- Offer Profile

-

Motors and drive technology individually and tailor-made

Our comprehensive range of modern drive technology is our offer - whether DC motors, geared motors, stepper motors or even AC motors.

Our comprehensive range of modern drive technology is our offer - whether DC motors, geared motors, stepper motors or even AC motors.

Our electric motors can be used universally in many applications. Regardless of the quantity, we can supply our catalog motors in small and large series on the one hand and implement customer-specific applications according to the specification of concrete requirement profiles on the other hand.

PowerTronic progressive drive technology

For over two decades, PowerTronic has stood for dynamics, reliability and progress: We’ll drive it! We offer a comprehensive range of modern drive technology – regardless of whether DC motors, geared motors, stepper motors or AC motors.

AC-Motors

-

AC motors are the most common motors and are therefore widely used in the industry. These AC motors are divided into two groups: single-phase motors and three-phase motors. In addition to the direct current motor, the alternating current motor is one of the motors between which a fundamental distinction is made.

The areas of application for AC-Motors from PoweTronic are very diverse. For example they are used in document shredders, Copiers and sorting machines.

Induction motors

-

The wide range of applications for induction motors covers various industrial applications, such as conveyor belts.

We have different sizes of induction motors in our range, which differ fundamentally in terms of nominal power, speed and other parameters. What they all have in common is the robust construction and high cost-effectiveness. Individually assembled motors with bevel or worm gears and with brakes are optionally available.

Induction motors basically have a very robust, brushless design and at the same time a good price-performance ratio. The available nominal voltages of e.g. 110V or 230V also make them very appealing.

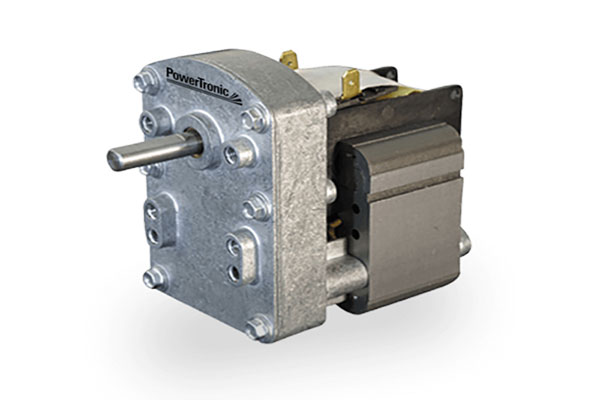

Unidirectional synchronous motors

-

Unidirectional synchronous motors have a wide range of possible applications. They are often used in automation technology as actuators/servo drives.

Because of their design, these motors have a good price-performance ratio. Due to the various gear combinations, a wide range of applications can be covered.

The motors have the typical advantages of synchronous motors with a compact design.

Bidirectional synchronus motors

-

Bidirectional synchronous motors have a wide range of applications. They are often used in automation technology, as actuators / positioning drives.

Due to their design, these motors have a good price-performance ratio. Due to the various gear combinations, a wide range of applications can be covered.

The motors have the typical advantages of synchronous motors, with compact design and simple possibility to specify the direction of rotation.

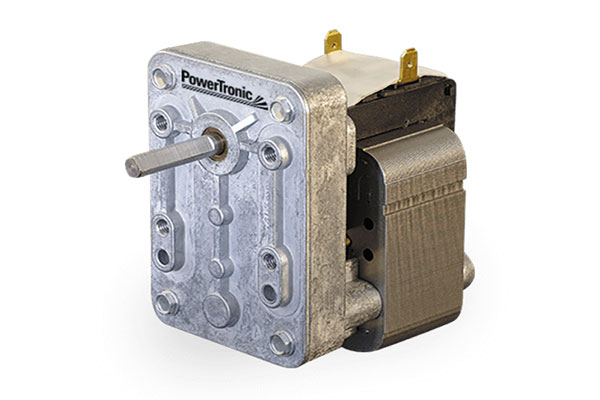

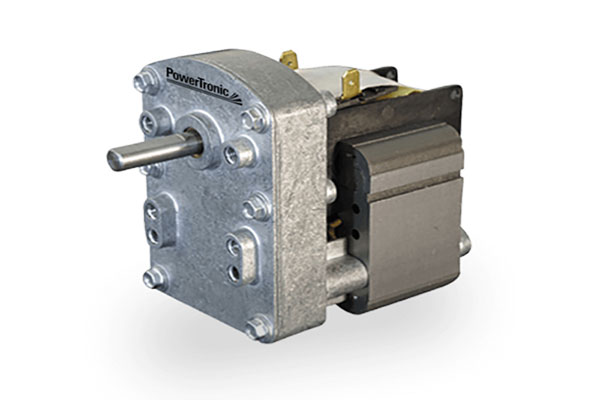

Shaded pole motors with gearbox

-

Shaded-pole motors are AC motors and belong to the group of asynchronous motors. These motors run on single-phase AC power.

Shaded pole motors have a very simple structure, which makes them robust and reliable. Since the direction of rotation is determined by the design, they are used in appropriate applications. They are often the motors used for different fans, pumps or cooling units.

The simple structure mentioned at the beginning, the associated freedom from maintenance and robustness are typical advantages of shaded-pole motors. They have a very long service life, run very smoothly and can be operated cost-effectively without complex regulation or control devices.

BLDC-Motors

-

Brushless DC motors – BLDC motors for short – are also operated with a direct current. Unlike the DC motor, however, this type of motor is operated with control electronics. These electronics convert the direct current. As a result, a moving magnetic field is generated that moves and drives the rotor.

BLDC motors are often used in automation technology such as industrial robots. Other areas where brushless DC motors are used are, for example, PC fans or hard disk drives.

A key benefit of BLDC motors is durability. The absence of brushes eliminates sources of error that arise from them. BLDC motors are also applicable for higher speeds they are more efficient and also more reliable. The brushes also eliminates wearing down parts, which make a motor of this type require less maintenance.

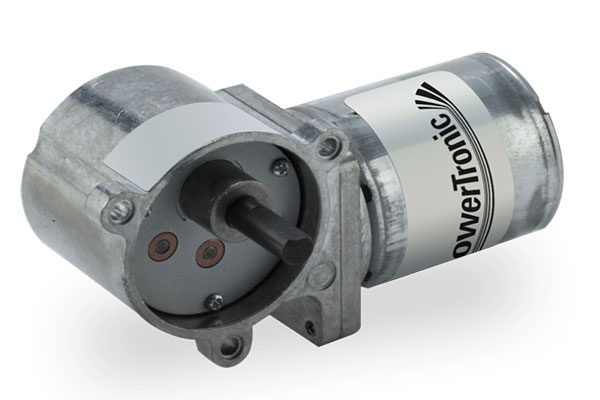

External rotor (Outrunner)

-

In external rotor motors, the rotor encloses the stator - hence their name. Compact design and freedom from maintenance are the main features.

Outrunners have a wide range of applications. These are most commonly found in fans, heaters and air conditioners. In the industrial environment, external rotors are used in pump drives, in gearbox construction and in actuators.

We also offer various options for our external rotor motors, such as gears or a B-side shaft, Special voltage and special shafts according to customer requirements are also possible.

Spur gear motor

Flat gear motors consist of a spur gear and an electric motor (AC, BLDC or DC).

This type of motor is mainly used in process engineering and conveyor technology as transport drives and travel drives. Due to their flat design, any given space conditions can be used well and the motors can be easily integrated into your application.

Very high gear reductions are possible, which means that a large torque range can be covered. We also offer you various options such as encoders, connectors and special shafts according to your specifications.

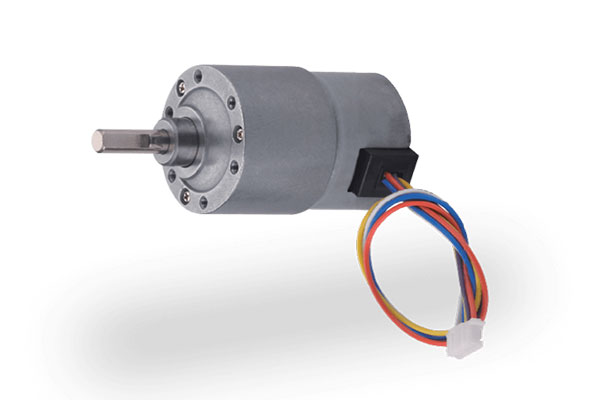

Motors with gearbox

-

Geared motors with integrated electronics are an excellent choice if your application has little space for the drive solution and tasks such as speed control or positioning still have to be implemented.

The built-in electronics significantly reduce the space required for these motors. This makes it useful for devices in medical technology, laboratory technology, or device construction in general.

Their use without an external control unit makes these motors particularly interesting for space-critical applications. The compact motors are easy to handle and offer you the advantages of a BLDC motor.

Motors without gearbox

-

Brushless DC motors (in short: BLDC motors) without gears are used where gears already exist.

Our motors without gears are versatile. If your own gears are already installed in the application and you want full flexibility when choosing the motor, our BLDC motors are a great choice.

Planetary geared motors

-

Motors with planetary gears are versatile and robust with a space-saving, cylindrical design.

Planetary geared motors can be found where high amounts of torque is required. This is often in conveyor technology, but also in machines in the wood, food and automotive industries.

At PowerTronic we offer different versions of planetary geared motors. In addition to the conventional, brushless motors, there are also versions such as the high-torque-low-noise-long-life planetary geared motors or a BLDC version with the same properties.

Planetary geared motors - high torque, low noise, long life

-

Motors with planetary gears are versatile and robust with a space-saving, cylindrical design.

Planetary geared motors can be found where high amounts of torque is required. This is often in conveyor technology, but also in machines in the wood, food and automotive industries.

Planetary geared motors have the advantage of a compact design with high possible torques. Another great attribute is that it runs very smooth

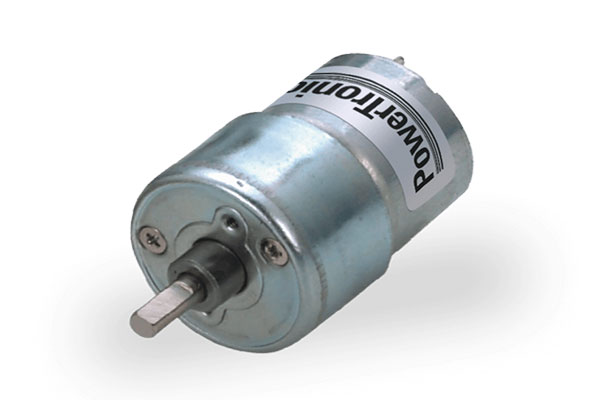

DC-Motors

-

Similar to AC motors, DC motors are very widespread in industry and have a large number of areas of application. The most common types of DC motors are brushed motors and brushless motors - i.e. brushless motors.

DC motors are used wherever precision and/or speed is required. Another example where DC motors are used is in applications where high power is required.

The high speed that a DC motor can reach makes these motors very suitable for grinding machines, saws or fans, for example. In DC motors, electrical energy is converted into mechanical energy. In most cases, these forces are created by magnetic fields in which the rotor generates the drive.

DC motors are very precise and fast. This is one of the advantages over AC motors. With DC motors, you can also control the speed and start, stop, accelerate or reduce speed faster.

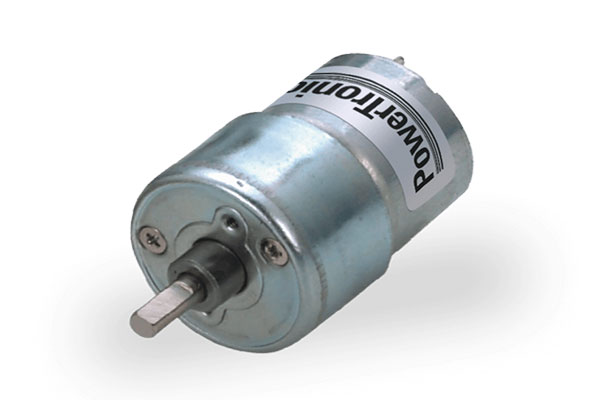

Motors (high-grade) up to Ø 80mm

- High grade motors with a maximum of 80mm are brushed DC motors from PowerTronic. They achieve higher values in all areas, including performance and torque.

Motors (low-cost) up to Ø 52mm

- These DC motors have a maximum diameter of 52mm and are therefore very space-efficient. These are brushed motors with a high possible nominal speed.

Planetary geared motors

-

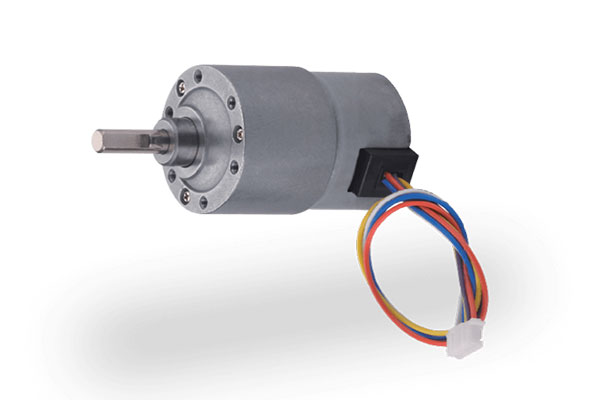

Our DC planetary geared motors are versatile and can be equipped with various options such as encoders, stranded wires, connector plugs, special shafts, B-side shafts and more.

Any of our DC planetary geared motors can be equipped with various options on request. The built-in brushed DC motors are available from 3V to 24V.

High-Torque-Low-Noise-Long-Life

-

Planetary gear motors work to transmit and increase torque. This type of transmission consists of so-called planet wheels, which are arranged around a central sun wheel, and epicyclic wheels, which lie around the central wheel.

Planetary gear motors are available in different versions. One of them is the design as a DC motor with the properties High Torque - Low Noise - Long Life. These have low noise levels, are durable and capable of high torque.

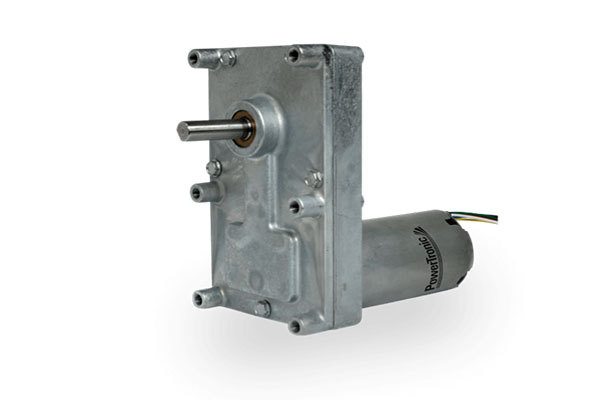

Spur geared motors (flat)

- This subcategory of DC motors includes so-called spur gear motors. They consist of a brushed DC motor and a spur gear.

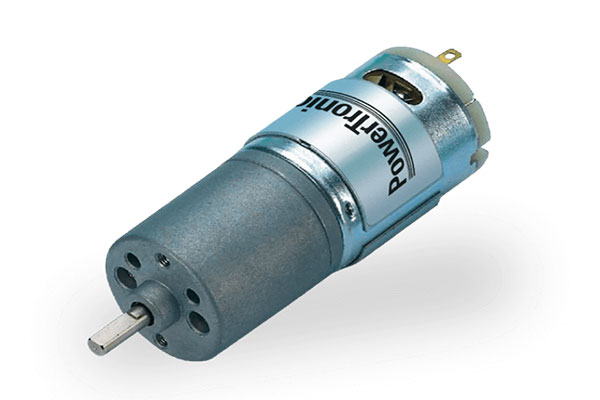

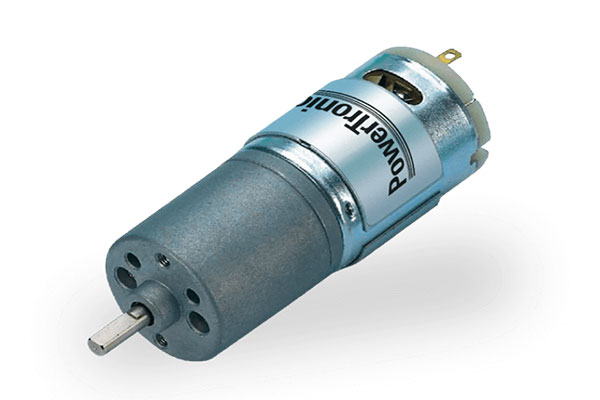

Spur geared motors (round)

This subcategory of DC motors includes so-called spur geared motors. They consist of a brushed DC motor and a spur gear.

In our range you will find various versions of spur geared motor designs with round gears or flat gears. What they all have in common is the very good price-performance ratio. A wide range of economical solutions is available over a large torque range.

Spur geared motors offer good running smoothness. Of course, the DC motors listed in this category also offer all the usual properties of brushed motors. Due to the simpler production compared to planetary gears, a suitable solution for many price-critical applications can be achieved with spur gears with good performance parameters.

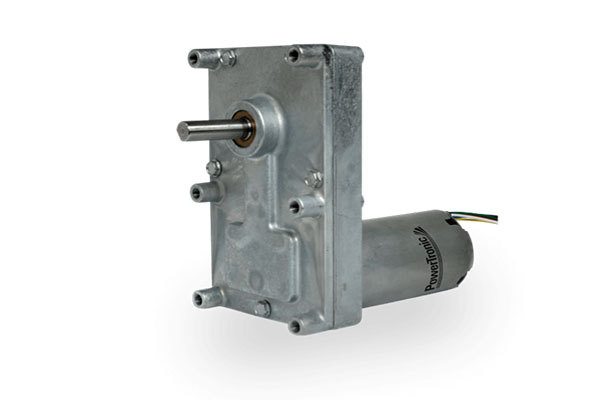

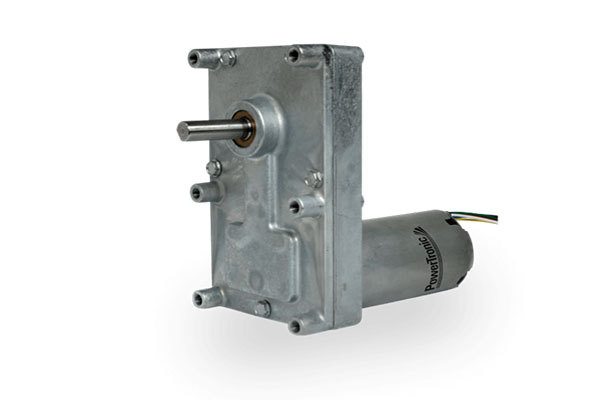

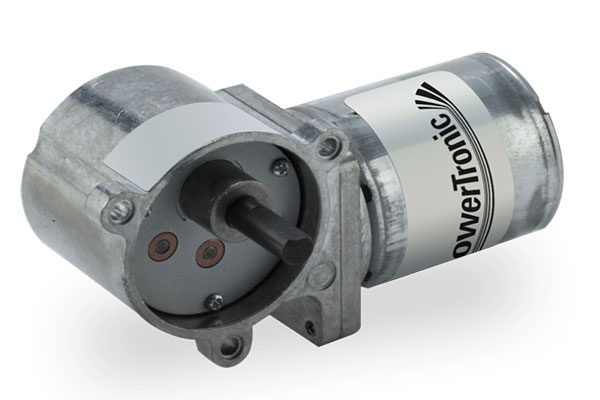

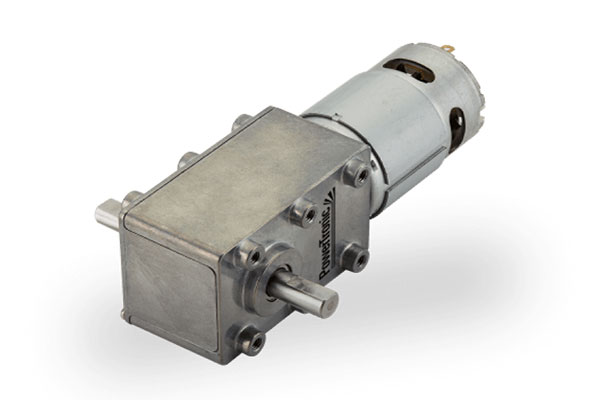

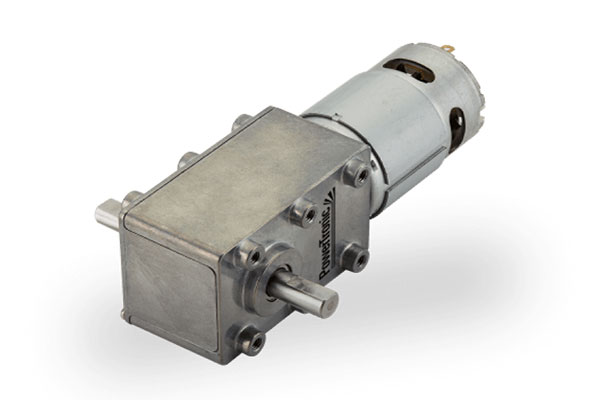

Right angle gearmotors

-

This subcategory of DC motors includes so-called right-angle geared motors. They consist of a brushed DC motor and an angular gear (bevel gear).

There are many different applications where angular geared motors are used. In industry very often with printing machines, in conveyor technology or in general in plant construction, in the automotive sector, in Agricultural machinery, building technology and many space-critical applications.

We offer you a range of appropriate drives to enable an economical solution wherever the installation situation requires an angle gear

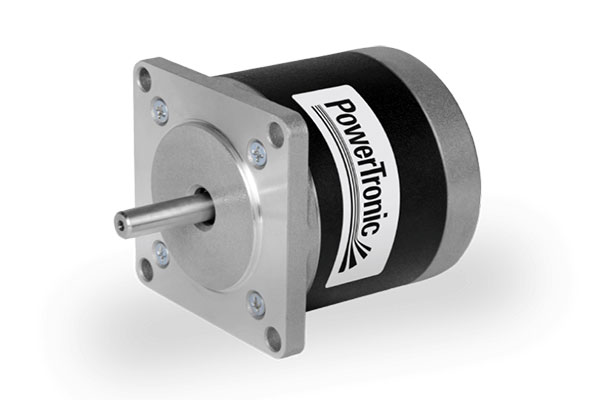

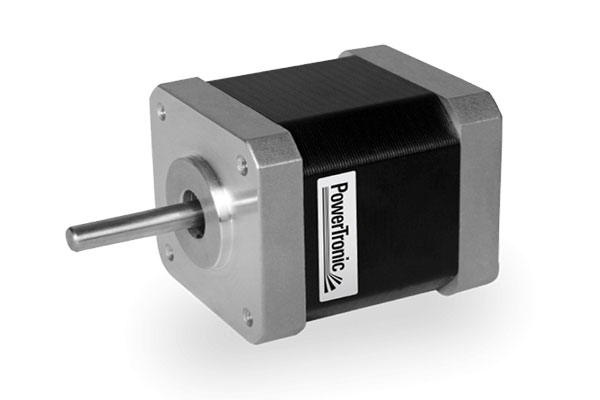

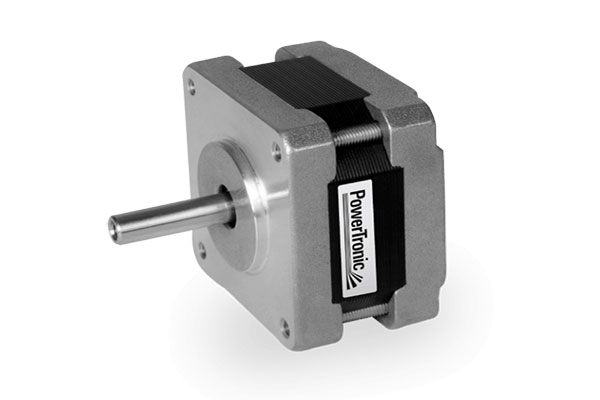

Stepper motors

-

A stepper motor is a brushless synchronous motor that converts electrical impulses into mechanical movement. In contrast to other motors, the rotor is only moved step by step here.

Stepper motors are used wherever automated processes need to place objects or align them precisely. This is often robotics or precision mechanics. Stepper motors are also very common in printers. It doesn't matter whether it's older models, such as dot matrix printers, or new 3D printers.

A major benefit of stepper motors is the accuracy and ease of controlling the position of the rotor and the speed of rotation of the rotor. Another advantage is the simple construction, which enables a finished product to be produced at comparably low costs. The lack of brushes in the stepper motor also increases the durability of the motor.

Hybrid Stepper motors

-

The hybrid stepper motors that are widespread today are a mixture of reluctance stepper motors and permanent magnet stepper motors that combine the advantages of both variants

Stepper motors in general are commonly found in 3D printers, computer drives and machine tools, as well as countless industrial applications. They are often the drive of choice for positioning tasks.

Do you need a special shaft, a linear actuator or an encoder for your application? Ready-made motors with planetary gears are also possible.

Bipolar with spur gearbox

-

Permanent magnet stepper motors - or PM stepper motors for short - are a type of construction in the stepper motor category. The motor stator is made of soft iron and the rotor is made of a permanent magnet. The simple structure leads to high efficiency.

PM stepper motors, like all other types of stepper motors, are ideal for use in positioning tasks. That is why they are often found in automation technology and robotics.

We offer you PM stepper motors in unipolar and bipolar versions. Both variants can be equipped with various spur gears.

Unipolar with spur gearbox

-

Permanent magnet stepper motors - or PM stepper motors for short - are a type of construction in the stepper motor category. The motor stator is made of soft iron and the rotor is made of a permanent magnet. The simple structure leads to high efficiency.

PM stepper motors, like all other types of stepper motors, are ideal for use in positioning tasks. That is why they are often found in automation technology and robotics.

The simple design of the PM stepper motor enables a cost-effective drive solution without having to forego the typical advantages of stepper motors in your application. High holding torques and peak torques, even at low angular speeds, as well as the typical, simple positioning in steps should be mentioned.

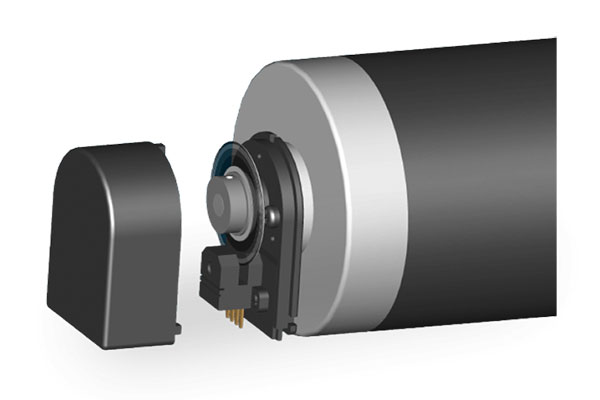

Encoders

-

Encoders are electromagnetic elements that are used in drive technology. They are often also referred to as rotary encoders, which act as a sensor for an angle of rotation and deliver digital signals

Encoders are used in many industrial areas. For example, encoders can be found in milling machines, CNC machines and many other machines in the processing industry.

The encoder works on the basis of a mechanical movement - in most cases a rotation. This is converted into an electrical output signal. The encoder is connected to the rotating element by means of a bore, grooves or a flange.

BLDC-Optical Incremental

- Encoder for BLDC Motor Optical Incremental Type

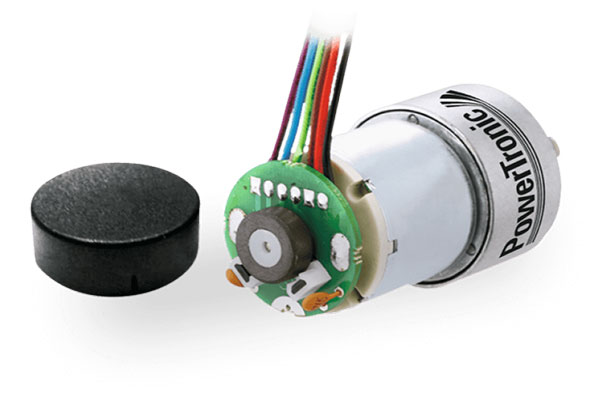

DC-Magnetic Incremental

- Encoder for DC Motor Magnetic Incremental Type One and Two Channel Hall Effect

DC-Optical Incremental

- Encoder Encoder for DC Motor Optical Incremental Type Two Channels

Our drive solutions in use with

-

Standardized or individual solutions for motors and drive technology

For more than two decades, PowerTronic is standing for motion, reliability and progress: We drive! We offer a comprehensive range of modern drive technology - whether AC, BLDC or DC motors, as well as gear motors

Everything that needs to be moved needs reliable, stable drive technology – whether for industry or for consumers. The areas of application for modern drive technology are so varied that one could speak of unlimited possibilities.

Our extensive range of drive technology allows the customer to access a variety of products at any time for reliability and innovation.

The range of applications for our AC and DC motors as well as geared motors and stepper motors are hard to beat in terms of variety: PowerTronic is always there to help when it comes to meeting the requirements.Examples of AC motor applications:

- Shredding machines

- Printing machines

- conveyors

- Small robots

- air conditioning systems

- Office Machinery

- Laminators

- Medical devices

- Parking ticket dispensers

- Potentiometers

- Pumps

- Rotisserie

- Auger drives

- Sorting machines

- Electricity meters

- Textile machinery

- Vending machines

Examples of DC motor applications:

- Automotive

- Office machines

- Turnstiles

- Labeling

- Ticket machines

- Franking machines

- Prison locks

- ATM

- Drinks machines

- Handling equipment

- Compressors

- Agricultural machinery

- Milking machines

- Window drives

- Stairlifts

- Door and gate technology

- Vending machines

- Packaging machinery