PIV Drives GmbH

- Offer Profile

- The

outstanding reputation of PIV Drives in global markets is the result of more

than 80 years experience of providing quality power transmission solutions

that meet the needs of every sector of industry.

PIV Drives was a pioneer in developing modular concepts for its comprehensive product range, a far sighted initiative that is benefiting customers today, by providing the flexibility to deliver optimised power transmission solutions, both standard and bespoke, quickly with high levels of quality and at competitive cost.

Product Portfolio

Gearboxes and Industrial Variators

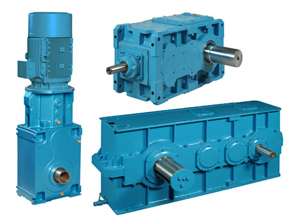

Parallel and Right Angle Gearboxes

- POSIRED 2 Parallel Shaft and Right Angle Gearboxes

Torque (T2 nominal): 1,000 up to 800,000 Nm

Transmission Ratio: 1.25 up to 710 iN

Power Rating: up to 4,400 kW

POSIRED N Parallel axis lifting gear with extended centre distance

Torque (T2 nominal): 8,000 up to 500,000 Nm

Transmission Ratio: 12.5 up to 500 iN

POSIRED D Universal and compact right angle gearmotor

Torque (T2 nominal): 3,000 up to 25,000 Nm

Transmission Ratio: 18 up to 112 iN

Power Rating: up to 173 kW

POSIRED TS Double Shaft Gear

Torque (T2 nominal): 1,000 up to 110,000 Nm

Transmission Ratio: 5 up to 140 iN

Centre distance (a): 122 up to 656 mm

Bevel Gear Units

- These bevel gears are characterised by a sturdy, non-torsional

and space-saving housing. Their wheelsets of alloyed case hardening steel

have a Klingelnberg-Cyclo-Palloid gearing and are case hardened and lapped

in pairs.The arrangement of the screw fastening faces enables a wide choice

of fitting positions.On request, contact-less shaft sealing variants as good

as the connection for an oil circulating lubrication may be provided.

Reinforced shafts are also available.Every precision-application in the

sector of printing, paper, textile and tool-machines draw advantages in

using this kind of gears.

Technical Data

Torque (T2 nominal): 30 up to 8,500 Nm

Transmission Ratio: 0.5 up to 5 iN

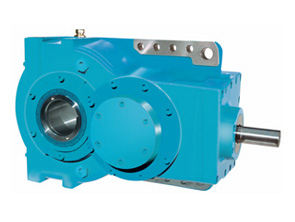

Single Screw Extruders Drive

- This series of gearboxes with attached or integrated

thrust bearing can be supplied as bevel or helical gear. Quiet operation and

strong design are key features. Mounting position horizontal or vertical,

splash lubrication and cooling coil with or without injection lubrication

are possible options. Their modular design is based on the POSIRED range,

plus appropriate thrust bearing-parts which are readily available.

Technical Data

Torque (T2 nominal) Nm: 3,000 up to 160,000

Transmission Ratio: 4 up to 160 iN

Axial force: F = 50 up to 2,000 kN

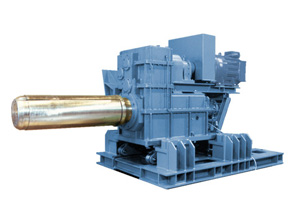

Twin Screw Extruder Drives

- Double shaft extruder gears have been built by PIV Drives

since 1984 for a variety of applications in the plastics and food industries

and have been put into operation around the world to our customers' complete

satisfaction. This extremely compact and appealing design means that we are

able to provide a modern, high-power gear in small installation spaces.

The gears are case hardened and ground and optimised with a profile correction according to the load, which consists of bending and torsion. A very good noise behaviour is achieved through a high contact ratio.

The axial forces which occur during extrusion from the process part are safely absorbed in the gear with tandem bearings and self-aligning roller thrust bearings.

Technical Data

Screw centre distance: a = 15 up to 200 mm

Input speed up to 1,800 rpm

Torque factor: df = 35 N/mm2

Power: up to 5,500 kW

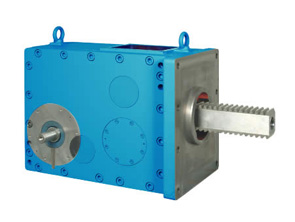

Injection Moulding Machine Drives

- PIV Drives has developed this range of rack-and-pinion

drives for closing the mould of injection moulding machines. This kind of

drives are quiet running spur gearboxes presenting a compact construction

with an integrated motor.

They have a double toothed rack as output.To achieve high performance it is important to realise an almost perfect load distribution on the rack: case hardened and grounded gear wheels are the base for these high performance drives with highest accelerating and decelerating torque and as very good noise behaviour.

Technical Data

Rack clamping force: up to 450 kN

Rack speed > 2,000 mm/s

Large Industrial Planetary Units

- This planetary gear series (5 sizes) is intended for

industrial application in the upper output torque range, up to 1,000,000 Nm.

They are backed by a long experience in the construction of planetary units

for variable speed drives.

Their most important features are:

- Compact design and high power density. The optimisation of the number of planets for each planet stage leads to an excellent torque / weight ratio.

- The modular structural design of the gear case leads to a universal range of uses. The majority of designs needed can be covered by standard models: in line and right angle versions.

- The housings are designed for flange or shaft mounting or foot design

- The output shafts are supplied as male or hollow shafts.

Technical Data

Torque (T2 nominal): 245,000 up to 1,000,000 Nm

Transmission Ratio: 20 up to 2,240 iN

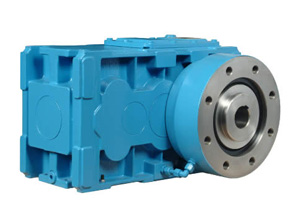

Ultra Compact Shaft-Mounted Gear Units

- POSIPLAN New range of ultra-compact planetary and bevel

helical gearboxes for industrial applications.

These new gear reducers, which are protected by a specific patent, feature a combination of planetary and helical/bevel helical gears that takes advantage of the strengths of each technology: compact size, reliability and easy maintenance.

This new series of lighter, more compact gear reducers surpass traditional solutions for planetary and bevel helical gear reducers and also ensure shorter production times and lower production costs.

The design of these ultra-compact gear units is based upon precise analyses using FEM (Finite Elements Method) techniques applied to 3D models, which means that performance, in terms of duration and silence, was optimized already in the virtual prototype phase.

Advanced engineering techniques, long experience and the use of high quality parts from Brevini Riduttori and PIV Drives led to the creation of a product that ensures high performance over time, a fact that has been confirmed by tests that simulate real operating conditions.

Technical Data

Torque (T2 nominal): 5,000 up to 67,000

Transmission Ratio: up to 2,000 iN

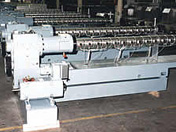

Special Purpose Gear Units

- PIV DRIVES manufactures customised and special drives for

almost each industry.

Worked out solutions exist for e. g.: different shifting gears, rack and pinion drives, extruder drives, distributor-mechanisms for needle-felting machines, gear boxes for pump-distributing devices, hoisting gears with shift-stage, gear boxes for printing-mechanisms for offset-machines, shift - and variable speed drives for paper-cross-cutters, multiple shaft gearboxes for many-wave-mechanisms for rack-dryers, grate-drives for continuous roller-hearths, feed-mechanisms for straightening- and punching devices, special shifting gears for printing-machines, special drives for ring-rolling mills.

The extensive part-assortment from the standard-program offers many components, with which can be constructed each customer-specific solution.

Explanation of the illustrated application (picture):For coiling up and decoiling of plate coils, sturdy special gearboxes are needed, in view to retain the reaction forces of the coiling process. PIV Drives provides customised solutions for lower and higher coiling power.

Technical Data

Special gearboxes weight: up to 20,000 kg

Industrial Variators and CVT

- POSICHAIN chain variable drives

Technical data

Speed range: R = 2 - 3 - 4 and 6

Performance: 1.1 up to 175 kilowatts

POSIDISC ball-disks variable speed drive

Technical Data

Variation Ratio: 6 - 10 or up to output speed = 0

Power Rating: 0.12 up to 3 kW

CVT for mobile applications

Technical Data

Power Rating: up to 150 kW

Speed range: R= up to 6

Markets and Applications

Construction / Earthmoving

Food / Beverage / Tobacco

Mining / Quarrying / Cement

Transportation / Material Handling

Marine / Port Installations

Water / Chemical

Energy / Petrochemical

Plastic / Rubber

Pulp / Paper / Print

Agriculture / Forestry

Industrial Equipment