Navigation : EXPO21XX > MOTION 21XX >

H13: Linear actuators & Linear Drives

> Schneider Electric Motion

Schneider Electric Motion

- Offer Profile

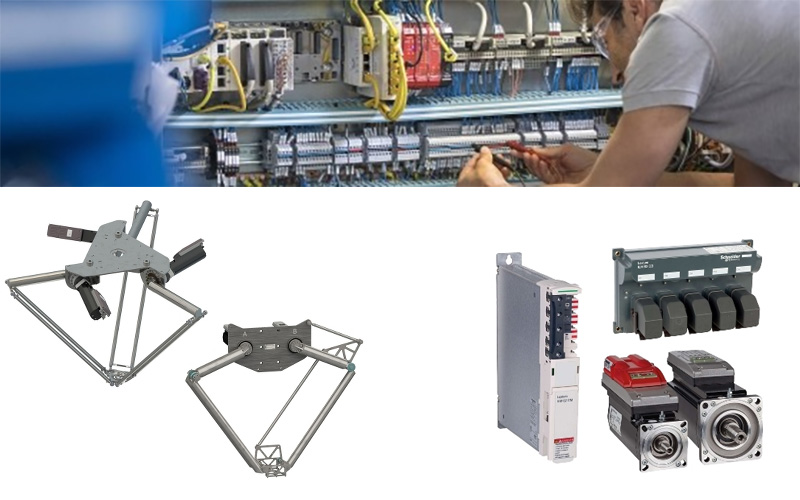

- We provide energy and automation digital solutions for efficiency and sustainability. We combine world-leading energy technologies, real-time automation, software and services into integrated solutions for homes, buildings, data centers, infrastructure and industries. We make process and energy safe and reliable, efficient and sustainable, open and connected.

Product Portfolio

Robotics

- Discover a complete linear motion and robotics portfolio, including fixed and multi-axis solutions, and delta robots for pick-and-place solutions.

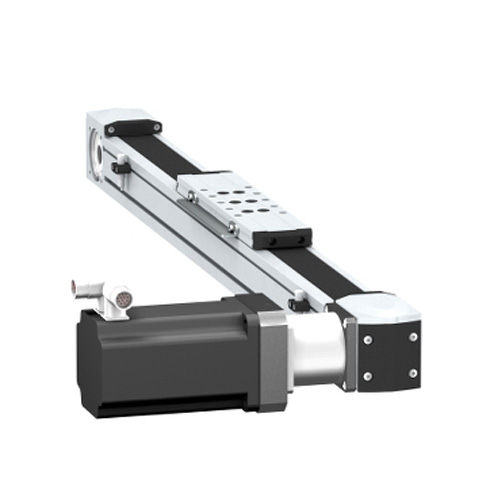

Lexium PAS

Portal axes with fixed axis body

Portal axes with fixed axis body and moving load carriage

Lexium CAS

Cantilever and telescope axes with moving axis body

Standardised cantilever and telescopic axes for a wide range of linear movements

Lexium TAS

Linear tables for high-precision positioning

Standardised linear tables for a wide range of linear movements

Lexium MAX

Multi-axes systems for 1, 2 or 3 dimensional positioning solutions

The Lexium MAX product family consists of double axes, linear positioners and portal robots for up to three dimensional movements.

Lexium T, P

Delta robots for pick & place solutions

Lexium Delta 2 and Delta 3 robots are designed for fast pick-and-place with payloads of up to 60 kg (Delta 2) and 15 kg (Delta 3).

Lexium STS

SCARA robots for fast positioning solutions

The Lexium STS robots are industrial manipulative robots for compact pick&place solutions with max payload of 8kg

Integrated Drives

- Lexium integrated servo drives are used as decentralized drives in machine building. When combined with a Modicon controller or a PLC, they can be used to create complex control system architectures simply and at minimum cost. The integrated drives can be equipped with an AC synchronous servo motor, a DC brushless motor or a stepper motor, thus providing numerous possibilities for use in a wide variety of applications.

Lexium ILA, ILE, ILS

Integrated drives for motion control

Decentralised Motion Solutions - Integrated Drives for motion control with stepper, servo or brushless DC motor

Lexium ILT, ILP

Integrated drives with two-phase stepper motor

Compact motion for decentralized solutions, ideal for machine builders who want an optimized motor with on-board electronics

Lexium 32i

Integrated servo drive from 0.6 to 2.2 kW

With servo motor and servo drive integrated in one housing, the Lexium 32i is designed for application areas requiring high precision and advanced motor control.

Lexium 62 ILM

Multiaxis integrated servo drives for PacDrive 3

Multiaxis integrated servo drives from 0.31 to 1.91 kW for automation solutions based on PacDrive 3

Servo Drives and Motors

- The Lexium servo drives and motors portfolio includes a wide variety of ranges with a power range up to 24 kW for independent or synchronized motion control. Lexium products can adapt to demand for high performance, power and simplicity of use in motion control applications.

Lexium 32 & Motors

Servo drives and servo motors from 0.15 to 11 kW

The Lexium 32 range of servo drives includes four servo drive models with power ratings from 0.15 to 11 kW and the servo motor ranges BMH and BSH series

Lexium 23 Plus

Servo drives and servo motors from 0.1 to 7.5 kW

The compact size of the Lexium 23 Plus servo range makes it ideal for use where space is limited and helps to reduce the size of the machine

Lexium 28 & Motors

Servo drives and servo motors from 0.05 to 4.5 kW

Lexium 28 servo drives & Lexium BCH2 servo motors: Optimized servo bundles for compact machines

Lexium 52 & Motors

Stand alone servo drives and servo motors for PacDrive 3

Stand alone servo drives from 0.4 and 7 kW for PacDrive based automation solutions

Lexium 62 & Motors

Multi axis servo system and servo motors for PacDrive 3

Multi axis servo drives and servo motors from 0,95 to 24 kW for PacDrive based automation solutions

Lexium 62 ILD & Motors

Detached servo drives and motors for PacDrive 3 automation solutions

Detached servo drives for PacDrive 3 based automation solutions with servo motors or AC motors with rated current up to 6 A

Motion and Drives Controllers

- Our motion controllers are developed to cover your needs for coordinated and synchronized motion control in a wide range of production and packaging machinery, as well as material handling and assembly system.

PacDrive 3 LMC Eco / Pro / Pro 2

Motion controllers for automating machines/lines with 0 - 130 servo or robot axes

PacDrive 3 LMC controllers provide scalable performance for synchronizing up to 130 servo axes at 1 msec network update rate and for up to 255 virtual axes. In addition to motion functionality, all controllers combine an integrated PLC, HMI interfaces, and IT functionalities on a single hardware platform.

PacDrive 3

A complete automation solution for motion-centric machines

PacDrive 3 is based upon proven logic motion technology, which unifies PLC, motion, and robotics control functionality on a single hardware platform. With its centralized system architecture, PacDrive 3 is the ideal solution for controlling a broad range of servo-driven production and packaging machines, as well as material handling equipment and robotics, using fully integrated, IEC 61131-3-compliant program structures. More than 80.000 machines worldwide are controlled by PacDrive to this day.

Modicon LMC058/LMC078

Motion controllers for coordinated, synchronised and interpolated motion control

A full range of scalable controllers to design all your applications, thanks to a single software suite, EcoStruxure Machine Expert, including the same Motion Libraries based on PLCopen, Embedded I/O, and numerous field buses.

Steppers Drives and Motors

- Wide selection of stepper drives of 2 to 3 phase range up to 19,7 Nm with high accuracy and high torque at low rotation speeds. Compact, simple to install and commission, Lexium stepper drives are designed to cover all applications, from simple to the most complex machines.

Lexium SD3 & Motors

3-phase stepper drives and stepper motors

Lexium SD3 & BRS3, Three-phase range up to 19.7 Nm with high accuracy and high torque at low rotation speeds

Lexium SD2 & Motors

2-phase stepper drives and stepper motors

Lexium SD2 & BRS2, Two-phase range up to 9.2 Nm with a high torque at low rotation speeds