- Sizes: 14 … 58

- Ratio: 30 … 160

- Ø Hollow Shaft: -

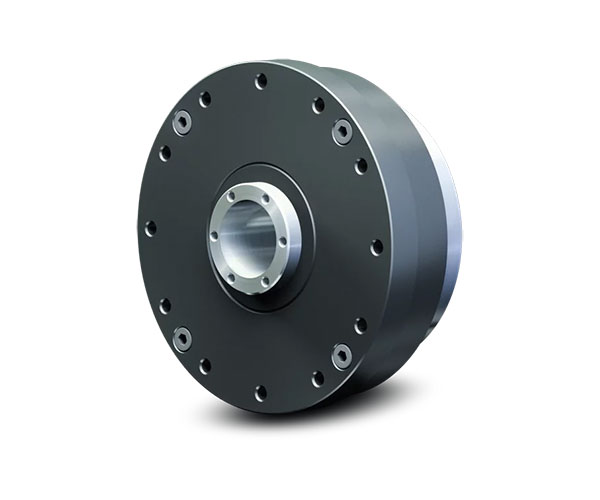

CPU-H

-

Closed Hollow Shaft Gear with Reinforced Output Bearing

- Maximum Torque: 9 … 1840 Nm

- Tilting Moment: 73 … 2222 Nm

- Sizes: 14 … 58

- Ratio: 30 … 160

- Ø Hollow Shaft: 14 … 70 mm

CPU-S

Gear with Input Shaft and Reinforced Output Bearing

- Maximum Torque: 9 … 1840 Nm

- Tilting Moment: 73 … 2222 Nm

- Sizes: 14 … 58

- Ratio: 30 … 160

- Ø Hollow Shaft: -

CSG-CPM

-

Motor Mounted Gear with Highest Torque Capacity and Reinforced Output Bearing

- Maximum Torque: 44 … 841 Nm

- Tilting Moment: 114 … 886 Nm

- Sizes: 17 … 40

- Ratio: 50 … 160

- Ø Hollow Shaft: -

CSG-CPH

-

Closed Hollow Shaft Gear with Highest Torque Capacity and Reinforced Output Bearing

- Maximum Torque: 44 … 841 Nm

- Tilting Moment: 114 … 886 Nm

- Sizes: 17 … 40

- Ratio: 50 … 160

- Ø Hollow Shaft: 14 … 46 mm

CSG-CPS

-

Gear with Input Shaft with Highest Torque Capacity and Reinforced Output Bearing

- Maximum Torque: 44 … 841 Nm

- Tilting Moment: 114 … 886 Nm

- Sizes: 17 … 40

- Ratio: 50 … 160

- Ø Hollow Shaft: -

CSD-2UH

-

Compact and Lightweight Motor Mounting Gear with Small Outer Diameter

- Maximum Torque: 12 … 823 Nm

- Tilting Moment: 41 … 759 Nm

- Sizes: 14 … 50

- Ratio: 50 … 160

- Ø Hollow Shaft: -

CSD-2UF

-

Compact and Lightweight Hollow Shaft Gear with Maximum Load Capacity

- Maximum Torque: 12 … 453 Nm

- Tilting Moment: 91 … 849 Nm

- Sizes: 14 … 40

- Ratio: 50 … 160

- Ø Hollow Shaft: 9 … 37 mm

SHG-2UH

-

Closed Hollow Shaft Gear with Maximum Torque Capacity

- Maximum Torque: 7 … 6175 Nm

- Tilting Moment: 74 … 2740 Nm

- Sizes: 14 … 65

- Ratio: 50 … 160

- Ø Hollow Shaft: 14 … 80 mm

SHG-2SH

-

Hollow Shaft Gear Without Input Bearing with Maximum Torque Capacity

- Maximum Torque: 7 … 6175 Nm

- Tilting Moment: 74 … 2740 Nm

- Sizes: 14 … 65

- Ratio: 50 … 160

- Ø Hollow Shaft: 14 … 80 mm

SHG-2SO

-

Motor Mounted Gearbox with Maximum Torque Capacity

- Maximum Torque: 7 … 6175 Nm

- Tilting Moment: 74 … 2740 Nm

- Sizes: 14 … 65

- Ratio: 50 … 160

- Ø Hollow Shaft: -

SHD-2SH

-

Light and Short Hollow Shaft Gear

- Maximum Torque: 12 … 453 Nm

- Tilting Moment: 37 … 424 Nm

- Sizes: 14 … 40

- Ratio: 50 … 160

- Ø Hollow Shaft: 11 … 40 mm

CSF Mini

-

Precision Gear for Low Torque Range

- Maximum Torque: 0.09 … 28 Nm

- Tilting Moment: 0.27 … 13.2 Nm

- Sizes: 3 … 14

- Ratio: 30 … 100

- Ø Hollow Shaft: -

PMG

-

Precision Gears for Low Torques

- Maximum Torque: 0.3 … 14.7 Nm

- Tilting Moment: -

- Sizes: 5 … 14

- Ratio: 50 … 110

- Ø Hollow Shaft: -

CSF-2UP

Short Gear for Direct Motor Mount with Tilt Resistant Output Bearing

- Maximum Torque: 1.8 … 28 Nm

- Tilting Moment: 15 … 75 Nm

- Sizes: 8 … 14

- Ratio: 30 … 100

- Ø Hollow Shaft: -

FBS-2UH

-

Largest Hollow Shaft with Smallest Outer Diameter

- Maximum Torque: 25 … 106 Nm

- Tilting Moment: 93 … 129 Nm

- Sizes: 25, 32

- Ratio: 30 … 100

- Ø Hollow Shaft: 41.0 … 55.1 mm

Harmonic Drive® Mechatronics

- Harmonic Drive® Mechatronics are the perfect combination of highly dynamic compact servo motors, precision Harmonic Drive® Gear Component Sets and integral high load capacity, tilt resistant output bearings.

IHD

-

Smart, Compact & Highly Integrated

- Maximum Torque: 44 … 229 Nm

- Maximum Speed: 35 … 120 rpm

- Tilting Moment: 114 … 254 Nm

- Sizes: 17 … 25

- Ratio: 50 … 160

- Ø Hollow Shaft: 18 … 25 mm

BHA

-

Lifetime Precision at High Cost-Efficiency

- Maximum Torque: 44 … 229 Nm

- Maximum Speed: 35 … 120 rpm

- Tilting Moment: 114 … 254 Nm

- Sizes: 17 … 25

- Ratio: 50 … 160

- Ø Hollow Shaft: 18 … 25 mm

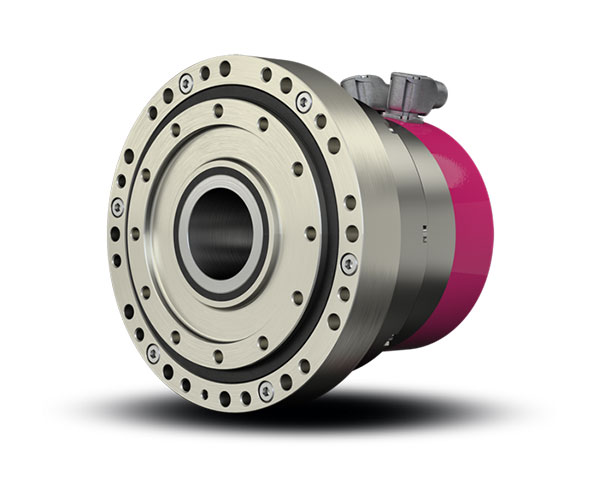

CanisDrive®

-

Highest Power Density Combined with Maximum Flexibility

- Maximum Torque: 23 … 1840 Nm

- Maximum Speed: 19 … 170 rpm

- Tilting Moment: 73 … 2222 Nm

- Sizes: 14 … 58

- Ratio: 50 … 160

- Ø Hollow Shaft: 12 … 65 mm

AlopexDrive

Largest Hollow Shaft for Extreme Environmental Conditions

- Maximum Torque: 18 … 647 Nm

- Maximum Speed: 25 … 170 rpm

- Tilting Moment: 73 … 886 Nm

- Sizes: 14 … 58

- Ratio: 50 … 160

- Ø Hollow Shaft: 12 … 39 mm

HHA

-

Reliable Precision in the Highest Purity

- Maximum Torque: 44 … 229 Nm

- Maximum Speed: 35 … 146 rpm

- Tilting Moment: 114 … 254 Nm

- Sizes: 17 … 25

- Ratio: 50 … 160

- Ø Hollow Shaft: 18 … 27 mm

FHA-C Mini

-

Compact Mini Servo Actuator

- Maximum Torque: 1.8 … 28 Nm

- Maximum Speed: 60 … 200 rpm

- Tilting Moment: 15 … 75 Nm

- Sizes: 8 … 14

- Ratio: 50 … 100

- Ø Hollow Shaft: 6.2 … 13.5 mm

Servo actuators with solid shaft

LynxDrive

Compact Design with High Corrosion Protection

- Maximum Torque: 9 … 1180 Nm

- Maximum Speed: 22 … 283 rpm

- Tilting Moment: 41 … 759 Nm

- Sizes: 14 … 50

- Ratio: 30 … 160

FLA

-

Ultra Flat and Ultra Light

- Maximum Torque: 1.8 … 33 Nm

- Maximum Speed: 80 … 500 rpm

- Tilting Moment: 1.2 … 2.4 Nm

- Sizes: 11 … 20

- Ratio: 50, 8, 9

FHA-C Mini MZE

-

Compact Mini Servo Actuator

- Maximum Torque: 1.8 … 28 Nm

- Maximum Speed: 60 … 200 rpm

- Tilting Moment: 15 … 75 Nm

- Sizes: 8 … 14

- Ratio: 50 … 100

Other

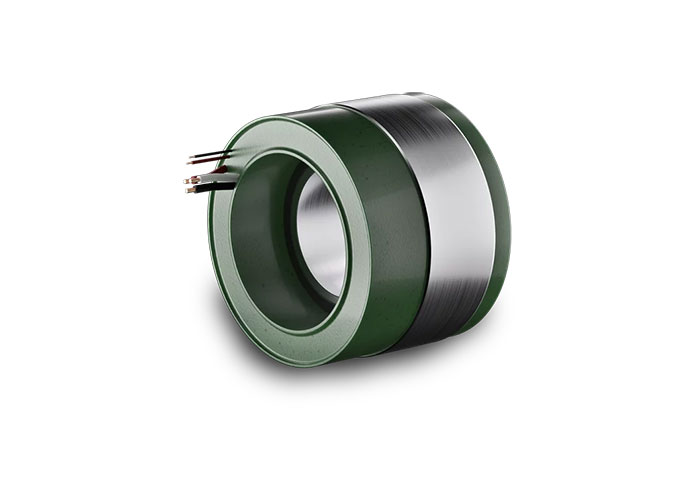

Frameless motor - BHK

-

High Dynamics in a Compact Assembly

- Continuous Stall Torque: 1 … 2 Nm

- Maximum Torque: 3 … 6 Nm

- Maximum Speed: 5600 … 7300 min⁻¹

- Ø Hollow Shaft: 37.6 mm

Servo controllers - YukonDrive

-

Universal Servo Controller

- Field Bus: EtherCat, Profinet IRT, CANopen, Profibus DBV1, Sercos II and III

- Maximum Current: 6 … 24 A

- Rated Current: 2 … 8 A

- Supply Voltage: 230 … 480 VAC

Planetary Gears

- Harmonic Planetary Gears have lower gear ratios ususally operating higher speeds where there is often the need for very high precision. Our special design with a flexible ring gear in the output stage means that we guarantee constant high precision over the entire lifetime – we call this Permanent Precision®!

HPN

-

Cost-Effective Planetary Gear

- Maximum Torque: 9 … 752 Nm

- Max. Input Speed: 6000 … 10000 rpm

- Backlash: ≤5 / ≤7 arcmin

- Sizes: 11 … 40

- Ratio: 3 … 50

HPG

-

Precision Gears in Numerous Sizes

- Maximum Torque: 7.8 … 2200 Nm

- Max. Input Speed: 3000 … 10000 rpm

- Backlash: ≤1 / ≤3 arcmin

- Sizes: 11 … 65

- Ratio: 3 … 50

HPGP

-

Performance Enhanced Precision Gear

- Maximum Torque: 10 … 2920 Nm

- Max. Input Speed: 3000 … 10000 rpm

- Backlash: ≤1 / ≤3 arcmin

- Sizes: 11 … 65

- Ratio: 4 … 45

HPG-R

-

Precision Gears with Helical Gearing

- Maximum Torque: 5 … 400 Nm

- Max. Input Speed: 6000 … 10000 rpm

- Backlash: ≤1 / ≤3 arcmin

- Sizes: 11 … 32

- Ratio: 5 … 45

Applications

Aerospace

- 40 years without any maintenance in space or 30 years of being built in to aircraft wings or under daily temperature changes between -60 °C to +40 °C – these are indicators of the reliability and quality of our products. New demands, such as special materials, extremely light constructions or dry lubrication have been developed for aerospace and defence purposes, only for them later to find use in our industrial products.

Medical Engineering

- It is not only world class athletes who want to be fit again quickly after an operation, and today in most cases, recovery is being supported by more technologies which permit targeted training of the body parts affected. The secret of success is programmable movement sequences which can be implemented via a precision actuator. Reliable and precise drive technology is also a fundamental design requirement in the field of surgery.

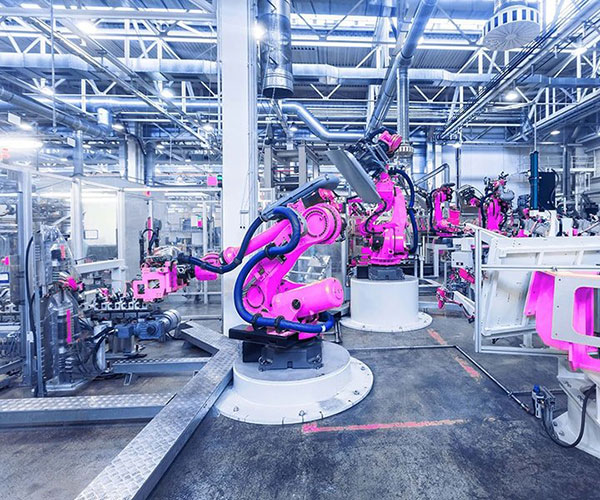

Robotics and Automation

- Robots have for a long time been taking over tasks which are too monotonous for humans to produce to the highest quality. With modern programming and performance improvements from drive technology, these helpers are now entering fields which were unthinkable a short while ago. This cooperation between man and robot has become an important trend in recent years – one meets each other in some sense.

Special Environments

- Harmonic Drive® products are designed to meet the highest requirements for use under the harshest environmental conditions, such as extreme temperatures or other special climatic conditions. Applications in defence, vacuum or cryogenic technology as well as in the depths of our oceans are often confronted with such extreme conditions where the integrated components have to prove themselves once again.

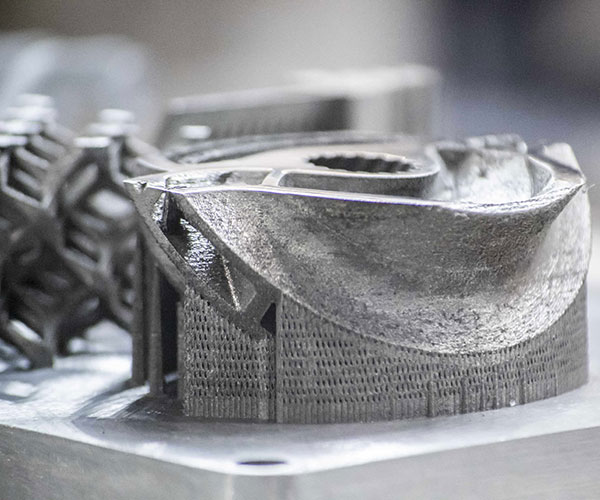

Mechanical Engineering

- Is it possible to hit a euro coin at a distance of 100 metres? It is not only possible, it must be absolutely feasible to produce high-quality machine tools. Harmonic Drive® products are mainly found where space is limited. They are usually not designed according to torque, but also according to stiffness or hollow shaft diameter.