- Offer Profile

-

Dunkermotoren offers innovative, economic and high-quality drive technology up to 5.000 Watts output power.

Our wide product and service range ensures you a high level of flexibility with standard components and customized system solutions:- Brushless DC servo motors/ Brush-type DC motors

- Integrated power- and logic controllers

- Planetary- and worm gearboxes

- Linear direct drives

- Encoders and brakes

Our drive is your success!

-

For over 75 years, Dunker has been pushing the boundaries of motor technology. We offer a comprehensive selection of DC, BLDC, and linear servo motors, each meticulously crafted to deliver unmatched performance from 1 watt to a powerful 5,000 watts.

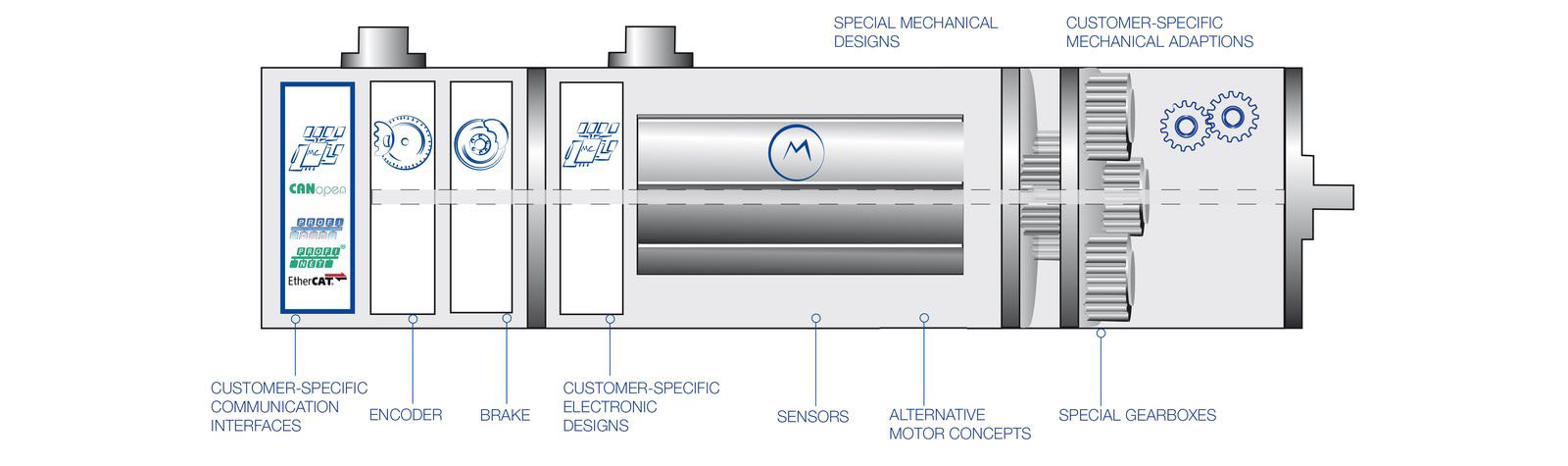

Unleash the power of custom automation! Dunkermotoren goes beyond just motors. We offer a vast array of brushless and brushed DC motors, stepper motors, AC motors, linear systems, and fans. All are precisely engineered and fully customizable with gearheads, encoders, brakes, integrated or external electronics, and more. Imagine the possibilities!

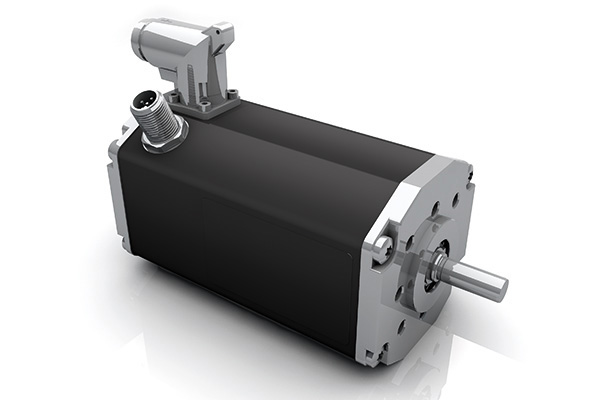

Brushless DC motors - BG

-

Dunkermotoren's brushless DC motors (also referred to as EC motors) convince with high efficiency, highly dynamic acceleration and high power density. The BLDC motors are available with gearboxes, brakes and encoders.

The Dunkermotoren BG range of brushless, direct current motors (EC motors) are notable for:

- Very long life

- High efficiency

- Highly dynamic acceleration

- Good regulation characteristics

- Wide speed range

- High power density

- Maintenance-free

- Robust design

- Integral Hall sensors for rotor position

- Low moment of inertia

- High degree of protection

- Winding insulation - Class E or B

- Neodymium magnets

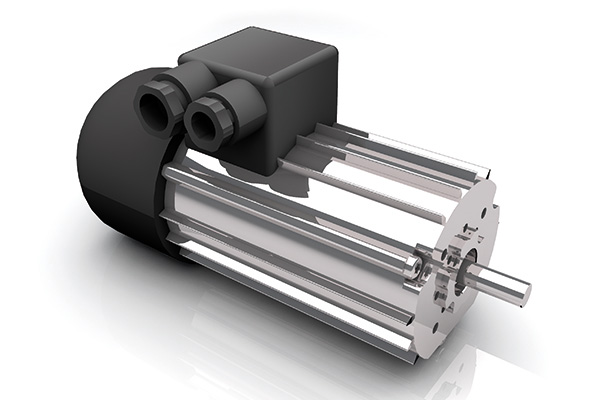

Brushed DC motors - GR

-

Dunkermotoren's DC motors - brushed DC motors (GR/G series) with gearboxes, brakes and encoders to create the perfect motor solution. Our brushed motor with low cogging torque, rugged designed and low moments of inertia.

The Dunkermotoren GR/G range (commutated DC motors) are notable for:- Longer life than commutated motors from other manufacturers

- Low detent torques

- High efficiency

- High dynamic acceleration

- Good regulation characteristics

- High power density

- Maintenance-free

- Robust design

- Low moment of inertia

- Motor insulation class E

- Winding insulation class F

- Extremely high short time overload capacity of the motor

- Surface protection

- Minimum interference radiation, optional interference versions

- Protection up to IP 65

- High quality due to fully automated production lines

AC motors - KD/DR

-

Our robust and maintenance-free AC motors are available in single-phase (KD series) and three-phase (DR series) winding solutions.

Special points:- Solid, maintenance-free

- Reversible

- Insulation to VDE 0530, insulating class F

- High degree of protection, IP 54

- Terminal box cover, can be turned by 4 x 90°

- Built-in fan tor optimum cooling

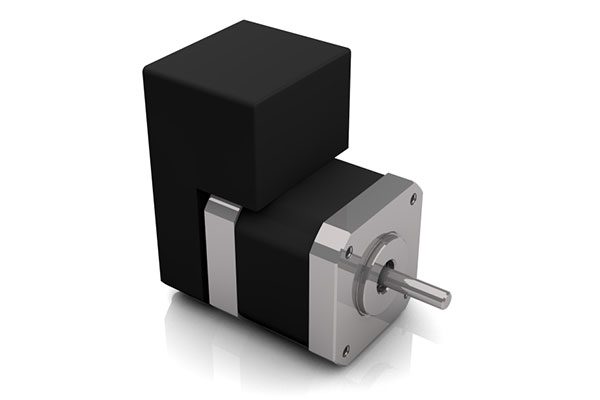

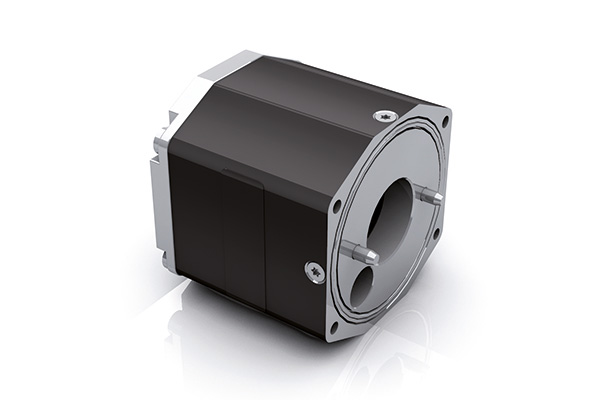

Stepper Motors

-

- Available in 3 NEMA sizes

- 2 phase Hybrid Stepper, 1.8° step angle

- Optionally available with planetary gearboxes and encoders from Dunkermotoren

- Optional variants with integrated controller

- High performance compared to competitive products

- Made in Europe

Venetian blind drives

-

Sun protection technology has been part of us from the very beginning - especially drives for indoor and outdoor venetian blinds. Our unique know-how in drive technology is reflected in the robust construction and maintenance-free operation of the blind drives.

- Single-phase capacitor motors for short time

operation with mounted gear box - Solidly designed and maintenance free for life

- With comfortable adjustment of the end

positions - Single- and double shaft motors are available

- With integrated (built in) temperature switch

- With integrated electro magnetical brake

- With cable 0.5m and mounted connector

- Single-phase capacitor motors for short time

Encoders

- Combine our encoder systems with our drives - optical and magnetic incremental and absolute encoders.

We offer incremental encoders in various sizes and resolutions. The range of signals per revolution extends from 2 to 2000. The signals can be doubled or quadrupled with the appropriate logical circuitry. The AE series is available with resolutions of up to 16 bit singleturn and 16 bit multiturn for recording the absolute position. High-resolution encoders of the MR series can also be integrated directly into the brushless motors.

PLG/STG/SG/KG/NG | Gearboxes

-

Smooth running, compact and excellent efficiency - these are our gearboxes of the series PLG, STG, KG und SG!

Planetary and right angle designs- the proper design for every application.

Controllers

-

Every brushless motor size available with integrated electronics - our philosophy when it comes to fieldbus and Ethernet-based communication interfaces.

We offer external control electronics and gateways for speed, positioning and integrated PLC functions.External controllers by Dunkermotoren are notable for the following characteristics:

- Optimised for driving bushless and brushtype motors by Dunkermotoren

- High efficiency

- High overload capability

- Control through bus or I/O's or stand-alone operation

- With safety function STO

Blowers

-

- Large selection of blowers based on universal motors and brushless motors

- The blowers are available in various sizes and optionally as Thru-flow or Bypass version

- All versions are available for 3-phase AC or low voltage DC supply

- Optionally with integrated control electronics with speed input (AI or PWM) and error output

Brakes

Brushless motors series BG and brush-type DC motors series GR/G can be fitted with brakes. As standard, power-off brakes are employed, i.e. the brake operates when no voltage is applied and releases when current flows. Power-on brakes are available on request. With this design, braking takes place when voltage is applied and current flows. IP 54 or higher covers are available for all brakes. Combinations of incremental encoders and brakes are possible. Depending on the motor-brake combination, classes of protection up to IP 65 are possible. In order to protect the DC contacts in your control system against arcing, we recommend the use of a freewheeling diode.

INTERFACES

-

We make every motor a smart motor!

>Dunkermotoren is known for integrating intelligence into its brushless DC drives. With the BG dPro series, this is easily possible. Likewise, with the launch of the BGE 5510 dPro, an external solution is possible, even for brushed DC motors. Which communication interface is the right choice for you - we provide an overview.

CANopen

-

The CAN-based fieldbus interface CANopen was developed by the company BOSCH and has been maintained by the user organization CAN in Automation (CiA) since the mid-1990s.

The history of Dunkermotoren and CANopen goes back many years. Dunkermotoren introduced the first smart motors with CANopen to the market back in the late 1990s. Today, CANopen is still a very popular communication standard and is preferred in some applications such as agricultural technology. The reason for this is, for example, the low cost of CAN.

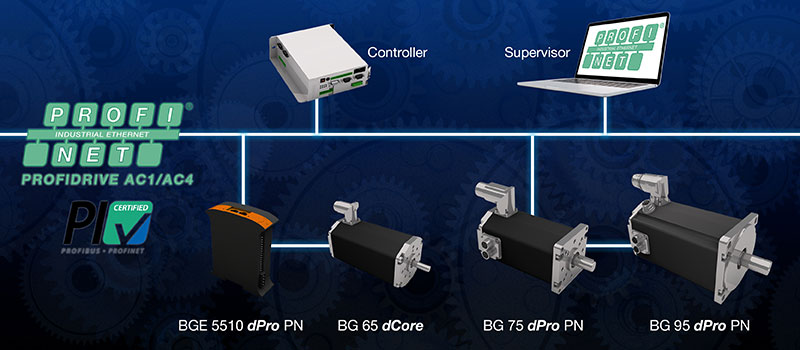

PROFINET

-

Among the Industrial Ethernet standards, PROFINET is considered the leading open standard and is predominantly used in industrial applications such as manufacturing or process automation. The PROFINET communication concept is modular and transmits data in real time.

Dunkermotoren and SIEMENS PROFINET have been working together for many years on the communication capability of Dunkermotoren's smart brushless drives. The first PROFINET drives were already introduced to the market in 2019. In 2021, Dunkermotoren will be the first drive technology manufacturer to completely integrate PROFIdrive classes 1 and 4 in the motor. This enables highly dynamic and synchronous servo applications. In this course, the BG dPro drives will also be certified via the PI user organization. PROFINET is available either integrated in the BG dPro PN drives or with the external control electronics BGE 5510 dPro PN. The Functional Safety function STO is included as standard.

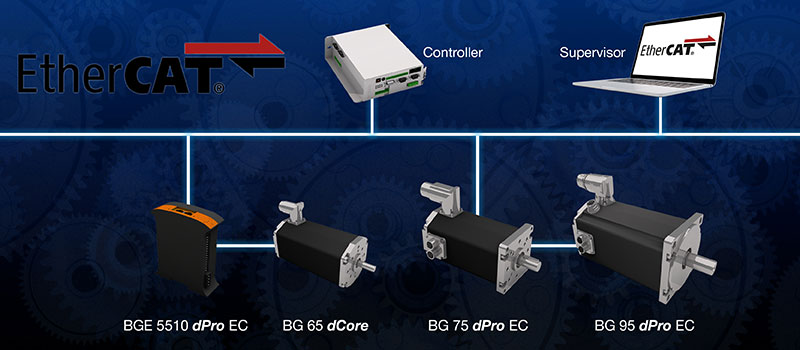

EtherCAT

-

Beckhoff and the EtherCAT Technology Group, ETG for short, have developed the Ethernet-based EtherCAT communication standard. Like PROFINET, EtherCAT is an open standard and is also suitable for time-critical Motion Control applications due to its fast transmission. With EtherCAT, data is exchanged according to the master-slave principle in which, for example, a PLC sends data to a field device.

Dunkermotors of the BG series have already been equipped with an EtherCAT communication interface for several years. Since 2020, the BG dPro series is now available with an EtherCAT interface. This interface is either integrated directly in the motor housing or available via the external BGE 5510 dPro controller. With the EtherCAT integration in the dPro portfolio, the possibility for real-time synchronization with distributed clocks is also given. The Functional Safety Function STO is integrated in all dPro EC drives as standard.

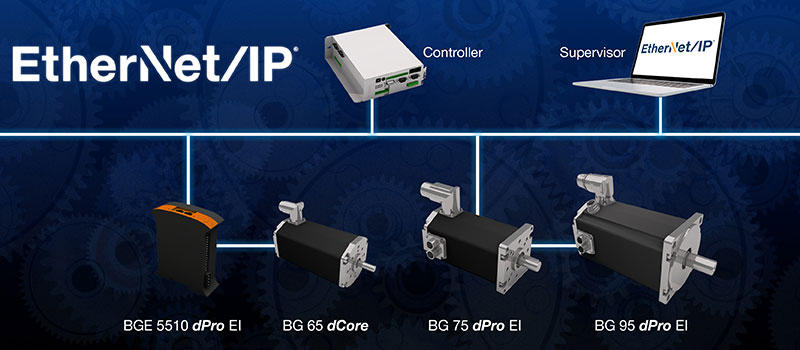

EtherNet/IP

-

Rockwell Automation and the Open DeviceNet Vendor Association (short: ODVA) developed the ehternet-based communication standard Ethernet Industrial Protocol, short EtherNet/IP. Like PROFINET and EtherCAT, EtherNet/IP is one of the open communication standards in the industrial environment. EtherNet/IP is mainly used on the American market together with Rockwell controllers.

Since 2021, Dunkermotoren has been a member of ODVA and thus also offers the EtherNet/IP communication interface for its smart motors of the BG dPro series. The EtherNet/IP interface is available integrated as dPro EI motor or external as BGE 5510 dPro EI. As of September 2022, EtherNet/IP for Dunkermotors is also officially certified by ODVA. As with all Industrial Ethernet drives, the dPr EI drives also have the Functional Saftey Funktion STOintegrated as standard.

Linear Systems

- Durable, precise and long-lasting linear systems are the ideal choice for driving your application. Whether you require high dynamics, precision, or a pneumatic system replacement, our linear solutions guarantee successful implementation. From dynamic linear direct drives to efficient spindle motors, our portfolio has exactly what you need.

Choose Dunkermotoren for environmentally friendly and energy-efficient linear solutions.

Linear Motors

-

Highly dynamic, precise, maintenance-free. The gamechanger for high throughput and precise manufacturing. Linear drives on a new level

Our Dunkermotoren Linear motors, ServoTube (ST) and ServoLinear (SL) are electromagnetic direct drives in tubular linear motor. The linear motion is fast, precise, maintenance and wear-free, without any intermediate coupling of mechanical gearboxes, spindles, robust design long lifetime.

» Tubular linear motor

» 3 phase technology

» Actuator, components and module

» High power density

» High efficiency

» Highly dynamic acceleration

» Very long life-time

» Freedom of maintenance

» Robust design

» Smooth controllability

» High-quality rare-earth magnets

» Integrated hall sensors for positioning

» Mounting options for DIN/ISO 6431

CAHB/CASM Electric Cylinder

-

Controlled, precise linear movements for a wide range of applications. Ideal for modernization of old pneumatic applications due to DIN15552 design 1:1 grindable. Duty cycle up to 100%.

Dunkermotoren offers two series of electric lifting cylinders. The CASM series, with its DIN15552 design, is ideal as an environmentally friendly replacement for your pneumatic cylinders. The CAHB opens up whole new areas with up to 10,000 N force even in harsh environments with IP65 protection.

Both series in combination with our BG motors bring many advantages and also new possibilities.

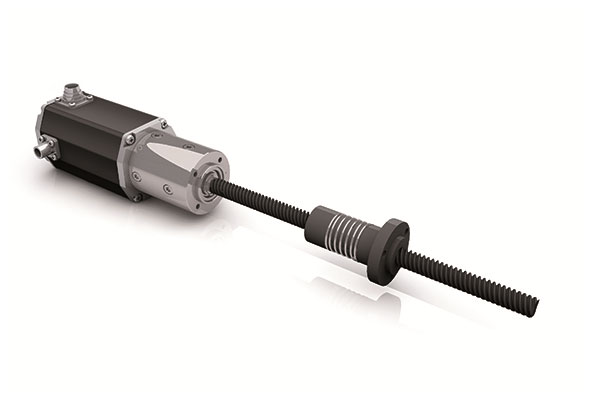

Spindle Motors

-

» Lead screws combined with brushless/ brushed motors

» Brushless DC motors combined with worm gearbox or planetary gearbox

» Compact and space saving

» Maintenance free

» Robust design for various applications

» Universal mounting position

» With or without integrated electronics

» Typical Applications: Linear adjustment and positioning

» Various installation position

» Temperature range -40°C up to +80°C possible

System Solutions

-

Dunkermotoren - we are your system partner!

With Dunkermotoren Systems, we offer you customer-specific system solutions beyond our modular construction kit. From the assembly of additional components, to attached linear solutions and special gears, to customer-specific controls with adapted hardware and software. We are your system partner!

Your advantages:

» Qualified and tested motor solutions

» Reduction of development times

» Fast availability of samples and prototypes

» Reduction of the number of suppliers

» Rationalization effects

» Technical competence and application-oriented support

» Fully tested and qualified systems ACCESSORIES