- Offer Profile

- You have your own requirements as regards the performance of a drive. And that is good. Because it provides us with the exact individual specifications for the development and construction of your very personal drive. As regards safety we do, however, have our own benchmarks. Because we are aware that our drives are a part if not the heart of systems sold to your customers for which you are responsible. We are happy to take on this responsibility. With drives, setting new benchmarks in durability and quality. You can thus rest assured that our drives will always deliver what they promise.

Motor technology

Three-phase motors

Asynchronous motors: constant and robust

- Asynchronous three-phase motors can be found everywhere where a constant performance is required. Due to their robust design, they can also be found in places where drives are subjected to more extreme mechanical stresses. For instance as vibration drives in the concrete industry. This type of motor is also preferably used for constant speed applications. For driving pumps, conveyor belts or also fans. Irrespective of their application, asynchronous three-phase motors offer a cost-effective solution. Provided there are no special size requirements.

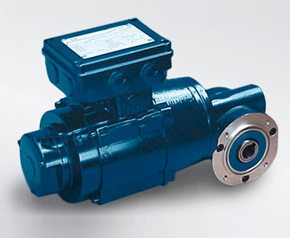

Asynchronous servo motors: robust and universal

- Three-phase motors, designed as asynchronous servomotors,

are as robust as purely asynchronous models. Due to their variable

speed they can, however, be universally used. For instance as main

spindle drive of machine tools, in test stand machines or even for grinding

applications.

This type of motor is also used as a travelling mechanism for, i.e. electrically operated stacker trucks. Where size is not an important factor, these three-phase motors also offer a cost-effective solution

Synchronous motors: efficient and precise

- Synchronous drives offer a particular high efficiency, making them especially interesting for continuous operation applications. The frequency accurate speed ensures for instance that the drive axles of conveyor belts are always synchronized. An advantage that is also the reason why synchronous drives are used in the beverage industry.

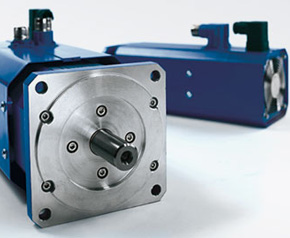

Synchronous servo motors: precise and highly dynamic

- Apart from being as energy saving as synchronous motors, synchronous servomotors not only offer controllable speeds but also other advantages: these include a high power density, a low moment of inertia and the option of a very compact design. All in all this results in a motor for highly dynamic applications. In particular where a short cycle is required or accelerations are part of the moving operation. This applies, for instance to drives for tool changers or for axle drives used in machine tool manufacture.

DC motors: Versatile and variable

- DC motors include shunt wound, serial wound and compound motors, as well as permanent magnet excited motors, with each version offering specific benefits. DC motors are generally used in Wind Turbine Generator Systems as blade adjustment or pitch drives. They are, however, also used as winding drives in the textile industry.

Permanent magnet excited motors

- The benefit of shunt wound motors is, in particular,

their extremely stable speed. The starting torque of these motors is

somewhat lower.

For serial wound motors, exactly the opposite applies. There is no defined idling speed and their speed under loading reduces more than in shunt wound motors. These motors do, however, offer a high starting torque. They therefore withstand high loads during short periods of operation and are thus also used in starter motors of, for instance, electric locomotives.

The compound motor combines the advantages of the shunt and serial wound motor. With a balanced rapport between speed and torque it is, for instance, used for drives of presses and punching machines.

Permanent magnet excited motors offer the advantage of not requiring any energy for generating a magnetic field. This improves the efficiency in particular in case of a low overall output. At the same time, these motors require little space. Also there are no losses from the excitation windings, as these are replaced by magnets

Drive Systems

Gears

- One could find out what every type of gear can offer. And then decide for which purpose the gear should be used. We prefer to establish what a gear should achieve. You do after all have quite definite requirements. And these can be quite specific, just like our options for meeting these requirements.

CEDS Duradrive offers you numerous solutions. From spur to cycloidal gears. And where a special solution is needed for a special requirement, we will provide exactly that. For instance by combining the advantages of different types of gears.

Spur gears: robust and efficient

- Spur gears have a simpler design compared to other gears. They are consequently extremely robust and cost effective and are highly efficient. Spur gears are therefore of particular interest for standard industrial applications. For instance in the railroad and materials-handling technology.

Worm gears: redirecting and self-locking

- Worm gears allow a redirection of power by, in most cases, 90°. These gears have a rather low efficiency but provide the major advantage of being self-locking whilst offering a high gear reduction. Worm gears are, in particular, used as power gears in, for instance presses, rolling mills, in materials handling technology or also in mining machines.

Bevel gears: space saving and highly efficient

- Like the worm gear, the bevel gear also produces a 90° redirection of power. This type of gear does, however, have the distinct advantage that it produces a much higher effectiveness due to the high gear ratio. As these gears produce hardly any inherent heat, bevel gears can also be designed much smaller. Apart from in general industrial applications these gears are often used in differential gears.

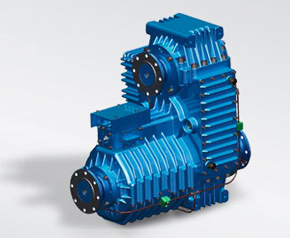

Planetary gear: compact and quiet operation

- Planetary gears are designed to offer high gear ratios and high torques. Their moment of inertia is low and they are extremely smooth running. Because of this and their compact design they are often used where space is at a premium. For instance in pitch drives or as main gears for Wind Turbine Generator Systems.

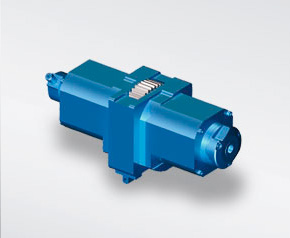

Cycloidal gear: durable and precise

- Cycloidal gears do not require gear wheels. In these gears, cam plates transfer the torque with a rolling movement. These types of gears are therefore extremely robust and nearly fault-proof. All in all, cycloidal gears require little maintenance and experience little wear, whilst offering a small design. They are very precise and are, for instance, used in industrial robots.

Converters: From simple to modular.

- Generally we offer three types of converters: frequency, servo and universal converters. But we regard this more as a starting point, as with our different modules and configuration options we offer you a converter technology precisely geared to your individual requirements.

Universal converters

- In general, converters can generate a voltage from an

alternating current with a certain frequency corresponding precisely to the

desired frequency. They are often used to drive an asynchronous motor. The

simplest form of converting voltage is the frequency converter. It controls

the speed without any feedback.

Servo converters, on the other hand operate dynamically. This ensures a high speed accuracy. As usual for servo motors, the specified speed is attained and maintained. The speed can also be quickly changed. To allow other different applications, servo motors have a modular design. A second transducer system can, for instance be integrated.

Universal converters combine the characteristics of frequency and servo converters. They can be operated with a simple speed control or speed feedback. Universal converters operate with a current recuperation, making them particularly energy efficient. In this way an asynchronous motor can be operated as a generator. The energy generated, for instance, during braking of an electrical locomotive is fed back into the grid and is thus not lost. The same also applies to motors of centrifuges or elevator drives.

Controls

Controls: From control cabinet to software

- Apart from drives and gears CEDS Duradrive also builds its

own control cabinets. We can consequently plan and implement also individual

requirements for the controls of your drive system. From the size of the

control cabinet, to the wiring plan and up to the installation of individual

components. Apart from proven standard PLC applications also

project-specific solutions are possible for the control software, which we

develop and program as per your requirements.

Alternatively we offer the option of using our manufacturing skills without the planning phase. For instance if you have already completed the planning of your controls. In this case we will just implement the design and build the control cabinets as a contractor.