- Offer Profile

-

Haydon Kerk Pittman is the combination of 3 world class brands in the field of motion control. Formed under AMETEK Advanced Motion Solutions (AMS), Haydon Kerk Pittman together offer a broad range of precision linear and rotary motion products. Recognized as a leading manufacturer of precision acme lead screw and anti-backlash nut assemblies, stepper motor based linear actuators, linear rail and guide systems, brushed and brushless motors and complete custom systems.

Haydon Kerk Pittman offers high performance solutions and global supply in demanding markets such as laboratory automation, medical instrumentation, semiconductor fabrication, transportation, building automation and industrial automation.

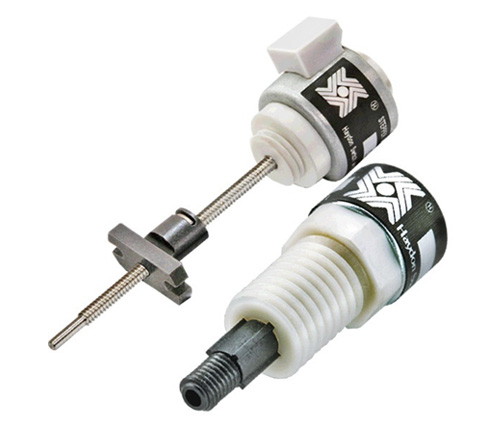

Lead Screws and Nuts Assemblies

Lead Screw Nut Selection

- Kerk Lead Screw Assemblies are modified acme thread forms optimized for performance and available in a broad range of lead screw diameters, leads and nut styles, custom designed for your application. Kerk lead screws are self-adjusting, maintenance-free and require no lubrication. Providing maximum accuracy, high reliability, smooth, quiet operation and low cost, Kerk lead screw assemblies are your best choice for high performance linear motion control.

Lead Screws by Size

- KERK® brand lead screws utilize the latest in precision rolling technology. Lead screws are available in standard diameters from 5/64" to 15/16" and includes metric and left hand threads. Most standard lead screws are manufactured from 303 stainless steel and are produced using Haydon Kerk Motion Solutions exclusive precision rolling process. Other lead screw materials are available for application-specific requirements.

Lead Screw Design Technology

- Screw Accuracy

Haydon Kerk uses a unique precision rolling process for screw manufacturing. Standard lead accuracy for Kerk screws is .0006 in./in. (mm/mm). Lead accuracies are available up to .0001 in./in. (mm/mm). Please consult the factory for higher lead accuracies. Assemblies have an extremely high bi-directional repeatability of 50 micro-inches (1.25 micron).

End Machining

Haydon Kerk can custom machine screws to your specifications or provide cut-to-length screws for your own machining.

Linear Actuators

- Haydon Kerk Motion Solutions has the exact size and type of linear actuator to solve your motion application.

Hybrid Stepper

- Haydon Kerk Motion Solutions offers a unique line of

hybrid stepper motor linear actuators that open new avenues for

equipment designers who require high performance and exceptional

endurance in a very small package. These high-performance hybrid

actuators directly drive a rotor drive nut on a stainless steel

precision acme lead screw. This patented interface reduces

tolerances and noise while increasing efficiency and durability

over v-thread and bronze nut configuration commonly used in

other linear actuators. Actuators are available in captive,

non-captive and external linear configurations.

Hybrid Stepper with IDEA Drive

- Available in size 17, single or double stack, the 43000 series Hybrid Linear Actuators with integrated IDEA™ Drive offers high performance and exceptional endurance in a compact package. The integrated IDEA™ Drive features a fully programmable control unit that uses an intuitive patent-pending Graphic User Interface (GUI). IDEA™ Drive software is simple to use with on-screen buttons and easy-to-understand programming guides. Offered in either USB or RS-485 communication.

Dual Motion

- The Haydon Kerk™ line of dual motion hybrid actuators

provide independent linear and rotary motion in either Size 14 or Size 17

actuators. Each actuator incorporates two stepper motors which can be

controlled independently using a standard two axis driver. Dual motion

actuators integrate precise 2 axis motion in one simple and compact

actuator.

Features:- Available in bipolar and unipolar coils

- Step resolution of 0.9° and 1.8° degree

- Available standard and custom winding voltages

- Large range of leads

- Run using a standard two axis driver

Can-Stack Stepper Motors

- Haydon Kerk Motion Solutions offers a full range of

can-stack linear actuators from 15 to 46 mm in size with a wide

range of force outputs. Actuators are available in Captive,

Non-Captive and External configurations. All stepper motor

linear actuators can be customized for application specific

needs.

Features:

Captive, non-captive and external linear configurations.

Linear Step Accuracy ranging from 3 – 400 microns.

Dual ball bearings for greater precision and durability.

Black Ice coated lead screws available.

Custom nuts and configurations available.

Linear Rail Systems

- Haydon Kerk offers both motorized and non-motorized linear rails, guides and splines that deliver enhanced system stability, high positional accuracy, low friction and long life for a variety of linear motion applications.

Slide Guided Rail Systems

- Haydon Kerk Slide Guided Rails are available in many styles and sizes to meet your application needs. Many rails are offered with integrated drive, motorized, non-motorized or guide only versions without lead-screw. Rails are available with wear-compensating, anti-backlash driven carriages to insure repeatability and accurate positioning. All moving surfaces include engineered polymers that provide a precise, strong and stable platform for a variety of linear motion applications.

Linear Rails with Recirculating Ball Slide

The Motorized Linear Rail combines many technologies into a single integrated linear motion platform. The system provides excellent load capability and is engineered for both normal and overhanging loads. High roll, pitch, and yaw moment loading capability allows the system to maintain tight accuracy and repeatability, even in applications requiring significant cantilevered loading. The lead screw drives a machined aluminum carriage mounted to a precision stainless steel ball rail resulting in a rigid, smooth-operating motion system. Offers an optional wear-compensating anti-backlash driven carriage. Kerkote® or Black Ice® TFE coated screw provides a permanent dry lubrication.

Linear Guide Element

- Spline Shafts and Guide Rails deliver low-cost, low

friction and long life for a variety of linear motion control applications.

KERK® SS and SZ Spline shafts are available in stainless steel and can be coated with our proprietary Kerkote® TFE or Black Ice® coatings. Spline Shafts provide anti-rotation for one axis motion or a drive mechanism with rotation for two axes of motion. The bushing is supplied with an integral brass collar to facilitate various mounting configurations without nut distortion.

KERK GR Guide Rail is the perfect choice for light load applications requiring minimal frictional drag, low cost and long wear. It features a burnished, centerless ground stainless steel shaft (available either uncoated or with Kerkote® TFE for additional lubricity) and a graphite and PTFE-filled thermoplastic bushing.

Mini Motorized Stages - MiniStage MLX Series New!

-

Combines core HKP hybrid actuator and lead screw technology with the guidance and load handling capacities of a recirculating ball bearing profile rail. The guide rail provides high load capacity, long performance life with maintenance-free operation, and guiding accuracy. The integration of the lead screw directly into the hybrid stepper motor without the use of a coupling results in the shortest overall product length, and the custom drive nut design and tight integration into the moving carriage creates a ride height of only 15mm. MiniStage is delivered as a fully assembled and tested solution from a single supplier, saving valuable time and money, reducing supply chain risk and management cost, and allowing the customer to focus on end-product design.

Mini Motorized Slides - MiniSlide™ MSA Series

-

Compact, low profile mini slides save engineering time. Perfect for small lab, medical equipment and optical stage applications. Highly configurable mini slide assemblies offer 2 motor options, 9 different lead screw options, 4 different lubrication options, as well as English or Metric standards.

Multi-axis Motion Systems

- Haydon Kerk offers pre-engineered and customizable solutions for multi-axis positioning requirements, leveraging our core actuator and linear rail technologies to deliver optimized system performance. Our integrated solutions solve the motion application challenges for technology driven original equipment manufacturers (OEMs) around the globe.

Z-theta

-

NEW! Performance in an Ultra-Compact 2-axis Design

Designed for easy integration in OEM assemblies, the Haydon Kerk Z-Theta offers linear + rotary point to point motion in an compact footprint. Unlike in-house component-up designs requiring engineering, multiple vendors and complex assembly integration, Z-Theta is a modular “bolt-in” package.

- Compact co-axial design enables small footprint

- Easy integration into system design

- Pre-engineered modular design reduces supply chain and time to market

- Configuration options optimize performance for specific applications

- Compatible with a wide range of drive and controllers

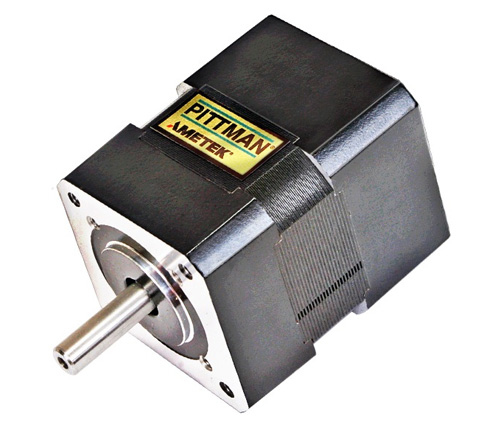

Motors

- Pittman and Haydon Kerk DC motor lines span a wide range of sizes in brushed, brushless and stepper motor technologies. We provide rapid turn-around for prototypes and production orders. Custom designs and special engineering requirements such as special shaft diameters, lengths and mounting flanges are welcome. If there’s a need for precision rotary motion, more than likely there’s a Haydon Kerk Pittman motor to meet your requirements.

Brushed DC Motors

- Pittman brush commutated DC motors have a wide range of

frame sizes and magnetic technologies from 22 to 54mm diameter and power

ratings from 3 to 94 watts. These motors are designed to offer smooth low

speeds, quiet operation and long life.

Features:- Spur and Planetary gears

- Optical Encoders from 50 to over 8000 counts of resolution

- Fail safe brakes in both rear and front mounting options

- Fully customizable per your requirements

Brushless DC Motors

- Pittman offers an extensive range of sizes and

configurations from 10 to 120mm diameter with power ratings from 6 to 2000W

and speeds to 100,000 rpm.

Features :- Spur and Planetary gears

- Optical Encoders from 50 to over 8000 counts of resolution

- Fail safe brakes in both rear and front mounting options

- Fully customizable per your requirements

Brushless Motors with IDEA Drive

- Pittman offers a new brushless motor line with integrated

drives.

Features :- GUI programming interface with RS-485

- Gearboxes

- Available in 3 lengths

- Fully customizable per your requirements

Can-Stack Rotary Motors

- Haydon Kerk's rotary motors are built to provide

exceptionally high torque to size ratios. By utilizing a patented enlarged

rotor with low inductance coils, the motors provide superior torque and

continuous, reliable high performance. At rated voltage, the 46 mm motor

produces 16 oz.-in. of holding torque, the 36 mm motor produces 4.5 oz.-in.,

the 26 mm motor produces 1.8 oz.-in. and the 20 mm motor produces 0.65

oz.-in. Optional rare earth magnets may be specified for even higher torque.

Bronze sleeve bearings are standard, ball bearings are also available.

Features:- High Energy Neodymium magnets

- Bipolar & Unipolar windings with 5 & 12VDC ratings

- 7.5° and 15° degree step angle

Motor Accessories

Drives

- Stepper Motor Programmable Drives

The IDEA™ family of programmable Stepper Motor Controllers uses an intuitive patent-pending Graphic User Interface (GUI) which greatly simplifies set up and use in the machine design process. Units are available in either USB or RS-485 communication. In addition to the stand-alone models shown, drives are available integrated on motor and linear actuator assemblies.- RoHS Compliant

- Stand-alone drive unit or integrated directly onto a linear actuator

- Programming done through Graphic User Interface (GUI)

- Automatic population of motor and drive parameters

- Programmable Speed / Current / Accel-Decel /

- Current Boost / Interrupts / I/O

- Encoder Input / Stall Detection with

- Compensation / Position Verification

- USB or RS-485 Communication protocols

- Movement Profile Plotter

- Interactive Program Debug Feature

Gearboxes

- PLG42S

The PLG42S is a 42 mm planetary gearbox suitable for servo applications where DC Servo brush or BLDC motor technology is specified. The PLG42S provides excellent efficiency in a compact and industry compatible output configuration.

Features:- Maximum Load torque up to 14 Nm

- All steel gearing for high torque capacity

- Dual ball bearings on output shaft

- High efficiency

Encoders

-

Haydon Kerk Pittman offers cost effective feedback devices for positioning applications with different technologies in the incremental encoder's format such as reflective optical technology, transmissive optical technology with and without differential line drives and multitude of line counts in compact low profile sizes. These incremental encoders are offered in both modular and bearing construction. The bearing style encoders provide significant performance upgrades in demanding applications.

- E21 Series

- E30 Series

- Q-V Series

- C-D Series

Sealed Switches

- Haydon's sealed switches are used in commercial jets, military aircraft, military ground equipment, space applications and industrial applications with harsh environmental conditions, such as gas turbines and high temperature research instrumentation. Haydon switches are built to meet stringent military specifications and are re-qualified through extensive retesting every three years. To achieve and sustain such high levels of quality requires a combination of skilled engineering and production teams, special support facilities and coordinated quality control from design through production. Haydon has all of these factors in place and, because of this, our switches are recognized for their quality and robustness by engineers and users throughout the world. The unique manufacturing methods, process controls and quality systems utilized in the production of our advanced aerospace switches are also integral parts of our motor operations.

6100 Series - Environmental Sealed Switches

6100 Series Environmentally Sealed Switches are designed for applications where high reliability is required in a high or low temperature environment. Combining long life and precise action, this switch is used in a wide variety of commercial and military aircraft and space applications. These switches can perform such functions as indication for Interlocks, landing gear position, valve position and throttle control. Military applications include brake lights on military vehicles, gear shift indicator for tanks and other applications where a resiliently sealed, high reliability switch is required.

6700 Series - Environmental Sealed Switches

The 6700 Series environmentally sealed switch is rated for one million cycles. The 6700 was developed for high cycle harsh environment applications. The need for high cycle limit switches has developed as aerospace and industrial systems have evolved from manual control and feedback to computer controlled mechanisms. The 6700 meets the high life cycle requirements of modern computer controlled systems.

6200 Series - Hermetically Sealed Switches

- The 6200 Series hermetically sealed switch is ideal for high temperature applications or anywhere extremely severe environmental conditions are encountered. Most commonly used on commercial and military aircraft, these switches can also be found in some space applications. Originally designed and developed for use on Mach 2 supersonic aircraft, the switch is currently being used in high temperature valves, thrust reversers and other severe environment applications.

6300 Series - Hermetically Sealed Switches

- 6300 Series hermetically sealed switches are designed for high reliability in extreme environments. This switch is used on military and commercial aircraft and in aerospace including the NASA shuttle program. Applications include valve limit switches, engine starters, overspeed switches, pressure switch and thrust reverser limit switches.

6600 Series - Hermetically Sealed Switches

- 6600 Series switch is designed for harsh environments where long life hermetic seal integrity of the switch is critical. The 130,000 cycle minimum hermetic life of the switch equates to life of aircraft reliability for many applications.

LC Series - Hermetically Sealed Switches

- The LC series switch assembly is designed to provide reliable operation in extreme environments. This switch is used in various applications on commercial jetliners. Available in leaf and roller leaf configurations these assemblies incorporate Haydon’s 6300 series hermetically sealed switch.

CASE STUDIES

- Learn why our customers design in Haydon Kerk Pittman! Check out our case studies.

Quick development in the Diagnostic Lab Instrument field using the new Pittman IDEA Motor

-

Industry - Application

Medical - Diagnostic Lab Instrument - Lab on a disc

Application Details

TTP is a design consultancy engaged in product research and development in several markets, including industrial, commercial, aerospace, communications, medical, and life sciences. TTP begins as early as scientific discovery and typically produces beta units to begin the production transfer to a selected manufacturer. TTP had begun development of a new diagnostic instrument and were challenged to present concepts on an accelerated time schedule.

Challenge

The instrument requirements included the following:

• Spin a drum of samples according to a defined velocity and acceleration profile

• Rotationally index the drum 12 degrees during the load, unload, and read cycles

• Reliable, quiet, and small enough to fit on a lab tableWhy Haydon Kerk Pittman?

• Performance and value compared to a new drive development

• Fast technical response to customer needs for proof of concept

• Quick turnaround on prototype parts

• Customized components for any application

• Motor and drive package designed to work as a single system

• Wide range of motion products from a single supplierSolution

TTP was contracted for development of a table-top lab on a chip style medical instrument that required precise velocity and indexing profiles. HKP approached TTP with a new Pittman product, the IDEA® Motor, a 42 mm, BLDC motor with an integrated servo drive that appeared to meet all the current requirements. After receiving and testing a sample unit and software, TTP was encouraged with the servo capabilities of the compact package.

As the development progressed, TTP provided a solid model of the drum that the IDEA Motor would spin in the instrument, as well as the desired velocity and acceleration profiles. Within a few days, HKP 3D-printed the drum, fabricated a coupling, and programmed the motion profiles into the drive. With the pieces assembled, HKP then recorded a video of the system tracking according to the specified motion sequence. The video and prototype were sent to TTP for testing. The indexing functionality was tested earlier and deemed sufficient. The IDEA Motor provided high flexibility and allowed TTP to test several concepts by making small changes to software and by utilizing the on-board inputs and outputs.

TTP was delighted with the performance and assembled a proof-of-concept for their end customer within weeks instead of months. The proof of concept worked well, but the IDEA Motor was too tall...

Collaboration with Altair results in high performance fluid dispensing within a small footprint

-

Industry - Application

Food & Beverage - Fluid Dispensing

Application Details

Precision linear actuator controlling a fluid handling syringe pump.

Challenge

Altair Engineering, a large design house based in Michigan, was tasked with modernizing outdated pneumatic technology on existing beverage machinery. To achieve this, they needed a precise, rapid, and highly customized linear-motion subassembly while reducing costs and improving throughput. Hygiene remains paramount in the food industry, and with the risk of incidental food contact, a “food friendly” actuator was required. Furthermore, a portion of the design was frozen before final motor selection, and this mandated a powerful actuator that had to fit in a tight footprint. As application testing progressed from dry testing to full fluid, the change in frictional forces from the fluid created unpredictable linear travel since the screw rotated relative to the plunger. Additionally, the application needed integrated feedback sensing, high force, and operated at a high speed.Why Haydon Kerk Pittman?

• Highly customized actuator with aggressive speed/force/footprint specs

• Integrated guide elements/feedback devices designed with assembly/servicing in mind

• “Food friendly” advanced polymers and lubricants

Solution

Facing a myriad of challenges, Altair teamed up with Haydon Kerk Pittman. The first step was to ensure the actuator generated enough force, so a custom Size 34 (87mm) hybrid non-captive actuator was selected. An integrated linear guide system was then created to prevent the screw from rotating while maintaining the target cost and staying within the permitted footprint. “Our Kerk tool engineers designed and molded a sliding bushing for the actuator’s lead screw geometry along with an extruded guide tube for the bushing to travel in. With design for manufacturing in mind, we modified the rear end bell of the actuator to accommodate the guide tube. This small tweak gave the customer the ability to attach and detach guide-element components during the assembly process, overcoming the tight footprint constraints while eliminating the need for a costly redesign of the machine’s enclosure.” said Dan Kish, HKP’s Sales Engineer for Altair.

The lead screw was also machined to include features specific to the customer’s assembly wrench to further ease the build. To remain “food friendly,” food grade grease was used for incidental food contact and a carbon fiber rotor insert was created and molded to meet high-speed and force specs. To simplify the customer’s supply chain, the HKP solution included the two required custom pinout wiring harnesses. The feedback device and custom mounting were supplied as a kit to simplify assembly for Altair and keep assembly time to a minimum.

A complete solution with reduced components for more efficient 3D printing

- Industry - Application

Business Machines - Professional 3D Printing

Application Details

3D Systems ProJet® MJP 2500 series 3D printers using Haydon Kerk lead screws and actuators to drive the Z-axis build plate and the Y-axis that moves the printhead.

Challenge

3D Systems was looking to minimize backlash and increase positional accuracy in their newest ProJet® MJP series of 3D printers. Preliminary designs used multiple components from various suppliers.

Why Haydon Kerk Pittman?

• Customer support for product development

• Quick turn around on prototype parts

• Precision lead screws

• Low friction coatings to improve efficiency, life, and eliminate lubrication

• Anti-backlash nut systems

• Integrated stepper motor solutions

Solution

3D Systems became interested in Kerk lead screws due to their high precision, long life, and brand history. The ProJet® MJP 2500 printers build 3D parts layer-by-layer. The Z-axis drive facilitates this by precisely moving the build plate vertically between image passes made by the Y-axis drive. The Y-axis drive precisely moves the printhead during construction of the layer. The performance of these drives is critical to the quality and precision of the printed parts. HKP was able to meet the accuracy and precision requirements with components that also met the product life and cost targets.

For their Y-axis or printhead drive, HKP recommended integrating the lead screw into the motor. The result was a more compact actuator that achieved the linear motion required with the fewest components. Moreover, the system utilizes the NTB series anti-backlash nut and KerkoteTM thread coating to reduce system backlash and eliminate lubrication of the drive. HKP was able to deliver a fully assembled and tested precision drive system that reduced assembly time and improved reliability.

Early into manufacturing, the customer also sought to improve the yield of the Z-axis drive assembly. Previously, multiple vendors were involved to manufacture the timing belt pulley, the leadscrew and then press the parts together. Difficulties in achieving tolerances for the press fit along with the custom fixturing required for the press operation were generating poor yields of the assembly. Haydon Kerk was able to procure the timing pulley and install it onto the screws. Controlling the complete process with a tested subassembly now generates a high yield, ready for final assembly.

A field-friendly solution for disinfecting robot – helping hospitals reduce infection rates by 50-100%, contributing to the fight against COVID-19

- Industry - Application

Environmental Hygiene - Ultraviolet Disinfection

Application Details

The Xenex robot uses ultraviolet light to disinfect and sanitize the surrounding area. A Haydon Kerk Dual Guide Rail mobilizes the UV light as it ascends and descends out of the robot.

Challenge

The application requires supporting a tall 20lb moment load with a safety margin of up to 40lbs. Tall, overhung loads are prone to vibration, noise and deflection. The application requires high thrust while maintaining smooth movement and controlled speed. In addition, the unit needed to be modular for simple field service of the robot.

Why Haydon Kerk Pittman?

• Achieved a controlled and smooth rate of motion

• Noise/vibration mitigation with a patented centralizer nut

• Achieved 40 lbs. of overhanging load support

• Wide variety of lead options

• Pre-aligned, turn-key solution facilitates simple and inexpensive installation

• Customizable System

Solution

For optimal functionality in the next generation of the Xenex robot, HKP designed a Dual Guide Rail specifically for Xenex’s application requirements. This provided a single assembly on one side of the UV light, eliminating the need for two separate assemblies. A single assembly is more robust and does not require alignment. HKP’s large catalog of lead options enabled HKP to provide an optimal mix of load support and speed. In this application, too coarse of a thread would have required the system to maintain position using holding current on the motor. Too fine of a thread would not have met Xenex’s desired movement profile. HKP was able to select the ideal thread size and lead for this application to meet Xenex’s torque, movement and load requirements. Overhung loads are prone to both vibration and noise. To reduce both the noise and vibration, HKP employed its newly patented centralizer. The centralizer applies light, constant pressure to the outer diameter of the lead screw. This pressure creates a damping effect while maintaining a low running torque. The centralizer can be added to both freewheeling nuts and anti-backlash nuts. Finally, HKP added additional features for electrical isolation such as custom Teflon coating and tapped holes to accommodate a grounding wire connection between the Dual Guide Rail and the frame of the Xenex robot.

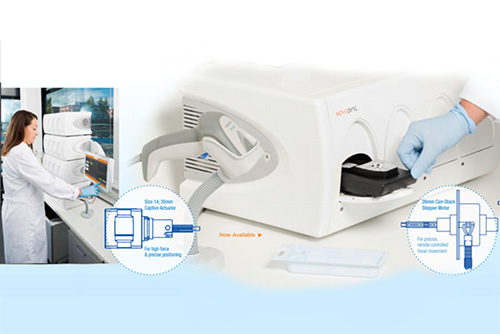

Haydon Actuators and Mobidiag in the fight against the COVID-19 virus

-

Positioned to answer the need in the diagnostic aspect of the fight

The newly released* Novodiag COVID-19 test operates using the ‘sample-in, result-out’ Novodiag system that allows for rapid detection of the SARS-CoV-2 virus, responsible for coronavirus infection, in about one hour. It’s a fully automated machine and closed system that can protect laboratory staff from potential contamination. It’s very user-friendly and designed for use in high risk and hard to reach areas without the need for highly trained personnel.How did you come to the idea of implementing linear actuators in the Novodiag instrument?

Novodiag integrates numerous biological functions which require motion specific elements within the instrument. These tasks are normally performed by an operator and our goal was to reproduce the various motions in an automated manner. As talking about motion often means talking about actuators, when the need for specific strokes, specific forces at specific speeds is established, it points in the direction of stepper motor-based solutions, and its integration within the Novodiag. Doing so, we are not re-inventing the diagnostic process itself (sample prep, PCR, hybridization). We intend to make it accessible to any operator, and to speed it up so he/she can focus on other operations. In addition, Novodiag allows to work with much smaller volume of fluids than when manually performed, and the sample preparation is done within the instrument, so it significantly cut down process time and inherent costs.Why Haydon Kerk Pittman?

I have been using Haydon’s LC15s, your smallest Ø15mm linear actuators since 2006, and was familiar with your proactive response at the design phase. Haydon provided the right information, early on, without the need for me to search for it. So, when I was envisioning technical issues, Haydon was already supplying corresponding answers.Among the 3 different Haydon actuators in use within the Novodiag, 2 required particular attention during the design phase. Can you tell me more about those?

The first actuator, a 19000 Captive, is used in a syringe pump. Such application requires the actuator to both perform high resolution motions for precise microfluidic dosing, and to push with enough force at various speeds, from low to high speeds, to help optimize the process times. What led me to select the 19000 Captive from Haydon was its capability to meet the previously mentioned specifications as well as its small footprint of only Ø20mm. Further customization like custom stroke, as well as the removal of the rear cover of the actuator to save space, further convinced me about the veracity of the actuator selection for this syringe pump. Despite searches, I could not find a market alternative which was able to meet the full criteria...

Aqua Massage Manufacturer Improves Linear Motion Control with Custom Lead Screw Assembly from Kerk

- The words “Relax, Reflect, Revitalize and Renew” flash on the homepage of Aqua Massage International’s (AMI) website. Based in Groton, CT, AMI is one of the world’s largest manufacturers of hydrotherapy “dry water” massage machines. You may not recognize the AMI brand but you are most certainly familiar with its flagship product—the Aqua Massage Machine.

Typically found in the center alleys of shopping malls, these capsule-like machines are often situated next to various vendor kiosks. If you have not seen one, they are similar in appearance to an MRI machine, and have been described by some as a cross between a tanning bed and a car wash.

When the company was first founded, in 1990, its machines were intended for fitness and sports centers, spas, and clinical and chiropractic settings. Over the last decade, AMI has expanded its product offering to capture a rapidly growing consumer market.

As healthcare costs continue to rise, millions of people are actively seeking products and services to enhance their overall well-being. Increasingly, consumers are turning to alternative therapies like massage to release tension, soothe aching muscles and relieve pain. Consumers have already poured more than $3.5 billion into massage services and products and some experts estimate that demand for these products and services will top $1 trillion by 2010.

While traditional massage is popular among consumers of all ages, and attracts a particularly upscale, affluent clientele, dry water massage therapy is attractive to a broad consumer market, including people that would not otherwise consider a traditional massage.

As opposed to traditional massage therapy which can take up to one hour, aqua massage therapy yields results in only 10 to 15 minutes. Additionally, aqua massage clients are able to stay fully clothed during the massage, no physical contact is necessary to complete the session, and an adjustable touch-pad control provides the client with the ability to adjust massage strength and location.

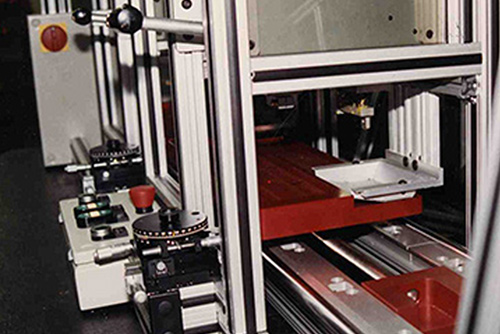

Kerk Lead Screw Allows RPT Motion to Create Quick and Cost-Effective Case Packer

- In today’s high-paced society, speed is a way of life. Such is the case in the industrial automation market, as an increase in speed results in an increase in production rates. Increased production rates, in turn, lead to increased profit, and higher profit margins are something that every company strives to achieve.

In the instance of case packing machines, whereby a machine or person moves a product down a conveyor to be packaged, it is important for manufacturers to move a large volume of products in a short amount of time. The case packer must not only be fast, but also cost-efficient and durable enough to ensure a long lifespan. Over the last few years, RPT Motion, a provider of custom modular linear motion systems, has experienced an increasing demand for case packers and other linear motion solutions from manufacturing customers across the board.

“So much of our business is driven by speed,” says Peter Ratcliffe, President of RPT Motion. Based in Quebec, Canada, RPT has been providing solutions for industrial automation applications since 1984. “Our customers have always looked to us for ways to speed automation, but in light of the recent globalization, we have observed an intense pressure to provide solutions that reduce downtime and thus, increase overall productivity,” said Ratcliffe.

A key segment of RPT’s business is based upon updating existing subsystems on machinery with higher performance linear motion to increase production rates and reliability.

Although speed is a critical component for linear motion applications, size plays a significant role as well – that is, increasing speed without affecting a machine’s or sub-assembly’s dimensions. This is because changes in dimension necessitate re-design, and re-design costs money.

Recently, RPT Motion teamed up with Kerk Motion Products, one of the world’s premier manufacturers of non-ball lead screws, for a challenging retrofit project involving a major tissue manufacturer whose operation was getting bottlenecked at the case packing stage. The manufacturer was looking to add a second case packer to its process in order to increase the speed and prevent the slowdown of its current production. However, the process required more than just dropping in the new case packer. The first obstacle lied in the fact that the existing system, which had a two-position lane changer powered by a pneumatic cylinder, wouldn’t provide the four required positions or the higher speeds. In order to service the four lanes, a stroke in excess of 40 inches was required and the lane changer needed to index on average every 10 seconds or less while maximizing time available for product flow...

Kerk Lead Screws Help Diamond Analyzer Achieve Dazzling Accuracy

-

Most of us are familiar with the four “C’s” that help determine the quality of a diamond: Clarity, Carat, Color, and Cut. These standards are commonly accepted as the determining factors for identifying a superior diamond.

The problem is, the traditional 4C information does not in actuality help separate a superior diamond from a diamond of inferior appearance. What makes a diamond beautiful and eye catching is the way it plays with light, otherwise referred to as Light Performance. GemEx Systems, Inc., a company committed to applying the latest in digital optics technology to the worldwide diamond industry, understands this concept. On the company’s Web site is the following explanation:

“Three of the 4 C's - Color, Clarity and Carat weight have very little effect on the appearance of the diamond,” the Web site explains. “These 3C's determine the rarity of the diamond. The fourth C, Cut, does affect the appearance, but it is not well-defined and it ignores the light characteristics of the diamond material. Even so-called "ideal cut" diamonds do not guarantee you great light performance… to experts and consumers alike, Light Performance is the overwhelming factor that determines diamond beauty.”

Not satisfied with simply educating the public on the importance of light in a diamond’s make-up, GemEx engineers created a sophisticated instrument called the BrillianceScope™ Analyzer. Developed and patented in 1998 with substantial venture and angel funding, the BrillianceScope Analyzer is an imaging spectrophotometer that measures the ability of a diamond to refract and focus light. Using complex optic technology, the device measures three types of light returned through its crown: white light (sometimes called “brilliance”), colored light (sometimes referred to as “fire”) and scintillation (commonly known as the “sparkle”). Superior performance in any one of these light categories will yield a beautiful diamond; the choice of the four C’s is made between the diamond professional and the consumer...“We have to be very accurate in where the rail stops,” explained Kurt Schoeckert, a GemEx co-founder and a mechanical engineer who was instrumental in the design of the BrillianceScope. “Because of its comparative scale, the diamond has to reside in the exact same five spots every single time we run an analysis. Without this precision, the device’s accuracy would certainly be called into question.”

Playing an integral role in the motion system’s meticulous performance is a lead screw assembly from Kerk Motion Products, one of the world’s premier manufacturers of non-ball lead screws located in Hollis, NH. The lead screw is integral in each of the five movements that the ring light makes; in fact, it has helped the BrillianceScope achieve a repeatability factor of +/- 5 percent, more than sufficient to ensure the validity of the test results.

The Kerk® lead screw was not part of the machine’s original design. In order to create the necessary movement, Schoeckert had designed his own “homegrown” system - an assembly constructed from a U-shaped piece of sheet metal, a 3/16-inch diameter drive screw, and a power nut with two bearings on the end of it. Unfortunately, this first iteration did not perform up to GemEx standards. What’s more, Kerk’s proprietary Kerkote® TFE coating was developed specifically for its lead screw and nut materials for maximum self-lubrication.

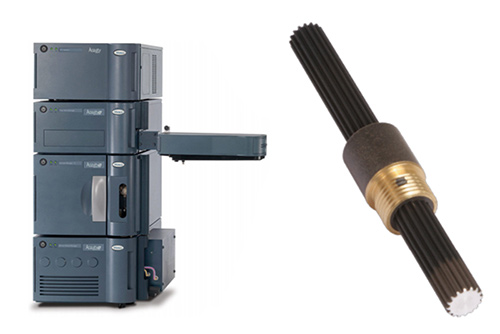

Kerk Motion Products Help Waters Corp. Make Large Splash with Small UPLC Unit

-

Pricing pressures, intense competition and strict regulatory demands are challenging scientists and researchers in the fast growing, highly‐regulated pharmaceutical, life science, biochemical, industrial and environmental industries to make important breakthroughs faster and more efficiently.

Heightened productivity in scientific labs has become paramount for companies to succeed. Waters Corporation, a leading manufacturer of high‐performance liquid chromatography instruments, mass spectrometers and thermal analyzers and rheology instruments, understands this pressure first hand. As a major supplier to analytical laboratories around the world, Waters is known for its constant commitment to providing innovative solutions that help customers better understand the secrets of chemistry and of life itself.Design Challenge: Achieving High Performance with a Small Footprint

While the performance of the ACQUITY system was certainly at the forefront for the Waters engineers who developed the product, it was not their sole design criterion. Management envisioned a system that would sport a much smaller footprint than traditional HPLC systems, ensuring that it would consume less of a laboratory’s valuable bench space. This compact footprint would also guarantee that users could more easily stack and arrange the various modules. The design engineers hoped that the completed basic system would consist of a sample manager, one of several UPLC detectors, and a high‐pressure pump. Several upgrades would also be available, including a high‐capacity sample organizer.

Accomplishing this goal would require the use of smaller internal components in both the main unit and the optional module, which holds an additional 21 sample plates. Initial efforts to create the required parts did not yield the desired results, according to Ken Plant, a principal engineer on the Waters ULPC project.Solution: Customized Motion Control from Kerk

One of Plant’s colleagues had worked with a company called Kerk Motion Products when he was involved in the automation industry, and he felt that Kerk might be able to offer the optimal combination of reliability and miniaturization for this mechanism.

After consulting with Waters’ engineers, Kerk presented Waters with components that would allow the engineers to produce a sample manager – the heart of the UPLC system – that would meet the company’s reduced size requirements and produce the increased speed and performance that was so vital to the UPLC concept.

“We considered several vendors, but Kerk had the best set of performance data,” said Plant. “While other vendors were selling off the shelf commodity items, Kerk’s products allowed for customization and flexibility to react to customer needs. We were impressed that Kerk was willing to work with our engineers to customize their components and ensure that they would mesh into our system.”

Kerk is quick to recognize the creativity demonstrated by Waters’ engineers. “At Kerk, we take pride in being a provider of innovative solutions,” says Kerk applications engineer, Bob Hawkins. “Waters has effectively utilized our products and resources and has achieved a truly remarkable solution to a difficult design challenge.”

OMEGA Design Saves A Bundle with New Kerk Rapid Guide Screw

-

Recognized as an industry leader for over 30 years, Omega Design Corporation manufactures a broad range of high-quality container handling and packaging equipment systems. The list of equipment produced by the Exton, Pennsylvania-based Company is impressive: plastic bottle unscramblers, puck unscramblers with container placement, shrink bundlers, stretchbanders, tray shrink packaging systems, wrap-around case packers, secondary orienters, canister desiccant feeders, and specialty equipment.

The wide range of markets served by the Omega equipment is equally noteworthy, with installations in the pharmaceutical, personal healthcare, cosmetic, food, beverage, dairy and chemical industries, to name a few.

One of the company’s flagship products, the “Classic” Series of Shrink Bundlers, has gained a particularly stellar reputation. Hundreds of units have been sold and are in operation throughout the world. This pneumatically-driven, PLC-controlled machine was designed for automatic shrink or stretch packaging of glass, plastic or metal containers, boxes or cartons into pre-determined bundle configurations. The design of the “Classic” series helps to eliminate the high cost of cardboard boxes and creates a more efficient, secure package, which lends itself to further automation down the line, such as case packing...Using Kerk’s RGS 10000, Omega Design has succeeded in producing a new machine with benefits for both Omega and their customers. The new bundler demands less maintenance and requires less labor to maintain. Omega has also realized significant cost savings, as less labor is needed to assemble the machine, and has reduced the number of components. No longer will Omega or its customers need to stock various sensors and pneumatic parts, which have now been replaced by the intelligent actuator.

“Before it was just a continuous motion, 0-50 inches/second,” said Shendge. “Now we can accelerate or decelerate the machine. This is critical, (because) when (you’re) dealing with some of the unusual shapes and heavier mass of some products, you can’t just thrust them through the machine at top speed. You can damage the machine as well as the product.” Additionally, changeover time between products has decreased, since the machine can be programmed to adjust to various products through recipe-driven settings that are specific for each product’s handling needs, and thus, accommodate alternative package shapes. “Plus,” said Shendge, “we can take the feedback from this intelligent motion and use it to improve the overall operation of the machine.”

MARKETS

- Our extensive experience in designing and manufacturing motion control products and systems around the world, combined with an in-depth knowledge of related applications and industries makes us an invaluable resource and partner for your next project. We have successfully developed DC motors and linear solutions over the past 80 years and have built a reputation upon our ability to deliver high quality products to our customers exact requirements. Whether it’s a miniaturized solution for low-noise patient care equipment, or an application for a clean-room semiconductor environment, Haydon Kerk Pittman has consistently met your critical needs.

Medical Equipment

- We develop solutions for demanding medical applications. Whether a Home Healthcare CPAP or complex Robotic Surgical System, Haydon Kerk Pittman can deploy a solution designed to your program requirements. We offer lube-free systems for clean, maintenance free operation; specialty materials for radiation, autoclaving and chemical environments; smooth and quiet operation for patient facing applications; and miniature and micro product designs for precision fluid pump and drug delivery systems.

Industrial Automation

- We have a considerable footprint into industrial applications and automation due to the wide variety of linear and rotary solutions from 1 – 2000 Watts of output performance. Large bearings, special lubrication, environmental sealing, corrosion resistance, and integrated drives are just some of the features we can employ to insure repeatable motion with high reliability in challenging environments. Look to Haydon Kerk Pittman for a single source of supply in linear and rotary motion components and complete systems.

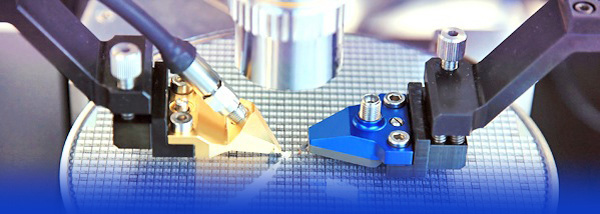

Laboratory Instrumentation

- Haydon Kerk Pittman has developed motion control systems used in: multi-axis sample management systems requiring high performance and reliability to meet high duty cycle requirements; microscopy stages demanding high precision positioning in multiple axis simultaneously; motion systems for automatic pipetting which requires very accurate motion for aspiration and dispense modes helping to eliminate manual pipetting errors.

Semiconductor

- The semiconductor industry faces continuous pressure to reduce device size and costs while improving performance and reliability. Semiconductor, test and assembly automation manufacturers demand the same improvements from the motion technology which drives it. Haydon Kerk Pittman continues to develop new technologies in motors, lead-screws, gears, encoders, actuators, slides, drives and complete sub-systems that increase operational speeds and accuracy while lowering the cost of ownership.

Transportation

- The use of automation and advanced motion solutions are opening up new applications in Transportation for Haydon Kerk Pittman. Convenience, safety, and increased performance are some of the factors driving demand for advanced motion. Motorized active suspension systems improve vehicle performance and driver comfort. Seed planting systems using both rotary and linear motion help farmers maximize field density and yield. Linear automation in bike rental kiosks provides city dwellers a convenient and a healthy form of transportation while providing urban planners solutions to city challenges. Haydon Kerk Pittman provides motion solutions in these and many other transportation applications.

Business Machines

- Innovation in 3D Printing, Automated Lighting, Mobile Communications, Commercial Printing and other industries is driving demand for linear actuators, lead screws and rails as well as DC motors. Haydon Kerk Pittman’s diverse product range and technology often makes it the preferred single source supplier of components or custom sub-systems. Whether you choose stepper, DC brushed or brushless technology as part of your rotary or linear mechanism, Haydon Kerk Pittman can provide the optimum solution.