HIWIN

Videos

Loading the player ...

- Offer Profile

- Our products and our attitude get things moving. As a specialist in linear technology, we are your movement partner, the world over. It is our job to find the right and most efficient movement solution. We manufacture and deliver drive technology products from individual components to the entire mechatronic system. It is our job to get you moving.

Product Portfolio

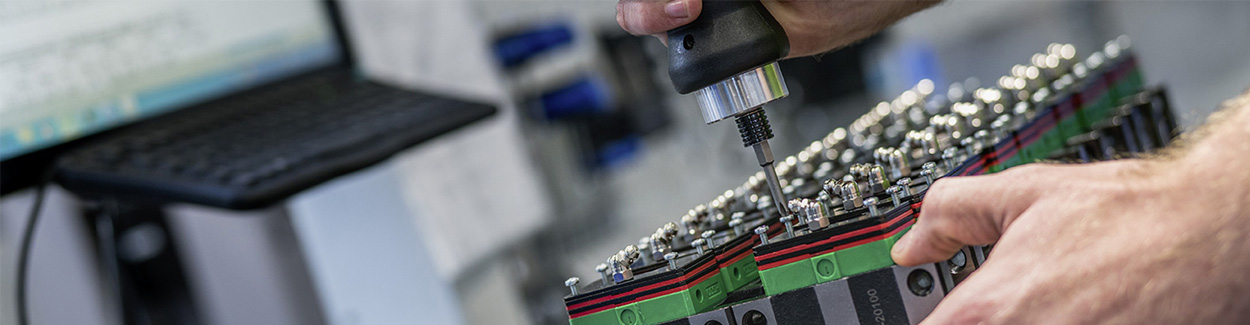

Linear guideways

- A linear guideway permits linear movement with the aid of rolling elements. By using balls or rollers between the rail and block, a linear guideway can attain an extremely precise linear movement. Compared with a standard sliding guide, the friction coefficient here is just one fiftieth. The good efficiency and zero play mean that the linear guideway can be used in various ways.

Selection via block

- Select the right block for your linear guideway. Depending on your requirements, the precise linear guideways are available in various series and versions. You will find the right profile rail among the accessories for the respective block or directly under the Profile rail menu item. You also have the option to configure blocks and rails together as one unit directly in our configurator.

Selection via profile rail

- Select the right profile rail for your linear guideway. Depending on your requirements, the precise linear guideways are available in various series and versions. You will find the right block among the accessories for the respective profile rail or directly under the Block menu item. You also have the option to configure rails and blocks together as one unit directly in our configurator.

Linear guideway accessories

- You will find the right accessories to perfectly tailor the linear guideway to your application here.

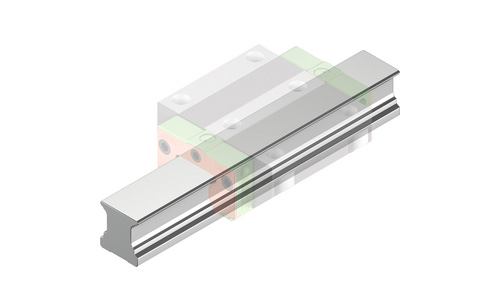

Ballscrews

- Ballscrews, also known as ball bearing screws or recirculating ballscrews, are used in a wide range of applications across virtually all areas of industry. They convert rotary motion into linear motion. Between the shaft, more precisely the threaded shaft, and the nut, the balls roll infinitely via a ball recirculation system, guaranteeing frictionless motion for your application. HIWIN offers a huge selection of spindle drives / drive spindles along with matching accessories.

Flange nut

- Flange nuts are the most commonly used nuts in ballscrews. They are easy to mount over the flange and take up little space outside the application. The flange includes a grease nipple which can be used to lubricate the ballscrew using a grease gun or a central lubrication system.

Cylindrical nut

- If space is limited, ballscrews with cylindrical nuts are ideal. They can be fully integrated into the application. To install them, the nut is clamped and secured against twisting by means of a feather key. Lubricant is supplied via a circumferential groove.

Safety nut SEM

- The safety nut consists of a ballscrew unit and a safety unit. The safety nut basically works just like a normal ballscrew nut. If the axial play increases due to wear, ball breakage or ball loss, the thread of the safety unit comes into contact with the ballscrew. This means the nut cannot be penetrated. The normal function of the unit is guaranteed up to an axial play of 0.4 mm.

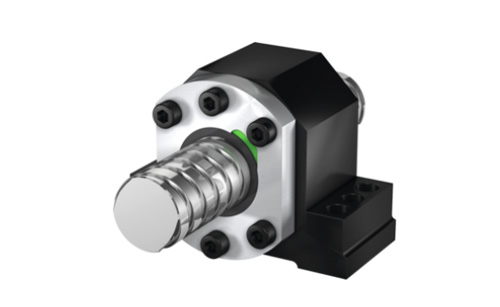

Driven nut unit AME

- The driven nut unit consists of a ballscrew unit and a bearing unit. The driven nut unit basically works just like a normal ballscrew nut, the difference being that the shaft is stationary. In applications with a very large stroke, ballscrews can be operated highly dynamically without being limited by the critical speed of the shaft.

Rolled shafts

- Rolled ball screws from HIWIN can be used with great versatility in almost all areas of the industry. When manufacturing these, HIWIN relies on the latest technologies in the rolling process by having the processes of material selection, rolling, heat treatment, processing, and installation coordinated as best possible. Rolled ball-screw spindles can be shipped on short notice with corresponding stockkeeping in the diameter range from 8 to 63 mm.

Ballscrew accessories

- To install the ballscrews, we offer compatible accessories matched to the various nominal sizes. These include complete bearing units which can easily be installed on your application or individual bearings with suitable locknuts, should the bearings need to be integrated into the machine bed.

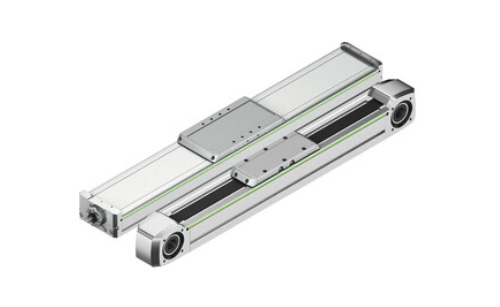

Linear axes & multiaxis systems

- Linear axes and axis systems are used in many industrial areas, e.g. to transport or position components. HIWIN offers linear axes with toothed belt drive for applications requiring high dynamic responses and speeds. The HIWIN modular system is a flexible solution for combining belt axes into twin and multi-axis systems, depending on the application. HIWIN linear axes with ballscrew drive are available for applications requiring high feed forces and precision. HIWIN linear axes with linear motor drive fulfil the highest demands on dynamics, accuracy and synchronism.

Single axes

- All HIWIN linear axes come with an extensive package of options for the optimal configuration to a certain application or particular ambient conditions. For instance, there is a range of positioning measuring systems and limit switches, as well as the most diverse sealing concepts to choose from for each linear axis. On request, HIWIN linear axes can also be supplied as end-to-end solutions consisting of a linear axis, gearbox, and motor adapter.

Multi-axis systems

- In addition to single axis components and axis assemblies, HIWIN also offers multi-axis systems tailored to each and every application. HS2 two-axis systems are suitable for two-dimensional handling tasks and therefore for positioning along the X and Y axes. The HIWIN HM-B belt drive axes or HIWIN HT-B linear tables ensure dynamic positioning along the Y axis. By contrast, HIWIN cross tables and gantry systems with linear motor drive meet the highest requirements with respect to precision and dynamic response.

Robot axes

- If the reach of a cobot is not sufficient for an application, the HT aluminium linear tables and the smart lightweight robots complement each other perfectly, both visually and technologically, to form a 7th axis system. Thanks to a freely adjustable stroke in millimetre increments as well as a variety of options (e.g. various drive types, steel cover strip, limit switch, energy chain), the axes can be individually adapted to the respective application requirements. The robot axes are available for various robot makes and are supplied directly with a suitable adapter for the robot. If desired, the 7th axes are supplied as a kit, including switch cabinet and software plug-in for controlling the axis via the robot controller.

Precision axes

- Our precision axes with the highest mechanical running accuracies are especially suitable for applications in the field of semiconductor, medical and measurement technology. The linear axes with high-resolution positioning measuring systems are available in different series and with a wide range of options.

Linear axes and multi-axis system accessories

- In terms of adaptation and limit switches, you are offered an extensive range of accessories, allowing you to perfectly tailor the linear axes to your requirements.

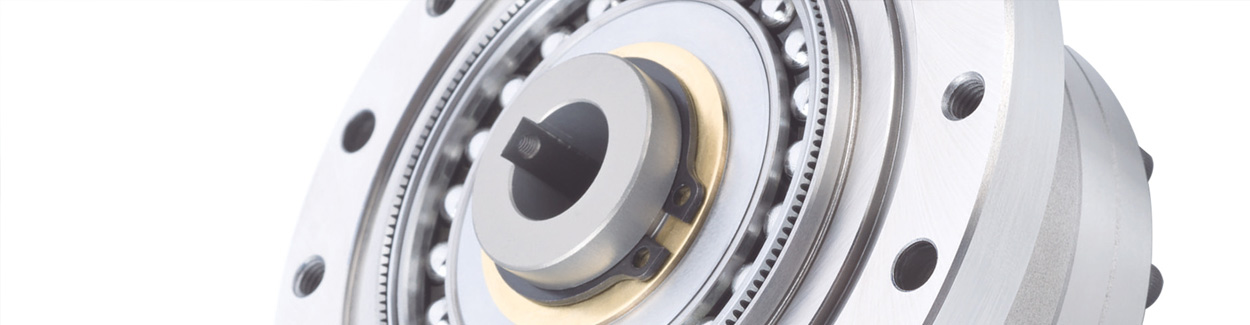

Strain wave gears

- DATORKER® strain wave gears feature high precision, high efficiency, high torsional stiffness and low starting torques. They are widely used in robotics, automation technology, semiconductor technology, machine tools and many other industries.

DATORKER® WUI-S-CO

- Gear units without output bearing with hollow shaft

DATORKER® WUT-S-PO

- Gear units with output bearing and shaft intake

DATORKER® WTI-S-PH

- Gear units with output bearing and hollow shaft

DATORKER® WTI-S-AH

- Sealed gear units with output bearing and hollow shaft

Servo drives

- The vector-controlled, fully digital servo drives are specially matched to the HIWIN motors. Servo drives D2T are used for the servo motors of the FR series, servo drives ED1 with safety function STO are used for the servo motors of the EM1 series, as well as for linear and torque motors. Different versions and performance classes are available depending on the area of application. Ready-assembled motor and encoder cables as well as the freely available HIWIN commissioning software are available for easy installation and commissioning.

Servo drive D2T

- For HIWIN servo motors of the FR series

Servo drive ED1

- For HIWIN servo motors of the EM1 series as well as linear motors and torque motors.

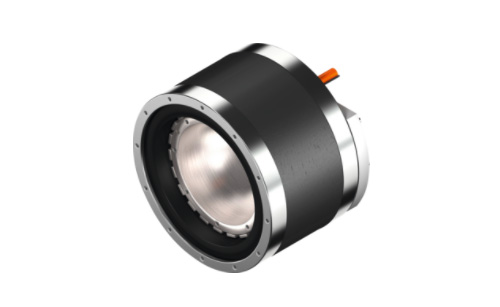

Torque motors

- Alongside complete rotary tables, HIWIN also offers individual torque motor components for the customised design of rotary tables and rotary axes. The torque motor components each consist of a rotor in the form of a ring and a stator with coil packages.

Torque motors DMR

- The standard DMR torque motors are high-torque motor components offering a high degree of efficiency and high dynamic response. Thanks to the integrated temperature sensor, the motor component is completely maintenance-free and wear-free.

Torque motors TMRW

- The water-cooled TMRW torque motors impress thanks to increased continuous and peak torques as well as lower motor temperatures. This allows additional process heat within the system to be avoided.

Torque motors TM-2

- The new generation of torque motors for the machine tool sector are ready-to-install motor elements consisting of stator and rotor. Thanks to the integrated cooling channels, the torque motor can be operated with liquid cooling. This means that no additional process heat is introduced into the machine and higher continuous torques can be achieved. The torque motors of the TM-2 series are based on the proven TMRW series. However, with identical dimensions, they are characterised by significantly higher torques and a reduced cogging torque.

Torque motors IM-2

- The high-speed torque motors for the machine tool sector are ready-to-install motor elements consisting of stator and rotor. Thanks to the integrated cooling channels, the torque motor can be operated with liquid cooling. This means that no additional process heat is introduced into the machine and higher continuous torques can be achieved. The torque motors of the IM-2 series are designed for field-weakening operation. They thus achieve a significantly wider speed spectrum and are therefore perfect for combined axes for turning and milling operations.

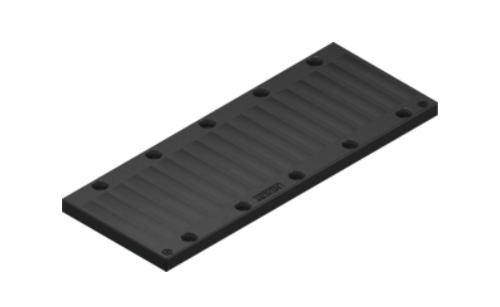

Linear motors

- Alongside complete linear motor axes and linear motor axis systems, HIWIN also offers individual linear motor components for customised axis design. The linear motors consist of the primary part (forcer) with motor windings, and magnet tracks (stators) with permanent magnets. By combining several stators, travel distances of any length can be created. Similarly, several forcers can be operated on one linear motor axis. These can either be independently controlled on the axis, or be connected in parallel to increase feed power.

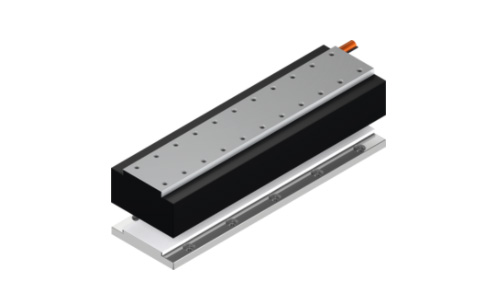

Linear motors LMSA

- The HIWIN LMSA synchronous linear motors are the compact power packs of linear actuators. The linear motors in the LMSA series stand out for their extremely high power density and very flat design. Due to their low motor mass, the actuators can be operated in a highly dynamic manner. A high synchronous operation is achieved through the optimised configuration of the permanent magnets in the stator. The benefits of LMSA linear motors make them the first choice for automation and handling applications.

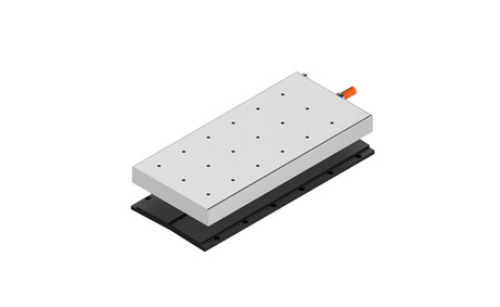

Linear motors LMS

- The HIWIN LMS synchronous linear motors are the solid all-rounders of linear motors. The proven linear motors in the LMS series stand out for their high thrust and acceleration. The permanent magnets of the secondary parts (stators) are protected by a sheet metal cover.

Linear motors LMFA

- The HIWIN LMFA synchronous linear motors are the cooled power packs of linear actuators. The UL-certified motors are fitted with a highly efficient cooling system. This enables even higher continuous forces and due to forced cooling, no additional process heat is introduced during machine construction. The linear motors in the LMFA series achieve extremely high thrust and acceleration. The benefits of the LMFA linear motors make them the preferred choice in fields with very high loads as well as in applications in which no additional process heat must be introduced.

Linear motors LMC

- The HIWIN LMC synchronous linear motors are the dynamic sprinters of linear actuators. With the light, ironless forcer and the U-shaped design of the stators with opposing magnets, no cogging torques occur between forcers and stators, and no magnetic forces are introduced into the guiding system. The linear motors in the LMC series thus achieve extremely high synchronism and high acceleration due to the minimal forcer mass. Due to their very high synchronism, the LMC linear motors are also suitable for application in testing and measuring machines.

Linear motors LMFP

- The HIWIN synchronous linear motors of the LMFP series are based on the LMFA series and thus share most of their properties. They achieve very high continuous forces, extremely high thrust forces and accelerations and, thanks to the liquid cooling, do not introduce any additional process heat into the system. The decisive advantage of the LMFP series compared to LMFA is the fully enclosed design with which it meets the requirements of protection class IP65. LMFP linear motors are thus the first choice for applications where very high loads encounter difficult ambient conditions with liquids or dust.

Linear motor accessories

Servo motors

- The highly dynamic AC synchronous servo motors deliver high torques throughout the entire speed range. Thanks to their minimal mass moment of inertia, they are also suitable for demanding dynamic drive tasks, such as high-frequency reversing operation. The special stator-rotor design achieves a very low torque ripple and high load density in a compact design.

Servo motors FR

- The 17-bit AC synchronous servo motors of the FR series are specially adapted to servo drive D2T and are available in different performance classes and encoder versions, each with and without brake.

Servo motors EM1

- The 23-bit AC synchronous servo motors of the EM1 series are specially adapted to servo drive ED1 and are available in different performance classes and encoder versions, each with and without brake.

Rotary tables

- HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. The rotary tables are play-free direct drives that are always used where classical motor/gear combinations come up against their limits. The fascinating features of these rotary tables are their unvarying torque, their rigid load coupling, and their maximised dynamic response, specifically under high load as well. Thanks to their high efficiencies and lack of gears, these rotary tables operate to great effect and are extremely quiet.

Rotary tables DMS

- DMS rotary tables are high-torque rotary axes that are ready to install. The extremely rigid coupling between the motor and load in conjunction with a quality servo drive controller provides for outstanding acceleration properties and an unvarying torque. DMS rotary tables are available in a range of sizes and with diverse options. Thanks to their hollow shafts, DMS rotary tables are ideal for applications in automation systems. Media, cable systems, and mechanisms can pass through with ease.

Rotary tables DMN

- The particularly flat and lightweight DMN rotary tables are suitable for all applications in which high rigidity and accuracy are needed along with the smallest dimensions possible. Typical applications include the manufacture of LEDs, solar cells and semiconductors. The zero-maintenance DMN rotary tables use precision bearings and optical encoders to achieve high positioning accuracy. The rotary tables, which are designed as hollow shaft versions, allow media, cable systems or mechanics to pass through easily and thus facilitate installation.

Bearing

- The HIWIN product portfolio contains bearings for an extremely wide range of applications. To provide a simple bearing arrangement for ballscrews, HIWIN offers ready-to-install flange bearing and pillow block units in fixed and supported bearing versions. Angular contact ball bearings are also available for mounting in a customer-specific housing. Crossed roller bearings can be used in applications requiring a particularly compact bearing arrangement with high moment rigidity.

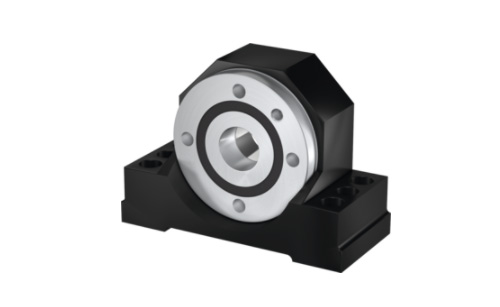

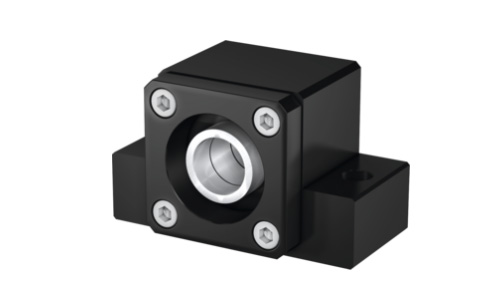

Bearings SFA/SLA

- Standard pillow block for shaft nominal diameters from 12 to 50 millimetres

Bearings WBK

- Flange bearing unit, specifically for use with heavy-duty ballscrews in various versions subject to loading.

Bearings EK/EF

- Compact pillow block for shaft diameters from 12 mm to 25 mm

Bearings BK/BF

- Compact pillow block for shaft diameters from 32 mm to 50 mm

Bearings FK/FF

- Standard flanged bearing for spindle nominal diameters from 12 to 40 millimetres

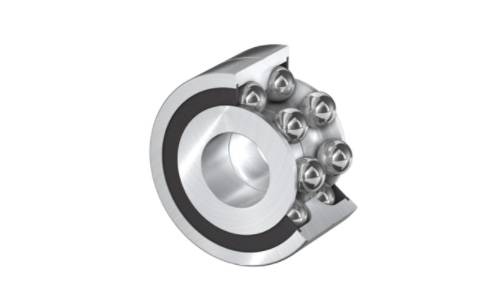

Axial angular contact ball bearing

- HIWIN offers various two-row angular contact ball bearings with or without a flange-mounted outer ring. These are particularly suitable for mounting ballscrews together with a bearing seat that has been integrated into the application.

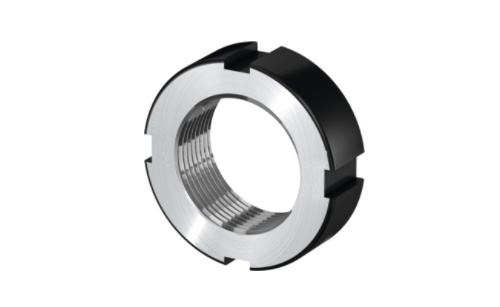

Bearing locknut

- To fasten the various bearings to the ballscrews, HIWIN offers compatible locknuts with radial or axial clamping.

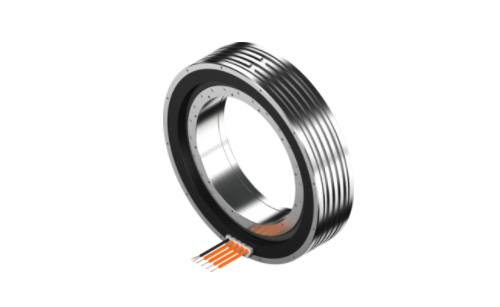

Bearings CRB

- HIWIN crossed roller bearings are characterised by high rigidity, very high concentricity and high torque capacity in all directions. These features make them ideal for use in industrial automation systems, robots, machine tools, precision rotary tables, measuring machines and medical devices, amongst other things.

Industrial robots

- The compact HIWIN-6-axis robot RA605 offers highest performance at minimized space requirements. Because of the high repeatability the RA605 can not only be used for simple handling of small parts, it can also be used for automated applications such as assembly, deburring and polishing of workpieces in production lines.

Jointed-arm robot

- The compact HIWIN-6-axis robot RA605 offers highest performance at minimized space requirements. Because of the high repeatability the RA605 can not only be used for simple handling of small parts, it can also be used for automated applications such as assembly, deburring and polishing of workpieces in production lines.

Switch cabinet

- The robot controller RCA605 is a compact all-in-one system for the economical solution of different control and drive tasks of a robot cell. In addition to the highly dynamic path calculation and control of the single axes in the robot controller, the integrated safety controller takes over all safety funktions which are usually required for a robot cell (light barrier, scanner, light grid, local or external emergency stop). With the integrated PLC, not only the robot, but also the entire robot cell can be automated via the control system.

Teach pendant

- The mobile KeTop T70 teach pendant with ist high-resolution display and ist fast processors is ideal for demanding visualization and operating applications.

Robot axes

- If the reach of a cobot is not sufficient for an application, the HT aluminium linear tables and the smart lightweight robots complement each other perfectly, both visually and technologically, to form a 7th axis system. Thanks to a freely adjustable stroke in millimetre increments as well as a variety of options (e.g. various drive types, steel cover strip, limit switch, energy chain), the axes can be individually adapted to the respective application requirements. The robot axes are available for various robot makes and are supplied directly with a suitable adapter for the robot. If desired, the 7th axes are supplied as a kit, including switch cabinet and software plug-in for controlling the axis via the robot controller.

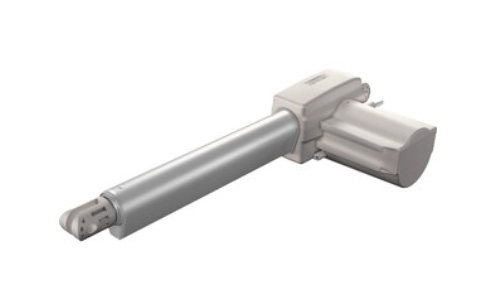

Linear actuators

- HIWIN linear actuators are not only employed in the fields of rehabilitation and homecare but also in industrial technology. The actuators have an intermediate gear that transmits the rotary motion of the motor to a trapezoidal or ball screw. This converts the rotary motion into a linear motion. In addition to our standard versions, linear actuators can also be individually designed according to customer requirements.

LAS linear actuators

- Standard linear actuator

Linear actuators LAN

- Heavy load cylinder

Direct drive rotary tables

- HIWIN direct drive rotary tables are ready-to-install rotary axes that can be incorporated directly into the machine concept without the need for any design work. The maintenance-free direct drives they use ensure that the rotary axes deliver high-torque performance with exceptional accuracy. Thanks to the range of encoder interfaces provided, the direct drive rotary tables can be integrated easily into all commercially available machine control systems and thus all existing machine concepts.

RAB

- The direct drive rotary tables of the RAB series with bearings on both sides are directly driven, maintenance-free precision axes. They use water-cooled torque motors, guaranteeing high levels of acceleration and torque. Equipped with various high-resolution encoders, the tilting axes achieve accuracies of just a few arc seconds and can be integrated into all standard control concepts. Featuring crossed roller and axial/radial bearings, the tilt-resistant mechanical design is able to accommodate maximum loads.

RAS

- The direct drive rotary tables of the RAS series with bearings on one side are directly driven, maintenance-free precision axes. They use water-cooled torque motors, guaranteeing high levels of acceleration and torque. Equipped with various high-resolution encoders, the tilting axes achieve accuracies of just a few arc seconds and can be integrated into all standard control concepts. Featuring crossed roller and axial/radial bearings, the tilt-resistant mechanical design is able to accommodate maximum loads.

RCV

- The vertical rotary tables of the RCV series with bearings on one side are directly driven, maintenance-free precision axes. They use water-cooled torque motors, guaranteeing high levels of acceleration and torque. Equipped with various high-resolution encoders, the rotary tables achieve accuracies of just a few arc seconds and can be integrated into all standard control concepts. Featuring crossed roller bearings, the tilt-resistant mechanical design is able to accommodate maximum loads.

RCH

- The horizontal rotary tables of the RCH series with bearings on one side are directly driven, maintenance-free precision axes. They use water-cooled torque motors, guaranteeing high levels of acceleration and torque. Equipped with various high-resolution encoders, the rotary tables achieve accuracies of just a few arc seconds and can be integrated into all standard control concepts. Featuring axial/radial bearings, the tilt-resistant mechanical design is able to accommodate maximum loads.