- Offer Profile

-

”Our Solutions Move“

- With our innovative and globally-leading standard products we cover a wide

range of linear guide applications.

SCHNEEBERGER offers a wide range of high quality products for linear motion such as linear profiled guidesways, measuring systems, gear racks, slides and miniature tables as well as mineral casting, precision positioning systems and ball screws

- With our innovative and globally-leading standard products we cover a wide

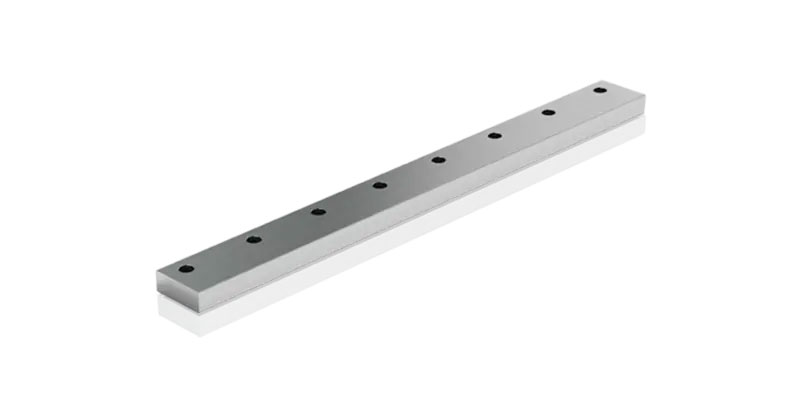

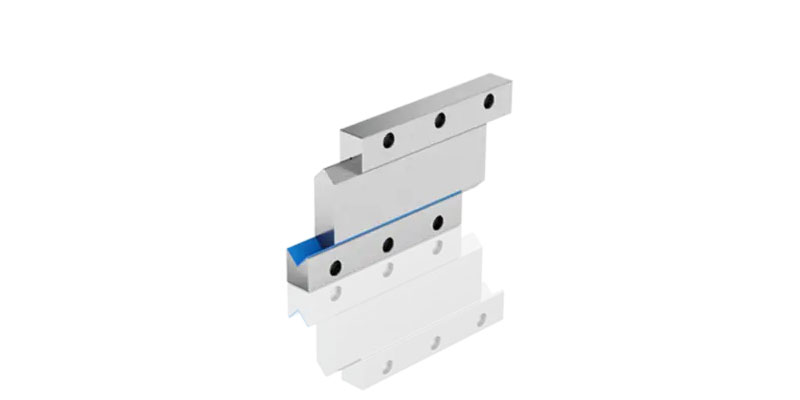

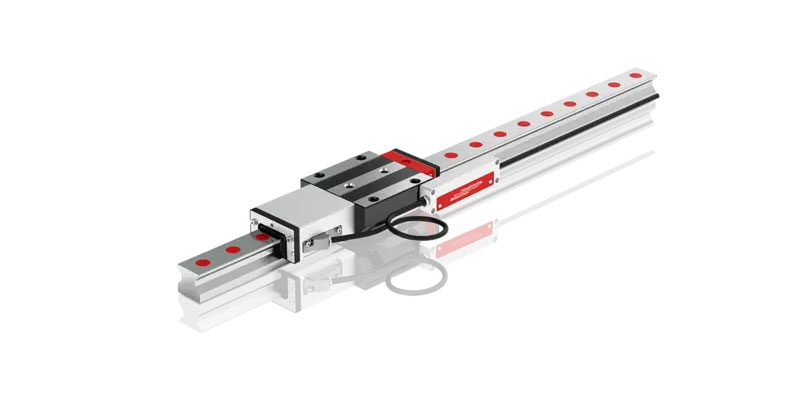

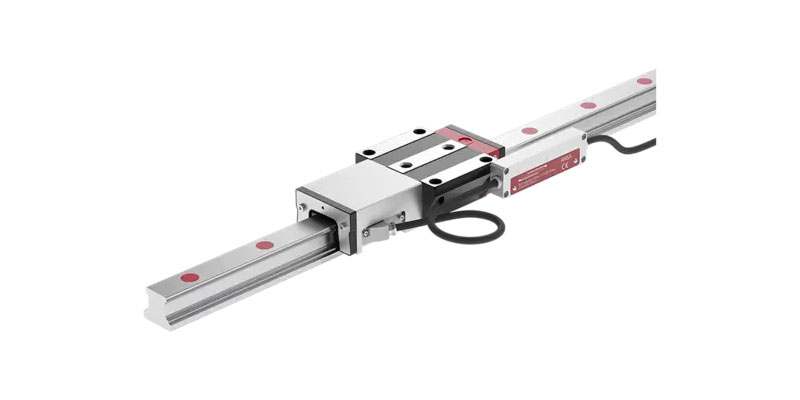

Linear guideways and profiled guideways

- Tailor-made solutions: Precise and reliable guide rails for every requirement

Cage guideways with limited stroke

Linear guidance with long stroke

Recirculating unit with long stroke

Customized bearings / Sliding guideways

- Roller and sliding guideways manufactured according to customer requirements

Anti-friction guideways outside the standard dimensions

Sliding guideways coating according to customer requirements

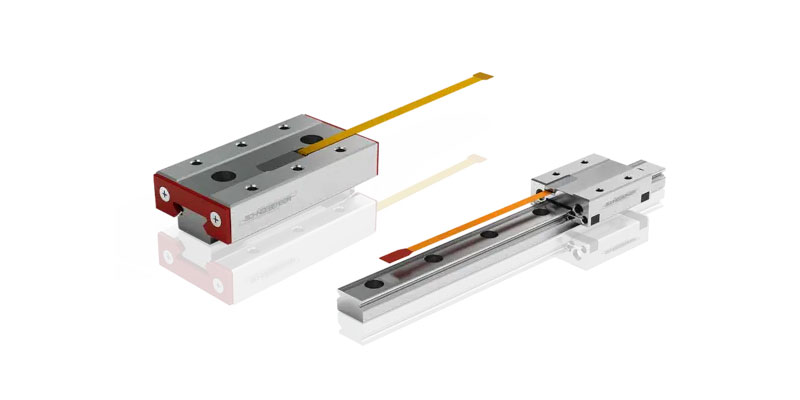

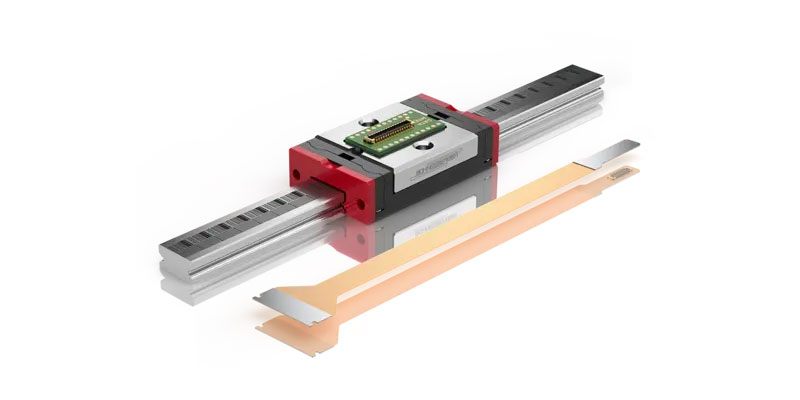

Linear bearing with integreated measuring system

- Digital or analogue with rollers or balls

Absolute / magneto resistive with rollers or balls

Analog or digital / magneto resistiv with rollers or balls

Analog or digital / optical

Analog / Absolute

Gear racks

-

Economic drive element, especially with long strokes of more than 2 m.

Gear racks are an economic drive element, especially with long strokes of more than 2 m.

Gear racks are preferred also with dirty environments and/or big axial forces. The stiffness is the same over the whole length.

SCHNEEBERGER offers any cross-section up to module 20 with metric or module pitch, with helical or straight gears. The maximum single piece length is 3000 mm, multi-piece butt jointed rails for longer lengths are warranted.

The teeth can be milled or ground, according to your wish. Interesting are the various hardening processes, depending on the applying load. Weak, inductive hardened or case hardened gear racks are available. The best gear quality is Q4 (individual adjacent pitch error fp=0,003 mm, cumulative pitch error Fp=0,015/1000 mm).

Standard gear racks straight tooth system

Standard gear racks helical thooth system

Customized racks

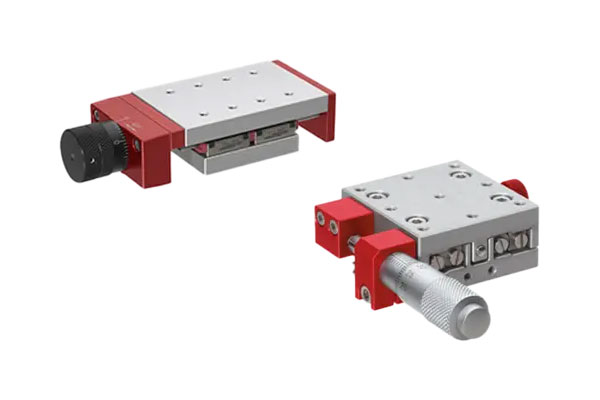

Slides and miniature tables

-

Linear bearings and micro frictionless tables

All linear and micro frictionless tables are delivered ready for installation, pre-lubricated and pre-loaded without play. Depending on the customer’s requirements, the smallest MS4 micro frictionless tables are the right choice in terms of space and flow, or an NK linear table for high loads with great rigidity. The principle also applies here: Ball cages move more quietly, and roller cages offer greater rigidity. The MSQ series as well as tables with inserted linear guides, which are combined with FORMULA-S can deal with the utmost accelerations and linear movements in all positions in a reliable way, without any cage creep.If the standard does not fit, we are the right partner to work with you to find the solution: we can find the right hole pattern, the optimum lubrication for your application, a defined sliding force window or even height pairing for several tables.

Frictionless tables with roller- or ball cages

Micro frictionless tables with roller- or ball cages

Positiong tables with rollers

Mineral Casting: Vibration-Free Precision with Environmental Responsibility

-

Mineral casting features clear technological, economic and ecological advantages over steel, gray cast iron or cast iron. Its excellent vibration damping, chemical resistance and thermal stability not only impress users in machine tool manufacturing, but also in many other industries such as medical technology, solar technology, electronics and packaging. In particular, the combination of linear technology and mineral casting creates essential customer benefits.

SCHNEEBERGER is a leading global manufacturer of mineral castings and not only offers innovative and high-precision mineral casting solutions, but also completely pre-assembled modules and assembly groups, equipped with the following components according to customer requirements

- linear guideways

- linear motors

- electronics and sensors

- drive units

Since we offer everything as a one-stop solution, we guarantee optimal matching of the various components. SCHNEEBERGER mineral castings are manufactured by specialized employees in our production facilities in Czech Rep. and China. The entire process, from the design phase to the actual casting process and finishing, is subject to strict quality specifications. This guarantees that complex machine designs and assemblies with integrated guides are manufactured in the specified dimensions and to the highest quality.

Mineral casting

- Mineral casting technology which, when employed in machine bases and foundations, delivers exceptional vibration damping, chemical resistance  and environmental sustainability. First introduced for use in the bases and platforms of metal grinding machines, today mineral-cast foundations are being applied  and making new and innovative applications possible  in electronics, medical devices, solar, and packaging equipment.

SCHNEEBERGER systems  precision positioning systems and motion systems

- Customer-specific positioning systems with a high degree of precision

The tried-and-tested components and expertise of SCHNEEBERGER Linear Technology and Mineral Casting are used in our positioning systems. This ensures that the diverse resources are consistently converted into customer-specific solutions. SCHNEEBERGER systems are basically developed and manufactured together with and for our customers. They are the epitome of extremely precise and reliable linear technology for high-end machines and devices. Positioning accuracy, speed, vacuum suitability, and the perfect fine-tuning of all individual components are part of the axiomatic setup.

High performance ball screw

-

High performance ball screw, telescopic actuators, boring spindles assemblies and milling spindles

Ball screw actuator

Our focus is always on optimal precision and cost-effectiveness. To ensure these characteristics over the long term, the ball tracks, bearing seats and contact surfaces for the ball screws are precision ground. This enables optimum force transmission with a high degree of positioning accuracy and repeat accuracy. The path distance is measured via the spindle.Areas of application for ground ball screws

- Machine tools

- Process machines

- General mechanical engineering

- Robotics and automation

- Drive technology

- Plastic injection molding machines

- Measuring and testing technology