Getriebebau NORD

Videos

Loading the player ...

- Offer Profile

- Getriebebau NORD is one of the world’s leading manufacturers of drive technology – for mechanical and electronic solutions. The range of products includes geared motors, motors, industrial gear units, frequency inverters, motor starters and frequency inverters for decentralised drive control.

Product Portfolio

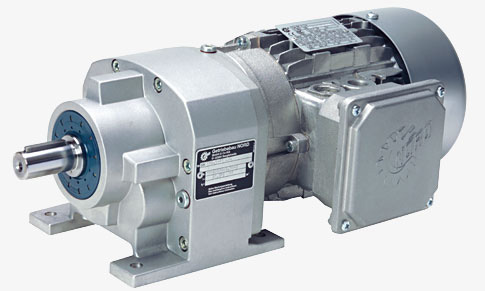

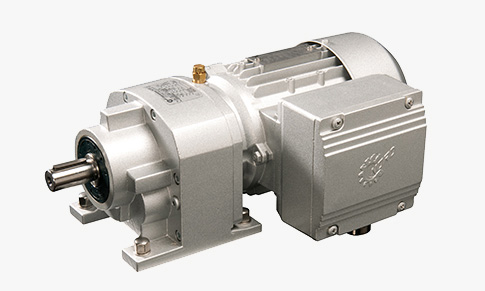

GEARED MOTORS

- We offer a wide variety of geared motors: Helical,

parallel, and bevel gears and of course the special NORD BLOC and UNIVERSAL

products.

As early as the 1980s, NORD developed the most important innovation in gear unit construction to the present day. The unicase concept. All bearing holes and sealing surfaces are machined in a single stage on the latest CNC centres. Helical geared motors

- Helical gear units and helical geared motors from NORD

Drivesystems are supplied in three product series to meet the individual

requirements of each application:

- Unicase, one-piece, helical gear units with the highest efficiencies, combined with energy-efficient motors and central or decentralised frequency inverters provide versatile system solutions with the highest levels of efficiency and economy

- NORDBLOC helical gear units can replace standard helical geared motors

- Standard helical gear units in split housings for various applications

UNICASE

- Sizes: 16

Mounting position: M1 - M6

Torque range: 10 - 26.000 Nm

Performance: 0,12 - 160 kW

Ratio: 1,35:1 - 14.340,31:1

Efficiency: >%95

NORDBLOC.1

- Sizes: 9

Mounting position: M1 - M6

Torque range: 55 - 3,300 Nm

Performance: 0.12 - 37 kW

Ratio: 2.10 : 1 – 456.77:1

Efficiency: >%95

STANDARD

- Sizes: 6

Torque range: 50 - 700 Nm

Performance: 0,12 - 7,5 kW

Ratio: 1,92:1 - 488,07:1

Efficiency: >%95

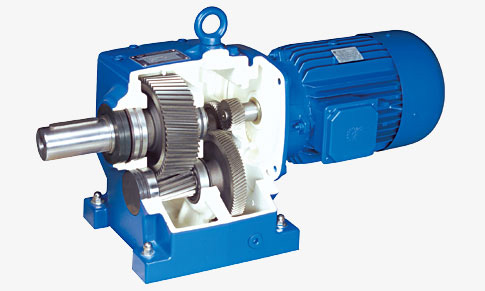

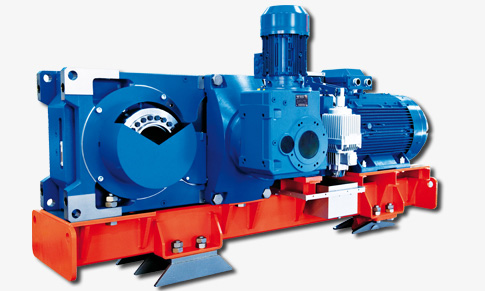

Parallel Shaft Geared Motors

- Parallel shaft gear units / Parallel shaft geared

motors from NORD Drivesystems are supplied in two product series to meet the

individual requirements of each application:

- Unicase, one-piece, parallel shaft gear units with the highest efficiencies, combined with energy-efficient motors and central or decentralised frequency inverters provide versatile system solutions with the highest levels of efficiency and economy

- Industrial Gear Unit upto 242.000 Nm

UNICASE

- Sizes:

14

Mounting position: M1 - M6

Torque range: 110 - 100,000 Nm

Performance: 0.12 - 200 kW

Ratio: 4.03:1 - 6616.79:1

Efficiency: >%95

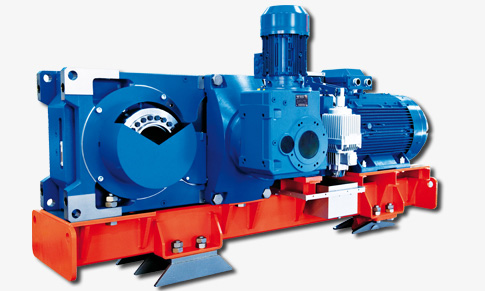

INDUSTRIAL GEARS

- Sizes: 8

Torque range: 25,000 - 242,000 Nm

Performance: 2.2 kW - 1.000 kW

Ratio: 5.54: 1 - 1,600 : 1

Efficiency: >95%

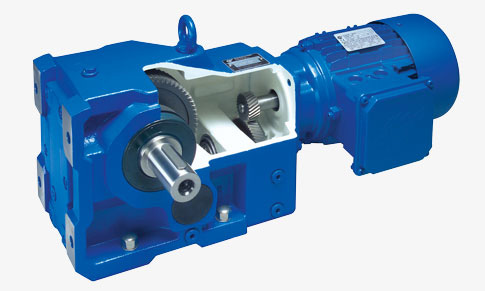

Helical-Bevel Geared Motors

UNICASE

- Sizes: 11

Mounting position: M1 - M6

Torque range: 180 - 50.000 Nm

Performance: 0,12 - 200 kW

Ratio: 8,04:1 - 13432,68:1

Efficiency: >%95

2-STAGE HELICAL BEVEL

- Sizes: 5

Torque range: 90 - 660 Nm

Performance: 0.12 - 9.2 kW

Ratio: 3.58:1 - 70:1

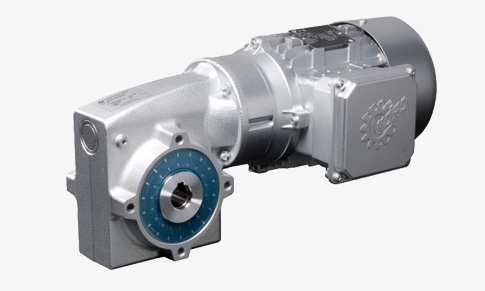

NORDBLOC

- Sizes: 5

Mounting position: M1 - M6

Torque range: 48 - 670 Nm

Performance: 0,12 - 9,20 kW

Ratio: 3,85:1 - 72,31:1

INDUSTRIAL GEARS

- Sizes: 8

Torque range: 25,000 - 242,000 Nm

Performance: 2.2 kW - 1.000 kW

Ratio: 5.54: 1 - 1,600 : 1

Efficiency: >95%

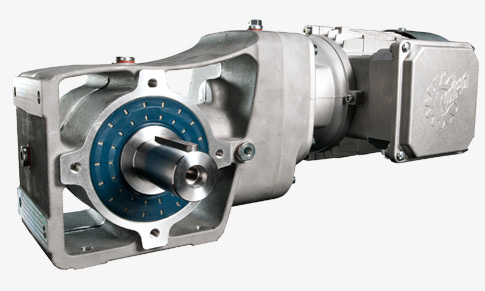

Worm Geared Motors

UNICASE

- Sizes: 6

Mounting position: M1 - M6

Torque range: 94 - 3058 Nm

Performance: 0,12 - 15 kW

Ratio: 4,4:1 - 7095,12:1

UNIVERSAL SI

- Sizes: 5

Torque range: 21 - 427 Nm

Performance: 0.12 - 4.0 kW

Ratio: 5.00:1- 3000.00:1

UNIVERSAL SMI

- Sizes: 5

Torque range: 21 - 427 Nm

Performance: 0.12 - 4.0 kW

Ratio: 5.00:1 - 3,000.00:1

Mechanical Variable Speed

UNICASE BELT VARIATORS

- Sizes: 12

Performance: 0.25 - 110,00 kW

Ratio: 6:1

UNICASE FRICTION DISC VARIATOR

- Sizes: 4

Performance: 0.12 - 4.00 kW

Ratio: 7:1

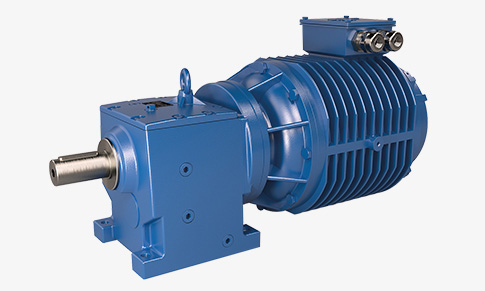

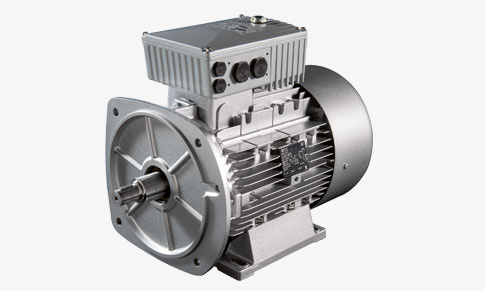

MOTORS

- NORD develops its own motors and supplies them to all the major markets throughout the world. Our own developments ensure a high level of independence from external suppliers and therefore provides our customers with the decisive advantage of short and highly dependable delivery times.

Standard Motors

- NORD fulfils all of the current efficiency regulations and supplies a wide range of energy saving motors for the international market, with which operating costs can be considerably reduced. In addition to reduced energy consumption, all energy NORD motors feature a very durable, low maintenance design.

ENERGY-SAVING MOTORS

- Performance: 0,12 - 1000 kW

NORD fulfils all of the current efficiency regulations and supplies a wide range of energy saving motors for the international market, with which operating costs can be considerably reduced. In addition to reduced energy consumption, all energy efficient NORD motors feature a very durable, low maintenance design.

The series are designed so that in most cases the external dimensions of the motors remain unchanged for a change to a higher energy efficiency class. Normally, no mechanical modifications need to be planned.

Efficient NORD motors are available for 50 Hz and 60 Hz mains, for use in a wide range of regions throughout the world.

Offerings:- IE2 motors

- IE3 motors

SWITCHABLE POLE MOTORS

- Performance: 0,1 - 45 kW

NORD switchable pole motors enable operation with two or more fixed speeds. Squirrel cage motors with this design provide an economical alternative for applications in which continuous speed control with inverters is not required.

Motor versions with 4/2, 8/4, 8/2 and 6/4 poles are available.

As an alternative to two separate windings Dahlander windings or PAM (Pole Amplitude Modulation) are possible. These variants offer the advantage that they only require a single winding for operation at two speeds. This means that both materials and valuable space can be used more efficiently than with separate windings.

NORD develops its own motors and supplies them to all the major markets throughout the world. Our own developments ensure a high level of independence from external suppliers and therefore provides our customers with the decisive advantage of short and highly dependable delivery times.

SINGLE PHASE MOTORS

- Performance: 0,12 - 1,50 kW

Single phase motors are equipped with starting and/or operating capacitors, or are supplied with a Steinmetz circuit as a cheap solution for simple requirements. NORD single phase motors can be operated on 50 Hz or 60 Hz mains with 115V or 230V and support the wide voltage range (220V to 240V). Alternatively, versions with an attached inverter can be used on single phase mains.

NORD develops its own motors and supplies them to all the major markets throughout the world. Our own developments ensure a high level of independence from external suppliers and therefore provides our customers with the decisive advantage of short and highly dependable delivery times.

Specific Motors

- The design of user-specific drive solutions with its customers and their supervision from the engineering phase right up to commissioning is what makes NORD a strong and dependable partner. Also a wide range of application-specific motors is part of NORD's complete solutions.

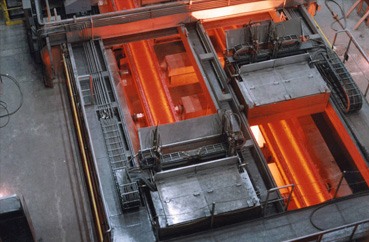

ROLLER TABLE MOTORS

- Throughout the world, NORD DRIVESYSTEMS provides

sophisticated and future-proof solutions for processes in the steel and

aluminium industry, which cater for present and future requirements.

Extensive expertise for the metals industry enables NORD to supply tough,

custommanufactured drives suited to the extreme environments in this field.

Solutions are available e.g. for:- Continuous casting

- Furnaces

- Hot rolling

- Accelerated cooling zones

- Handling

- Processing lines

Unventilated (IC 410) Motors – reliable under extreme conditions.- Completely enclosed design (up to IP66)

- Available as circular fin or longitudinal fin designs

- Shock-absorbing cast iron housings EN‑GJL-200 (GG200)

- Reinforced A end shield made from robust cast iron EN‑GJS-400-15 (GGG40)

- Heavy-duty bearings and shafts

- Individual project-based winding adaption

- Hard torque characteristics with high breakdown torque value

- Insulation systems for inverter feedings

- Insulation class ISO H

Ventilated (IC411 or IC416) NORD motors and other options are also available.

SMOOTH MOTORS

- Performance: 0,37 - 2,2 kW

Motors with smooth surfaces are especially easy to clean thoroughly. In particular in combination with gear units with smooth surfaces (e.g. helical or bevel gear units from the NORDBLOC.1 series or SMI worm gear units) these motors are excellently suited for uses with high hygienic requirements, for example in the food industry.

NORD systems made from aluminium also comply with protection class IP69K, so that they can be cleaned with high pressure liquids. Thanks to the washdown design, these liquids drain off quickly and reliably. For optimum corrosion protection, these motors can also be equipped with an nsd tupH coating. With these properties, the lightweight metal versions are a very attractive alternative to stainless steel drive units - not only in food production and other hygienically sensitive areas, but also in harsh environments with atmospheres containing salt water.

Further practical advantages of NORD smooth motors include:- High efficiency for a long service life, reduced operating costs and low heat dissipation (on request, surface temperatures of below +60 °C can be achieved)

- Maximum flexibility due to the NORD modular system (combination with all types of gear unit)

- Optional equipment with brakes, fans and other extras (see "Options" tab)

NORD develops its own motors and supplies them to all the major markets throughout the world. Our own developments ensure a high level of independence from external suppliers and therefore provides our customers with the decisive advantage of short and highly dependable delivery times.

EXPLOSION PROTECTION GAS ATMOSPHERES

- Performance: 0,12 - 1000 kW

Explosion protected NORD motors can be supplied according to ATEX Categories 2D and 3D for Zones 21 and 22. These systems utilise the ignition protection type "Protection by enclosure" (tD)

NORD has many years' experience in gas and dust explosion protection and has produced explosion protected drive units which comply with the requirements of the European Directive 94/9/EC since 2003. Certification is performed by the Physikalisch-Technische Bundesanstalt (PTB) and by the DEKRA EXAM GmbH.

Drive units with combined protection for gas and dust atmospheres (Categories 2 or 3) are available on request. However, these cannot be used in environments where there are hybrid mixtures, i.e. where hazardous gases and particles occur simultaneously.

NORD develops its own motors and supplies them to all the major markets throughout the world. This autonomy offers customers the decisive advantage of short and highly reliable delivery times.

EXPLOSION PROTECTION DUST ATMOSPHERES

- Performance :0,12 - 1000 kW

Explosion protected NORD motors can be supplied according to ATEX Categories 2G and 3G. Various solutions are available on the basis of ignition protection classes "Increased safety" (e), "Pressure resistant encapsulation" (d/de) and "Non-Sparking Design" (n).

NORD has many years' experience in gas and dust explosion protection and has produced explosion protected drive units which comply with the requirements of the European Directive 94/9/EC since 2003. Certification is performed by the Physikalisch-Technische Bundesanstalt (PTB) and by the DEKRA EXAM GmbH.

Drive units with combined protection for gas and dust atmospheres (Categories 2 or 3) are available on request. However, these cannot be used in environments where there are hybrid mixtures, i.e. where hazardous gases and particles occur simultaneously.

NORD supplies motors from its own development for all important markets world wide. This autonomy offers customers the decisive advantage of short and highly reliable delivery times.

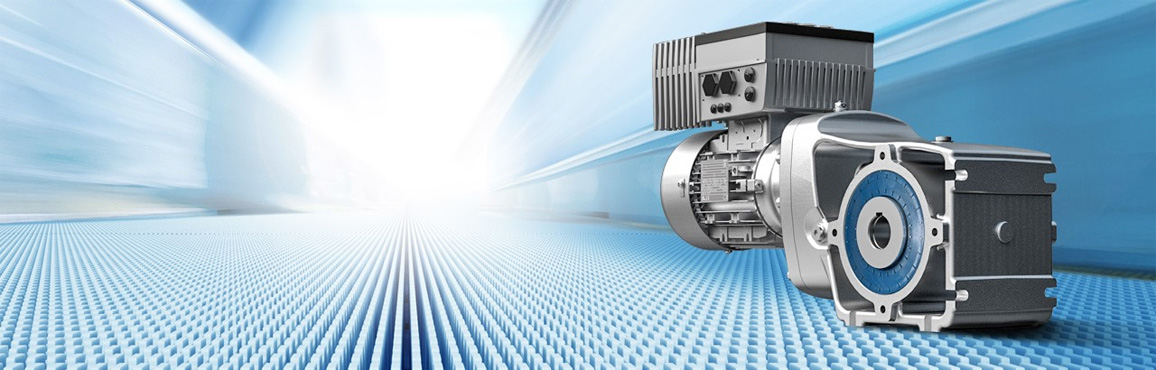

DRIVE ELECTRONICS

- NORD produces frequency inverters and servo controllers

for the necessary power electronics. Inverter solutions are available both

for classical installation in switching cabinets as well as for

decentralised and fully integrated drive units.

NORD Electronic Drivesystems has developed and produced electronics components since 1984. Profit from our many years of know-how with innovative products and great flexibility. Our product range includes electronic motor starters, frequency inverters and servo controllers from a single source. Cabinet Frequency Inverter

SK 500E

- Performance:

0.25 - 160 kW

Performance:

1 AC 110 ... 120 V: 0.25 ... 1.1 kW

1 AC 200 ... 240 V: 0.25 ... 2.2 kW

3 AC 200 ... 240 V: 0.25 .... 15 kW

3 AC 380 ... 480 V: 0.55 .... 160 kW

Output frequency:

0 ... 400 Hz

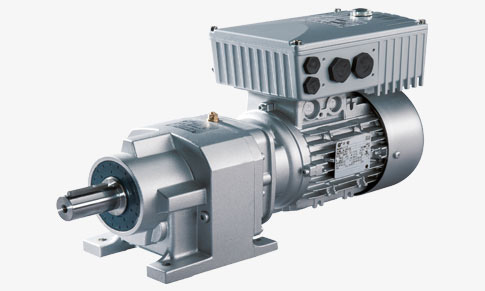

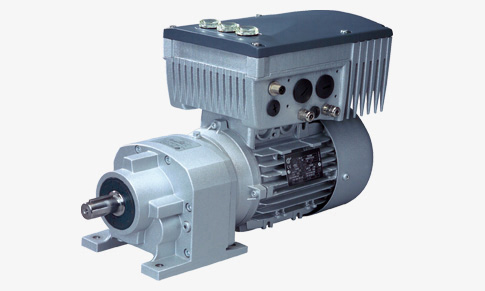

Decentral Drive Solutions

- Decentralised frequency inverters for various applications - for simple speed control (SK 180E) or more complex applications (SK 200E)

SK 135E

- Performance: 0,25 – 7,5 kW

SK 135E – Decentralised motor starter

Many applications, including those in the field of material handling require electronic starting and stopping of the drive units. NORD has developed the new, innovative motor starter SK 135E for this. Due to its versatility, not only motor starting functions, but also gentle starting or reversing mode are possible.Extensive monitoring functions e.g. protect against overheating. Thanks to the I2t triggering characteristic, a motor protection switch is not required. The integrated mains filter of the motor starter SK 135E (with motor-mounting) meets the very highest EMC requirements.

SK 180E

- Performance: 0,25 – 2,2 kW

SK 180E - economical decentralised frequency inverter

The SK 180E is the answer for all applications in the lower power range, where the main task is speed control. Tried-and-tested NORD know-how is used, so that the proven sensorless current vector control ensures an optimum voltage/frequency ratio at all times.The SK 180E achieves significant advantages for the EMC classification. Because of this, a motor-mounted frequency inverter with an integrated mains filter can even be used in a residential environment (Class C1).

SK 200E

- Performance: 0.25 - 22 kW

The frequency inverter SK 200E for decentralised system versatility - up to 22.0kW

After many years of experience with motor-mounted frequency inverters, with the release of the SK 200E NORD has introduced a series of devices which enable a wide range of decentralised drive technology solutions. These robust, reliable and economic systems are suitable for extensive plant, e.g. conveyors, and were specially optimised for price-sensitive market segments. Similar to the SK 500E Panel Mount family, an application-oriented performance level is available which offers the same high quality functionality. Expected features of decentralised components such as robust design, integration of plug connectors, rapid replacement and decentralised modules for communication and I/O signals ensure reliable integration of distributed drive units at the field level.

Motor starter

- Motor starters from NORD Drivesystems with soft start and reversing functions. The SK 135E combines the 3 functions of a typical "electronic motor starter", which are know under the terms starter, reversing starter and soft starter.

SK 135E

- Performance: 0,25 – 7,5 kW

SK 135E – Decentralised motor starter

Many applications, including those in the field of material handling require electronic starting and stopping of the drive units. NORD has developed the new, innovative motor starter SK 135E for this. Due to its versatility, not only motor starting functions, but also gentle starting or reversing mode are possible.Extensive monitoring functions e.g. protect against overheating. Thanks to the I2t triggering characteristic, a motor protection switch is not required. The integrated mains filter of the motor starter SK 135E (with motor-mounting) meets the very highest EMC requirements.

MARKETS

Energy

- PARTNERS

IN MOTION - ENERGY-EFFICIENT AND ECONOMICAL

We have always spent a lot of energy helping our customers to save energy. Continually increasing energy prices make it essential for companies to reduce their operating costs in order to remain competitive. The fact that almost 2/3 of industrial electrical energy consumption is used by drive components, motors, inverters and similar devices creates a demand for drive products and services with high energy efficiency.

We are well aware of our responsibility to the environment and our customers, and sustainability has been an important part of our company policy for many years. Because of this, we have consistently orientated both our range of products and our production facilities to finding and implementing potential energy saving initiatives and ideas.

Drive solutions from NORD DRIVESYSTEMS are highly regarded - not just because of their high energy-efficiency. The industry relies on our products and know-how, particularly for the generation of alternative energies such as wind power, solar energy and hydro-electric power stations. Grain

- CLEAN, SAFE, RELIABLE & EFFICIENT

Clean & Safe

NORD's efficient and reliable reducers, motors and AC Vector Drives contribute to a clean, safe design. By offering a clean, compact, directdrive alternative, your application is free of belts and resulting in no exposed, rotating components.- Optimized drive selections with safety in mind.

- Reduced pinch points and external rotating components.

- Bolt on carriers and housing splits are eliminated.

Reliable Downtime. It’s the last word you can afford to hear when you work in the grain industry. Reliability is a direct result of NORD's unique design and our components work in unison to keep key operations safe and profitable.- An industry leading ratio range and mounting option flexibility.

- Unicase™ gear housings provide accurate positioning of bearings and shafts.

- AUTOVENT helps ensure a leak-free design.

- Infinite-life, high quality gearing, up to AGMA Class 13.

- Exceptional durability, quiet operation and long service life.

Efficient

NORD is commitmented to reduce overall carbon emissions harmful to our environment. NORD motors offer superior insulating materials, low temperature rise and voltage spike resistance.- 95-97 % efficient for 2 and 3-stage select NORD gearboxes.

- Low-inertia, inverter-rated motors meet the latest global energy requirements

- Efficient operation and optimized motor performance.

- Reduced operating temperatures.

- Longer service life and lower total cost of ownership.

Cranes

- SAFE

AND EFFICIENT DRIVE TECHNOLOGY FOR CRANES

The tasks of cranes in picking up loads and setting them down gently at a precise location requires special drives and integrated brakes as well as a frequency inverter technology, which ensures a soft start and generator braking via defined adjustable ramps. Smooth motion with high positioning accuracy is essential - and is often required with the simultaneous movement of the crane and the trolley as well as the control and synchronous operation for travelling drives. This places the very highest demands on the drive systems used.

Throughout the world, manufacturers of cranes and trolleys rely on parallel shaft geared motors from NORD DRIVESYSTEMS with power ratings up to 200 kW and a wide range of gear ratios. Speeds are around 80 m/min for crane movement and 32 m/min for trolley movement, with accellerations of 0.2 m/sec. Two or three-stage basic types are available with hollow or solid shafts, in foot mounted, flange mounted or face mounted versions, each with the same housing. The unicase concept enables parallel shaft gear units with high output power and extremely compact gear unit dimensions. These in turn can be combined with many elements of the NORD modular system.

A further emphasis is on bevel gear units, usually with hollow shafts and torque arms. With this drive version, the large range of standard components also allows the gear unit to be precisely matched to the requirements of the application. In addition to the high efficiency of gear units with helical, parallel shaft, bevel and worm gears, there are further decisive benefits to operators: highest operational reliability, high output torques, high axial and radial load capacity, quiet running, high efficiency, reduced maintenance and longer operating life. Additionally, products with protection classes IP55 and IP66 as well as rust and dust-protected versions with a special coating are used. Furthermore, gear units may are also befilled with synthetic oil if the cranes are to be used at high temperatures, for example in foundries. Airport

- FOR

LARGE AND SMALL

Whether for baggage handling, moving large hangar doors or perfectly positioning the passenger finger to the fuselage of an aircraft – NORD DRIVESYSTEMS provides the optimum drive solution for every application.

For more than 45 years, NORD DRIVESYSTEMS has been at home in almost every branch of industry, where conveyor solutions are used for internal transport logistics. Our drive components and systems are essential wherever things need to be moved, as every movement needs a drive system which is as efficient and reliable as possible. Because of this, we offer a complete range of mechanical, electrical and electronic drive technology from a single source, from motors and gear units to central and decentralised control technology. Food

- INDIVIDUAL

DRIVE SOLUTIONS - IDEAL FOR EVERY APPLICATION

NORD DRIVESYSTEMS provides individual drive solutions for the food industry.

We optimise your operating costs

We always keep the total costs (TCO = Total Cost of Ownership) in view Comprehensive solutions for the industry:- Low energy consumption with IE2 /IE3 energy saving motors, optionally with frequency inverters.

- Reduced maintenance costs through the use of high quality lubricants

- Reduced waste heat prevents heating of the cooled area

- Minimum downtime through simple assembly and dismantling (Harting plugs)

- see also case study Energy Efficiency

Our worldwide service concept- 24 / 48 / 72 hour service

- Service hotlines for mechanics and electronics

Steel

- SUPPORT AT EVERY STAGE

Today’s steel industry has evolved into one gigantic, complex, segment catering to the world’s requirement for automobiles, ships, construction, structures, etc. Steel plants demand peak performance on a 24x7 basis with zero-maintenance and at the highest possible efficiency levels.

With its great expertise in drive technology solutions, NORD Drivesystems is now well known in the steel industry as a systems supplier with individual project consultancy, and has made a name for itself due to the use of its motors in the harsh environment of the steel industry. Although motors only form a small proportion of the investment volume of a steel works, they are a vital part of the plant as a whole. The drive units must operate in a harsh environment, which often involves extremely high temperatures. This means that they must be appropriately designed to cope with the requirements of the steelmaking industry. NORD drive units are used for roller conveyors, which run continuously and are only rarely accelerated, and in contrast for reversing steel rolling mills, in which the direction of rolling is reversed after each rolling process. Reversing operation places extreme electrical, mechanical and thermal stresses on the drive unit. Rolling operation is characterized by the fact that the rollers, including the material to be rolled, has to be accelerated within a very short time, with rapid switching cycles, and reversal of the direction of rotation.

Delivering quality globally

NORD stands for a 45 year tradition of quality and reliability with its roots in Germany. With a global presence in more than sixty countries, every industry vertical relies on us to offer the very best. Our successful climb to the elite list of gear motor manufacturers is due to our strategy to listen to and work closely with our customers. Together with the help of our customers we have created optimal drive solutions and have had solid growth as a company as well. Our products embody an innovative combination between compact mechanics and intelligent electronics. We market and produce a complete product line of mechanical and electronic drive components including, quality gear reducers, motors, frequency inverters, servo controllers and decentralized drive technology. Together, NORD and our customers are building long term successful business relationship. Intralogistic

- EFFICIENT DRIVE SOLUTIONS FOR INTRALOGISTICS

Whether for baggage handling, moving large hangar doors or perfectly positioning the passenger finger to the fuselage of an aircraft – NORD DRIVESYSTEMS provides the optimum drive solution for every application.

For more than 45 years, NORD DRIVESYSTEMS has been at home in almost every branch of industry, where conveyor solutions are used for internal transport logistics. Our drive components and systems are essential wherever things need to be moved, as every movement needs a drive system which is as efficient and reliable as possible. Because of this, we offer a complete range of mechanical, electrical and electronic drive technology from a single source, from motors and gear units to central and decentralised control technology. Cement

- EFFICIENT

DRIVE SOLUTIONS FOR THE CEMENT INDUSTRY

Cement based materials are essential for sustainable building. However, cement manufacture is a sophisticated process whose individual stages require a great deal of energy. This makes energy costs one of the largest cost factors for the industry.

Because of this, cement production requires drive units which can stand up to harsh conditions and are also especially energy-efficient.

For more than 45 years, NORD DRIVESYSTEMS has been at home in almost every branch of industry where conveying solutions are used.

Our drive components and systems are essential wherever things need to be moved, because all movement needs drive - as efficiently and safely as possible. Because of this, we provide an entire spectrum of mechanical, electrical and electronic drive technology from a single source - from energy-efficient motors and low-loss gear units to centralised and decentralised control technology. Water

- EFFICIENT AND WELL PROTECTED

For more than 45 years, NORD DRIVESYSTEMS has been at home in almost every branch of industry, where conveyor solutions are used for internal transport logistics. Our drive componemts and systems are essential wherever things need to be moved, as every movement needs a drive - as efficiently and safely as possible. Because of this, we provide the entire spectrum of mechanical, electrical and electronic drive technology from a single source, from motors and gear units to central and decentralised control technology.

Especially for waste water treatment and outdoor applications, drive units are often subjected to extreme environmental conditions such as moisture, dust, dirt or chemicals. Even in their standard versions, NORD gear units provide a high level of protection against such influences. In order to cater for extreme requirements, NORD DRIVESYSTEMS takes appropriate measures to protect the high quality technology and ensure the reliability and functionality of the drive system. Stage

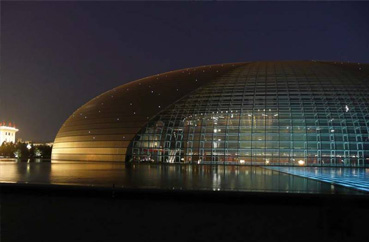

- DRIVE SOLUTIONS FOR GREAT EVENTS

Stages in community halls, theatres and opera houses require safe, reliable and quiet drive technology. Curtains, podiums, rotating, lifting or sliding stages and stage structures must be brought into the correct position unnoticed by the audience and without endangering the actors and stage hands.

For these applications the trend is towards electromechanical drive systems as these are more suitable than relatively complex, high-maintenance hydraulic drives, especially where space is restricted. As compact and cheap alternatives to hydraulic drives, they have proved themselves above all for raising and lowering loads on the stage. For more than 45 years, NORD DRIVESYSTEMS has been at home in almost every branch of industry where transportation solutions are used for internal logistics. Our drive components and systems are essential wherever things need to be moved, because all movement needs drive - as efficiently and safely as possible. Because of this, we provide the entire spectrum of mechanical, electrical and electronic drive technology from a single source, from motors and gear units to central and decentralised control technology.