- Offer Profile

-

Drivers of innovation in mechatronic drive technology

WITTENSTEIN develops, produces and sells customized products, systems and solutions for highly dynamic motion, maximum-precise positioning and smart networking for mechatronic drive technology.

It is our unique capacity for innovation that drives us to further develop the essential technology for electromechanical drive systems and pioneer new areas of application. An example of this is the revolutionary Galaxie drive system, honored with the prestigious Hermes Award at the 2015 Hannover Trade Show.

Servo gearboxes

-

Maximum precision and dynamics, combined with exceptional torque density, are the key requirements specified for reliable servo gearboxes in practice. WITTENSTEIN alpha offers servo gearboxes for any application and any performance range. Our low-backlash planetary and right-angle gearboxes reflect our passion for innovation and the highest levels of precision.

Our sizing tools help you achieve the optimal design for a complete drive train including servo gearboxes from WITTENSTEIN alpha.

CP planetary gearbox

- Geared up to Fit

Tailored to applications in the mid-range and economy segment with low to medium requirements for positioning accuracy, the CP planetary gearbox do not fail to impress. The key benefits offered by the gearboxes are high flexibility combined with maximum efficiency.

CPS planetary gearbox

- Geared up to Fit

The CPS planetary gearbox is doubly convincing with two different output variants: the flange attachment for B5 mounting enables increased forces to be transmitted while the long centering results in reduced installation space and maximum compactness.

This gearbox also offers maximum efficiency for applications in the mid-range and economy segment with its unbeatable value for money.

LPB+ planetary gearboxes

- Economical multitalent

Low backlash planetary gearbox with output flange or belt pulley combines maximum quality with economical precision. The LPB+ is especially suitable for compact belt drives.

NP planetary gearbox

-

Individual Talents

The alpha Value Line is universally suitable and represents the most economical solution whatever the requirements. For example, the NP planetary gearbox is ideal for all mid-range applications requiring an output shaft.

NPS planetary gearbox

-

Individual Talents

The proven output geometry of our best-selling SP+ has been adapted to the NPS and is now also available in the Value segment. This planetary gearbox also enables transmission of higher external forces.

NPL planetary gearbox

-

Individual Talents

The NPL’s reinforced bearing and B14 output geometry are the highlights of this planetary gearbox. As a member of the alpha Value Line, this product is also unbeatably efficient in operation.

NPT planetary gearbox

-

Individual Talents

The NPT planetary gearbox with output flange is based on the familiar output geometry of the TP+ gearbox. And with the HIGH TORQUE version, a product offering maximum power density is now also available in the Value segment.

NPR planetary gearbox

-

Individual Talents

The NPR planetary gearbox, another member of the alpha Value Line, is designed for applications with average demands in terms of positioning accuracy. The NPR particularly impresses with its slotted holes in the output flange and is perfect for rack and pinion mounting.

NTP planetary gearbox

-

Qualified for more Value

The NTP planetary gearbox with output flange uses the familiar output geometry of the TP+ gearbox. The reinforced roller bearings on the output allow very high external forces. Coupled with the new toothing and the backlash of ≤ 5 arcmin, the NTP offers unique performance parameters for this product segment.

HDV Hygienic Design planetary gearbox

-

Reliably clean

Low-backlash planetary gearboxes with an output shaft in Hygienic Design. Reliable and efficient cleaning of the gearbox is a key feature of the gearbox series developed in accordance with EHEDG guidelines. The new concept gives designers unprecedented degrees of freedom to develop machines that meet the most exacting requirements for hygienic and sterile production processes.

SP+ planetary gearbox

-

The classic all-rounder

The standard version of these low-backlash planetary gearboxes with output shaft is ideally suited for high positioning accuracy and highly dynamic cyclic operation. The SP+ HIGH SPEED is particularly well suited for applications with maximum speeds during continuous operation.

TP+ planetary gearbox

-

Compact precision

Compact top performers with output flange. The standard version is ideally suited for high positioning accuracy and highly dynamic cyclic operation. The TP+ HIGH TORQUE is particularly well suited for high-precision applications in which high torsional rigidity is required.

HDP+ Hygienic Design planetary gearbox

-

Reliably clean

Sterile, highly dynamic and outstanding positioning accuracy – the HDP+ meets the strict hygiene requirements of production and packaging facilities. The gearbox in Hygienic Design not only offers you maximum safety against contamination-related product and process risks, but also guarantees maximum system availability and productivity.

DP+ Planetary gearboxes for Delta robots

-

The right solution for all requirements

The DP+ planetary gearbox is designed especially for Delta robot applications. Several different versions are available for use in dry and spray areas. Apart from an optimized sealing system, this drive solution provides numerous benefits such as the higher dynamics in the version with an optimized moment of inertia.

XP+ planetary gearbox

- Perfection in new dimension

The XP+ with specially designed output and extremely compact design offers new dimensions in power transmission that far exceed industry standards. The XP+ impresses with the highest torque density in the market – coupled with maximum torsional rigidity and titling moment capacity,

- Shorter cycle time because acceleration is maximized

- Higher permissible masses and process forces

- Smoother running and higher repeatability

- Implementation of high precision linear systems

- Installation space savings through downsizing

Servo right-angle gearboxes

CPK bevel gearboxes

-

Geared up to Fit

Economically around the corner. The CP bevel gearbox with output shaft of the alpha Basic Line is specially designed for applications with medium requirements for positioning accuracy. The extremely compact bevel gear stage enables use in applications with space constraints.

CPSK bevel gearboxes

-

Geared up to Fit

The CPSK bevel gearbox with output shaft is available both with long centering and with a replaceable B5 output flange. These two output options open up new opportunities for machine design in applications with medium requirements for positioning accuracy.

CVH worm gearbox

-

The quiet endurance runner

The servo worm gearbox CVH of the V-Drive Basic family with hollow shaft. The gearing of this gearbox was specifically developed to minimize the noise level in S1 operation. It also convinces with optimal value for money and short delivery times.

CVS worm gearbox

-

The quiet endurance runner

The CVS worm gearbox of the V-Drive Basic family features an optimized output bearing tailored to the most diverse areas of application. Due to a very long operating noise together with a top price/performance ratio, this gearbox is particularly suitable for continuous operation.

LPBK+

- Economical right-angle precision

LPBK+ − Low backlash right-angle gearboxes with output flange for economical applications – especially for belt drives.

NPK bevel gearboxes

-

Individual Talents

An extremely compact and high-performance bevel gear stage, an elegant design and unbeatable efficiency in operation are excellent arguments for the NPK bevel gearbox.

NPSK bevel gearboxes

-

Individual Talents

The NPSK bevel gearbox combines our SP+ output geometry with an elegant and compact angular stage. An economical purchase and a high level of efficiency speak for the NPSK.

NPLK bevel gearboxes

-

Individual Talents

The highlights of the NPLK bevel gearbox are a reinforced bearing and the B14 output geometry for the transmission of higher forces. The extremely compact design of the angled step enables use even in very restricted installation spaces.

NPTK bevel gearboxes

-

Individual Talents

NPTK – the bevel gearbox with output flange and high efficiency. The compact design of the angled step enables use even in very restricted installation spaces. Together with the flange based on the TP + planetary gearbox and a flexible motor connection, this results in new design freedom.

NPRK bevel gearboxes

-

Individual Talents

The NPRK bevel gearbox of the alpha Value Line impresses with its slotted holes and is therefore a perfect solution for rack and pinion mounting.

NVH worm gearbox

-

Economical servo worm

Low backlash servo worm gearbox with hollow shaft. The NVH of the V-Drive Value-family impresses with its high power density and medium torsional backlash. It is especially suitable for economical applications in continuous operation.

NVS worm gearbox

-

Economical servo worm

The NVS servo worm gearbox with output shaft is the perfect choice for both cyclic and continuous operation. The gearbox has a constant low backlash over the entire service life and affords consistent high quality with high positioning accuracy.

Special gearboxes

- We are the perfect partner for special gearboxes that go beyond the standard such as customized planetary, spur or bevel gearboxes. For special requirements such as HIGH SPEED, LOW NOISE or HIGH TORQUE, we develop optimal customer solutions thanks to our many years of experience. From the initial prototype to series production, all our special gearboxes can be manufactured in-house.

Special gearboxes

- The best, not the rest

For unusual ideas standards do purely not exist. Therefore you won’t find our special gearbox solutions in any catalogue. Being part of the WITTENSTEIN group, the solution provider for mechatronic drive systems, we provide individual gear unit solutions with high focus on the complete drive train system. Our strength is the close relationship between engineering, manufacturing and assembly concentrated at our “urban production” in Fellbach. Our manufacturing opportunities range from prototypes, small-scale production up to series. WITTENSTEIN alpha offers extended expertise for high-speed gearing technology for up to 100.000 rpm, high torque and low-noise optimization.

Servo actuators Rotary - servo actuators

axenia value – servo actuator in Hygienic Design

-

Built to protect

The compact axenia value servo actuator was specially developed and produced for challenging applications according to EHEDG guidelines. It provides decisive improvements in process and machine reliability as well as availability. It is made from highly resistant stainless steel and therefore enjoys long-term resistance to numerous aggressive cleaning agents and disinfectants. The dynamic combination of planetary gearbox and servo motor offers reliably scaled performance data for various maximum surface temperatures.

TPM+ DYNAMIC rotary servo actuators

-

Dynamic. Shorter. Quieter.

Experience extraordinary dynamics thanks to modern motor technology with high power density, a low moment of inertia and optimal torsional rigidity. Benefit from the reduced installation length: The coupling-free connection integration of the motor and gearbox and the space-saving attachment of motor instruments make the TPM+ DYNAMIC over 50% more compact than conventional gearbox motors. Helical-toothed precision planetary gearboxes ensure low-vibration and silent operation.

TPM+ HIGH TORQUE rotary servo actuators

-

Stronger. More compact. Higher torsional rigidity.

This servo actuator takes you even further: with 50% more torque and improved performance. Even better power transmission due to the more rigid drive train offers higher acceleration and shorter cycle times. Effectiveness from which you benefit. An additional planet in the gearbox significantly increases the torsional rigidity of the particularly short and light servo actuator. The coupling-free integration of the motor and gearbox and the efficient attachment of motor instruments are the formula for success.

TPM+ POWER rotary servo actuators

-

Stronger. More compact. Quieter.

Generate more power: More torque, high performance. This perfect combination of motors and efficient planetary gearboxes makes light work of even the most difficult motion applications. 40% more compact due to the coupling-free integration of the motor and gearbox and the efficient attachment of motor instruments. Shorter installation length for greater flexibility when mounting. Helical-toothed precision planetary gearboxes for extremely quiet and low-vibration operation reduce operating noise to a minimum.

SPM+ / TPM+ endurance

-

Stronger – shorter – cooler

Actuators with water cooling for maximum efficiency, high power density and minimum cycle times. Thanks to a flexible modular system, various gearboxes can be integrated in a manner tailored to the motors. The highly compact design opens up numerous possibilities in terms of construction: smaller machinery thanks to maximum power density.

premo® SP Line rotary servo actuators

- The entry level class

- Especially suitable for positioning tasks

- Short cycle times

- Special benefits with moving axes: the low weight and short overall length

- Mechanical interface with output shaft

- Ideal for connecting couplings, toothed belt pulleys and pinions

- In addition to the smooth shaft version, key and splined shaft versions are also available

- Electric interface with resolver as standard

premo® TP Line rotary servo actuators

- The dynamic class

- Perfect for challenging positioning and processing tasks

- Minimal backlash and maximum torsional rigidity allow for the shortest cycle times and excellent surface finish

- Mechanical interface with output flange

- Ideal for connecting lever arms or pinions

- Electric interface with HIPERFACE® singleturn absolute encoder for high positioning accuracy as standard

- Optionally extendable with all available encoders and connector versions

premo® XP Line rotary servo actuators

-

The extra class

- Particularly high power density and load capacity

- Extremely low backlash, high torsional rigidity and maximum load capacity of the output bearings enable a highly compact servo actuator platform for enhanced machine performance

- Mechanical interface with output shaft, ideal for connecting couplings or pinions

- In addition to the smooth shaft version, key and splined shaft versions are also available

- Electric interface with HIPERFACE DSL® singleturn absolute encoder as standard incl. functional safety and single-cable connection

Linear systems

Value Linear Systems

-

Flexible all-rounder in the Value Segment

Our Value Linear Systems are tailored to linear applications in the Value Segment with comparatively low smooth running, positioning accuracy and feed force requirements. More degrees of freedom can now be achieved in design thanks to the R-flange adapted from the premium segment. Typical applications in woodworking machinery, plasma cutters and automation.

Advanced Linear Systems

-

Strong performance in the Advanced Segment

These systems are adapted to applications with medium to high smooth running, positioning accuracy and moving force requirements. They simultaneously ensure compliance with increased statutory requirements regarding machine safety. Different gearbox variants and options, such as HIGH TORQUE or HIGH SPEED, are your guarantee of the perfect system whatever the application. The systems are suitable for use in processing equipment for wood, plastic and composite materials as well as in machining centers or automation solutions.

Premium Linear Systems

-

Perfection in use

Our Premium Linear Systems are optimized for applications with high to very high smooth running, positioning accuracy and moving force requirements. They combine drives producing maximum power density with very high overall linear stiffness – as well as extreme precision, both in the decentralized drive and in the master-slave configuration, for unprecedented degrees of freedom in the design. The option of downsizing moreover results in significant potential savings in the drive train. The systems are suitable for use in laser machines, CNC machining centers for wood, plastic and composite materials, metal-cutting machine tools such as HSC milling machines and precise, highly dynamic handling applications.

Systems with straight toothing

- Know-how of linear technology for rotary applications

Applications for gearboxes with a straight-toothed output pinion can be found where smooth operation has a low priority, axial forces generated by helical teeth should be prevented, or a straight-toothed mating is already chosen. We offer an extensive portfolio for such applications. Depending on the requirements regarding positioning accuracy and feed force one can choose between a variety of alternative solutions for the segments Value, Advanced and Premium.

Racks and pinions

Racks

-

The suitable rack for every requirement

Needless to say, finding the appropriate rack is an essential component in realizing your machine concepts. You are guaranteed to find the perfect rack in our portfolio. You can select the ideal rack for your application, depending on your demands in terms of smooth running, positioning accuracy, feed force and ease of installation.

Pinions

-

A pinion perfectly suited for any application

Our preferred linear systems already offer the ideal pre-selection of pinions in terms of smooth running, positioning accuracy and feed force – matched with the gearbox and rack. Furthermore, an additional wide selection of different variants are available. cymex® 5 gives you the option of selecting the perfect pinion.

Accessories for linear systems

LUC+400 – lubricator

-

Optimum lubrication for a perfect system

To maximize machine service lives you need proper lubrication. The LUC+400 lubricator supplies the lubrication points with a precise quantity of lubricant, depending on your requirements.

- Fully integrable into the machine control system with pulse control and 24 V power supply

- Use of replaceable cartridges

- Designed for use with a splitter, progressive distributor and lubrication pinion.

LUC+125 – lubricator

- Optimum lubrication for a perfect system

Proper lubrication maximizes the service life of the products you use. The LUC+125 lubricator supplies the lubrication points with a precise quantity of lubricant, depending on your requirements.

- Minimum quantity lubrication

- Various control options:

- Pulse control - 24 V

- Time control and 24 V (optionally with battery)

- Replaceable cartridges

- Ideal for use with a splitter, progressive distributor and lubrication pinion.

LMT-Lubrication pinion

-

Optimum lubrication for a perfect system

Since high feed forces are generated with a rack and pinion drive, the open toothing must be lubricated to prevent damage. During relubrication with the PU lubrication pinion, the lubricant is continuously and automatically applied to the toothing. Lubricant is supplied as needed via a lubricator, e.g. LUC+125/400.

LUP-Progressive distributor

-

Optimum lubrication for a perfect system

The use of distributor systems ensures that the lubricant is distributed from the lubricator to several lubrication points. As a result, complete machines can be supplied centrally, with just one lubricator.

LUS-Splitter

- Optimum lubrication for a perfect system

Distribution systems are used to distribute the lubricant supplied by the lubricator to a number of lubrication points. As a result, complete machines can be supplied centrally via one lubricator. Depending on the requirements regarding the distribution system, splitters or progressive distributors can be used.

Servo motors - Rotative synchronous motors

- WITTENSTEIN cyber motor develops and produces technologically advanced servo motors with maximum power density. Our product know-how encompasses rotative and linear synchronous servo motors as well as servo actuators. Our expertise is in specialized motors for extreme conditions like ultra-high vacuums, radioactive environments or high temperatures.

cyber® dynamic motor – brushless servo motors

-

dynamic – high torque – efficient

cyber® dynamic line servomotors are the smart choice for limited space applications. These stainless steel housed motors are equipped with absolute feedback (Singleturn and Multiturn) and deliver unparalleled performance, reliability and value from the smallest package. The motors can be optionally extended with a holding brake in Inox- and Hygienic design, planetary gearboxes or ball screws.

cyber® kit line small – frameless servo motors

-

high torque – highly integrated – flexible

The frameless servo motors of the cyber® kit line product family offer maximum torque and flexibility in a compact size. In additional, the frameless design with small and large hollow shaft gives the maximum possible freedom of integration to develop unique solutions for specific applications. The cyber® kit line assembly kit consisting of rotor and stator can be flexibly integrated into the machine thanks to the variety of variants.

cyber® kit line medium – frameless servo motors

- flexible - high torque - highly integrated

The frameless servo motors of the cyber® kit line product family offer maximum torque and flexibility in a compact size. In additional, the frameless design with a small and large hollow shaft gives the maximum possible freedom of integration to develop unique solutions for specific applications.

cyber® kit line large – frameless servo motors

-

high torque – highly integrated – flexible

The frameless servo motors of the cyber® kit line product family offer maximum torque and flexibility in a compact size. In addition, the frameless design with a large hollow shaft gives the highest possible freedom of integration to develop unique solutions for specific applications. The assembly kit, consisting of rotor and stator, can be flexibly integrated into the machine thanks to the variety of variants.

cyber® kit motor – frameless servo motors

- compact – dynamic – highly integrable

cyber® kit motors offer the ultimate performance and flexibility in a compact size. Stator and rotor kits give the design engineer the highest degree of integration freedom to develop unique solutions for application specific needs.

cyber® power motor

-

powerful – compact – easily maintained

The cyber® power motors are high-performance servomotors, which are characterized by their outstanding power-to-weight ratio and their efficiency.

When throughput matters the most, the ability of servomotors to accelerate faster is often the limiting factor. Our cyber® power motors can be designed with an ultra low rotor inertia, which allows for much faster acceleration rates than traditional servomotors.

Linear actuators

cyber® force line – linear actuators

- efficient – precise – highly integrated

The electromechanical linear actuators of the cyber® force line are the ideal solution for applications that require high precision, force and speed. The actuators impress with their high efficiency and maximum power density. They also ensure fast and precise throughput rates in the production process.

The compact linear actuators enable simplified integration and flexibility within the machine design. All this ensures a significant reduction in overall operating costs and represents an advantageous alternative to pneumatic and hydraulic solutions.

cyber® dynamic actuator L with ball screw

-

dynamic – high torque – efficient

The linear actuators in the cyber® dynamic line are ideally suited for precise and flexible position control. As servo motors with an integrated ball screw, they represent an energy efficient and maintenance free alternative to pneumatic cylinders. The version with a closed pushing rod as well as a built-in linear guidance and anti-rotation mechanism forms a very compact unit. Optionally, the motors can be extended with a holding brake (size 40) in Inox and Hygienic design.

cyber® force actuator – linear actuators

-

reliable – compact – precise

cyber® force motors integrate a precision ball or planetary screw directly into a brushless servo motor for a uniquely compact package with flexible mounting options. The resulting linear servo actuator is reliable, durable, precise and delivers excellent dynamic performance.

Special motors

cyber® hightemp motor – High temperature motors

-

reliable – long life – efficient

These brushless servo motors for high temperature environments provide outstanding reliability, long lifetime and the highest efficiency. They withstand ambient temperatures up to 260°C and pressures up to 2,100 bar in the presence of extreme shock and vibration.

cyber® radhard motor – Motors for radiation environment

-

reliable – precise – compact

These brushless servo motors for the nuclear industry provide outstanding reliability and precision in the most challenging radiation environment. Featuring a high-grade stainless steel housing and specialized materials, they perform reliably in fields up to 5 Mrad/hr with a service life up to 5 MGy total ionizing dose.

cyber® vacuum motor – Motors for vacuum environment

-

reliable – low outgassing – efficient

These brushless servo motors provide outstanding reliability and performance in the high vacuum environment. Featuring a high-grade stainless steel housing and specialized materials chosen to eliminate outgassing, they significantly reduce pump down cycle time in vacuum at pressures down to 10-8 mbar and ambient temperatures up to 200 °C.

Galaxie®

Galaxie® D

-

Galaxie® D is a hollow-shaft compact drive with integrated synchronous motor and same characteristics as gearbox version: zero backlash with highest torque density, torsional rigidity and positioning accuracy with compact integrated synchronous motor.

Advantages

- Highest torque density

Extreme torsional rigidity - Hollow shaft for efficient media supply

- Complete freedom from maintenance

- Improved synchronization accuracy

- Robust and precise output bearing

- Zero backlash

- Highest torque density

Galaxie® G

-

Galaxie G® is a backlash-free gearbox with optional inline planetary input stage and adapter plate for mounting on standard industrial servo motors.

Configurable zero backlash gearbox with optional planetary pre-stage and motor mounting adapter plate

Advantages- Highest torque density

- Extreme torsional rigidity

- Completely maintenance free

- Improved synchronization accuracy

- Robust and precise output bearing

- Zero backlash

- Easy integration

Galaxie® GS

-

The Galaxie® GS is a compact, configurable, zero backlash gearbox with hollow shaft and input drive flange.

Advantages

- Configurable gearbox

- Highest torque density

- Extreme torsional rigidity

- Maintenance free

- Improved true running

- Robust and precise output bearing

- True zero backlash

- Easy integration into machine design

Galaxie® GH

-

Galaxie GH® is a right-angle gearbox with hypoid input stage and adapter plate for mounting on standard industrial servo

motors.Advantages

- Highest torque density

- Extreme torsional rigidity

- Completely maintenance free

- Improved synchronization accuracy

- Robust and precise output bearing

- Zero backlash

- Easy integration

Galaxie® gearbox miniaturized

-

The most compact hollow-shaft gearbox with the highest torsional rigidity

With the miniaturized Galaxie®, we have taken the functional principle of our classic Galaxie® a step further. The result: innovative kinematics enabling almost full surface contact during power transmission – with an extremely compact footprint. Thanks to this unique concept, the miniaturized Galaxie® performs significantly better than established gearbox types with the same diameter in almost all dimensions. It combines the highest levels of rigidity, torque density and overload capacity with a very large hollow shaft and maintains zero backlash throughout its entire service life.

Galaxie® actuator miniaturized

-

Probably the most compact hollow shaft actuator with the highest rigidity

The highest levels of torque density and rigidity, excellent dampening properties, zero backlash and the largest hollow shaft – all of this is combined in the new miniaturized Galaxie® actuator from WITTENSTEIN SE, probably the most compact, all-in-one servo drive system of its kind. Thanks not least to its special overload capacity and torsional rigidity, it is perfect for surgical and high-precision robotics. The actuator’s performance parameters and features are individually configurable depending on the desired task – for instance the motor sizing, brake, connection to the application, power supply, electrical connection and feedback system – and it is also easy to integrate.

Gearing

- When it comes to gearing, WITTENSTEIN alpha stands for the highest levels of development and manufacturing expertise. We manufacture spur gears with external or internal teeth for you as well as bevel gears with spiral or hypoid teeth in ground design – from the initial prototype to series production. Our strength is the close relationship between engineering and manufacturing. We will also be happy to implement your customized gearing solutions.

Bevel gears

-

Precision around the corner

Bevel gears by WITTENSTEIN alpha are all about maximum precision, load-bearing capacity and smooth running. We develop and manufacture spiral and hypoid bevel gears in milled or ground designs – in the closed-loop of our high-precision production system. In addition to this, we have accrued years of expertise in the areas of bevel gear design, optimization and testing. For special applications, we supply DIN Q1 in series production.

Spur gears

-

A perfect mesh of expertise

Spur gears by WITTENSTEIN alpha are known and prized the world over.

We offer a complete range of different geometries, production processes and quality levels – as a recognized system supplier for high-speed, low-noise and high-torque applications.

We also boast exceptional expertise in spur gears in ground designs for prototype and series applications.

Gearing solutions

- Innovation plus performance

As a company in the WITTENSTEIN group, we are at home in all areas of application for smart, controllable drive systems. We implement all key production steps related to drive, control and regulation technology in-house. Our customers includes companies in sectors such as machine construction, robotics technology, aerospace, automotive, motor racing, etc.

We tailor the properties of the gearing to our customers' needs: torque, motor speed, running noise, displacement sensitivity and rotary transmission are all arranged according to your specifications. Thanks to maximum consistency in gearing quality, we can guarantee reliable solutions.

Internal gearing

-

A tooth for a tooth – quality from within

Internal gearing by WITTENSTEIN alpha: Whether you need straight, helical or bevel gearing, we can provide you with the full range of high-precision internal gearing. All under one roof, including thermal treatment, and in different production processes and quality levels. Please contact us.

Servo systems

SSEAC® electrical subsea actuator

-

Safety, reliability and competence

Redundant AC servo drive for operation in oil for pressure compensation. In combination with the modular electronics, our drive systems are suitable for long-term use under pressure at depths of up to 3000 meters. The SSEAC® can actuate choke, gate and ball valves as well as high integrity pressure protection systems (HIPPS) and chemical injection metering valves (CIMV).

Subsea servo systems for the oil and gas industry

-

Safety, reliability and competence

Integrated systems under one roof: perfectly tailored components for the regulation and control of your movements. We are specialists in power and signaling electronics for high-voltage and low-voltage applications.

Integrated system solutions

cyber® dynamic system – drive system

-

connective – compact – dynamic

The industrial drive system cyber® dynamic system offers maximum connectivity thanks to its multi-ethernet interface and scores with decentralized intelligence. The inertia-optimized motors and high current resolution also ensure highly dynamic and precise movements. The system is the professional choice for decentralized applications in demanding environmental conditions with limited installation space. This system is optionally available with various encoder variants as well as planetary gearboxes, ball screw and holding brake.

cyber® iTAS® system 2 – servo drive system for AGV / AMR

-

safe – compact – simple

The cyber® iTAS® system 2, consisting of a servo drive and actuator, combines a lean and integration-friendly safety architecture with maximum power density. This gives the AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots) a decisive gain in performance and increases productivity. The system design of the differential drive system with an integrated brake and wheel also impresses with its industrial simplicity, which minimizes commissioning and service costs in the long term. Benefit from all these advantages in the development of Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs).

cyber® iTAS® system

-

- Size 004 - 050

- DC bus voltage 24 - 48 VDC

- Max. feed force 380 - 5200 N

- Continuous feed force up to 2,6 m/s

- Optional: dynamic brake, additional encoder for speed control, wheel

Control Loading Systems for simulators

Inline Solution

-

Control Loading Systems – Active Force Feedback Systems

The WITTENSTEIN turnkey inline electromechanic control loading solutions drive the pilot controls via mechanical linkages and provide a compact and integrated actuator, sensor and software system for all levels of simulators. A range of actuators is offered to drive the pilot control linkages directly with inline or flange mounted force sensors. Many inline solutions are in operation for fixed and rotary wing applications like Boeing 707, EC135/635 or AW139. A special version of the inline solution was developed for General Aviation applications. WITTENSTEIN delivers the Control Loading Systems for DA40/42 (FTD Level 5 and 6 simulators).

Drop-In Solution for Helicopter Simulators (rotary-wing)

-

Control Loading Systems - Active Force Feedback Systems

The RHMT (Re-configurable Helicopter Mission Trainer) is an integrated control loading system incorporating a variety of WITTENSTEIN simulation components. The configuration allows users to create a system using any combination of cyclic centerstick, collective lever with aircraft type specific grips and directional pedals to meet unique requirements. The AVCATT (Aviation Combined Arms Tactical Trainer), an example for a rotary wing system, is a mission training and rehearsal device used by the US Army. Various types of helicopters can be simulated. The system recognizes the sticks and grips and reconfigures itself via software to represent the aircraft type.

Drop-In Solution for Aircraft Simulators (fixed-wing)

-

Control Loading Systems – Active Force Feedback Systems

The RAMT (Re-configurable Aircraft Mission Trainer) is an integrated control loading system incorporating a variety of WITTENSTEIN simulation components. The configuration allows users to create a system using any combination of sidestick, centerstick, linear throttle, rotary throttle, rudder pedals, and other devices to meet unique aircraft requirements. Each system includes the WITTENSTEIN System Control Module (SCM), the Aktiv8© control software, System Power Supply (SPS) and appropriate cabling. The WITTENSTEIN Aktiv Toolkit Graphical User Interface can also be added to provide system set-up and diagnostic capabilities.

Servo systems for aviation applications

Flight Control System - Active Sidestick

-

MGSSA (Motor Gearbox Sensor Spring Assembly) for Supersonic Aircraft

The T-50 Golden Eagle is a family of supersonic advanced trainers and multirole fighters. WITTENSTEIN provides the electromechanical and sensing elements of the aircraft's active sidestick consisting of motor-gearbox units, the mechanical backup system and triple redundant position sensors for each axis, packaged in a highly compact mechanical arrangement. WITTENSTEIN also provides the design of the motor control electronics and software together with the know-how for force feel control. This aircraft family is the first to be equipped with active sidesticks in series production.

Cargo Loading Systems

-

A380 PDU (Power Drive Unit)

The PDUs are located in the cargo compartments of the A380. The main role of the PDUs is to provide adequate traction under all environmental conditions to move air freight pallets and containers into and out of the cargo compartment. Self-erecting PDUs are equipped with two separately acting AC servo motors. The first motor provides the necessary traction force and the second motor provides the lift function to positively engage or disengage the drive. Spring loaded PDUs are mounted between the roller tracks in order to move the pallets within the cargo compartment.

Canard actuation system for rockets and space vehicles

-

Canard Actuation System

The Canard Actuation System is a position controller for the canard control surfaces of rockets and space vehicles. This electro-mechanical actuation system with electronics must withstand enormous accelerations and temperatures, 80g and 900°C. It represents an entirely new concept in highly integrated compact electro-mechanical drives. The new galaxie gearbox technologies provide unprecedented torque and speed to the space industry. A system was developed for the SHEFEX II program conducted by the DLR (German Aerospace and Space Center) to investigate new re-entry technologies focusing on new heat shield designs for protection against high temperatures.

Servo drives

cyber® simco® drive 2 – servo drive

-

connective – intelligent – safe

In combination with various servo motors and servo actuators, cyber® simco® drive 2 is the ideal solution for fast and precise moving and positioning tasks. With a continuous output of up to 5 kW and a short-term peak output of 10 kW, the servo drive is suitable for high-precision applications, e.g. automated guided vehicles or packaging industries – as a switch cabinet version with protection class IP20 or decentralized version with protection class IP65.

cyber® simco® drive 1 – servo drive

- connective – intelligent – safe

In combination with various servo motors and servo actuators, cyber® simco® drive 1 is the ideal solution for fast and precise motion and positioning tasks as well as mobile applications. With a continuous output of up to 2.5 kW and a short-term peak output of 5 kW, the servo drive with protection class IP20 is suitable for use in automated guided vehicles or in control cabinets.

cyber® power drive

-

Compact and modular – powerful and flexible – smart and safe

The cyber® power drives by WITTENSTEIN cyber motor are a complete product line of compact motor drives with highest power density. The motor drives offer the controlled operation of synchronous machines in applications with DC supply voltage up to 750 VDC and provide a maximum output power of up to 250 kVA.

Control and power electronics for the oil and gas industry

-

Safety, reliability and competence

Control and Power Electronics for AC Servo Motors with Resolver Specifications: Current output: 15 A peak, 6A nominal Supply voltage: 320 VAC ... 480 VAC Interface: CAN open / 3p 400 VAC Dimensions: 11.81 x 9.84 x 3.15'' Weight: 8.82 lb Operating temperature range from -22° F to +158° F

Sizing software

- The engineers at WITTENSTEIN alpha have fundamentally redesigned the cymex® sizing software. The result is a sizing tool that sets benchmarks in every respect. Thanks to cymex® 5, the entire drive train can now be dimensioned and designed faster, more easily and more reliably than ever before. After downloading the software, you can design optimally sized and more efficient motors by abstracting all important influencing factors.

cymex® 5 – The new sizing software

-

Calculate on the Best

WITTENSTEIN alpha’s engineers have fundamentally redesigned the cymex® sizing software. The result is a sizing tool that sets benchmarks in every respect. Thanks to cymex® 5, the entire drive train (application + transformation + gearbox + motor) can now be sized and designed quicker, more easily and more reliably than ever before. Its calculations are considerably simplified by predefined standard applications. Optimally sized and more efficient motors are achieved by abstracting all important influencing factors.

Nanoprecise interferometry solutions

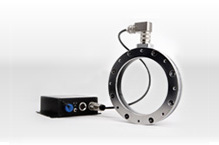

IDS3010

-

Pico-precise three-axes displacement sensor IDS3010

The IDS3010 is an ultra-compact interferometric displacement measurement sensor equipped with three fiber-based sensor heads. It is perfectly suited for machine integration and compatible with various industrial networks. Due to an integrated webserver, the sensor can be aligned, initialized and (re-)configured remotely at any time. Unmatched technical specifications top off the system performance: The IDS3010 provides a data acquisition bandwidth of 10MHz at a subatomic resolution of 10-12 m. Despite its exceptional sensitivity, the sensor reaches working distances of up to 5 meters and is capable of tracking target velocities up to 2 m/s.

Piezo drives

Linear Piezo Drive ECSx5050

-

Linear Piezo Drive ECSx5050

The ECSx5050 is the drive with the largest footprint of attocube's Industrial Line. It provides high-resolution positioning over a travel range of 30 mm. Its high guiding accuracy is achieved with crossed roller bearings.

Linear Piezo Drive ECSx3080

-

Linear Piezo Drive ECSx3080

The ECSx3080 provides high-resolution positioning over a travel range of 50 mm. Its high guiding accuracy is achieved with crossed roller bearings.

Linear Piezo Drive ECSz5050

- The ECSz5050 piezo drive has been developed for vertical positioning tasks and offers a drive force of up to 8N. Its high accuracy is achieved with crossed roller bearings.

Linear Piezo Drive ECSz3030

- The ECSz3030 piezo drive has been developed for vertical positioning tasks and offers a drive force of up to 8N. Its high accuracy is achieved with crossed roller bearings.

Monolithic Piezo Drive ECSxy5050

- The ECSxy5050 piezo drive has been developed for XY positioning tasks. The monolithic design in combination with crossed roller bearings offers highest guiding accuracy.

Nanoprecise Rotator ECR5050

- The ERC5050 enables precise 360° endless rotation of samples in both directions. With a xy- stack of ECS5050 it provides space efficient sample positioning.

Nanoprecise Rotator ECR4040

-

Nanoprecise Rotator ECR4040

The ECR4040 enables precise 360° endless rotation of samples in both directions. With an integrated 1/2" aperture it is the instrument of choice for all optical experiments.

Nanoprecise Rotator ECR3030

-

Nanoprecise Rotator ECR3030

The ERC3030 enables precise 360° endless rotation of samples in both directions. It is compatible with any of the other ECS positioners. With a xy- stack of ECS3030 it provides space efficient sample positioning.

Nanoprecise Goniometer ECGp5050

-

Nanoprecise Goniometer ECGp5050

The ECGt5050 provides high resolution Θ-positioning over 10° range. Combined with the ECGp5050, the ECGt5050 forms the upper positioner of a powerful Euler Goniometer with a common center of rotation. It can be combined with a xy-stack of ECS5050 to add two more degrees of freedom to the motion of the sample.

Nanoprecise Goniometer ECGt5050

-

Nanoprecise Goniometer ECGt5050

The ECGp5050 provides high-resolution Φ-positioning over 10° range. Combined with the ECGt5050, the ECGp5050 forms the lower positioner of a powerful Euler Goniometer with a common center of rotation. It can be combined with a xy-stack of ECS5050 to add two more degrees of freedom to the motion of the sample.

Linear Piezo Drive ECSx3030

-

Linear Piezo Drive ECSx3030

The ECSx3030 has the smallest footprint of attocube's Industrial Line nano drives. It provides high resolution positioning over a travel range of 20 mm. For xyz-positioning, two ECS positioners are mounted on top of each other in perpendicular orientation and a third one is added with a L-bracket. Its high accuracy is achieved with crossed roller bearings.

Linear Piezo Drive ECSx3050

-

Linear Piezo Drive ECSx3050

The ECSx3050 provides high-resolution positioning over a travel range of 30 mm. Its high accuracy is achieved with crossed roller bearings.