SPL

Videos

Loading the player ...

- Offer Profile

- For your success: spindle

technology - versatile, innovative and precise

Our work focuses on you personally as our client and on your technical requirements and expectations. This has been our credo since the company was founded. This is why our first products were special spindles made according to specific customer requirements.

We offer you quick and flexibly intelligent solutions and contribute to improving your performance and competitive position. The dedication of our personnel to precise manufacturing and assembly, as well as to all-round service, are our trump cards that we use to your advantage.

Since SPL was founded, we have therefore developed and continuously perfected our engineering, precision manufacturing, component assembly with innovative testing and our spindle service.

Owing to this ongoing development, we offer a performance package with which your machine tools, systems or testing beds deliver optimal technical and economic results.

Product Portfolio

Spindles

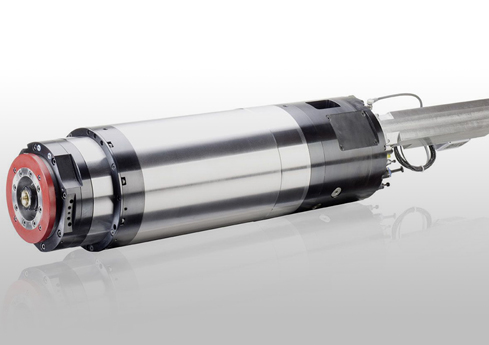

Grinding spindles

-

enhanced precision

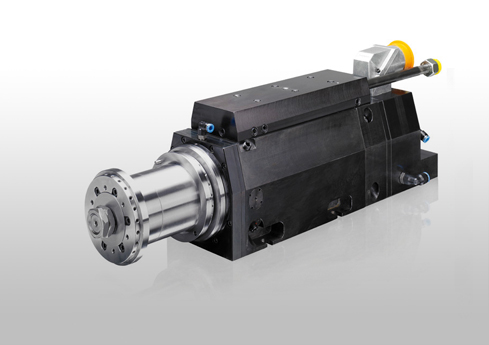

SPL motor spindles for grinding machines

SPL motor spindles for grinding machines are customized precisely to the processing task and to your machine tool. They can be fitted with an asynchronous or synchronous motor, as well as a variety of rotary encoder solutions. The bearings are also available in various configurations:- Multi-lobe hydrodynamic bearings

- Hydrostatic bearings with various throttle systems

- Precision angular contact bearings

- Hybrid bearings

As a result of the wide range of applicability we can offer grinding spindles for the following types of machines:- OD cylindrical grinding machines

- Roll grinding machines

- Centerless grinding machines

- Tool grinding machines

- Form grinding machines

- Gear grinding machines

- Knife grinding machines

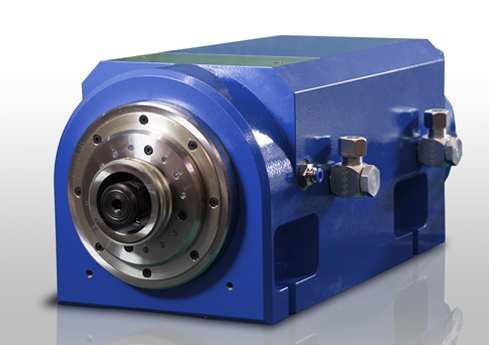

Head spindles

-

robust bearings, long lifespan

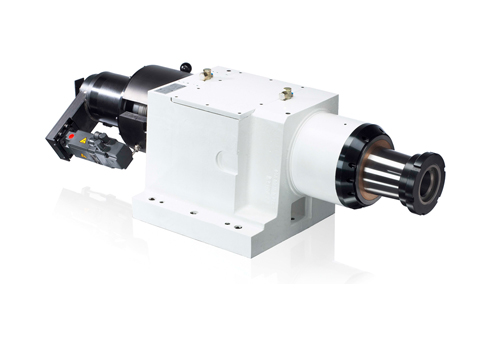

SPL motor spindles for lathes and vertical turning centers

Lathe Spindles/Head Spindles/Work Piece Spindles from SPL are all designed with high precision bearings to ensure maximum stiffness for the specified speed. Using the highest quality components in the construction of the spindles ensures both axial and radial run-out compliance over the life of the spindles.

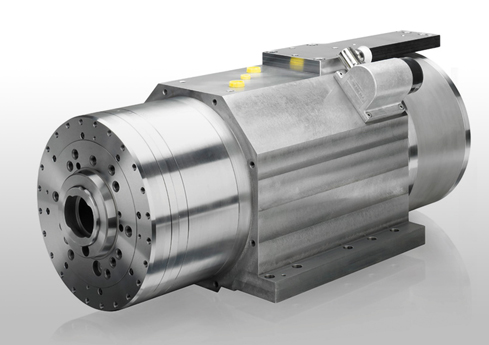

Milling spindles

-

low mass inertia, high dynamism

SPL motor spindles for milling machines and machining centers

SPL motor spindles for milling machines and processing centers are mainly fitted with spring preloaded hybrid bearings or hydraulic bearing preloading. This can cover a range of rotational speeds with the highest possible firmness of the precision bearings. Hydraulic preloading also has the advantages of damping, which improves the surface quality of the work piece and extends the lifespan of the spindle.

Special drives

-

high torque at highest rotational speeds

SPL special drives for test rigs and machine tools

SPL offers various motors to drive spindles such as torque motors, synchronous motors, and asynchronous motors.

With the various motor options and special bearing designs the usage covers a broad machine market consisting of:- Machine tools

- Test rig applications of all types

- Water treatment plant pump units and motors

- Air conditioning system motors

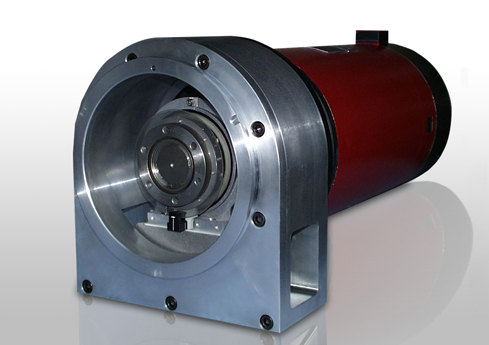

Hydrodynamic spindles

-

best damping properties

SPL hydrodynamic spindles for machine tools and test rigs

In a hydrodynamic spindle the bearing load capacity is created by shaft rotation. Hydrodynamic bearings have the best damping characteristics of all bearing types and this allows extremely high speeds to be achieved.

Hydrodynamic spindles are used in the following applications:- OD cylindrical grinding machines

- Roll grinding machines

- Centerless grinding machines

- Noise testing in laboratory test rigs

- Bursting test rigs

Hydrostatic spindles

-

highest concentricity accuracy

SPL hydrostatic spindles for machine tools and test rigs

In a hydrostatic spindle the bearing load capacity is created by the pressure of the oil from the supply unit. The high loads achieved can also be maintained when the spindle is stopped. Hydrostatic spindles can achieve maximum concentricity and excellent damping characteristics.

SPL Hydrostatic Spindles are used in the following applications:- Noise testing in laboratory test rigs

- Roll grinding and knife grinding machines

- Polishing machines

Component sets

- We supply not only spindles, but also complex systems with several axes. Simply make an enquiry. We draw up complete system concepts with you.

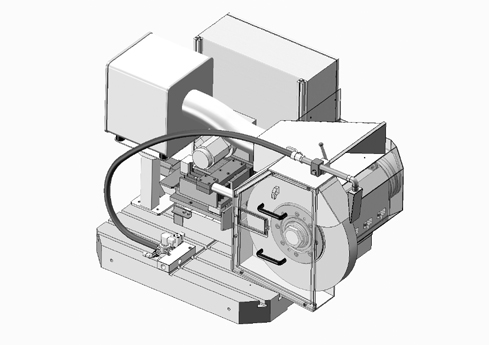

SPL Typ 2097.0

- Hydrodynamic grinding spindle with integrated belt drive free of transverse forces, oscillation unit and CNC dresser. All protective casing, motors and CNC axes are included in this set.

SPL Typ 2033.0

- Grinding motor spindle with integrated CNC dresser. All components such as protective casing, motors and suction are included on a pallet. This is fitted completely into a large lathe as grinding support.

SPL Typ 2082.0

- Hydrodynamic grinding spindle with belt drive free of transverse forces. An additional motor enables axial feed (cycles) during the grinding process. Apart from cylindrical grinding, it also allows the grinding of flat surfaces on the work piece.

SPL Typ 2611.0

- Hydrodynamic bearings as wall duct to counterbalance turbine shafts. This unit stands with a turbo transmission and drive motor on an axial slide for supplying the balancing system.

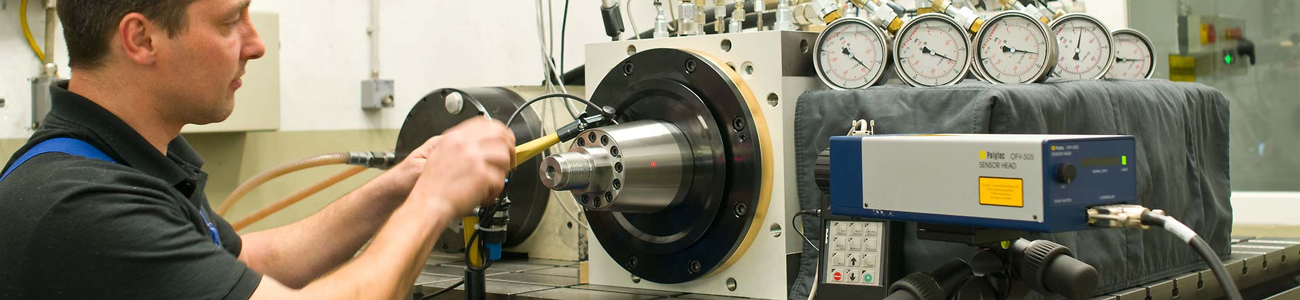

Test Rig Technology

-

Special bearings or complex test benches? We supply you with optimally customized systems.

Owing to our past as an engineering firm, we are trained in developing cost-efficient, customer-specific and intelligent test beds and test spindles.

Since the founding of SPL, we therefore deliver spindles with hydrodynamic or hydrostatic bearings with excellent damping properties for noise testing, as well as for centrifugal and burst test benches.

We offer many types of high-speed bearings with minimal dissipation for motor test benches.

Special motors and mechatronics systems for a range of uses and sectors complement our spindle units. Components and systems with accessories, as well as drive axes and controls, are the result of our continuous development work. Your technical requirements represent a challenge for us to find individual and innovative solutions.

Apart from our main spindles, this has also led to complex testing systems that we adapt and develop further according to customer requirements. We are therefore quick and cost-efficient and respond flexibly to your requirements. Service

Customer service

-

Not just perfect spindles but also perfect customer service

We offer customer service for your spindle systems, regardless of original manufacturer:- technical advice and fault diagnosis

- maintenance and “spindle up-time” service

- repairs / servicing / maintenance

- overhaul of bearings / modernization

- precision balancing on or off site

- on-site spindle analyses

We are aware of the importance of spindles in running processes. Faults should not occur, but heavy-duty use takes its toll. We therefore ensure that faults are addressed quickly. We can analyse and diagnose incoming spindles straight away. After a brief consultation with you, the spindle is repaired without delay, so that the interruption to your production process is minimized.

With expert maintenance and ongoing service, you can achieve a reliably high operational performance and extend the lifespan of your spindles. Avoid unforeseen malfunctions of your spindles through our maintenance and preventive servicing.

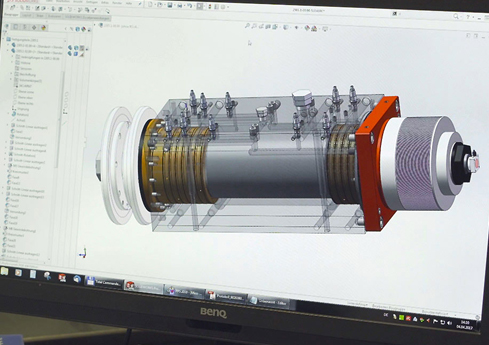

Engineering

-

If you have your own individual specification, we can custom-build a spindle specially for you

With innovative development and construction services for spindles and spindle components, our development team rises to the challenge of the rapidly changing technical conditions on the market. Owing to continuous cooperation with universities and research institutes, as well as regular participation in research association projects, we continue to push the boundaries of feasibility.

We work with various calculation programs such as 3D CAD and 2D CAD systems. The results and plausibility of our constructions can be tested on our test benches. Our development and construction performance is therefore efficient and achieves technically innovative solutions.

Our many years of experience in spindle technology enable us to offer you development and design solutions – even if you then prefer to manufacture your own spindle units.

We are familiar and comfortable with the notions of exclusivity, confidentiality and loyalty.

Manufacture

-

Expertise in turning, milling, grinding

As an associate company of and parts supplier to SPL Spindel und Präzisionslager GmbH, we at SPL Präzisionsfertigung GmbH in Fraureuth are an experienced and highly competent partner whom you can count on.

Give us the opportunity to convince you of the quality we deliver.

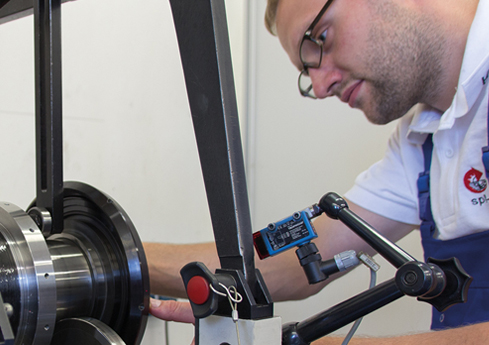

Balancing

-

A range of balancing machines - for rotor weights from 500 g to 350 kg

We are happy to balance your shafts and rotors. Please send us an enquiry with a drawing.

If required, we can make mounting mandrels and other aids.

Our service also comprises advice about the type of balancing, achievable balancing levels, as well as choosing at what points on the work piece mass balancing should be carried out.

With our mobile vibration measurement technology and balancing technology, we can carry out balancing either on our or your premises. We document the vibrations and the condition of the bearings.

Spindle assembly

-

We carry out contract assembly and test runs on customer request. Our service comprises:

- Incoming goods inspection and checking of quality-relevant production parts

- Carrying out all adjustment and setting work during the assembly process

- Balancing and operational balancing of rotating parts, including documentation

- Assembly, wiring of electric components

- Setting encoding systems and sensors

- Test runs, running-in processes with documentation

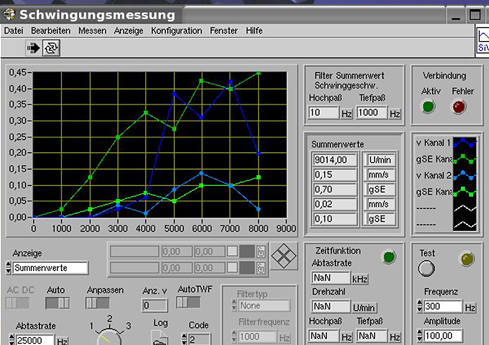

Vibration measurements

- As an integral component of our assembly and spindle service, we carry out vibration measurements and natural frequency measurements either on our test beds or at your site. We document the vibrations and the condition of the bearings.