- Offer Profile

-

Design and manufacture of hydraulic components

HYDRO LEDUC is a specialist in the design and manufacture of piston pumps, hydraulic motors, hydropneumatic accumulators, and customized hydraulic components.

With over 180 patents filed and granted, HYDRO LEDUC continues to be a pioneer in many fields. Extensive experience in design, development, production and sales of hydromechanical components means HYDRO LEDUC is a company well recognized for its know-how. The quality of the products is centered on user’s needs and on satisfying customer requirements. The combination of design choices, high quality materials and the entire production process well mastered ensure the reliability of all products.

Hydraulic Pumps - Fixed displacement pumps

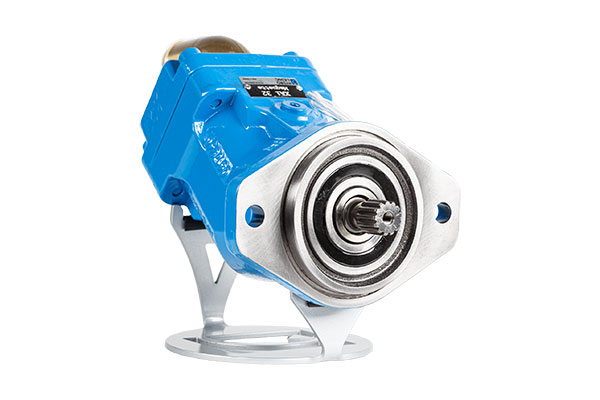

XR pump

-

Our new XR series of spherical piston pumps features a redesigned distribution section, allowing it to achieve the highest self-priming speeds on the market, with high overall efficiency. They are specially designed to meet the increasingly demanding needs of truck equipment>

All models are built with 7 pistons to ensure optimal flow consistency. These fixed displacement pumps can handle continuous working pressures up to 400 bar and peak pressures up to 450 bar.

The inlet fitting is provided with the pump.

Features and benefits:

- Mounting flange according to DIN ISO14 (DIN 5462) + ISO 7653,

- Models from 63 to 130 cm³/rev,

- 400 bar continuous and 450 bar peak,

- Highest self-priming speed on the market,

- FKM seals standard for the toughest environments,

- Bi-material head developed in-house,

- Original synchronization between swashplate and cylinder block,

- Compact design,

- Use of materials with high mechanical strength,

- Compatible for use on rear engine take-off (with bypass).

New pump XRT6868

-

Our new XRT6868 fixed displacement pump is the ideal solution for applications requiring two independent circuits, and it is especially suited for mounting on a disengageable power take-off or rear engine take-off (with BPT bypass).

The appropriate inlet fitting is provided with the pump.

Features and benefits:

- Dual flow of 68 + 68 cm³/rev,

- Mounting flange according to DIN ISO14 (DIN 5462) + ISO 7653,

- 2 x 5-piston design,

- Compact design,

- High overall efficiency,

- Low noise level,

- Original synchronization between swashplate and cylinder block,

- Use of materials with high mechanical strength,

- Rear engine take-off mounting possible with BPT bypass valve.

New pump XRE41

-

Our new XRe series of fixed displacement spherical piston pumps is quiet and efficient, and specifically designed for mounting on an electric power take-off (e-PTO). Its 9-piston design and innovative distribution reduce flow and pressure pulsations, as well as noise levels. The inlet fitting is provided with the pump.

Features and benefits:

- Models from 41 to 63 cm³/rev,

- Mounting flange according to DIN ISO14 (DIN 5462) + ISO 7653,

- Compact design,

- Maximum self-priming speed of 2800 rpm,

- High overall efficiency,

- Innovative distribution for enhanced performance,

- Use of materials with high mechanical strength,

- Original synchronization between swashplate and cylinder block,

- Specifically designed for mounting on an electric power take-off (e-PTO).

- Currently available in SH version only.

XPi series pump

-

Bent axis XPi pumps are specially designed to meet the needs of truck equipment. Their compact design allows a direct flange-mounting on the PTO. All models are of 7 piston design to ensure optimal flow regularity, and can withstand continuous working pressures up to 380 bar and 420 bar peak.

These bidirectional pumps require no user intervention to change the direction of rotation (simple switching of the inlet fitting). Available in displacements from 12 to 130 cc/rev, HYDRO LEDUC offers the most extensive range of fixed displacement truck pumps on the market. Suitable inlet fitting supplied with the pump.Characteristics and advantages :

- flange according to DIN ISO14 (DIN 5462),

- models from 12 to 130 cc/rev.

- operating pressure 380 bar continuous, and 420 bar peak,

- max. speed 1750 to 3150 rpm

- compactness allowing installation in environments where space is very limited (PTO)

- automatic setting of pump direction of rotation (pump can be used CW or CCW),

- easier installation and start-up,

- suitable for engine PTO (with by-pass valve).

XAi series pump (SAE version)

-

Of the same design as the XPi pumps, the XAi fixed displacement pumps are with SAE flange and shaft and are available in displacements from 18 to 63 cc/rev.

Characteristics and advantages :

- flange according to SAE B (2 bolts, or 4 bolts) –US version,

- models from 18 to 63 cc/rev.

- operating pressure 380 bar continuous and 420 bar peak,

- max. speed of 2300 to 2650 rpm,

- 7 pistons,

- compactness allowing installation in environments where space is very limited (PTO),

- automatic setting of pump direction of rotation (pump can be used CW or CCW),

- easier installation and start-up,

- suitable for engine PTO (with by-pass valve).

PA-PAC series pumps

-

With their unique design, PA-PAC pumps offer a robust and durable solution to the high pressure needs of truck applications. Combining the automatic dual direction of rotation, high operating pressure (up to 500 bar peak), and their relative insensitivity to lower performance fluids, PA-PAC pumps are the solution for the most demanding environments.

Characteristics and advantages :

- flange according to DIN ISO14 (DIN 5462),

- Single-flow versions : 25 to 114 cc/rev.

- twin-flow versions : from 2 x 25 cc/rev. to 2 x 75 cc/rev.

- model with 2 different displacements : 75 – 40 cc/rev.

- dual direction of rotation, high output pressure,

- 400 bar continuous and 500 bar peak,

- of simple and reliable design.

Variable displacement pumps

TXV series pump

-

Specifically designed to meet the needs of truck hydraulics, the TXV variable displacement pumps with LS (Load Sensing) control allow flow regulation to suit the application requirements. The pump regulates to only supply the correct flow for each movement. Its compact size envelope enables direct flange mounting on the PTO (motor or gearbox), or via an input drive shaft. The TXV pump is available in max. displacements of 40 to 150 cc/rev. and can operate at working pressures of up to 400 bar.

Characteristics and advantages :

- fitted with “load sensing” regulation,

- flange according to DIN ISO14 (DIN 5462),

- available in 150 cc/rev. (unique on the market),

- operating pressure up to 400 bar depending on model,

- speed at full displacement from 1900 to 3000 rpm,

- compact design,

- through shaft version available (to drive a second pump),

- available with constant torque control (Pressure x flow = constant),

- optional maximum displacement adjustment screw on request,

- fitted with FKM seals as standard.

TXVA series pump (SAE version)

-

Of similar design to the TXV series pump, with SAE C flange and shaft, the TXVA series pumps are available in 2 models with a maximum displacement of 75 and 92 cc/rev. Maximum operating pressure is up to 400 bar.

Caracteristics and advantages :

- flange according to SAE C (2 bolts, or 4 bolts) – US version,

- UNF ports,

- models of 75 and 92 cc/rev.

- max. operating pressure 400 bar (420 bar peak),

- max. displacement at full displacement of 1900 to 2000 rpm depending on the model,

- fitted with “load sensing” regulation for flow adaptation in the pump,

- can be mounted directly on the engine PTO or on the vehicle gearbox PTO,

- drive shaft in splined or keyed version.

TXV pump with constant torque control

-

The TXV pump can be fitted with a constant torque control. This device allows the pump to continuously regulate to keep: Pressure x Flow = Constant. Overall size remains compact. Particularly well suited for large equipment, such as handling cranes that require high flow or high pressure, the TXV pump with Constant Torque pump ensures operation within the power/torque limits of the PTO.

Characteristics and advantages :

- control available on the entire TXV pump range from 40 to 150 cc/rev,

- max. pressure up to 400 bar depending on models,

- max. speed at full displacement 3000 rpm,

- torque range from 90 to 700 Nm,

- available in 130 cc with through shaft.

Mobile and industrial pumps

TXVA series pump (SAE version)

-

Of similar design to the TXV series pump, with SAE C flange and shaft, the TXVA series pumps are available in 2 models with a maximum displacement of 75 and 92 cc/rev. Maximum operating pressure is up to 400 bar.

Caracteristics and advantages :

- flange according to SAE C (2 bolts, or 4 bolts) – US version,

- UNF ports,

- models of 75 and 92 cc/rev.

- max. operating pressure 400 bar (420 bar peak),

- max. displacement at full displacement of 1900 to 2000 rpm depending on the model,

- fitted with “load sensing” regulation for flow adaptation in the pump,

- can be mounted directly on the engine PTO or on the vehicle gearbox PTO,

- drive shaft in splined or keyed version.

W-WA series pump

-

The W/WA pumps have been developed to meet the needs of both the industrial and the mobile hydraulic market.

The W series (ISO version) is available in displacements from 5 to 180 cc/rev.

The WA series (SAE version) is available in displacements from 12 to 180 cc/rev.Characteristics and advantages :

- high efficiency,

- high speed (from 150 to up to 3000 rpm depending on the model),

- max. pressure up to 400 bar continuous (450 bar peak) while maintaining a high global efficiency and low noise level,

- self-priming and self-suction,

- FKM seals as standard (NBR as an option),

- 7 piston technology to reduce pulsations,

- available with keyed or splined shaft,

- speed sensor as an option on request.

Powerpack

Powerpack 7.3

-

Introducing the GEP7.3, an innovative powerpack tailored for hybrid vehicles. Compact, lightweight, and user-friendly, this powerpack is an ideal choice for a variety of applications. With its brushless DC electric motor, variable speed drive, and hydraulic radial piston pump, the GEP7.3 delivers reliable performance. The internal oil circulation within the unit ensures optimal motor cooling, enabling continuous operation. It can also be submerged (excluding the drive) into the oil tank. The flow/pressure curve is programmable upon request to adapt to the available electrical power on your application via CANopen or a simple potentiometer. Multiple electric pump units can be connected together to provide greater flexibility.

Features and Benefits:

- Displacement of 7.3 cm³/rev,

- Rated voltage of 12, 24, 48, 96, or 400 Vdc,

- Variable speed between 300 and 3500 rpm,

- Weight: 27 kg.

Accessories for fixed/ variable displacement pumps

Inlet fittings for fixed displacement pumps

-

HYDRO LEDUC proposes a wide range of inlet fittings for fixed displacement pumps.

Inlet fitting for XPi – XAi pumps (inlet fitting supplied with the pump on XPi and XAi series, please specify the desired type of connection when ordering)

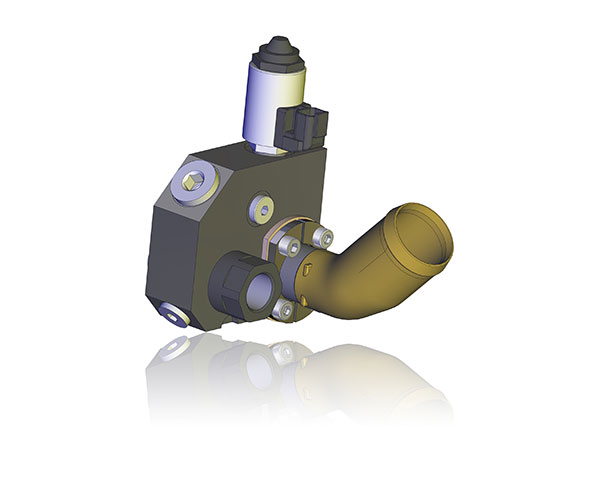

By-pass valve

-

Description of the product :

For use with XPi and XAi pumps driven by a continuous running PTO,

there is a solution for continuous operation of the hydraulic pump:- to reduce the heating of the pump supply fluid;

- without altering the life of the pump;

- without having to modify the hydraulic circuit of the truck equipment.

This is the by-pass valve flanged on the back of the XPi and XAi pumps.

Inlet fittings for variable displacement pumps

- HYDRO LEDUC proposes a wide range of inlet fittings for variable displacement pumps.

Fluid valve circulation FCV

-

Description of the product :

The FCV fluid circulation valve is designed for applications where the variable displacement hydraulic pump is used in stand-by mode for a long period of time (example continuous running PTO).

This valve allows oil to circulate in the pump, which prevents overheating.

- the flow rate consumed by the FCV valve varies between 20 and 22 l/min for a stand-by setting of about 30 bar,

- maximum pressure is 420 bar,

- closing pressure can be adjusted between 2 bar minimum and 7 bar maximum.

For variable displacement pump TXV

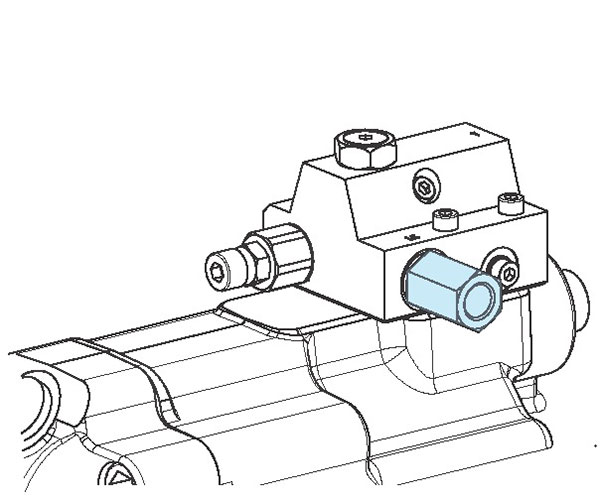

Fitting kit with integrated filtre

-

Adapter equipped with a filter that is mounted on the LS port of the control system.

It protects the control system against pollution from the circuit.

The filter is removable, in order to facilitate maintenance.Possibility to add an additional nozzle for the LS signal.

Filtration fineness: 150 microns

Part number : 0525567 in BSP version

Part number : C001144 in UNF version.

Hydraulic motors

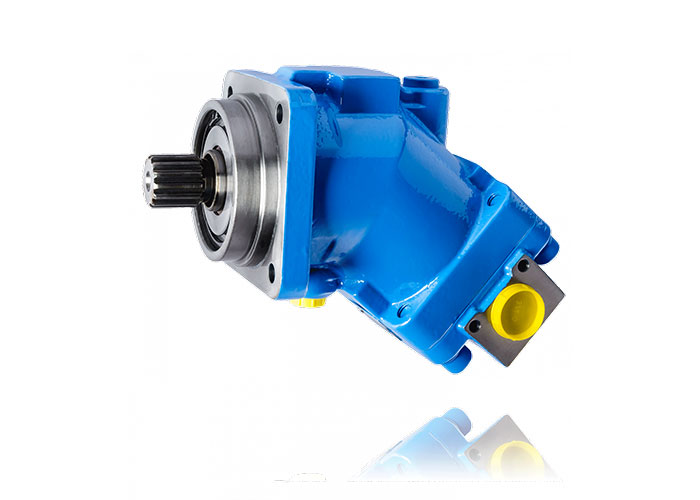

M series motor (ISO version)

-

Hydraulic motors are of bent axis design with a 40° angle, they combine high performance and reduced size envelope.

M series piston motors are designed for fixed and mobile applications, and can be used in either closed or open loop systems.

The service pressure of these motors is up to 400 bar continuous and 450 bar peak, maximum rotation speeds of 3400 to 8000 rpm depending on the model.

M motors exist with keyed or splined shaft.

A and B port options are available.

Characteristics and advantages :

- high efficiency,

- displacement 5 cc/rev – CETOP,

- displacements of 10 to 180 cc/rev – standard ISO3019-2,

- continuous maximum speed up to 8000 rpm depending on the model,

- maximum allowable continuous pressure of 400 bar and 450 bar peak,

- speed sensor and flushing valve as options,

- on request : anti-cavitation valve, pressure limiter.

MA SERIES MOTOR (SAE VERSION)

-

Hydraulic motors are of bent axis design with a 40° angle, they combine high performance and reduced size envelope.

MA series piston motors are designed for fixed and mobile applications, and can be used in either closed or open loop systems.

The service pressure of these motors is up to 400 bar continuous and 450 bar peak, maximum rotation speeds of 3400 to 8000 rpm depending on the model.

MA motors exist with keyed or splined shaft.

A and B port options are available.

Characteristics and advantages :

- high efficiency,

- SAE (J744),

- displacements of 10 to 180 cc/rev,

- available in 250 cc/rev version,

- continuous maximum speed up to 8000 rpm depending on the model,

- maximum allowable continuous pressure of 400 bar and 450 bar peak,

- speed sensor and flushing valve as options,

- on request : anti-cavitation valve, pressure limiter.

MSI series motor (semi-integrated)

-

Hydraulic motors are of bent axis design with a 40° angle, they combine high performance and reduced size envelope.

MSI motors offer a valid choice for applications with displacement from 28 to 180 cc/rev, in a reduced size envelope.

The « semi-integrated » (cartridge) design, means MSI motors can reduce the size of the assembly.

MSI series piston motors are designed for fixed and mobile applications, and can be used in either closed or open loop systems.

Operating pressures of these motors are up to 400 bar continuous and 450 bar peak, maximum rotation speeds from 3400 to 6300 rpm depending on the model.

MSI motors are delivered as a standard with splined shaft (keyed shaft on request).

Several A and B port options are possible, to allow interchangeability with the products already used.

Characteristics and advantages :

- high efficiency,

- ISO 3019-2 – semi-integrated,

- displacements of 28 to 180 cc/rev,

- continuous maximum speed up to 6300 rpm according to the model,

- maximum operatingpressure of 400 bar continuous and 450 bar peak,

- speed sensor and flushing valve as options.

MXP/MXA series motor

-

Hydraulic motors are of bent axis design with a 40° angle, they combine high performance and reduced size envelope.

The MXP/MXA motors can be used in either closed or open loop systems.

In displacements from 25 to 126 cc/rev for MXP series, and from 25 to 63 cc/rev for the MXA series (SAE version) these motors are designed for use in truck equipment and construction machinery applications, for intermittent service.

(For heavy duty applications, HYDRO LEDUC offers M/MA and MSI motor series ; see our catalogue).

Characteristics and advantages :

- MXP series : 25 to 126 cc/rev (according to DIN ISO14),

- MXA series : 25 to 63 cc/rev (according to SAE J744),

- maximum rotating speed up to 6900 rpm according to the model,

- maximum operating pressure up to 400 bar continuous and 450 bar peak,

- can rotate in either direction of rotation (CW or CCW),

- can be used in all mounting positions,

- suitable for intermittent duty cycle.

MV-MVA-MVSI series motors

-

Of 7 or 9 piston design to ensure high starting torque and regularity even at low speed, with a working ratio of 5:1, the LEDUC variable motors are suitable for working pressures up to 400 bar continuous and 450 bar peak.

They are destined for medium and heavy duty applications in construction equipment and agricultural machinery.

Current models available are in displacements of 28, 85, 115cc/rev, in both ISO or SAE flange versions, and semi-integrated « plug-in » configurations.

Three control options exist :

- HPA automatic displacement control, high pressure

- H2N two speed hydraulic displacement control

- E2N electric two speed displacement control

For other control options, please consult us.

As an option, these motors can be fitted with a speed sensor and/or a flushing valve.

Characteristics and advantages :

- high efficiency,

- displacement of 28, 85 and 115 cc/rev,

- large setting range of minimum and maximum displacements,

- suitable for closed or open loop systems,

- reduced size envelope ; high weight-power ratio,

- high rotation speed and operating pressure.

2-displacement motors MSI2C45 & MSIC249

-

M : Motor.

SI : Semi-integrated, model definition already used for the fixed and variable displacement motors, meaning that the flange is further back so the motor can easily be fitted into a gearbox or hub. These motors are usually used for vehicle wheel drive.

2C : 2 displacements. More often referred to as 2 speed, because with a constant inlet flow, the change in displacement induces a change in shaft speed and therefore in vehicle speed.

45/49 : Maximum displacement varying the angle of the swashplate changes the stroke of the pistons and thus the displacement of the motor.

Control : the motor is naturally at maximum displacement. Supplying oil to the control piston through an orifice in the back piece pushes the swashplate to minimum displacement position.Characteristics and advantages :

- high efficiency,

- 2-displacement motors, max. displacement 49 cc/rev.

- on request, the minimum and maximum displacement can be factory adjusted,

- pilot pressure on the X line to change the displacement : from 17 to 70 bar,

- maximum pressure of 5 bar in the housing (whatever the shaft speed),

- extreme operating temperature : -25 to 115°C,

- can be used in either closed or open loop systems,

- semi-integrated – cartridge motor,

- bidirectional,

- options available on request : flushing valve, speed sensor. Please consult.

MT45 series motor

-

The MT45 is an in-line piston motor.

Its « semi-integrated » design makes it very compact.

Equipped with a conical keyed shaft, it is optimal for mounting on fan drive.

On request, the MT45 motor can be fitted with an anti-cavitation valve, and with an integrated pressure relief valves, thus further reducing size envelope of the function.

Characteristics and advantages :

- displacement of 45.1 cc/rev,

- maximum continuous speed of 4000 rpm,

- continuous maximum pressure of 280 bar, and 300 bar peak,

- dual direction of rotation,

- available options : anti-cavitation valve + integrated pressure limiter (different settings on request),

- semi-integrated – ISO.

Drainless motor

-

Hydraulic circuits and installations can be simplified, and costs reduced, using this bent axis innovative motor able to operate without a drain connection.

The back piece of the motor is designed to allow the drain flow to go to the low pressure line, thus ensuring that the pressure in the housing is equal to the minimum pressure in the circuit.

For bi-directional rotation, a spring-loaded accumulator is incorporated, which takes out the pressure peaks which occur with rapid change in direction.

Characteristics and advantages :

- maximum pressure on the return line : 25 bar,

- no drain line,

- only inlet and outlet lines are needed,

- the motor is drained via the return line.

Hydropneumatic accumulators

Spherical accumulators AS

-

The LEDUC spherical accumulators (AS-AC) consist of two hemispherical shells screwed together and holding a diaphragm. This diaphragm has a metal stud which closes off the fluid pat when the fluid is completely drained: any risk of damage to the diaphragm is thus avoided. The gas-side port is fitted with a charging valve to control the nitrogen pressure in the accumulator.

Characteristics and advantages :

- useful volumes from 0.02 to 10 litres,

- max. pressure 400 bar depending on the model,

- extreme operating temperature as standard : -20°C to +120°C (depending on the diaphragm),

- different types of elastomers for the diaphragm NBR-FKM-EPDM,

- suitable to different types of fluids on request,

- on request, ARCOR® anti-corrosion treatment or painting.

Bladder accumulators ABVE

-

HYDRO LEDUC ABVE bottle type accumulators consist of a forged steel body, a bladder, a charging valve and a fluid pat that is used as a connection. It is precisely this fluid pat that is equipped with a poppet valve that will prevent the bladder from being extruded, and with gas side valve used when the hydraulic pressure is applied to the circuit.

Characteristics and advantages :

- useful volumes from 4 to 50 litres,

- max. pressure of 330 or 350 bar depending on the model,

- extreme operating temperature as standard : -20°C to +100°C,

- interchangeable components with those of major accumulators available,

- dimensions for easy installation and also use in batteries,

- NBR bladder (other elastomers on request),

- high discharge speeds.

Welded cylindrical accumulators ACS(L)

-

Using bladder-diaphragm (designed for working pressures up to 330 bar), these hydropneumatic accumulators represent a particularly attractive solution for mobile applications. Available for useful volumes from 0.7 to 4 Litres, the ACS(L) accumulators series are available as standard version for operating temperatures between -20°C and +100°C, and in “low temperature” version from -40°C to +100°C. All these accumulators are equipped with screw or charging valve, allowing verification and charging by the customer, but can also be supplied with a charging pressure P0 according to the customer’s request.

Characteristics et advantages :

- useful volume from 0.7 to 4 litres,

- max. pressure 250 or 330 bar depending on the model,

- extreme operating temperature as standard : -20°C to +100°C (NBR),

- «low temperature» version -40°C to +100°C (HNBR),

- long service life in number of cycles (by its bladder-diaphragm design),

- high operating ratio.

Welded piston accumulators AP(L)

-

AP(L) piston accumulators are built from a body made of high mechanical resistance forged steel. The fluid-gas separating piston is equipped with seals adapted to the fluids to convey and the temperatures to be supported. AP(L) accumulators, which can be fitted with a charging screw or valve, are a modern solution to the needs of hydraulic circuits.

Characteristics and advantages :

- useful volumes from 0.16 to 4 litres,

- max. pressure of 250 or 350 bar depending on the model,

- extreme operating temperature as standard : -20°C to +80°C,

- support very high compression ratio,

- ensure a total and fast discharge of the fluid,

- can be mounted without position preference,

- guarantee a very low gas loss over time,

- can be adapted to the fluids and temperatures of the circuit (on request),

- long service interval.

Microhydraulic components and solutions

MICROPUMPS

-

For the design and manufacture of its micro-hydraulic components for the most demanding markets, HYDRO LEDUC offers a whole series of complete solutions allowing you to build micro-hydraulic power units capable of combining the pump, an electric motor, the distribution circuit, the tank, a pressure limiter and hydraulic actuators. HYDRO LEDUC micro-hydraulic components can provide a force of several tons in a small footprint while using minimal power. As a result, they are adapted to exceptional environmental and temperature conditions. HYDRO LEDUC also ensures the ease of implementation and installation of its components.

Permanent research in micro-hydraulics is one of HYDRO LEDUC’s main concerns and it is only in this way that the company can successfully carry out all its national and international projects, proposed by the main major clients.

MICROPUMPS

The components of the range :

- micro-pumps with fixed displacement from 7 to 1500 mm3,

- micro-pumps with variable displacement from 0 to 1500 mm3,

- pressure : 1000 bar.

MH450DS micromotor

-

The MH450DS micromotor is capable of operating in both directions of rotation (clockwise and counter-clockwise). Available in a displacement of 463mm3, its maximum pressure is 330 bar continuous and 400 bar peak, and this in a compact size (length 119 mm).

Characteristics and advantages :

- Maximum operating temperature: 150°C and 175°C allowed at 5% of the time at peak,

- Type of fluid supported; hydraulic mineral oils (consult us for other fluids),

- Weight: 0.7 kg.

Applications

-

Discover our products and the sectors of activity concerned

Are you looking for French hydraulic solutions for your business? At HYDRO LEDUC, we are proud to offer a comprehensive range of solutions tailored to various industry sectors. Since 1938, our expertise as a French manufacturer of hydraulic components has allowed us to meet the specific needs of each industry.

Truck equipment

- For decades, HYDRO LEDUC has been the undisputed French leader in hydraulic equipment for heavy-duty trucks. Our history since the 1960s demonstrates our ongoing commitment to providing innovative solutions perfectly suited to the evolving demands of modern trucks.

Construction equipment

-

Thanks to its expertise in rotating piston products, HYDRO LEDUC has developed a complete range of products dedicated to the highly demanded applications of construction equipment.

Since our founding in 1938, we have been committed to providing sustainable and effective hydraulic solutions that meet the toughest challenges of construction and maintenance sites.

Materials handling equipment

-

With proven expertise in terrestrial mobile applications, HYDRO LEDUC stands as a trustworthy partner. We offer remarkable hydraulic solutions in sectors such as industrial vehicles, agricultural machinery, and public works equipment.

Our extensive know-how is also reflected in our diverse offering of components dedicated to handling equipment, providing cutting-edge performance and unmatched reliability for lifting and handling operations.

Industry

- Although specialized in mobile hydraulics, HYDRO LEDUC offers its expertise and resources to meet your needs in industrial sectors. We are proud to provide high-pressure hydraulic solutions suited to the equipment in your plants and systems, whether static or otherwise.

Agricultural machinery

- At the heart of current and future agricultural challenges, innovation and performance are essential. At HYDRO LEDUC, our engineers work daily to design cutting-edge hydraulic solutions that meet the evolving needs of the agricultural industry. Our expertise comes from close collaboration with our many clients in agricultural machinery manufacturing, combined with strategic partnerships that help shape the agricultural machines of tomorrow.

Oil & gas

-

For over half a century, HYDRO LEDUC has been a crucial partner for major players in the oil research industry. We design and manufacture tools to extract oil and gas more distantly and efficiently.

Our expertise in designing and manufacturing specialized hydraulic tools enables us to effectively meet the unique challenges of this sector, including high pressure, extreme temperatures, and resistance to shocks and vibrations.

Marine applications

- In the current maritime industry context, environmental preservation has become imperative. Increasingly stringent environmental regulations have driven demand for eco-friendly technological solutions. At HYDRO LEDUC, we position ourselves as a strategic partner to meet these challenges, combining our technical expertise with a commitment to ecological practices in the marine sector.

Aeronautics

-

Aeronautics is the origin of HYDRO LEDUC. Our founder, René Leduc, was primarily an aircraft designer-manufacturer and the inventor of the “ramjet” which equipped many prestigious fighter jets.

With this prestigious past and close technical relationships with major aeronautics stakeholders, HYDRO LEDUC provides original and custom hydraulic solutions in sectors such as landing gear, drones, fighter aircraft, and business and civil aviation.