JVM

- Offer Profile

- Vibratory Drive Units by JVM

Proven engineering and experience, from over 90 years of manufacturing vibratory motors, and innovative developments guarantee the operational reliability you can trust. All drives are developed, manufactured and assembled at our offices and shop in Dulmen. Because of our complete in-house production, we can guarantee the quality of our full line of products and services.

Sales across the globe, and use in the most extreme conditions, testifies to our demanding standards.

Product Portfolio

Vibratory Drive Units by JVM

Unbalance motors JV

-

The modern aluminium housing and 3-piece design ensures a low weight

and high thermal conductivity for great efficiency and clearly

defined, direct power transmission.

Practice has testified to our technical concept – across the globe, even under the most difficult operating conditions.

- 2-, 4-, 6- and 8-pole Execution

- Connection 230V/400V 50Hz; 460V 60Hz

deviating voltages up to 690 V

- Working moment up to 3300 kgcm (102 kN)

- Infinite oscillation amplitudes

- Suitable for S1 continuous operation at 100% centrifugal force

- Tropical protection from JV 08

- Protection system IP 66 as per EN 60529 (JV072 IP44)

- Winding Iso F, VDE 0530

- Ambient temperature -20...+40°C

- Explosion proof models acc. to ATEX II 3DG, ATEX II 2DG and cCSAus (UL)

Electromagnetic vibrator MS

-

Tried-and-tested, reliable engineering together with ro-bust,

practice-oriented designs provide high operational reliability, even

under the most difficult conditions.

- Oscillating Frequencies 25/50 Hz resp. 30/60 Hz

- 230/400V 50Hz or 440/460V 60Hz

via thyristor controller

- Effective weight up to 1300 kg

- Switch-on time 100% (operating mode S1)

- Protection system IP 65 acc. to EN 60 529

- Explosion proof models; ATEX II 3 DG, cCSAus

We would also be happy to provide you with further details or inform you about special models built to your specifications.

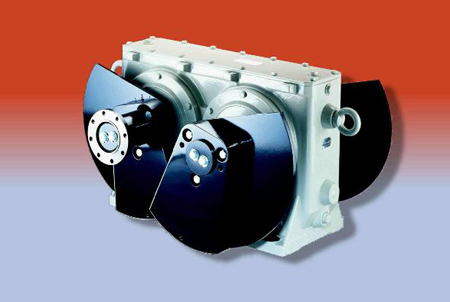

Exciters JR

-

JVM

exciters are primarily used for large and heavy vibration

machines. Forced mechanical synchronisation dispenses with the

critical synchronisation phases and the associated high loadings

during starting and stopping. An oil splash system supplies the

gears and bearings with a constant supply of lubrication.

Their long service lives and problem-free operation throughout the world – even under the most difficult industrial conditions - testifies to the JVM technical design.

- 6- and 8-pole execution

- Working moment up to 20400 kgcm (630 kN)

- Adjustable centrifugal weights

- Switch-on time 100% (operating mode S1)

- Ambient temperature -20...+80°C°C

Dosing drives JD

-

JVM

dosing drives generate only little noise, are main-tenance-free

and have naturally been designed for con-tinuous operation. The

tried-and-tested engineering and the compact, minimised dead

point construction in pro-tection system IP65 ensures

operational reliability and easy cleaning.

- Usable weight up to 22 kg per each drive

- Mains voltages 115...230 V, 50/60 Hz

optional 42...230 V, 50/60 Hz

by Thyristor controller TK5

- Switch-on time 100% (operating mode S1)

- Protection system IP 65 acc. to EN 60 529

- Explosion proof models ATEX available

- Paintwork Hammer tone finish pure silver 91

Shaft drives JW

-

Shaft drives are the traditional circular vibration drive used on

vibrating screens and shake outs. The power is transmitted by a

standard, external motor. With the machine off, the oscillation

amplitude for all JVM shaft drives can be set by adjusting the

centrifugal weights. Proven engineering and experience, from over 90

years of manufacturing vibratory motors, and innovative developments

guarantee the operational reliabilty you can trust.

- Torque up to 12500 kgcm

- Speed 800-1000 min-1

- Inner widtgh 800-2500 mm

- Usefull mass up to 10000 kg

Heavy duty bearings and quality components selected specifically for this purpose gaurantee that our drives have a long service life. The precisely-fitted JVM shaft drives are supplied ready for connection including all the required components and sturdy safety hoods.

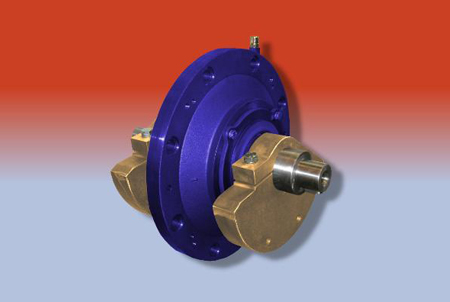

Circular exciter cells WE

-

The traditional drive used on vibrating screens and shake outs

generates circular oscillations. The power is transmitted by a

standard, external motor. With the machine off, the oscillation

amplitude for all JVM exciter cells can be set by adjusting the

centrifugal weights.

The tried-and-tested oil splash lubrication ensures long service lives and economic operation also at high ambient temperatures and under the most difficult conditions.

- Working moment up to 18500 kgcm/unit

- Centrifugal force up to 377 kN/unit

- Speed 500....1500 min-1

The data stated in the table always applies to the use of one unit consisting of two cells.

Electric control and regulating systems

-

Thyristor Control Units TK5

for operating dosing drives series JD

Thyristor Control Units Series JT

for operating magnetic oscillators MS

Frequency Measuring Instrument SFM

Double flange motors Vi

-

Mounted in a vertical position, the Vi motors generate horizontal

circular oscillations. They are fastened at the centre of the

generally round vibration machines by customer- supplied flanges.

Oscillation amplitudes as required

Centrifugal weights fit by the customer ensure flexibility in machine construction and operation.

Operational reliability

Proven engineering and experience, from over 90 years of manufacturing vibratory motors, and innovative developments guarantee the operational reliabilty you

can trust.

Ready for connection and easy to install

JVM double flange motors are supplied ready for connection. Their space-saving geometry and transport eyes make them very easy to install. Our motors are equipped with a re-lubrication feature right from the standard versions.

Dimensioning

Heavy duty, quality components and optimised electrical performance guarantee long service lives and fast motor run-up times – this way you conserve your vibration equipment.

Quality

Every JVM motor undergoes stringent mechanical and electrical quality inspections, during which all windings are tested. All motors have naturally been dimensioned for S1 continuous operation – even when the centrifugal force is set to 100%.