Bonfiglioli Group

Videos

Loading the player ...

- Offer Profile

- We design, manufacture and

distribute a complete range of gearmotors, drive systems and planetary

gearboxes to satisfy the most demanding needs for industrial processes,

automation, mobile and renewable energy applications. We offer tailored

solutions, whose strength lies in the high technology content of each

product and the careful integration of different technologies.

As a leading company in the global power transmission market, we are committed to satisfy our customers' requirements, thanks to high quality products and a comprehensive pre- and post-sales service.

Product Portfolio

Industrial Gearmotors

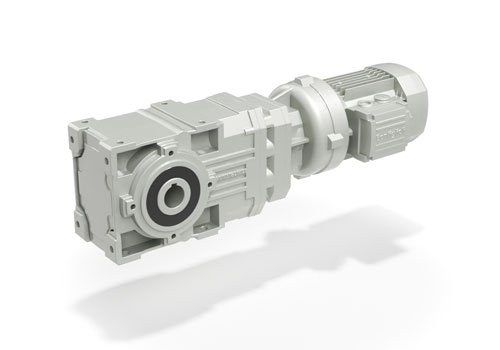

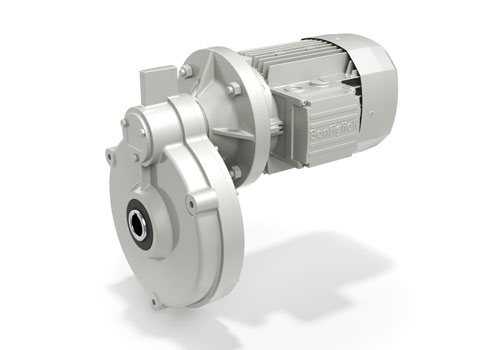

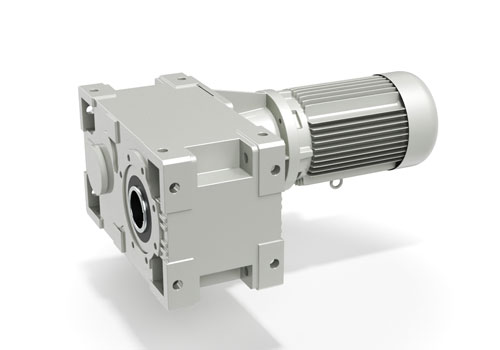

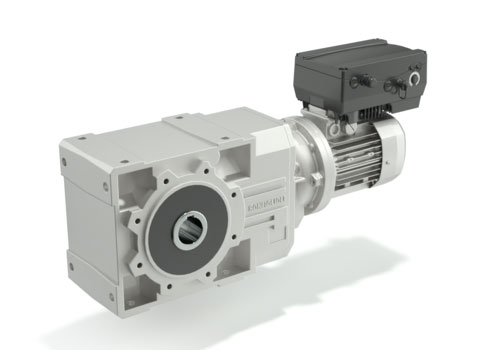

RIGHT-ANGLE GEAR UNITS - A Series

- Helical Bevel Gearmotors & Units

The A Series combines high efficiency and reliability, low maintenance costs and a wide torque range. The right angle layout between INPUT and OUTPUT makes the A Series particularly compact. The gear set combination makes this right-angle product the most efficient and durable in Bonfiglioli's light- and medium-duty portfolio. The A Series can be completed with a wide range of electric motors entirely manufactured by Bonfiglioli. Asynchronous motors both IEC and compact (BN-BE-BX/M-ME-MX), servomotors (BMD) and reluctance motors (BSR) can be coupled with the A Series.

Key benefits- Minimized mounting space

- Wide output speed selection range

- Reduced standard backlash

- High dynamic and energy saving solution

- Wide output speed selection range

- ATEX gearbox for explosive environnements 2G/2D

Torque range- 100 ... 14,000 Nm (885 … 123,910 in-lb)

Gear ratios- 4.9 ... 1,715

RIGHT-ANGLE GEAR UNITS - VF/W Series

- Universal Worm Gearmotors & Units

VF/W Series are worldwide known: they succeeded in combining uncompromising quality with state-of-the-art technology and price effectiveness. Absolute flexibility is achieved by the wide choice of mounting options, shaft configurations and motor interfaces, all offered as standard. Furthermore, thanks to several patented manufacturing techniques Bonfiglioli's VF/W Series stands out for their long operating lifetime and reliability. Finally our VF/W Series can be completed trough the selection of a wide range of electric motor entirely manufactured by Bonfiglioli. Asynchronous-motors, both IEC and compact (BN-BE-BX/M-ME-MX), can be coupled with VF/W Series providing to our customers a complete drive solution. Looking for an Enhanced Protection gearmotor suitable for Food & Beverage, Chemical and Pharma industries as well as for harsh environemtns in general?

Key benefits- Cost effective solution

- Low noise High peak load capacity

- Minimized mounting space

- Long operating life

- High reliability

- High number of possible configuration

- Wide output speed selection range

- Wide output torque selection range

- ATEX gearbox for explosive environnements 2G/2D

Torque range- 13 ... 7,100 Nm (115 … 62,840 in-lb)

Gear ratios- 7 - 300 ... 2,300

RIGHT-ANGLE GEAR UNITS - RAN Series

- Right Angle Gear Units

The RAN Series are designed to fit the purpose of transmission laid out in right angle setting. Easy to fit and almost maintenance-free, RAN Series offer multiple shaft arrangements and a choice of several exact gear ratios, beside the 1:1, that come handy when designing synchronized drive system. Also available in the version for screw jack duty.

Key benefits- Cost effective solution

- Easy to fit

- Easy maintenance

- High positioning accuracy

- Minimized mounting space

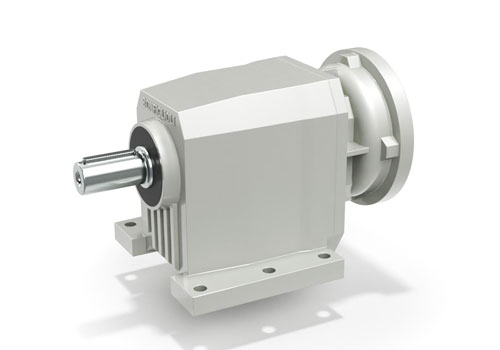

IN-LINE GEARED UNITS - AS Series

- Specific Helical In-Line Gearmotors & Units

The AS Series benefits from years of recognition in the industry and has become a best seller for quarry and mining applications, where reliability and low maintenance are key factors. These Series can be completed with a wide range of electric motors entirely manufactured by Bonfiglioli. Asynchronous motors both IEC and compact (BN-BE-BX) and reluctance motors (BSR) can be coupled with the AS Series: Thanks to the breadth of its e-motor portfolio, Bonfiglioli can always provide customers with the perfectly balanced solution, in terms of efficiency, dynamics and cost-effectiveness.

Key benefits

Minimized mounting space

Reduced installation space and wide output speed selection range

Reduced standard backlash

Highly dynamic, energy-saving solution

Wide output speed selection range

Torque range- 50 ... 12,000 Nm (442 … 106,208 in-lb)

Gear ratios- 4.34 ... 202.1

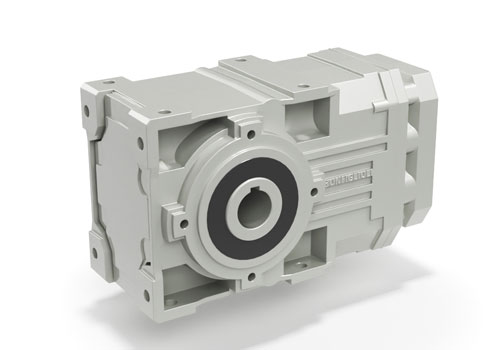

IN-LINE GEARED UNITS - C Series

- In-line Gearmotors & Units

The C Series is designed for the requirements of standard tasks in the industrial environment. These series achieve first-rate reliability, efficiency, robustness, and a wide output torque range. The extremely wide range of gear ratios, achieved through 2-, 3- or 4-stage versions, allows the customer to adapt the C Series to every application and to find the perfect match for output speed requirements. The C Series can be completed with a wide range of electric motors entirely manufactured by Bonfiglioli. Asynchronous motors both IEC and compact (BN-BE-BX/M-ME-MX), servomotors (BMD) and reluctance motors (BSR) can be coupled with the C Series.

Key benefits- Minimized mounting space

- Robustness

- Reduced standard backlash

- Highly dynamic, energy-saving solution

- Wide output speed selection range

- ATEX gearbox for explosive environments 2G/2D

Torque range- 45 ... 12,000 Nm (398 … 106,208 in-lb)

Gear ratios- 2.6 ... 1,481

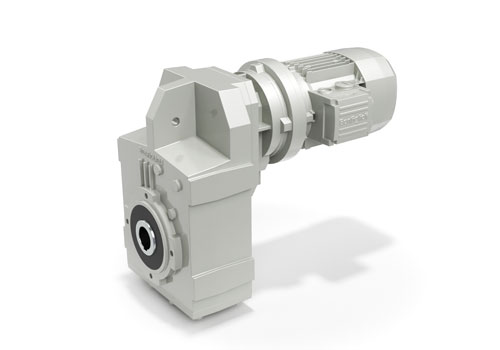

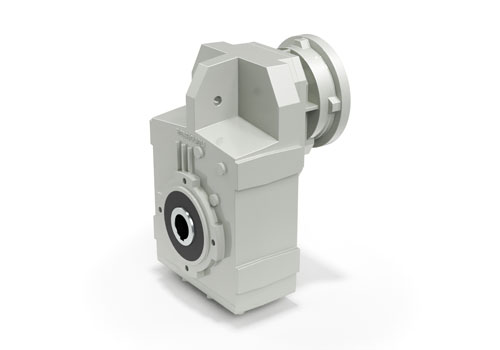

PARALLEL SHAFT GEARMOTORS - F Series

- Helical Parallel-Shaft Gearmotors & Units

The F Series is an outstanding solution for customers looking for a drive that can maximize mounting flexibility. Thanks to the housing's lateral holes, the F Series can also be side mounted directly into the machine, in addition to all the conventional mounting positions. This gearmotor guarantees elevated efficiency, reliability and low-noise operation. High torque density, a range of wide gear ratios and a compact design complete the F Series' characteristics. The F Series can be completed with a wide range of electric motors entirely manufactured by Bonfiglioli. Asynchronous motors both IEC and compact (BN-BE-BX/M-ME-MX), servomotors (BMD) and reluctance motors (BSR) can be coupled with the F Series.

Key benefits- High mounting flexibility

- Minimized mounting space

- Robustness

- Reduced standard backlash

- High dynamic and energy saving solution

- Wide output speed selection range (ATEX) gearbox for explosive environnements 2G/2D

Torque range- 140 ... 14,000 Nm (1,239 … 123,910 in-lb)

Gear ratios- 6.4 ... 2,099

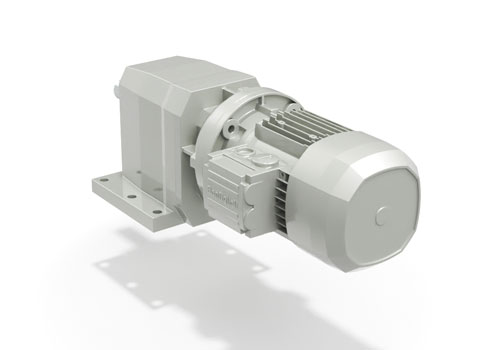

PARALLEL SHAFT GEARMOTORS - S Series

- Helical Single-Stage

The S Series design makes this gearmotor particularly effective for pump, fan and blower applications. To meet the needs of customers in these sectors, the S Series is also available in the foot or flange versions and can be completed with a wide range of electric motors entirely manufactured by Bonfiglioli. Asynchronous motors both IEC and compact (BN-BE-BX/M-ME-MX) and reluctance motors (BSR) can be coupled with the S Series. With the breadth of its portfolio, Bonfiglioli provides customers with an outstanding balance of efficiency, dynamics and cost effectiveness.

Key benefits- Cost effective solution

- Minimized mounting space

- Robustness

- Reduced standard backlash

- High dynamic and energy saving solution

Torque range- 21 ... 200 Nm (185 … 1,770 in-lb)

Gear ratios- 1.4 ... 13.1

PARALLEL SHAFT GEARMOTORS - TA Series

- Specific Shaft Mounted Gearmotors & Units

The TA Series has long has long been established as a best seller for quarry and mine applications where absolute reliability and low maintenance are key factors. Another winning factor is the backstop option that prevents back driving in the case of inclined conveyors. This gearbox can be completed by selecting from a wide range of electric motors entirely manufactured by Bonfiglioli. Asynchronous motors, both IEC and compact (BN-BE-BX/M-ME-MX), can be coupled with the TA Series providing our customers a complete drive solution.

Key benefits- Cost effective solution

- High Reliability

- Robustness

- Very Compact design

- Prevent the movement in the wrong way

- Highly customizable product

Torque range- 150 ... 16,000 Nm (1,327 … 141,611 in-lb)

Gear ratios- 5 ... 33.2

Industrial Heavy-Duty Geared products

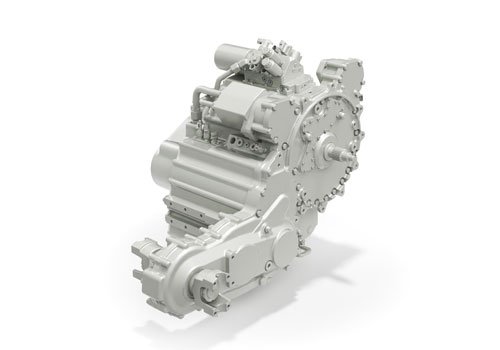

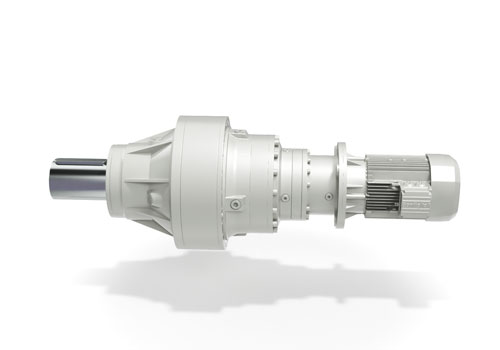

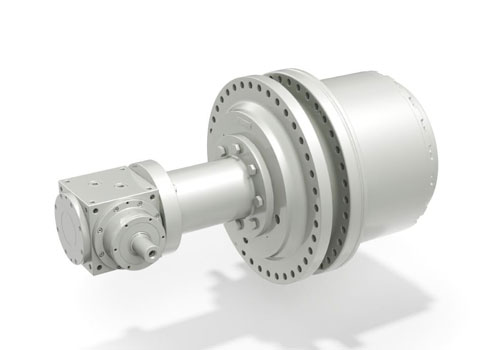

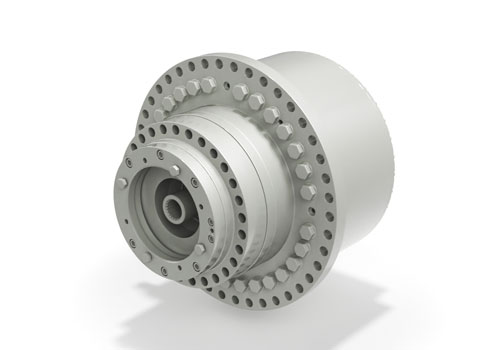

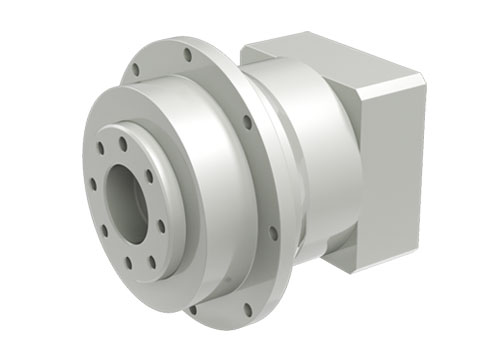

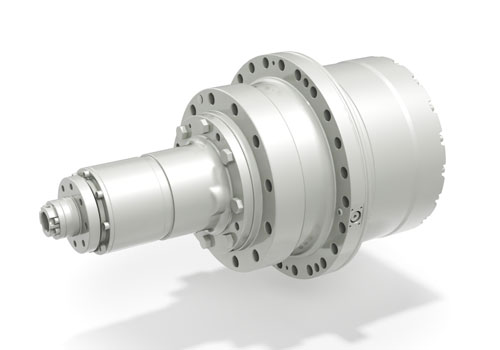

PLANETARY GEARED UNITS - 300M Series

- Industrial Planetary Gearmotors & Units

Bonfiglioli's 300M Series is an outstanding solution for all heavy-duty applications where compactness is not an option. Thanks to its modular design, the 300M Series can be customized to match an extremely wide range of applications. Bonfiglioli's expertise in planetary technology ensures high-quality product design and manufacturing procedures. The 300 Series operates without unwanted downtime even in the harshest environments. This planetary gearbox achieves top-class flexibility thanks to several outputs, as well as input configurations available for all 20 sizes. The 300M Series can be completed with a wide range of electric motors entirely manufactured by Bonfiglioli. Asynchronous motors (BN-BE-BX/M-ME-MX) can be coupled with 300M Series gearboxes, providing our customers a complete solution.

Key benefits- High torque density

- Extreme speed reduction and high output torque Low maintenance cost

- Extremely customizable

- High customization leve

- Flexibility - ATEX per explosive atmosphere 2G/2D

Torque range- 1,250...1,286,700 Nm (11,063 … 11,388,254 in-lb)

Gear ratios- 3.4 ... 2,916

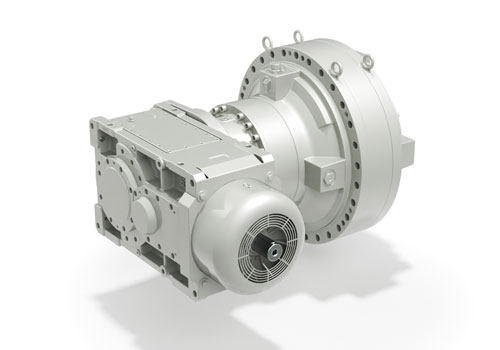

RIGHT-ANGLE GEARMOTORS AND GEARED UNITS - HDO Series

- Helical Bevel Heavy Duty Gear Units

When high output torque, robustness reliability and long operating life must be achieved, Bonfiglioli's HDx Series represent the best solution for our custmers needs. Thanks to high quality materials and an optimized design, HD Series can operate in the harshest environemt, as well as in explosive atmospheres, with low maintenance costs and long time service intervals. The output shaft can be chosen both in the parallel (HDP) or right angle(HDO) configuration and to always ensure the minimization of mounting space. HDx Series, furthermore, can be deeply customized thanks to an extremely wide options and accessories portfolio, thus matching most of the requirements of a large applications number.

Key benefits- Highly transmissible power

- Robustness

- Mounting flexibility

- Reliability

- Usable in explosive environments

Torque range- 8,990 ... 209,000 Nm (79,568 … 1,849,805 in-lb)

Gear ratios- 5.6 ... 490

RIGHT-ANGLE GEARMOTORS AND GEARED UNITS - 3/H Series

- Combined Planetary/Helical Bevel Heavy Duty Gear Units

The Bonfiglioli 3/H Series combines the high torque density of planetary gear units with the robustness and high-speed operation of the helical bevel heavy-duty products. This configuration can provide great power transmission in a very compact space, thanks to its angular layout. The 3/H Series can also come with a set of features such as hydraulic couplings or cooling circuits, adapted according to customers' needs..

Key benefits- Extremely high transmissible torque and power

- Suitable for all heavy-duty applications

- High shock resistance

- Reliability

- Easy maintenance

- High customization level

Torque range- 135,000 ...1,750,000 Nm (1,194,850 … 15,488,805 in-lb)

Gear ratios- 89.1... 1,070

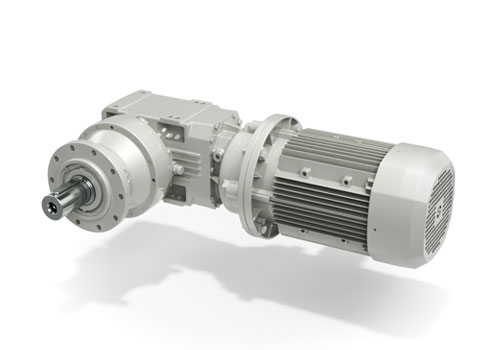

RIGHT-ANGLE GEARMOTORS AND GEARED UNITS - 3/A Series

- Combined Planetary/Helical Bevel Gearmotors & Units

The Bonfiglioli 3/A Series combines the high torque density of planetary gear units with the robustness and high speed of helical bevel products. This configuration provides great power transmission in a very compact space, thanks also to its angular layout. The 3/A Series is available for the lower range of the 300M Series and represents a smart path to medium-duty power transmission for the industrial market. The 3/A Series can be completed by selecting from of a wide range of electric motors entirely manufactured by Bonfiglioli. Asynchronous motors both IEC and compact (BN-BE-BX/M-ME-MX) and reluctance motors (BSR) can be coupled with the 3/A Series. With its broad e-motor portfolio, Bonfiglioli can always provide customers an outstandingly balanced solution in terms of efficiency, dynamics and cost-effectiveness.

Key benefits- Cost effective solution for high torque continuous duty application

- High shock resistance

- High transmissible power

- Compact Layout

- High mounting flexibility

- High performance gearmotor solution

Torque range- 1,250 ... 15,680 Nm (11,063 … 138,779 in-lb)

Gear ratios- 18.7 ... 731

RIGHT-ANGLE GEARMOTORS AND GEARED UNITS - 3/V Series

- Combined Planetary/Worm Gearmotors & Units

Thanks to more than 60 years of experience in worm and planetary technologies, the Bonfiglioli 3/V Series offer our customers the highest performance and reliability: the high torque density of the planetary gear units with the high gear ratio and cost-effectiveness characterizing worm technology. The result a solution which is ideal for intermittent duty applications, characterized by elevated reliability and highly customizable thanks to its great modularity. Finally, our 3/V Series can be completed by selecting from a wide range of electric motors entirely manufactured by Bonfiglioli. Asynchronous motors both IEC and compact (BN-BE-BX/M-ME-MX) and reluctance motors (BSR) can be coupled with the 3/V Series. With its broad e-motor portfolio, Bonfiglioli can always provide customers an outstandingly balanced solution in terms of efficiency, dynamics and cost effectiveness.

Key benefits- Cost effective solution for high torque intermittent duty applications

- Compact layout

- High mounting flexibility

- Wide range of output speeds

- Reliability

Torque range- 1,250 ... 655,740 Nm (11,063 … 5,803,788 in-lb)

Gear ratios- 18.7 ... 5,234

PARALLEL SHAFTGEARMOTORS AND GEARED UNITS - HDP Series

- Helical Parallel Shaft Heavy Duty Gear Units

When high output torque, robustness reliability and long operating life must be achieved, Bonfiglioli's HDx Series represent the best solution for our custmers needs. Thanks to high quality materials and an optimized design, HD Series can operate in the harshest environemt, as well as in explosive atmospheres, with low maintenance costs and long time service intervals. The output shaft can be chosen both in the parallel (HDP) or right angle(HDO) configuration and to always ensure the minimization of mounting space. HDx Series, furthermore, can be deeply customized thanks to an extremely wide options and accessories portfolio, thus matching most of the requirements of a large applications number.

Key benefits- High transmissible power

- Robustness

- Mounting Flexibility

- High customization level

- Reliability ATEX for explosive atmosphere 2G/2D

Torque range- 5,190...210,000 Nm (45,935 … 1,858,656 in-lb)

Gear ratios- 7.1...500

Travel drives

WHEEL DRIVES - 600 Series

- The Bonfiglioli 600 Series is the best solution when designing wheeled off-road machinery. With a compact design, high torque and load capacities, a negative multi-disk parking brake and an optional disengagement device to tow the vehicle in an emergency, these solutions precisely match the application requirements.

Torque range- 3,000 ... 85,000 Nm (26,552 … 752,313 in-lb)

Gear ratios- 4.3 ... 153

WHEEL DRIVES - 600WE Series

- Bonfiglioli 600WE planetary drives incorporate an integrated, maintenance-free electric motor and offer significant benefits, including compact dimensions, low noise and high efficiency. 600 Series drives are designed for use with all kinds of aerial platforms and other types of mobile machinery, for indoor and outdoor use. This advanced powertrain solution uses a two- or three-stage gearbox offering reduction ratios of up to 1:145 to satisfy the widest possible range of needs. The gearbox is coupled with a low-voltage induction motor (BT Series), specially developed for traction power and control applications.

Torque range- 900 ... 10,000 Nm (7,965 … 88,507 in-lb)

Gear ratios- 20 ... 145

WHEEL DRIVES - 600WT Series

- Bonfiglioli 600WT wheel drives are the best choice for wheeled agricultural equipment, such as self-propelled agricultural sprayers. This solution is the perfect combination of proven mechanical parts, with a new, integrated 68cc variable hydraulic motor, especially developed for closed-loop, highly demanding applications.

Torque range- 12,000 ... 22,000 Nm (106,208 … 194,716 in-lb)

Gear ratios- 22 ... 43.8

WHEEL DRIVES - 600Y Series

- Pneumatic tyred roller wheel drives

When designing a latest-generation pneumatic tyred roller machine, integration of the unique 600 Y3 drive is the right choice for your vehicle. Flexible design simplifies installation on the machine frame.

Torque range- 14,000 ... 22,000 Nm (123,910 … 194,716 in-lb)

Gear ratios- 30 ... 32

WHEEL DRIVES - 600W0C Series

- 600W0C units are typically applied in the rear section of 3- and 4-wheel counterbalanced forklifts. They can be axles or steering units for twin wheels. Depending on the steering unit model, anti-vibration parts can be included, and they serve as support for fixing brackets. The hydraulic steering guarantees a high steering angle to minimize the vehicle's steering radius and allow the truck to move easily in narrow aisles. Depending on the customers' needs, it is possible to customize the unit's main dimensions and other characteristics, such as adding a potentiometer to read the steering angle.

WHEEL DRIVES - 600D Series

- Bonfiglioli supplies versatile, low-noise drives coupled with electric motors for all-electric, battery-powered vehicles such as urban passenger cars, commercial vehicles and delivery trucks. This solution ensures a more energy-efficient operation and extended autonomy from the battery thanks to optimized, low backlash helical gears and high-speed bearings. The Bonfiglioli 600D Series of drives is extremely lightweight thanks to cast aluminum casings developed with Bonfiglioli's extensive process expertise. The 600D drives allow vehicle manufacturers to satisfy even the toughest restrictions on gross vehicle weight. They are complemented by a range of electric motors, inverters and matched mechanical joints and shafts to provide vehicle OEMs with complete powertrain solutions.

Torque range- 1,000 ... 8,500 Nm (8,850 … 75,231 in-lb)

Gear ratios- up to 15

WHEEL DRIVES - 600F Series

- Bonfiglioli supplies high-efficiency, low-noise planetary axles and drives with integrated high performance electric motors and low maintenance braking systems for Class 1 material handling vehicles. Typical applications include 3- and 4-wheel counterbalance lift trucks and ground support equipment. Bonfiglioli electric powertrains are fully tested in the factory and guarantee reduced energy consumption. This, in turn, means longer battery operating times, extended service intervals and lower cost of ownership. Bonfiglioli 600F Series drives are complemented by a range of idle steering systems based on axles or steering units, depending on the number of wheels on the vehicle.

Torque range- 3,000 ... 18,000 Nm (26,552 … 159,313 in-lb)

Gear ratios- 26 ... 42

WHEEL DRIVES - El Series

- Bonfiglioli EL powertrains are a perfect match for the most demanding warehousing applications (Class 2 and Class 3). Warehousing trucks require high maneuverability in tight spaces, provided by drives like the EL series drives, with the smallest operating radius in vertical arrangements.

Torque range- 450 ... 1,900 Nm (3,982 … 16,816 in-lb)

Gear ratios- 13 ... 32

WHEEL DRIVES - FR Series

- The FR Series is the best solution when designing large wheeled off-road machinery. With a compact design, high torque and load capacities, a negative multi-disk parking brake and an optional disengagement device to tow the vehicle in an emergency, these solutions precisely match the application requirements.

Torque range- 20 ... 60 kNm (14,751 … 44,253 ft-lb)

Gear ratios- 28 ... 34

WHEEL DRIVES - TRAVEL & TRACK DRIVES - 600 Series for AWD graders

- When designing an all-wheel drive grader, the integration of the 600 series, developed for this high speed application, is the best possible choice for your vehicle. The solution includes a high-speed clutch device.

Torque range- 15,000

Gear ratios- 30

TRAVEL & TRACK DRIVES - 700CK Series

- Extremely compact, lightweight, efficient and smooth to operate, 700CK Series track drives are powered by integrated axial piston hydraulic motors, developed in cooperation with Kayaba.

Torque range- 1,200 ... 220,000 Nm (10,620 … 1,947,164 in-lb)

Gear ratios- 20 ... 120

TRAVEL & TRACK DRIVES - 700 XT

- Bonfiglioli 700 XT track drives excellently combine proven mechanical systems with ground-breaking hydraulic components, making them the best choice for closed-loop applications and demanding construction equipment machines, such as compact track loaders (5.5 to 7.5 tons), small dozers (5.5 to 7.5 tons) or pavers (12 to 15 tons).

Torque range- 12,000 ... 22,000 Nm (106,208 … 194,716 in-lb)

Gear ratios- 22 ... 53

TRAVEL & TRACK DRIVES - 700 CE

- Bonfiglioli 700CE planetary drives coupled with a high-power density electric motor are specifically designed for high-voltage hybrid powertrain systems. Many years of installation on crusher machines is concrete proof of the efficiency of these electric drive solutions. An integrated, maintenance-free IPM (internal permanent magnet) electric motor is included, giving significant benefits in terms of dimensions and efficiency. The motor design is flexible from a cooling type standpoint: 700CE series drives coupled with air-cooled motors are designed to be installed on all kinds of crushers and screeners, weighting up 60 tons and with a max. speed of 3.5 to 4.0 km/h. Because they use the same motor with liquid cooling, some of these solutions can also be applied to other types of new-generation off-highway tracked machinery in the construction industry. For outdoor use on rough soils, the motor protection class is IP67. The overall length of the SAHR brake, is particularly limited, close to the size of a hydraulic motor.

Key benefits

Benefits for OEMs- Ability to downsize and downspeed combustion engines

- Ease of installation: electric solution dimensions comparable to standard hydrostatics

- Higher system reliability: fewer mechanical parts

- Virtually maintenance-free electric motors

- From sprocket to electric wire with only one supplier

Benefits for the end-user - Reduced fuel consumption

- Increased productivity

- Better machine maneuverability

- The electric solution is cleaner: lower risk of oil spills

Torque range- 26,000 ... 60,000 Nm (230,119 … 531,044 in-lb)

Gear ratios- 123 ... 350

TRAVEL & TRACK DRIVES - 700CT Series

- Extremely compact, lightweight, efficient and smooth to operate, 700CT Series track drives are powered by integrated axial piston hydraulic motors.

Torque range- 3,500 ... 22,000 Nm (30,977 … 194,716 in-lb)

Gear ratios- 15 ... 270

TRAVEL & TRACK DRIVES - 700CP

- Extremely compact, lightweight, efficient and smooth to operate, 700CP Series track drives are powered by integrated axial piston hydraulic motors, developed in cooperation with Poclain hydraulics.

Torque range- 1,200 ... 5,000 Nm (10,620 … 44,253 in-lb)

Gear ratios- 18.5 ... 57.5

TRAVEL & TRACK DRIVES - 700C Series

- Bonfiglioli 700C series units are unsurpassed by any crawler or milling machines. Thanks to compact, rugged design, high torque and load capabilities, and optional mechanical lifetime seals, these solutions are the best possible option for the machine. All units are available with a fail-safe parking brake and most have the option of cartridge type fixed or variable systems.

Torque range- 1,000 ... 625,000 Nm (8,850 … 5,531,716 in-lb)

Gear ratios- 5.25 ... 492

TRAVEL & TRACK DRIVES - FP Series

- The FP Series are perfectly suitable with any crawler, large excavators and milling machines. Thanks to compact, rugged design, high torque and load capabilities, these solutions are the best possible option for the machine. All units are available with a fail-safe parking brake and for most cartridge type fixed or variable systems. Different disengagement systems are available on demand for all the sizes.

Key benefits

Special executions on request- Mechanical disconnect device

- Low and high temperature version

Torque range- 100 ... 1.100 kNm (73,756 … 811,318 ft-lb)

Gear ratios- 248 ... 825

TRAVEL & TRACK DRIVES - F Series

- The F Series is perfectly suited to any crawler and milling machine. Thanks to compact, rugged design, high torque and load capabilities, these solutions are the best possible option for thes machines. All units are available with a fail-safe parking brake and for most cartridge type fixed or variable systems. Different disengagement systems are available on demand for all the sizes.

Key benefits

Special executions on request- Mechanical disconnect device Low and high temperature version

Torque range- 13 .. 3,000 kNm (9,588 … 2,212,686 ft-lb)

Gear ratios- 19 ... 989

Slew drives

YAW & PITCH DRIVES - 700 TW Series

- Bonfiglioli products are used in the latest state-of-the-art wind turbines to control the necessary functions of pitch and yaw drive systems. 700TW series planetary speed gearboxes (wind turbine yaw control gear motors) are used by a number of leading wind turbine manufacturers due to their advanced technical features, ensuring the highest level of performance.

Key benefits- High transmissible torque High radial/trust load capacity High shock resitance Compact dimensions Low weight Low cost

Torque range- 2,500 ... 300,000 Nm (22,126 … 2,655,223 in-lb)

Gear ratios- 60 ... 3,000

SLEW DRIVES - 700T Series

- The Bonfiglioli 700T series provides the safest, most effective solution for cranes, excavators and forestry machines. Highly appreciated by all major manufacturers, the 700T Series has long been established in the crane, excavator and special equipment industries.

Torque range- 1,000 ... 80,000 Nm (8,850 … 708,059 in-lb)

Gear ratios- 3.48 ... 2,000

SLEW DRIVES - S Series

- The Bonfiglioli S series provides the safest and most effective solution for cranes, excavators and forestry machines. Its compact design allows it to perfectly fit cranes, excavators and special equipment where installation space is limited.

Torque range- 5,500 ... 130,000 Nm (48,679 … 1,150,596 in-lb)

Gear ratios- 23 ... 67

SLEW DRIVES - 700TK Series

- The 700TK Series is the compact and powerful slew drive package for 1.5- to 150-ton excavators. The units are powered by integrated axial piston hydraulic motors, developed in cooperation with Kayaba and can be fitted in very small spaces.

Torque range- 750 ... 30,000 Nm (6,638 … 265,522 in-lb)

Gear ratios- 7 ... 40

Winch drives

800 Series

- Units of the 800 series are specifically designed for winch applications, and can be easily accommodated within the drum itself. Available in various gear ratios, units feature heavy-duty bearings and an optional failsafe parking or emergency multi-disk brake.

Torque range- 5,000... 42, 000 Nm (44,253 … 371,731 in-lb)

Gear ratios

21 ... 108

700C Series

- The Bonfiglioli 700C Series is highly suitable for any crawler. Thanks to compact, rugged design, high torque and load capabilities, and optional mechanical lifetime seals, these solutions are the best possible option for these machines. All units are available with a fail-safe parking brake and most have the option of cartridge type fixed or variable systems.

Torque range- 2,500 ... 30,000 Nm (22,126 … 265,522 in-lb)

- 5.3 ... 492

FW Series

- The planetary winch gearboxes of the FW Series are suitable for a large spectrum of winch applications thanks to the availability of a wide torque range. The compact design allows the gearbox to be integrated into the winch drum. The failsafe brake can be integrated inside the gearbox or mounted externally, with common lubrication for the gears. Electrically driven versions are available with both in-line and right-angle configurations. Torque ratings are organized by FEM class, in accordance with minimum approved class safety factors for gears.

Torque range- 5 ... 210 kNm (3,687 … 154,888 ft-lb)

Gear ratios- 35 ... 490

700C Series

- Planetary winch gearboxes of the 700C series are composed of 18 finely spaced frame sizes. The compact design allows the gearbox to be integrated into the winch drum. The failsafe brake can be integrated inside the gearbox or mounted externally, with common lubrication for the gears. Electrically driven versions are available with both in-line and right-angle configurations. Torque ratings are organized by FEM class, in accordance with minimum approved class safety factors for gears.

Torque range- 1,000 ... 625,000 Nm (8,850 … 5,531,716 in-lb)

Gear ratios- 5.3....492

Transit mixer drives

500 Series - Hydraulic solution

- Absolute dependability, low maintenance, compactness and cost-effectiveness are the key features of the redesigned 500 series, the unparalleled line of drives for transit mixers. Eight models available for mixing capacity ranging from 1 to 14 m3.

Torque range- 3,000 ... 75,000 Nm (26,552 … 663,805 in-lb)

Gear ratios- 17 ... 161

500 Series - Electric solution

- This solution is designed for use with medium/large mixer trucks that have medium/long delivery distances to travel. Bonfiglioli's innovative solution comprises a Bonfiglioli 500 Series gearbox coupled to an AC electric motor, providing normal power, and a DC electric motor for emergency use. This product not only guarantees greater energy efficiency and reduced fuel consumption, but also helps cut cement mixer truck operating costs. Performance is improved too: rotation speed control is more accurate, operating noise levels are significantly lower. Finally, functionality remains higher in the event of a failure: the presence of a second backup DC motor provides reassuring redundancy and eliminates the risks and potentially hazardous situations caused by failures of the drum emptying system.

Key benefits- Increased energy efficiency

- Reduced fuel consumption

- Optimized gear design for maximum efficiency and minimum noise

Torque range- 60,000 Nm (531,044 in-lb)

Gear ratios- Main: 1:220 Emergency: 1:2200

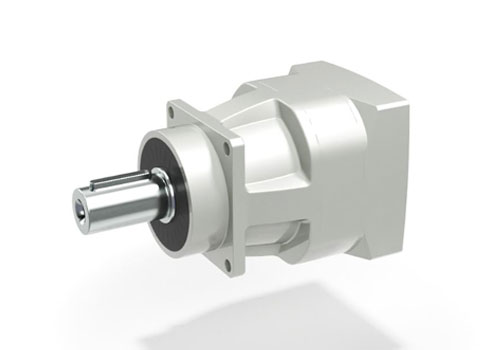

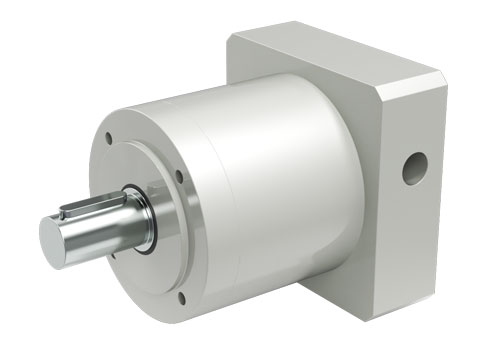

Precision Planetary Gearboxes & Gearmotors

IN-LINE PRECISION PLANETARY GEARBOXES - PERFORMANCE LINE - TQ Series

- The TQ series scores in each performance category: high torque density, high overload capacity, exceptional precision and low vibration. TQ is particularly suited for the highly demanding requirements of servo systems, such as fast dynamics and frequent reverse motion, precise position, motion control and high numbers of starts and stops.

Gear ratios- 1 stage: 3 ... 10

- 2 stages: 16 ... 100

IN-LINE PRECISION PLANETARY GEARBOXES - PERFORMANCE LINE - MP

- The MP series is characterized by a wide range of torque, multiple sizes, great modularity due to multiple design configurations, wide ratios range, two backlash classes and different optimized lubrications ensuring high reliability and the most fitting response to different applications requirements.

Gear ratios- 3 ... 1000

IN-LINE PRECISION PLANETARY GEARBOXES - PERFORMANCE LINE - TQF

- The TQF series features a standardized compact flange interface for an easy installation. High tilting moment, high stiffness and overload capacity characterize this robust gearbox within its product category.

Gear ratios- 1 stage: 3 ... 10

- 2 stages: 16 ... 100

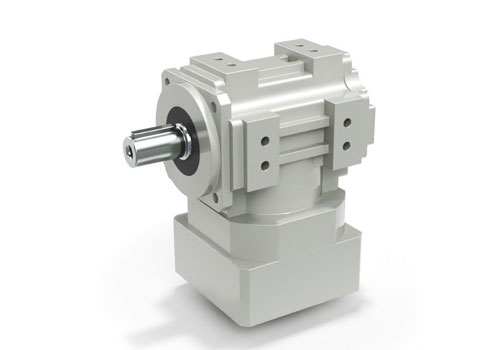

RIGHT-ANGLE PRECISION PLANETARY GEARBOXES - PERFORMANCE LINE - TR

- In addition to optimal performance, very low backlash, high overload capacity and easy installation, the TR series is characterized by great modularity due to multiple design configurations, wide ratios range, two backlash classes and different optimized lubrications, ensuring high reliability and the most fitting response to different applications requirements.

Gear ratios- 3 ... 1000

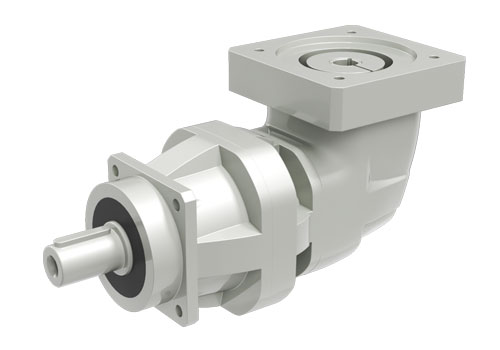

RIGHT-ANGLE PRECISION PLANETARY GEARBOXES - PERFORMANCE LINE - TQK Series

- The TQK right-angle series represents the best solutions for issues of space saving, while maintaining the same top performance levels of the TQ in-line series. This series is particularly suited for the highly demanding requirements of servo systems, such as fast dynamic response, frequent reverse motion, precise position, motion control and high number of starts and stops.

Gear ratios- 1 stage: 3 ... 10

- 2 stages: 16 ... 100

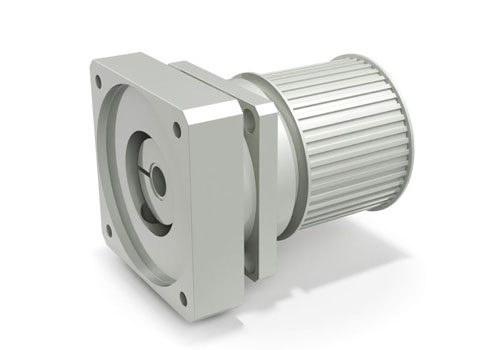

IN-LINE PRECISION PLANETARY GEARBOXES - EFFECTIVE LINE - SL

- The SL series features a compact design optimized for timing belt pulley drive systems. This series represents the most suitable solution for belt servo-drives conveyors and all other applications requiring positioning accuracy, an ultra-compact size and high radial load capacity. The output design compatible with market standards allows easy retrofits and a high level of freedom in projects development.

Gear ratios- 1 stage: 3 ... 10

- 2 stages: 9 ... 100

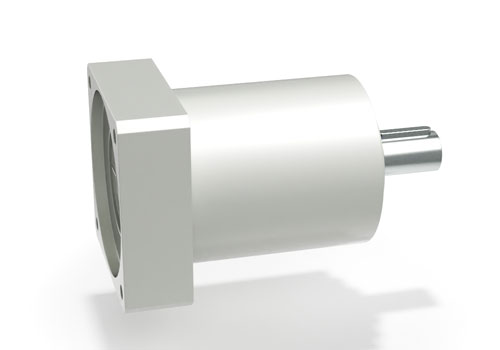

IN-LINE PRECISION PLANETARY GEARBOXES - EFFECTIVE LINE - LC

- LC precision planetary gearboxes represent a flexible solution and valuable alternative with optimal performance and reliability levels. The output design in line with market standards ensures great compatibility for easy retrofits and a high level of freedom in projects development.

Gear ratios- 1 stage: 3 ... 10

- 2 stages: 16 ... 100

IN-LINE PRECISION PLANETARY GEARBOXES - EFFECTIVE LINE - TQFE

- The TQFE series combines exceptional compactness with a standardized fl ange interface, ensuring a quick and easy mounting suitable for a wide variety of applications. With TQFE it is possible to have high levels of performance and precision at an optimum value-price ratio.

Gear ratios- 1 stage: 3 ... 10

- 2 stages: 9 ... 100

IN-LINE PRECISION PLANETARY GEARBOXES - EFFECTIVE LINE - MPE

- The MPE series offers a cost-effective solution for applications that require medium levels of positioning accuracy. It offers high flexibility in terms of sizes, ratios and mounting configurations for a variety of applications requirements. The output design in line with market standards ensures great compatibility for easy retrofits and a high level of freedom in projects development.

Gear ratios- 1 stage: 3 ... 10

- 2 stages: 9 ... 100

RIGHT-ANGLE PRECISION PLANETARY GEARBOXES - EFFECTIVE LINE - KR

- The KR flexible series represents an alternative for applications that require space-saving and medium precision levels. It is available in multiple configurations such as solid/hollow shaft, single/double shaft extension, shrink disk version or flange option.

Gear ratios- 1 stage: ratio 1; 2; 5

RIGHT-ANGLE PRECISION PLANETARY GEARBOXES - EFFECTIVE LINE - LCK

- LCK precision planetary right-angle gearboxes represent a flexible, reliable and cost-effective solution for machines that require a very compact layout. The output design in line with market standards ensures great compatibility for easy retrofits and a high level of freedom in projects development.

Gear ratios- 2 stage: 6 ... 20

- 3 stages: 24 ... 100

RIGHT-ANGLE PRECISION PLANETARY GEARBOXES - EFFECTIVE LINE - TQFEK

- The TQFEK series offers optimized performance and features at an optimum price-performance ratio. An exceptionally compact and standardized flange interface combined with optimal positioning accuracy make it suitable for a wide range of industrial applications. Its right angle-design allows even more compactness for space-saving layouts.

Gear ratios- 2 stages: 3 ... 10

- 3 stages: 9 ... 100

RIGHT-ANGLE PRECISION PLANETARY GEARBOXES - EFFECTIVE LINE - MPEK

- The MPEK series offers medium levels of performance and position accuracy at a competitive value-price ratio. The output design in line with market standards ensures great compatibility for easy retrofi ts and a high level of freedom in projects development. Its right angle-design allows more compactness for space-saving layouts.

Gear ratios- 2 stages: 3 ... 10

- 3 stages: 9 ... 100

GEARMOTORS - BMS Series

- Using an integrated solution, rather than a traditional gearhead/motor combination, the BMS series offers revolutionary space-saving machine design, a wider range of options and a higher performance due to the synergies between permanent magnets, synchronous motors and precision planetary gearboxes technologies. With very reliable tested features, the customer has the flexibility to select three types of performance with an excellent combination variants low overspeed, medium overspeed and high overspeed. All these variants have been designed to optimize the output needed with the benefits of supreme compactness, highest torque / input speed and optimization of drive size. These excellent benefits are achieved using 5 gearboxes sizes and 14 motors in combination with 3 types of Yarn Winding machines. Excellence and reliability allow continuous duty to run your application safely.

Torque range- 45 ... 1,200 Nm (177 ... 10,620 lb-in)

Specific geared units

PLANETARY DRIVES FOR MOBILE - 300 Series

- The 300 series is compact and powerful. Their planetary drive train makes them the ideal choice for all severe duty applications where shock loads and impacts are more the rule than the exception. The product configuration is highly versatile, due to several options for mounting, gear layout, output shaft and motor interface. All the features are available for each of the 20 finely spaced frame sizes, with a torque range of 1,000 to 1,100,000 Nm.

Torque range- 1,000 ... 1,100,000 Nm (8,850 … 9,735,820 in-lb)

Gear ratios- 3.4 ... 5,000

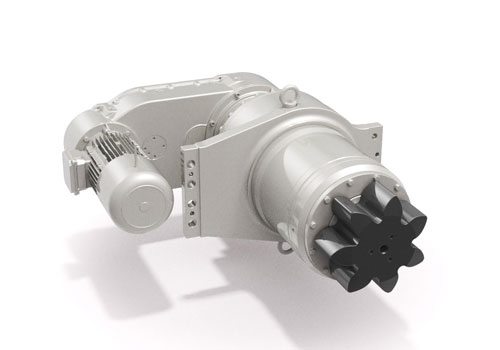

CUTTER DRIVES - FA Series

- Dual stage planetary drive units with integrated pulley support, designed for cold planers, milling machines and surface mining machines with engine power from 80 to 1200kW and different rotor widths. The offset input option ensures higher machine productivity due to the increased cutting depth. The shiftable 2 speed solution allows two possible cutting speeds with huge benefits in terms of machine performance.

Torque range- 8.5 ... 115 kNm (6,269 … 84,819 ft-lb)

Gear ratios- 16 ... 26

CUTTER DRIVES - 700C Series

- Dual-stage planetary drive units with integrated pulley support designed for cold planers and milling machines with engine power from 200 to 550 kW and rotor width from 1.0 to 2.5 m. The offset input option ensures higher machine productivity due to increased cutting depth. The unique integrated cooling system allows greater performance, easier system maintenance and optimal level of reliability.

Torque range- 20,000 ... 45,000 Nm (177,014 … 398,283 in-lb)

Gear ratios- 16 ... 22.9

JACK-UP - 700T Series

- With these planetary gearboxes, Bonfiglioli offers the opportunity for operating the rack to raise and lower the entire hull. The units can be in-line or with a bevel gearbox to facilitate installation of the motor. They can be operated electrically or hydraulically, with or without a negative parking brake. They can be complete with output, with integrated torque arm for easy installation on the machine and with integrated pinion shaft with 50 or 100 toothing module, and large capacity bearing.

Key benefits- Parking brakes

JACK-UP - O & K

- The specific design of the O & K Jack-up Series has been assessed by ABS to work in lifting and lowering legs and hulls of drilling and service jack up rigs, lift boats and windmill installation vessels. Units can be in-line or have a drop box for offsetting the motor installation. They can be electrically or hydraulically driven, with or without a negative parking brake. These jack-up drives can deliver integrated pinions from m50 to m100 and lantern pieces with integrated torque arm for easy installation. Units have class approval from ABS and DNV GL, and full 3.2 certification of the load-bearing parts of the gear transmission with full traceability from raw material to final machined component.

AUGER DRIVES - 700T Series

- With a reliable optimized design, the Bonfiglioli 700T Series for auger applications meets all feed mixer requirements. The different interfaces make this series very flexible. Two shafts for the in-line and multi-auger models are also two fundamental features.

Torque range- 1,600 ... 21,000 Nm

Gear ratios- 15.4 ... 18.3

ENHANCED PROTECTION GEARED UNITS - VF/W-EP

- Enhanced Protection Worm Gearmotors & Units

The VF/W-EP Series is designed to meet the requirements of the food & beverage and pharma & chemical industries and, more generally, to ensure risk-free operation in harsh environments. This version of the gearmotor is manufactured with improved sealing, enhanced corrosion protection and paint suitable for accidental food contact as the standard option. All these features work together to meet the highest hygienic requirements and to greatly increase gearmotor cleanability and operating lifetime in harsh and humid environments.

Key benefits- No dust ingress and protected against water jets

- Minimized environmental contamination Mounting flexibility

- Food zone compliant (FDA & NSF)

- Suitable for humid environment

- Anti-rust Easy to wash

Torque range- 55 ... 440 Nm (486 … 3,894 in-lb)

Gear ratios- 7 ... 300

ENHANCED PROTECTION GEARED UNITS - HDPE

- Helical Parallel Shaft Heavy Duty Gear Units

This product is dedicated to the extruder market and provides high customization of output and gear ratio combinations to fulfill our customers' needs. This gear unit provides a robust nodular cast iron gear case suitable for high loads and specific heavy duty thrust bearing sourced exclusively from primary brands. This solution also allows easy machine integration thanks to a universal mounting gearbox case (customized screw interface can be provided too) and can come with an auxiliary thermal aid device (cooling coil, oil to water heat exchanger), and oil temperature and level sensors to easily monitor its functioning.

Key benefits- Easy machine integration thanks to universal mounting gearbox case (customized screw interface can also be provided)

- Suitable for high loads

- Adaptability to customers' requirements

Torque range- 4,600 ... 77,100 Nm (40,713 … 382,392 in-lb)

Gear ratios- 7.1... 125

ENHANCED PROTECTION GEARED UNITS - A ATEX Series

- ATEX Helical Bevel Gear Units

Some industrial environments are characterized by the presence of explosive atmospheres and thus require additional safety measures. Industrial equipment operating in such conditions must be specifically designed to prevent ignition of the flammable substances present in the atmosphere. To meet our customers' needs, Bonfiglioli has developed an entire line of gearboxes that can be safely used in explosive environments in accordance with ATEX Directive 201/34/EU. If the ATEX version is selected, gearboxes of VF/W, ACF, HD and 300M Series will be manufactured for the utilization in zones 2G/2D and 3G/3D.

Key benefits- Minimized mounting space

- Reduced installation space and wide output speed selection range

- Reduced standard backlash

- Wide output speed selection range

- Gearboxes can operate safety in explosive environments

Torque range- 100 ... 14,000 Nm (885 … 123,910 in-lb)

Gear ratios- 4.9 ... 1,715

ENHANCED PROTECTION GEARED UNITS - C ATEX Series

- ATEX Helical In-Line Gear Units

Some industrial environments are characterized by the presence of explosive atmospheres and thus require additional safety measures. Industrial equipment operating in such conditions must be specifically designed to prevent ignition of the flammable substances present in the atmosphere. To meet our customers’ needs, Bonfiglioli has developed an entire line of gearboxes that can be safely used in explosive environments in accordance with ATEX Directive 201/34/EU. If the ATEX version is selected, gearboxes of VF/W, ACF, HD and 300M Series will be manufactured for the utilization in zones 2G/2D and 3G/3D.

Key benefits- Minimized mounting space

- Robustness

- Reduced standard backlash

- Wide output speed selection range

- Gearboxes can operate safety in explosive environments

Torque range- 56 ...1,600 Nm (495 … 14,161 in-lb)

Gear ratios- 6.4 ... 8,84.9

ENHANCED PROTECTION GEARED UNITS - F ATEX Series

- ATEX Helical Parallel-Shaft Gear Units

Some industrial environments are characterized by the presence of explosive atmospheres and thus require additional safety measures. Industrial equipment operating in such conditions must be specifically designed to prevent ignition of the flammable substances present in the atmosphere. To meet our customers’ needs, Bonfiglioli has developed an entire line of gearboxes that can be safely used in explosive environments in accordance with ATEX Directive 201/34/EU. If the ATEX version is selected, gearboxes of VF/W, ACF, HD and 300M Series will be manufactured for the utilization in zones 2G/2D and 3G/3D.

Key benefits- High mounting flexibility

- Minimized mounting space R

- obustness

- Reduced standard backlash

- Wide output speed selection range (ATEX) gearbox for explosive environments 2G/2D

Torque range- 140 ... 2,900 Nm (1,239 … 25,667 in-lb)

Gear ratios- 11.2 ...1,539

ENHANCED PROTECTION GEARED UNITS - VF-W ATEX Series

- ATEX Universal Worm Gear Units

Some industrial environments are characterized by the presence of explosive atmospheres and thus require additional safety measures. Industrial equipment operating in such conditions must be specifically designed to prevent ignition of the flammable substances present in the atmosphere. To meet our customers’ needs, Bonfiglioli has developed an entire line of gearboxes that can be safely used in explosive environments in accordance with ATEX Directive 201/34/EU. If the ATEX version is selected, gearboxes of VF/W, ACF, HD and 300M Series will be manufactured for the utilization in zones 2G/2D and 3G/3D.

Key benefits- Cost-effective solution

- Low noise

- High peak load capacity

- Long operating life

- High reliability

- Many possible configurations

- Wide output speed selection range

- Wide output torque selection range

- Reduced installation space and wide output speed selection range

- (Atex) gearbox for explosive environments 2G/2D

Torque range- 11... 700 Nm (6,195 in-lb)

Gear ratios- 7 ...100

TUNNELING DRIVES - FTU Series

- The FTU Series are perfectly suited to tunnel boring machines and large mining equipment. Robust, powerful and durable these drives are matching all the requirements of this specific application.

Key benefits- Water jacket

- Oil & air cooling system

- Safety clutch

Electric Motors

SYNCHRONOUS MOTORS - BCR Series

- BCR high-performance servomotors are designed to satisfy the needs of continuous and transient high torque applications. A wide torque range and above-average instantaneous overload ratings make BCR servomotors robust enough for even the most demanding drive applications. Equipped with IP65 push-pull connectors (IP67 connectors are optional), in conformity with EMC requirements, and with a PTC temperature probe with reinforced insulation, these motors guarantee secure electrical connection under all ambient operating conditions.BCR high-performance servomotors are designed to satisfy the needs of continuous and transient high torque applications. A wide torque range and above-average instantaneous overload ratings make BCR servomotors robust enough for even the most demanding drive applications. Equipped with IP65 push-pull connectors (IP67 connectors are optional), in conformity with EMC requirements, and with a PTC temperature probe with reinforced insulation, these motors guarantee secure electrical connection under all ambient operating conditions.

Torque range- 0.2 ... 115 Nm

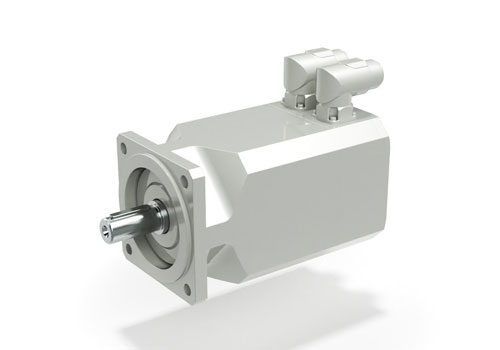

SYNCHRONOUS MOTORS - BMD - Servomotors

- BMD servomotors are permanent magnet synchronous motors with highly compact dimensions and low inertia. They meet the most stringent demands for precision, dynamics and speed settings thanks to their high-quality neodymium iron boron rare-earth magnets and our excellent design. The motors are equipped with the latest encoder technology and are optimized for operation with frequency inverters and precision planetary gearboxes, offering an excellent synergy. More modularity is given with many options availabilities. Flywheel option provide excellent control characteristic for application with high load inertias, brake option, forced ventilation extend the performance in continuous duty operation and critical environment temperature. Even more flexibility is get due to our own design. Together with customer we are partners in developing tailored made solution wherever more functionality and features are needed to meet specific requirements.

Torque range- 0.85 ... 45 Nm (7.5 ... 531 lb-in)

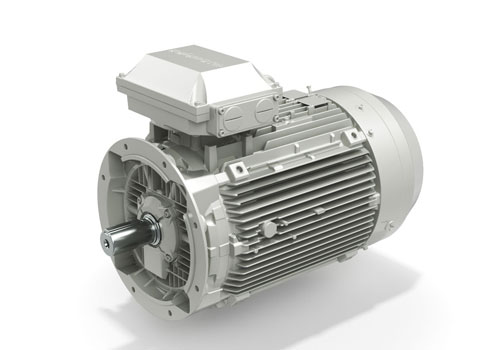

ASYNCHRONOUS MOTORS - BX Heavy Duty Series

- Asynchronous IE3 Three Phase Motor

BX Heavy Duty asynchronous motors are manufactured to exceed the requirements of the most demanding industrial applications. Bonfiglioli Heavy Duty Asynchronous motors, indeed, comes with a best in class set of features: cast iron frame, C3 corrosion protection, regreasable bearings, and Shock Pulse Measurement predisposition as standard on all sizes, are only few of the characteristics that makes these motors the most suitable also in the harshest enviroments. Moreover, Heavy Duty BX can be further personalized and adapted to our customers needs thanks to a wide range of available options. Additionaly, independetly by the motor size, all the BX Heavy Duty motors can be equipped with DC brake. Concluding, BX Heavy Duty are available with IEC frame and IE3 Efficiency and are certified to fulfill the Minimum Efficiency Performances, set by most of the worldwide countries.

Key benefits- Robustness

- Long lifetime

- Wide power range

- Energy saving

- Compliant to all the MEPS Complete (Gearbox+Motor) Solution

- Control flexibility

- Global motor (can be utilized in most of the markets)

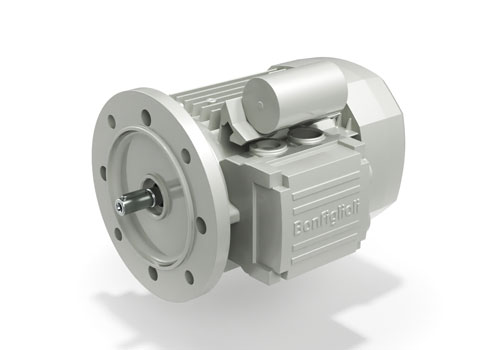

ASYNCHRONOUS MOTORS - BN Series

- Asynchronous IE1 Three Phase motor

BN Series asynchronous motors with aluminum frames are the right solution for a wide range of general purpose industrial applications. Both the IEC and Compact motor are available in IE1 (BN/M) IE2 (BE/ME) and IE3 (BX/MX) efficiency classes according to the international standard IEC 60034-30. Furthermore, Bonfiglioli's e-motors can be equipped with several options: protection class up to IP 56, tropicalized, corrosion-resistant paint, and anti-condensation heaters. Moreover, the BN/M and BX/MX motor Series are also available in the BrakeMotor version with a selection of AC or DC brakes. To maximize our e-motor flexibility, all of them can be controlled with inverters.

Key benefits- Reduced operating cost

- Energy saving

- Compliant to all the MEPS

- Complete (Gearbox + Motor) Solution

- Control flexibility

- Global motor (can be utilized in most of the markets)

ASYNCHRONOUS MOTORS - BE Series

- Asynchronous IE2 Three Phase motor

BX, BE and BN Series asynchronous motors with aluminum frames are the right solution for a wide range of general purpose industrial applications. Both the IEC and Compact motor are available in IE1 (BN/M) IE2 (BE/ME) and IE3 (BX/MX) efficiency classes according to the international standard IEC 60034-30. Furthermore, Bonfiglioli's e-motors can be equipped with several options: protection class up to IP 56, tropicalized, corrosion-resistant paint, and anti-condensation heaters. Moreover, the BN/M and BX/MX motor Series are also available in the BrakeMotor version with a selection of AC or DC brakes. To maximize our e-motor flexibility, all of them can be controlled with inverters.

Key benefits- Reduced operating cost

- Energy saving

- Compliant to all the MEPS

- Complete (Gearbox + Motor) Solution

- Control flexibility

- Global motor (can be utilized in most of the markets)

ASYNCHRONOUS MOTORS - BX Series

- Asynchronous IE3 Three Phase motor

BX Series asynchronous motors with aluminum frames are the right solution for a wide range of general purpose industrial applications. Both the IEC and Compact motor are available in IE3 efficiency classes according to the international standard IEC 60034-30. Furthermore, Bonfiglioli's e-motors can be equipped with several options: protection class up to IP 56, tropicalized, corrosion-resistant paint, and anti-condensation heaters. Moreover, the BN/M and BX/MX motor Series are also able available in the BrakeMotor version with a selection of AC or DC brakes. To maximize our e-motor flexibility, all of them can be controlled with inverters.

Key benefits- Reduced operating cost

- Energy saving

- Compliant to all the MEPS

- Complete (Gearbox + Motor) Solution

- Control flexibility

- Global motor (can be utilized in most of the markets)

ASYNCHRONOUS MOTORS - BS Series

- Asynchronous Single-phase e-motor

Single-phase motors of the BS Series are manufactured according to IEC standards and provided with the run capacitor permanently connected. For applications requiring high starting torque, the version with both the run and the starting capacitor can be selected.

Key benefits- Cost effective

- Plug & play solution

SYNCHRONOUS RELUCTANCE MOTORS - BSR Series

- The synchronous reluctance motor guarantees a sustainable ecological solution which decreases the total environmental impact thanks to the absence of magnets and increased efficiency. Reduced operating costs allow a fast return. This product benefits from the proven simplicity and reliability of induction motors and the higher efficiency of synchronous motors.

Key benefits

Both Bonfiglioli packages are IES2 according to the International Efficiency of Systems (IES) classification for the drive and motor combination (IEC 61800-9-2).

Inverters & Servo drives

PREMIUM INVERTERS - Active Cube Series

- The Bonfiglioli Active Cube is a frequency inverter offering both compactness and flexibility. This specific solution is adaptable on a wide range of machines, starting from servo to heavy industry applications. The broad support for various field bus systems and the standardized interface for motion control applications make Active Cube an excellent jack of all trades for your application needs.

PREMIUM INVERTERS - Active Series

- The Bonfiglioli Active Series contains flexible frequency inverters that are both versatile and easy to use. This product features high performance control and unbeatable advantages in scalability and compact size.

STANDARD INVERTERS - AGILE Series

- The Agile Series of inverters by Bonfiglioli sets new standards in technology for a broad range of users. Agile inverters are particularly suited for the food & beverage, textile, wood, packaging and ceramic industries, where they can be used in a variety of medium complexity automation processes.

SERVO DRIVES - iBMD Series

- iBMD can be controlled by a master or in standalone mode. It reduces both cable and electrical cabinet costs. Total unit size is reduced by more than 35% compared with a classic servo drive solution.

Torque range- 2.7 ... 36 Nm (23.9 ... 318.6 lb-in)

SERVO DRIVES - ANG Series

- The servo inverter series ANG Active Next Generation, has been designed to provide machine builders with high performance. The new integrated micro controller allows enhancement of new functionalities such as cyclic synchronous positioning mode with cubic interpolation, brake control, and evaluation of feedback contact. This solution has been developed to meet the specific requirements of special machinery in a broad range of industries. With this new servo inverter series, Bonfiglioli offers the broadest connectivity with the most advanced control technology and the highest power density.

COMPACT INVERTERS - S2U IP66

- The compact S2U IP66 plug & play inverter for single-phased 230-volt networks and three-phase 400-volt networks comes in three sizes with motor power ranging from 0.4 kW to 18.5 kW. The new S2U IP66 inverter series is particularly suited to harsh environment applications. The heat sink is specially designed for extreme environmental conditions such as dust, humidity, and cleaning chemicals.

COMPACT INVERTERS - S2U standard

- The S2U, plug & play frequency inverter has been designed for entry level applications such as pumps, fans and conveyors. This product offers a cost-effective, easy-to-use solution.

REGENERATIVE UNITS - AEC Series

- Decades of experience in electronic industrial drives and renewable energy have enabled Bonfiglioli to offer an effective solution for recovering braking energy. This solution comes as the new Active Regenerative System inverters (AEC). In a large number of electrically controlled industrial applications, inertia in moving mechanisms can drive electric motors as they act as brakes. They convert kinetic energy into electrical energy. In a regenerative process, this energy is returned to the grid.

Key benefits

Reducing local and worldwide energy consumption.

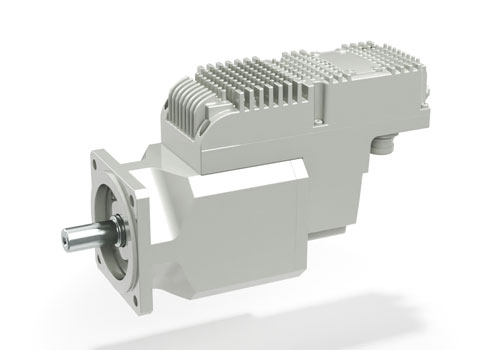

DECENTRALIZED GEARMOTORS - DGM

- Bonfiglioli’s experience brings you DGM - the new range of decentralized inverters for asynchronous motor control. DGM is supplied with the gearmotor or separately, for wall or onboard assembly. If the inverter is supplied with the gearmotor, the mechanical assembly, wiring and basic programming are performed by Bonfiglioli, thus reducing installation times and operations required and limiting the risk of errors to a minimum. Design and installation are faster compared to inverters installed in centralized switchboards.

Key benefits- Application switchboard volume and cooling system reduction

- Streamlined and simpler plant design. Plant extensibility not affected by switchboard capacity.

- No expensive shielded power cables required (otherwise necessary to meet the EMC standards).

Motion Control and Human Machine Interface

MOTION CONTROLLER - BMC 440

- The BMC 440 controller combines high performance with a compact design. It represents the optimal solution for complex, multi-axis applications characterized by strong necessity of control. BMC 440 allows access to Motion features in combination with the ANG (Active Next Generation) servodrives and it is ideal for performing complex movements with accurate synchronization. Its OPC-UA and MQTT functionality ensure local and remote connectivity with full responsiveness to the needs of digital integration for smart manufacturing, including cloud based ones.

EXPANSION MODULES - BMX Series

- With our BMX expansion modules you can customize BMC controllers to suit any automation task. The host of expansion modules and virtually unlimited combination possibilities give you the freedom to create the machinery or system suitable for your requirements.

MOTION HMI - BMV Series

- Human Machine Interface

High-performance, touch-screen control panels BMV are characterized by an essential and compact design and by a high level of frontal protection (up to IP66). The HMIs BMV offer a universal widescreen display with Projected Capacitive Touchscreen (PCAP). The HMI has two Ethernet ports with switch functionality and is ideal for integration into existing networks. It comes with a scratch-proof and dirtrepellent real glass surface. Through busfield interfaces (native ModbusTCP and optional CanOpen), BMV allows a direct management of frequency Inverters and servo drives thanks to its integrated PLC functions, combining in one device visualization and the set up and control of movement functions.

GENERAL PURPOSE HMI - BMI Series

- Human Machine interface

The BMI offers a complete cost effective automation solution which is fully customizable to suit customers' needs. Combined with a Bonfiglioli drives system, the BMI series is a powerful solution dedicated to a wide range of applications.

Construction equipment transmissions

ECGenius

- Bonfiglioli Continuously Variable Transmissions

ECGenius is a high-power, efficient and cost-effective CVT dedicated to telehandler vehicles but also suitable for other equipments. The patented technology at the core of this product is the result of over 15 years of development and enables OEM’s downsize engine while providing unmatched operational ease, and overall vehicle performance improvements in the 20-30% range.

Key benefits

Reliability by Experience- Proven technology with over 500,000 cumulative hours completed in the lab and by OEMs in real life applications

- Precise and stable control system not affected by load variations

- Robust design to handle typical applications shock loads

Adaptability by control- The Transmission Control Unit algorithm uses, engine and transmission data ensuring maximum vehicle efficiency and overall system optimization.

- The Transmission control software is easy to integrate and to include special operating modes for specific applications resulting in maximum productivity

- The open architecture and customizable software allows maximum flexibility and to adjust to various geographic requirements

Genius by design- Traction drive toroidal architecture offers smooth, seamless shifting with no steps through an infinite number of effective forward speeds

- The innovative transmission design with advanced control and clutch reduces the number of mechanical components, therefore reducing mechanical and viscous losses

- Seamless shifting allows the engine to operate at its optimal operating point translating into fuel efficiency.