Gooch & Housego

- Offer Profile

-

Gooch & Housego is a global leader in photonics technology. Our expertise extends from research through the development of prototypes to volume manufacturing and enables innovation and effective manufacturing in the aerospace & defence, industrial, life sciences and scientific research (big science) sectors.

When combined with the company’s optical, mechanical, electronic and software design capabilities, G&H is able to provide complete optical system design services.

Product Portfolio

ACOUSTO-OPTICS

-

Gooch & Housego has been a leader in acousto-optic (AO) device design and manufacturing for over 35 years, bringing together some of the best minds and technologies in the field to create a comprehensive line of high-quality products backed by premier service and reliability.

We hold our multiple worldwide manufacturing sites to exacting standards, from the in-house growth of our own tellurium dioxide (TeO2) to polishing, antireflection coating, fabrication and testing of devices. The result is unmatched optical power handling, and optical performance delivered consistently over time and in volume.

ACOUSTO-OPTIC MODULATORS

- Acousto-optic modulators (AOM) allow the intensity of light to be controlled and modulated at rates that far exceed mechanical shutters, even up to 70 MHz. Our modulators are optimized for low scatter and high laser damage threshold. Rise time, modulation rate, beam diameter, and power handling needs of the application need to be understood in order to identify the best acousto-optic modulator and RF driver solution.

FREQUENCY SHIFTERS (AOFS)

-

Transmission through an acousto-optic (AO) device causes the input light to experience a frequency shift equal to the RF drive frequency. Our acousto-optic frequency shifters (AOFS) are optimized for the needs of applications like interferometry, with the ability to achieve high extinction ratio between modes.

We offer standard products with frequency shifts of over 300 MHz and integrated low-power AOFS modules in which the RF driver has been built into the housing. Our team can also customize frequency shifters for specific application, including frequency shifts up to 600 MHz.

MODE LOCKERS (AOML)

-

Acousto-optic mode lockers (AOML) modulate the loss within a laser cavity at its resonant frequency, effectively “locking” the phase of the longitudinal modes to generate very narrow laser pulses of high intensity.

Our mode lockers for Nd:YAG, Nd:YLF, Ti:Sapphire and Argon Ion lasers can modulate at up to 200 MHz, yielding near-theoretical mode locked laser pulse widths. We offer antireflection (AR) coated and Brewster angle options. We design customized one-off mode lockers for demanding scientific and OEM applications.

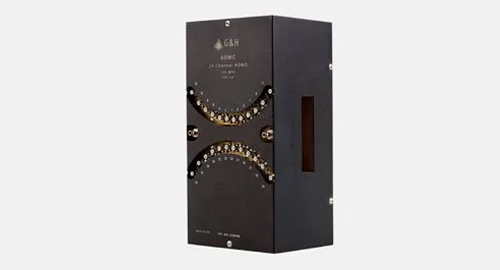

MULTI-CHANNEL MODULATORS (AOMC)

-

Acousto-optic multi-channel modulators (AOMC) allow multiple beams to be modulated or deflected independently by integrating an array of transducers with a single acousto-optic crystal. We have minimized crosstalk through proprietary optical and electrical designs to allow concurrent operation of up to 48 channels for modulation, and up to 8 channels for beam deflection. Our multi-channel modulators are known for their reliable operation and high performance.

Multi-channel modulators are most often used for high speed applications like micromachining and direct-write lithography, as each beam can be modulated independently. They are also used to increase throughput when writing large media by writing multiple beams at the same time.

PULSE PICKERS, CAVITY DUMPERS

- Pulse pickers and cavity dumpers are high speed acousto-optic modulators that can separate and divert a single laser pulse within a pulse train to a new optical path. Both require a very fast rise time with a low duty cycle. With rise/fall times as short as 4 ns and a variety of materials at our disposal, we can create a complete solution to select individual laser pulses with speed and synchronization.

Q-SWITCHES (AOQS)

-

An acousto-optic Q-switch (AOQS) works within a laser cavity to generate high intensity, pulsed light by actively controlling the Q-factor (loss) of the cavity. Our acousto-optic Q-switches are rugged, reliable, and long-lasting, backed by millions of hours of service in the field.

We offer low insertion loss, highly efficient acousto-optic Q-switches capable of handling very high peak power, and will draw on our 35 years of experience to match the cavity length, repetition rate, wavelength, beam diameter, polarization state and output power of a laser to the best acousto-optic Q-switch solution.

ACOUSTO-OPTIC TUNABLE FILTERS (AOTF)

-

Acousto-optic tunable filters (AOTF) are used to rapidly and dynamically select a specific wavelength from a broadband or multi-line laser source. As the applied RF frequency is varied, the transmitted wavelength changes, “tuning” the wavelength of the beam or image in tens of microseconds or less.

We offer an extensive line of AOTFs for wavelength regions from the UV through mid-IR, with resolution bandwidths of less than 1nm. We also offer options such as large-aperture imaging filtering and sideband suppression. Fiber-coupled AOTF devices are available upon request.

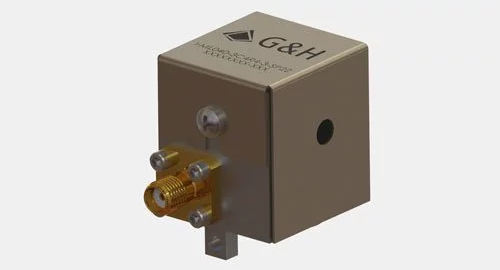

RF DRIVERS

-

An RF driver generates an RF signal that is used to generate the acoustic wave within the crystal of an AO device. The frequency and intensity of the applied RF signal will determine how much an optical beam is modulated, deflected, or tuned.

G&H offers a wide variety of stable high frequency drivers with analog and digital modulation capability, optimized by application. Explore our new line of flexible Smart Dual drivers, or contact us to discuss a custom OEM design.

DEFLECTORS (AODF)

-

Gooch & Housego acousto-optic deflectors (AODF) provide precise spatial control of an optical beam, whether performing 1D or 2D scanning or executing beam deflection through a fixed angle.

Our acousto-optic deflectors offer highly uniform diffraction efficiency across the full scan angle, with consistent power throughput for scanning applications like material processing and digital imaging.

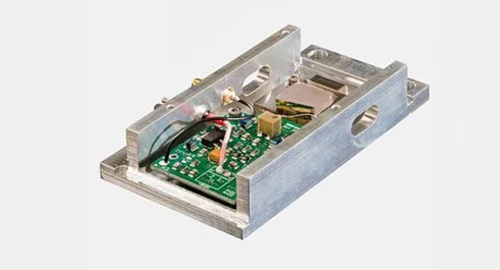

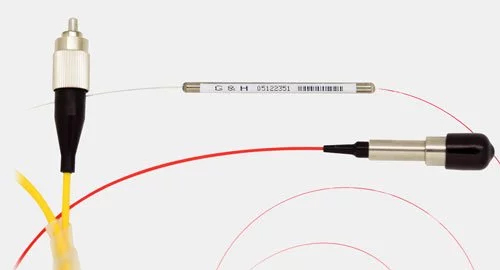

FIBER-Q® FIBER COUPLED MODULATORS (FCAOM)

-

Fiber-coupled acousto-optic modulators (FCAOM) offer an elegant and robust solution for amplitude modulation of fiber lasers, allowing direct control of the timing, intensity, and temporal shape of the laser output. Our Fiber-Q® modulators offer high extinction ratio, low insertion loss, and excellent stability in both polarization maintaining (PM) and non-PM formats at modulation frequencies up to 80 MHz for visible and infrared wavelengths. Built for reliability, the Fiber-Q® series of products features a rugged hermetic design in a compact, low-profile package, ideal for ease of integration into all-fiber and OEM systems, including medical laser systems.

Each Fiber-Q® acousto-optic modulator requires an RF driver to generate the RF signal creating the acoustic wave within the embedded AO crystal. Modulation of the beam through the Fiber-Q will depend upon the frequency and intensity of the applied RF signal.

CRYSTAL OPTICS

-

Gooch & Housego produces many different crystals from a variety of materials. We grow, orient, fabricate, finish, coat, and mount BBO, CdS, CdSe, KDP, and KD*P crystals in housings with apertures from 3 mm to larger than 300 mm.

We manufacture our crystals to work in optical components such as acousto-optic modulators, lithium niobate Mach-Zehnder modulators, Pockels cells, waveplates, and harmonic generating crystals. Large KDP and KD*P crystal plates grown, cut, and finished by G&H are used at The Commissariat à l'énergie atomique et aux énergies alternatives (CEA) and National Ignition Facility (NIF) for laser fusion.

LITHIUM NIOBATE WAFERS

-

Lithium niobate (LiNbO3 or LN) is one of the most versatile and well-developed active optical materials. The crystal finds wide application in electro-optics, acousto-optics, nonlinear optics and guided-wave optics. Attractive fundamental properties of lithium niobate include: wide transparency range, high electro-optic and nonlinear optic coefficients, very high electro-mechanical coupling coefficients, and chemical and mechanical stability.

Gooch & Housego offer a variety of sizes and thickness with wafer diameters ranging from 75 to 125 mm. Standard thicknesses are 0.5 mm, 0.7 mm and 1.0 mm. The standard orientations are x-axis and z-axis growth. Lithium niobate is available in two compositions: congruent and 5.0 mol % magnesium doped.

CRYSTALS AND NONLINEAR OPTICS

-

Gooch & Housego designs and produces nonlinear optic (NLO) crystals for nonlinear frequency conversion applications from the deep UV to the far IR. G&H offers crystals, complete with AR coatings and packaged in housings, for wavelength conversion and polarization control over a wide spectral range.

We offer a wide selection of materials such as ?-Barium Borate (BBO), Cadmium Selenide (CdSe), Cadmium Sulfide, (CdS), Potassium Di-hydrogen Phosphate (KDP), and Potassium Di-deuterium Phosphate (KD*P). All are fabricated on a made-to-order basis in-house using advanced orienting, sawing, grinding, and lapping technologies. From one-off to volume OEM applications, we supply bespoke crystals for research and industry use.

PERIODICALLY-POLED LITHIUM NIOBATE (PPLN)

- Gooch & Housego PPLN nonlinear crystals allow for efficient conversion of wavelengths in the range from visible to 5 µm. The poling pattern is lithographically defined and highly customizable. This allows the crystals to be used in a wide range of applications using wavelength conversion. Phase-matching over very long propagation lengths at infrared wavelengths is possible with our congruently grown PPLN manufactured from highly uniform Z-axis wafers.

ELECTRO-OPTICS

- A Pockels cell alters the polarization state of light passing through it when an applied voltage induces birefringence changes in an electro-optic crystal such as KD*P and BBO. When used in conjunction with polarizers, these cells can function as optical switches, or laser Q-switches. Frequently, laser cavities incorporate Q-switches to shorten the output pulse, resulting in a light beam with enhanced peak intensity.

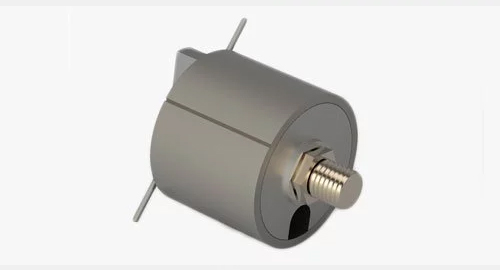

POCKELS CELLS

-

Gooch & Housego are a leading crystal grower with decades of electro-optic device design experience. We manufacture a comprehensive range of Pockels Cells for applications in wavelengths from the UV to the IR. Factors such as average power, repetition rate and the design configuration determine the recommended type of device.

Utilizing proprietary crystal growth, fabrication, and polishing techniques, we manufacture both longitudinal and transverse electrode configuration Pockels cells in beta barium oxide (BBO), cadmium telluride (CdTe), potassium dihydrogen phosphate (KDP) and potassium dideuterium phosphate (KD*P).

These operate by virtue of the Pockels effect, also known as the linear electro-optic effect.

POCKELS CELL DRIVERS

- Gooch & Housego has developed Pockel Cell Drivers to complement its range of Pockels Cells. High quality components are integrated into our designs to maximize lifetime, safety, and reliability. Our Pockels cell drivers are available in several configurations: benchtop drivers, integrated systems, or OEM versions. Drivers have been developed for commercial, military, and scientific Q-switched laser systems as well as regenerative amplifiers for ultrafast laser pulse selection.

LITHIUM NIOBATE Q-SWITCHES

-

The G&H electro-optic Q-Switch employs the highest optical quality lithium niobate available. The electro-optic effect of lithium niobate makes it extremely useful for Pockels cell Q-Switching of several laser types including Nd:YAG, Nd:YALO, Nd:YLF and Er:YLF. Lithium niobate Q-Switches are used in both military and commercial applications, including target designating, range finding and opthalmic surgery.

Our crystals offer low loss, high contrast ratio, and low wavefront distortion, and are qualified for use at 300 MW/cm2. The temperature-stable (TS and XTS) versions of our electro-optic LN Q-Switches allow operation over a wide range of temperatures while maintaining excellent contrast ratio.

FIBER OPTICS

-

Gooch & Housego’s line of active and passive fiber optic components and modules offer the performance and reliability required for some of the most demanding and challenging applications in the world.

Our designs have been qualified and deployed in space applications and are widely used in terrestrial and submarine telecommunications systems.

We support customers through all aspects of system development, lending our expertise in integration of end-to-end fiber optic systems and design for harsh environments. From custom packaging of semiconductor devices to fiber optic assemblies and fused biconical tapering, we have developed best in class design and manufacturing techniques to optimize performance and reliability.

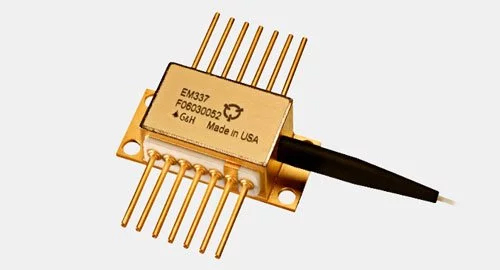

FIBER-COUPLED PUMP LASERS (SM & MM PUMPS)

-

Gooch & Housego’s line of high power diode lasers feature ruggedized, epoxy-free designs intended for use in a wide range of harsh, long-life environments. Cooled and uncooled options are available to meet the most demanding diode laser applications.

Single-mode (SM) pump lasers emit low noise, precisely controlled level of light at a specific wavelength out of a small-core fiber. We offer FBG (fiber Bragg grating) stabilized lasers with up to 700 mW rated output power in the 974-981 nm range, as well as PM fiber-coupled lasers.

Our multi-mode (MM) pump lasers offer up to 7 W output power in the 808-975 nm range, typically in a 14-pin package. We also support 2-pin, 3-pin, 8-pin, and other package sizes upon request.

DFB LASERS AND MODULES

- Distributed feedback lasers (DFB lasers) simultaneously provide smooth, tunable control of wavelength and the extremely narrow spectral width required for precise fiber optic communication and spectroscopy applications. Integrated modules provide further narrowing of the spectral line in a compact OEM package that features simple tuning interface. G&H offers a broad range of DFB lasers in the C-band and L-band on 50 or 100 GHz channel spacing as well as at 1310 nm, 1064 nm, and custom wavelengths. Power level options include 40-100 mW out of the fiber for high power 14-pin lasers and 10-18 mW options for high bandwidth 7-pin configurations.

HIGH SPEED DETECTORS (HSDS)

- Analog optical communication applications continue to serve markets where the expense and overhead of digital conversion is not required. High fidelity applications require a photonic RF signal to be cleanly converted to an electrical RF signal. Gooch & Housego’s line of high speed detectors (HSD) facilitate the crucial conversion at a high bandwidth. Our photodetector designs offer low dark current or noise, and perform with excellent responsivity.

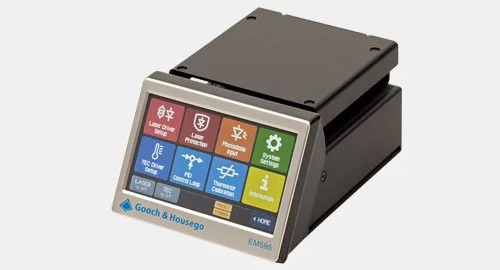

BENCHTOP LASER CONTROLLERS

- Laser diode drivers often require a convenient or computer user interface for operation in production or laboratory environments. To meet this need, Gooch & Housego offers the EM595 benchtop controller, a laser diode driver with a series of easy to use features backed by solid performance. Suitable for driving single-mode and DFB lasers in standard 14-pin butterfly packages, the EM595 meets a variety of needs.

FUSED FIBER OPTIC COMPONENTS

-

Gooch & Housego manufactures a comprehensive line of fused fiber couplers for visible and NIR wavelengths using single-mode and polarization maintaining fiber; we also offer multimode pump combiners. Our fused fiber components possess low insertion loss and high extinction ratio, and are manufactured to exacting standards for quality and reliability.

Widely used for branching optical signals and interfacing in telecommunications, sensor, and biomedical systems, our fiber couplers have been selected for deployment in environments requiring rigorous quality and reliability standards such as undersea and space, as well as in OCT systems.

FIBER OPTIC ASSEMBLIES

- Gooch & Housego designs and manufactures custom modules - fiber assemblies of passive and/or active optical components integrated to provide higher functionality in a compact footprint. Customers sourcing fiber optic assemblies stay focused on their core competence while reducing time to market and development costs. Our in-depth understanding of optical component performance, combined with the use of low loss G&H products, ensures optimized designs. Advanced assembly techniques such as ribbon splicing and fiber recoating are used to provide robustness, reduce form factors, and minimize manufacturing costs.

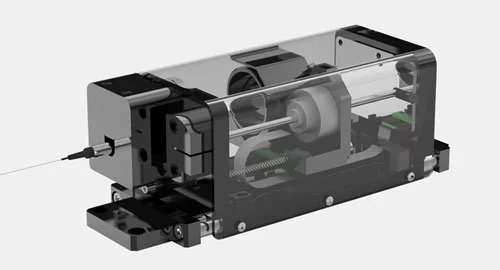

OCT COMPONENTS AND SUBSYSTEMS

-

Gooch & Housego is an established manufacturer of high quality optical components and optical sub-systems for the biomedical imaging market with manufacturing bases in the UK and the USA. G&H enables fiber optic OCT systems with the high-performance OCT components and subsystems needed to achieve high-resolution optical imaging.

Our extremely wideband optical coupler offers uniform performance over a 140 nm wavelength range for spectral domain OCT, and can be integrated into modules like our OCT optical delay line. We also offer a compact OCT optical spectrometer with high resolution and image capture rate, completing a line of modular OCT components that may be purchased for research and OEM use, or integrated by our engineering team into a customized, complete system.

G&H is the perfect partner, providing innovative high-tech optical solutions, whether your requirement is for low volume, prototype units, or for higher volume OEM manufacturing supply.

HIGH RELIABILITY FUSED FIBER OPTIC COMPONENTS

- The G&H line of HI REL fused fiber optic components are deployed in environments such as undersea and space where the costs of component replacement are prohibitive and reliability is of premier concern.?G&H is established as a preferred supplier of these components to most major undersea telecommunications equipment manufacturers. Our HI REL capability is built upon the foundation of an extended history of also manufacturing very reliable components for land-based (or terrestrial) systems in volume.

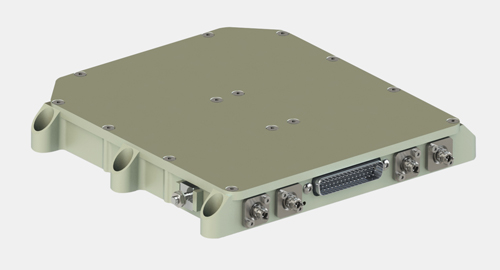

HIGH RELIABILITY BOOSTER ERBIUM-DOPED FIBER AMPLIFIER

-

Gooch & Housego manufacture high-reliability Erbium-doped (EDFA) and Erbium/Ytterbium co-doped (EYDFA) fiber amplifier modules. These amplifiers operate in demanding thermal, vibration, and radiation environments.

Offered as OEM modules, our fiber amplifiers can be controlled and monitored through an electrical interface, making them ideal for system integration into laser transmitters, including satellite laser communication terminals. Customized optical performance, enclosures, port configurations, and amplifier arrays in a single housing are available on request.

PRECISION OPTICS

-

Gooch & Housego manufacture precision optical components and assemblies for applications in research, industry and defense. Our products for laser cavity and beam conditioning include active and passive components as well as nonlinear crystals. Our custom lenses and housed subassemblies find application in transmission and imaging.

Much of our business involves creating high quality, custom optics for volume OEM applications and unique optics for research. Our ring laser gyro mirrors are used by every commercial airline in the world. We have provided 0.5x0.5 m KDP waveplates into national ignition facilities.

From components to modules, the deep vertical integration of our supply chain allows us to maintain control over design, materials and processes, while ensuring quality and security of supply.

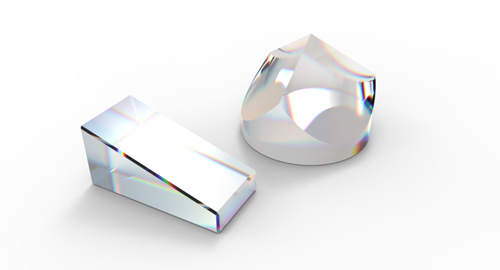

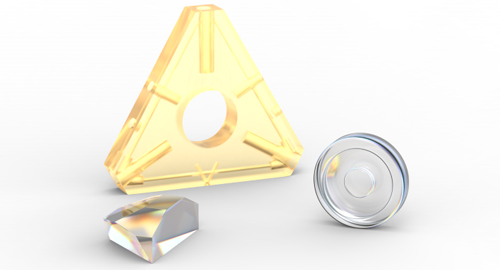

PRECISION PRISMS

-

The simplicity of the prism function belies the complexity of its manufacture. Each surface that is polished and coated must also be held in the strictest of angular tolerance to the other surfaces.

G&H produce precision prisms for a wide variety of applications, from high energy laser cavities to broadband imaging systems.

Prisms bend, fold, invert, reinvert, displace, and deviate light. Though not used as often as lenses and mirrors, prisms are critical components in the systems which utilize their bending or refracting properties. Prisms are challenging to manufacture as each surface and its angular tolerances to the whole are difficult to maintain during polishing and coating. Precision prism fabrication requires complex tooling as difficult to manufacture and maintain as the prism itself.

In order to collapse or control the optical path, optical engineers may generate designs which require optical contacting of multiple prisms to create complex optical structures. Each angle and surface must be held in the tightest of tolerances to the whole piece.

Our precision prism production capabilities include precision angular tolerancing, accurate wavefront control, and polishing of a wide variety of materials (see Materials page for a complete list).

Coatings are similarly difficult, as surfaces may receive different coatings, fixturing is complex, and the final surfaces may need to be completely flat to enable proper contacting, bonding, and alignment to the whole assembly.

Prisms types include: Abbe, Amici, Dove, Leman, Penta, Periscope, Porro, Rhomboid, Schmidt, Wollaston, Zeiss, and others.

Our prisms may be assembled into cubes or more complex opto-mechanical sub-systems including epoxy bonding, optical contacting, or air-spacing.

LASER APPLICATIONS

Our prisms are used in a variety of laser applications because of their high angular tolerancing and high laser damage threshold performance. High energy laser line dielectric coatings complete the component.

IMAGING APPLICATIONS

Prism optimized for imaging applications demonstrate broadband performance and precision wavefront control. Backside metal coatings can further improve off-axis reflectivity. Protective black coatings are often added to improve handling and minimize stray light.

APPLICATIONS

Biomedical, dermatology, fluorescence, laser cavities, laser range finders, laser systems, metrology, periscope optics, optical interferometry, optical sights, spectroscopy, targeting.

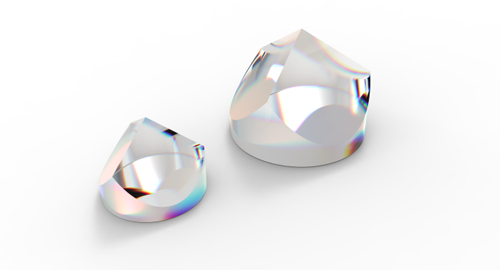

CORNER CUBES

-

High laser damage threshold corner cubes from G&H are used in laser rangefinders to collapse the optical cavity, reduce weight, and improve system performance. They are used in laser cavity designs as a circulator or in instrumentation for compact beam-folded designs.

Corner cubes comprise three mirrors, or reflective prism faces, which return an incident light beam in the opposite direction.

Corner cubes are primarily used in either imaging or laser applications.

IMAGING

Corner cubes for imaging applications are used where it is difficult or too time-consuming to attain precision alignment of the returned beam. The monolithic structure of the component eliminates mounting errors such as can arise when using mirrors and is also less sensitive to thermal errors.

Corner cubes for imaging applications are optimized for broadband performance and minimal transmitted wavefront distortion. Corner cubes may be supplied with or without coatings on the reflecting surfaces as they operate on the principles of total internal reflection (TIR). Coatings are recommended in applications where TIR angles are exceeded or the surfaces cannot be kept clean.

High-precision retro-reflectors offer excellent parallelism between input and output beams. They can be used in surveying applications or other imaging applications. Backside protective black coatings protect the working surface of the corner cube while mounting or handling.

LASER CAVITIES AND LASER RANGE FINDING

Corner cubes from G&H are most often used in laser cavity designs as a circulator. These are often deployed in laser range finding applications to keep system size and weight to a minimum. For laser applications, our cubes are optimized for laser damage threshold and minimization of losses (absorption, reflections, transmission, and scattering).

Our corner cubes for laser ranging finding are compact, precise, and designed to withstand environmentally challenging operation conditions.

INSTRUMENTATION APPLICATIONS

Corner cube reflectors can also be used in spectrometer designs, as the returned beam is highly parallel to the input beam due to the inherent monolithic structure of the corner cube.

APPLICATIONS

Laser cavities, range finding, surveying, satellites, spectroscopy.

PRECISION LENSES

-

Custom precision lenses are a key optical component for many transmission and imaging applications in the aerospace, security, defense, machine vision, health care, and life science industries.

G&H manufacture custom precision lenses for imaging, focusing, collimation and illumination, using standard polishing and grinding techniques, as well as single point diamond turning and MRF®.

We take a design-for-manufacture approach to lens production, facilitating the production of cost-effective, high quality custom precision lenses.

Our lens processing capabilities include CNC generating, grinding, and polishing. We polish spherical, semi-spherical, and aspheric lenses. 5-axis grinding and polishing machines are utilized for manufacturing high precision aspheric surfaces on optical glass. Single point diamond turning is used for aspheric and diffractive optical elements.

A unique, stand-out capability for G&H is our ability to manufacture complex shapes on lenses, such as step profiles or off-axis shapes.

A unique, stand-out capability for G&H is our ability to manufacture complex shapes on lenses, such as step profiles or off-axis shapes.

Precision Lenses In addition to singlets, we produce a wide variety of doublets, triplets, and more complex lens assemblies.

From high transmission broadband anti-reflection coatings to V-coats for high energy applications, our extensive coating capabilities deliver performance across the spectrum from the UV to the FIR.

We have made significant investment in metrology equipment to ensure that our customers receive quality, high-performing products. More details on our metrology capabilities can be found in the metrology section of the catalog.

Environmental testing of components and coatings is critical for assurance of performance in rugged conditions. G&H environmental testing capabilities include MIL-C-675C, MIL-C-48497A, MIL-E-12397, and MIL-M-13508C for endurance against abrasion, adhesion, humidity, temperature, and environmental conditions.

APPLICATIONS

Dental imaging, dermatology, endoscopy, hyperspectral imaging, lasers, machine vision inspection, metrology, optometry, projection, range finding, reconnaissance, surveillance, target identification, targeting and designating, thermal imaging.

VIS-SWIR LENS ASSEMBLIES

-

G&H engineers precision SWIR and VIS-SWIR assemblies for demanding applications in commercial and military aerospace, defense, industry, life sciences, and scientific research.

We have developed custom bonded multi-element optical components, athermalized designs, mounted optical assemblies, and modules with integrated electronics.

4_SWIR_Lens_Diagram Our lens modules are specifically optimized for operation at visible and/or SWIR wavelengths and leveraging the benefits of the new, larger InGaAs detector offerings. Considered selection of lens system parameters, materials, and coatings improve resolution, accuracy, and exposure limits; criteria which are critical in low light situations.

Our custom products are designed for purpose, and can be optimized for use at visible through long-wave infrared (LWIR) wavelengths, as per application requirements.

Custom and standard lens assemblies are designed for manufacture, using optical and mechanical modelling to optimize performance within known manufacturing limits, and to ensure a consistently high level of product quality.

OPTIMIZED VIS-SWIR STANDARD LENS DESIGNS

G&H have developed a series of athermalized, high precision lens systems for a wide variety of short-wave infrared (SWIR) imaging applications. The lens design, material selection, and coatings for each lens are optimized for high resolution, high signal to noise, and high performance in low light conditions.

4_SWIR_Lens_Header The Barle lens is optimized for InGaAs camera applications. The large field of view is designed to work with the latest InGaAs detection systems.

The Avill high resolution VIS-SWIR lens is optimized for short focal length applications and a wider spectral range than the Barle.

OPTO-MECHANICAL ASSEMBLIES

-

Protecting the customers’ investment in precision optical components, we offer a value-added service of design, manufacture, and assembly of the optical components into protective easy-to-handle housings.

G&H can provide integrated optics and electronics, build-to-print designs, and optical modules optimized for optical performance, footprint, and/or power consumption.

The cost and time benefits to production when sourcing an opto-mechanical assembly from G&H can be significant:

Pre-alignment of complex optical components enables drop-in final assembly

Precision alignment of various and varied optical surfaces reduces production time and internal metrology requirements

Ease of handling minimizes internal production time

Minimization of damage to precision surfaces reduces yield losses

Relaxation of cleanroom requirements lowers customer facility costs

The opto-mechanical assemblies we produce for customers are wide ranging. A few examples of the breadth of opto-mechanical assemblies:

Prisms potting in aluminum housings

Waveplates in ring-mounted housings

Periscope prism assemblies

25x magnification lens assemblies

Zoom lenses

APPLICATIONS

Laser cavity designs: Lasers, range finding, reconnaissance, surveillance, targeting and designating, target identification.

Imaging designs: Dermatology, endoscopy, hyperspectral imaging, inspection, machine vision, metrology, optometry, projection, thermal imaging.

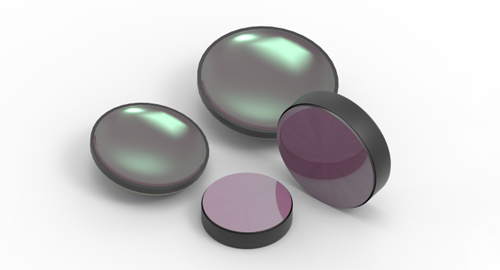

PRECISION MIRRORS

-

G&H provide high energy precision mirrors for laser cavities and demanding applications. Our custom high-reflectivity mirrors deliver superior performance and value to customers designing and building laser cavities from small, lightweight range finding lasers to high laser damage threshold industrial lasers.

We understand that the smallest defect leads to a system failure. Our goal is to minimize or eliminate system failures due to coating or polishing defects.

Precision mirrors are fabricated in a number of shapes and sizes. Conventional optical grade flats or shaped substrates are precision polished and inspected at magnification to ensure there are no underlying defects before coatings. Careful cleaning and coating processes ensure microscopic particles are not encapsulated into the coating.

DIELECTRIC MIRRORS

Dielectric laser cavity and beam routing mirrors demonstrate very high reflectivity and high laser damage threshold. Mirrors can be optimized for single laser lines or reflectivity over a specific wavelength range. Narrower bandwidths generally deliver higher energy performance than broadband designs.

METAL MIRRORS

Metal mirrors are often used in applications with broader bandwidth requirements than broadband dielectric coatings can meet. Silver metal mirrors are used in low power visible wavelength applications, as it has the highest reflectivity of all the metal coating options. For UV to VIS applications, aluminum provides consistently good performance from 200 to 800 nm. Gold metal mirrors are typically used in IR applications.

Enhanced metal reflector coatings are metal mirrors overcoated with dielectric layers to broaden the inherent metal reflectivity over a limited spectral range.

Protected coatings are advised to improve abrasion and climatic resistance. This is especially important for aluminum mirrors, which unprotected will degrade very quickly in humid environments.

METROLOGY AND TESTING

To ensure performance in the field, we leverage extensive metrology capabilities to qualify every component at every step in the manufacturing process.

Environmental testing of components and coatings is critical for assurance of performance in rugged conditions. G&H environmental testing capabilities include MIL-C-675C, MIL-C-48497A, MIL-E-12397, and MIL-M-13508C for endurance against abrasion, adhesion, humidity, temperature, and environmental conditions.

APPLICATIONS

Laser cavities, laser range finders, target designators.

SYNCHROTRON & RESEARCH GRADE MIRRORS

-

As the original provider of superpolished optical components, G&H have been producing superpolished surfaces for over 40 years. Our proprietary process serves high volume production requirements as well as small volume, specialized applications.

Superpolished substrates feature surface roughness lower than 1 Å, scratch/dig < 5/2, and inspection criteria of up to 320x magnification. The results are low scattering losses and significantly fewer defects. Substrates demonstrate an impressive 1/20th wave or better surface accuracy.

Our custom optics have enabled scientists to achieve prize-winning results in LIGO, NASA's Mars Curiosity Sky Crane, and in synchrotron facilities around the world.

SYNCHROTRON MIRRORS

Synchrotron sources generate extremely high heat load densities on front end optics, requiring sophisticated cooling and reflection geometries. Monocrystalline silicon with its high heat load capacity is the preferred material choice for front end systems.

Small grazing incident angles, in turn, generate a requirement of a 4:1 or 20:1 length-to-width ratios. As a consequence, the geometries and materials are very different from conventional optical components. Conventional polishing techniques can cause rounding on corners of rectangular shaped optics; therefore, specialized fabrication and polishing techniques have been developed to maintain flatness across the entire rectangular surface.

RESEARCH GRADE MIRRORS

Research grade mirrors are highly specified, superpolished substrates with high energy coatings. These may be used as back end optics in synchrotron or in other highly demanding research applications where accuracy is required.

ACID-ETCHED BEVELS

Most of our synchrotron optics and research grade flats are supplied with polished or acid-etched diameters and bevels. These extra touches add to the level of cleanliness and durability that can be achieved.

To complement our superpolished surfaces, we offer ion beam sputtered (IBS) coatings which provide very low levels of total loss (absorption and scatter) and exceptional environmental stability.

APPLICATIONS

DUV experiments, high-energy applications, interferometry, laser & X-ray research, reference standards, synchrotron mirrors, ultra fast laser systems.

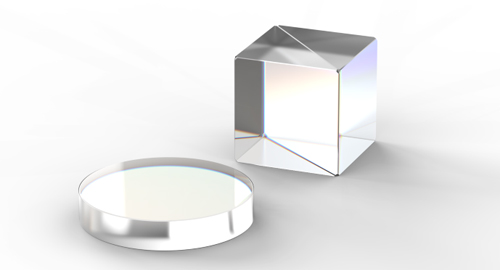

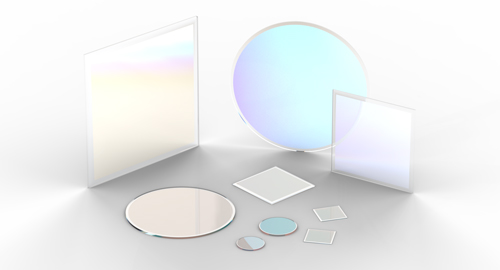

PLATE & CUBE BEAMSPLITTERS

-

Optimized beamsplitter designs from G&H demonstrate superior laser damage performance for each unique wavelength, split, and incident angle combination. High-energy coatings are optimized to accommodate specific application requirements.

For maximum power handling, we recommend optically contacted cubes or plate beamsplitters. For durability and handling, G&H suggests cube beamsplitters.

Cube beamsplitters can divide the incident beam based on polarization (S or P) or power (ratio of energy into each arm). The S and P polarization components are separated by reflecting the S component at the dielectric beamsplitter coating while the P component passes through the cube. Alignment markings on the cubes ensure correct placement in the optical path. Beamsplitting cubes are easy to mount and mechanically durable. Cube beamsplitters from G&H may be provided cemented, optically contacted, or even air-spaced. For some applications, higher power handling and lighter weight is required.

Plate & Cube Beamsplitters

Plate beamsplitters display intrinsically higher beam power handling capability than cube beamsplitters. Plate varieties are preferred in high laser energy applications, or where cost or weight limits on the assembly come into play. They are typically designed to work at 45° angles, though other angles can often be specified.

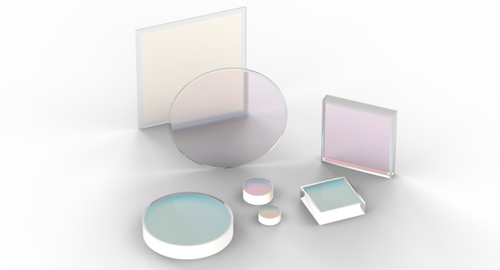

OPTICAL WINDOWS AND FLATS

-

G&H deliver high performance optical windows and flats across a wide range of applications. From small precsion optical flats for interferometry applications, to large windows installed in military vehicles, our components are custom designed to deliver performance and value.

Optical windows are a critical component in a variety of applications which require minimal optical impact with maximum mechanical separation between two environments.

Ideally, the window has minimal impact upon the beam transmission properties: does not reflect, absorb, or scatter the beam; does not distort or impact the wavefront; does not bend or deviate the beam path.

The mechanical separation may require thermal, chemical, or environmental tolerance. Careful material selection and coating design is often required to achieve all of the mechanical separation as well as the optical needs.

OPTICAL WINDOWS FOR INDUSTRIAL APPLICATIONS

Optical windows are utilized in lasers, testing chambers, and other systems where the environment on one side may be pressurized, filled with a specific gas, or otherwise need to be chemically separated from the other. The window needs to transmit the photon energy with minimal disruption (highest transmission, lowest absorption and scattering, and minimal polarization or optical path distortion).

The highest quality optical windows from G&H demonstrate very high parallelism, supremely low surface roughness, low transmitted and reflected wavefront errors, and are optical transparent at the operational wavelength range.

Window material is chosen based on environmental factors such as acidity of atmosphere, strong vacuums, high pressures, or high temperatures and the operational wavelength range.

WINDOWS FOR DEFENSE APPLICATIONS

Defense-grade windows from G&H are significantly larger and may be coated with diamond-like coatings to withstand abrasive environments in the desert.

Window thickness is determined by environmental factors: pressure differentials, thermal conditions, and mounting mechanics.

APPLICATIONS

Biomedical instrumentation, corrosive chemistry, directed energy applications, industrial instrumentation, IR imaging, laser cavities, machine vision, multiphoton imaging.

WAVEPLATES

-

From crystal growth, crystal orientation and cutting, to waveplate fabrication and coating, no other waveplate supplier has as much control over the fabrication stages as G&H.

Our waveplates been used in the cutting edge of research at Lawrence Livermore National Laboratory’s NIF project to the most demanding of production environments in semiconductor metrology equipment.

For all wavelength ranges, we orient, cut, and polish the optical crystals for waveplate production. Tight internal controls enable better retardation tolerances within and between production runs.

waveplate_graphic Polishing, coating, assembly, and metrology complete the manufacturing process.

Compound zero-order (also known as net-zero order) and achromatic waveplates are often optically contacted to reduce reflection losses at the surfaces. Air-spacing is recommended for high energy applications. Speciality waveplate designs such as off-axis or true-zero order waveplates are produced to custom specifications.

SUPERPOLISHED SROC

-

Gooch & Housego has been producing superpolished surfaces for over 40 years and is the world’s original provider of superpolished optical components. We have evolved our proprietary process to handle high volume and specialized R&D requirements.

Superpolished substrates feature surface roughness lower than 1 Å, scratch/dig <5/2, and inspection upwards of 320x magnification. The result is extremely low scatter, losses and defects – a requirement for any high performance laser application. The substrates offer an impressive 1/20th wave or better surface accuracy.

In keeping with the high standards of our superpolished surfaces, most of our optics are supplied with polished or acid etched diameters or bevels. These extra touches add to the level of cleanliness and durability that can be achieved.

To complement our superpolished surfaces we offer ion beam sputtered (IBS) coatings which achieve very low levels of total loss (absorption and scatter), and exceptional environmental stability.

APPLICATIONS

Cavity enhanced absorption spectroscopy, ring laser gyroscopic systems, ultrafast laser research, ultraviolet laser systems.

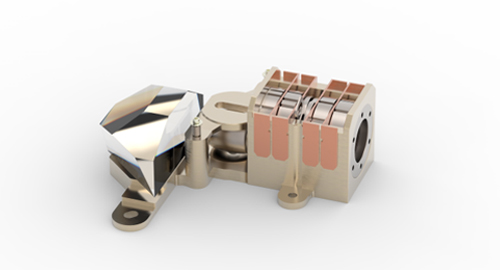

RING LASER GYROSCOPE COMPONENTS

-

Ring laser gyroscopes from G&H are deployed in commercial aircraft, missiles, satellites, and other military vehicles. Vertical integration enables us to supply the entire ring laser gyroscope package: RLG frame and optical components. Our integration of capabilities delivers superior performance and streamlines sourcing.

There are many components within the ring laser gryoscope (RLG) -- each performs unique functions and is optimized accordingly.

The Zerodur® frame must deliver maximal stability over a large range of operating environments (namely, temperature, humidity, and environmental composition). We have 40 years of experience producing high-quality, consistent, Zerodur® frames.

Ring Laser Gyroscope Components Flat, wedged, and curved mirrors used in RLGs are superpolished with surface roughness better than 1 Å RMS with high-reflectivity low-loss IBS coatings designed to survive extreme environmental conditions.

Precision beam splitters, prisms, and wedges complete the assembly.

Extensive metrology capabilities are critical to the abilities of G&H to meet and exceed difficult specifications.- Zygo® ZeMapper™ for surface roughness and structure <1 Å

- OGP® CMM for geometrical tolerances down to sub-micron features

- 18” Zygo® Interferometer measures flatness up to 1/50th wave

APPLICATIONS

GPS, hyperspectral imaging, infrared microscopy, laser scanning microscopy, metrology, optical failure analysis for semiconductor processing, range finding, reconnaissance, surveillance, target identification, targeting and designating, thermal imaging.

INFRARED OPTICS

-

G&H deliver highly integrated, superior performing, infrared optical components leveraging our combination of technical skills, unique manufacturing competencies, and extensive metrology capabilities.

G&H brings together a set of capabilities which enables our customers to combine techniques, even on the same part. A unique, stand-out capability for G&H is our ability to manufacture complex shapes on lenses, such as step profiles or off-axis shapes.

We utilize several techniques either separately or in tandem to achieve superior product specifications, such as surface accuracies to better than 100 nm:

High precision CNC processing

Diamond turning

Magnetorheological finishing (MRF®)

Traditional polishing

Durable antireflection coatings from G&H are tailored to the application. Typical antireflection (AR) coatings include: Broadband, V-coat, and dual band. Broadband coatings perform well from 400-14000 nm wavelength ranges. Reflectivity as low as 0.25% for the 3-5 micron range is achievable.

Extensive metrology capabilities are critical to the abilities of G&H to meet and exceed difficult specifications.

QED SSI stitching interferometry measures aspherics, full hemispheres, and OD up to 200 mm

Taylor Hobson contact metrology tools measure surface roughness and surface accuracies up to 60 nm

NewView™ 5000 white light interferometer is use for surface analysis and micro-roughness down to 2 Å RMS

Computer generated holograms (CGH) can be utilized for volume production and high precision surface measurement.

Environmental testing of components and coatings is critical for assurance of performance in rugged conditions. Environmental testing capabilities include MIL-C-675C, MIL-C-48497A, MIL-E-12397, and MIL-M-13508C for endurance against abrasion, adhesion, humidity, temperature, and environmental conditions.

APPLICATIONS

Hyperspectral imaging, infrared microscopy, laser scanning microscopy, metrology, optical failure analysis for semiconductor processing, range finding, reconnaissance, surveillance, target identification, targeting and designating, thermal imaging.

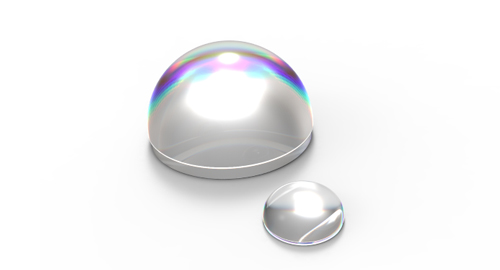

OPTICAL DOMES

-

High numerical aperture (NA) optical domes from G&H are produced using precision tooling. Our product line includes Zinc Selenide, Zinc Sulphide, or Germanium materials.

CNC processing, combined with extensive metrology capabilities, deliver precision domes for aerospace and military applications.

Optical domes are essentially windows: two parallel surfaces, curved. The dome protects and isolates critical sensors and electronics from the environment with minimal disruption to the optical path.

Optical domes can be found on forward looking infrared systems, seeker head optical systems, in submersibles, and underwater camera systems. Airborne systems must be designed to withstand sand, intense temperature differentials, and other challenging environmental conditions. Diamond-like coatings can be used to improve performance in the field. Submersible optics must likewise be designed to withstand sea salt, spray, and more humid challenging conditions.

Optical domes are difficult to measure; therefore, we have developed proprietary stitching interferometry processes to minimize errors due to reflections. To ensure performance in the field, we leverage our extensive metrology capabilities to qualify every component at every step in the manufacturing process.

Environmental testing of components and coatings is critical for assurance of performance in rugged conditions. Environmental testing capabilities include MIL-C-675C, MIL-C-48497A, MIL-E-12397, and MIL-M-13508C for endurance against abrasion, adhesion, humidity, temperature, and environmental conditions.

APPLICATIONS

FLIR, seeker head optics, submersibles, underwater cameras.