- Offer Profile

- 3D MicroPrint GmbH is

specialized in the production of micro metal parts by Micro Laser Sintering

and the sale of the associated machines.

Our company was founded in 2013 in Chemnitz (Germany) as a result of a cooperation between EOS GmbH and 3D-Micromac AG. Experts from both companies have been working with an exceptional pioneering spirit on the development of the Micro Laser Sintering process since 2006.

Your requirements for micro metal parts are our inspiration. Thanks to the additive production technology, quality and costs can be optimized while simultaneously expanding the functionality of the specific products of our customers.

Technology

- Micro Laser Sintering combines the advantages of

additive manufacturing and micro machining for the first time. Micro metal

parts of incredible accuracy, detail resolution and surface quality are

manufactured this way. These advantages result in the ability to manufacture

moveable parts and assemblies in a single step.

The basis of these outstanding results is the combination of a very small laser beam spot size, special micro powder and super thin layers.

What is Micro Laser Sintering?

Micro Laser Sintering is a powder bed based additive manufacturing technology, often called Selective Laser Sintering or Selective Laser Melting. Micro Laser Sintering is an industrial technology, providing micro metal parts to several industries.

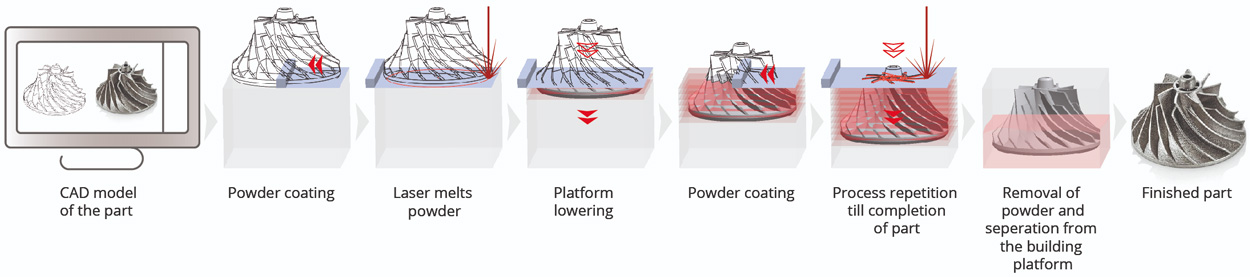

Micro Laser Sintering – functional principle

A 3D-CAD model of the target geometry contains all details of the final part. This CAD model is split into several cross sections, called layers. During manufacturing, a thin layer of powder is applied to a build platform. The powder is selectively fused by a laser beam according to each cross section. After that the building platform is lowered, the procedure of powder coating, fusing and platform lowering is repeated layer by layer, until the part completed.

Micro Laser Sintering for finer details

Micro Laser Sintering combines the advantages of additive manufacturing and micro machining for the first time. Micro Metal parts of incredible accuracy, detail resolution and surface quality are manufactured this way. These advantages result in the ability to manufacture moveable parts and assemblies in a single step. The basis of these outstanding results is the combination of a very small laser beam spot size, special micro powder and super thin layers.

The parts are used in any industry requesting small metal parts of high accuracy, smooth surface finish, outstanding detail resolution and complex shapes. Current main industries are Medical, Semiconductor, Mechanical Engineering, Aerospace, Energy and Chemical as well as Jewelry and watchmaking.

Benefits

Micro Laser Sintering combines the advantages of Additive Manufacturing and Micro Machining, enabling the manufacturing of parts of incredible shapes. Expect micro parts of very good dimensional accuracy, incredible detail resolution and smooth surface finish even if they are very complex, with internal channels, complex 3D-structures or even complete assemblies manufactured in one shot. This works with thousands of parts as well as with just one customized part, as no tooling is required. Case Studies

- Additive manufacturing technologies offer unique possibilities to create innovative products. By comparing conventional and additive manufacturing technologies, a function-driven redesign of products is often beneficial. In particular, the Micro Laser Sintering provides a high level of accuracy and detail resolution of the desired micro parts. The case studies of 3D MicroPrint GmbH illustrate innovative solutions for various applications which demonstrate the exceptional potential of the Micro Laser Sintering technology.

Case Study flow measuring probes

- Small probe, big effect – Micro Laser Sintering makes

tailor-made flow measurement technology possible

Accuracy is mandatory in the field of fluid dynamic measurement technology. Flow probes help to determine fluid flows simply and accurately. By means of Micro Laser Sintering, the components are developed flexibly for the respective application and manufactured on demand. Size and shape are adapted according to the different application areas.

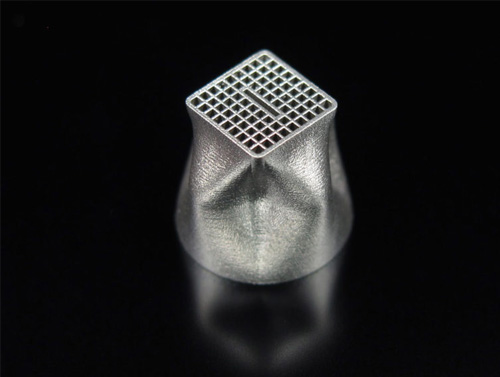

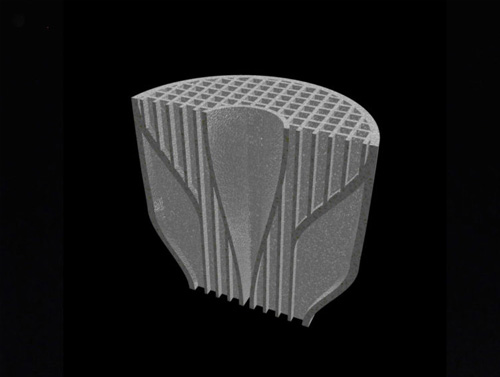

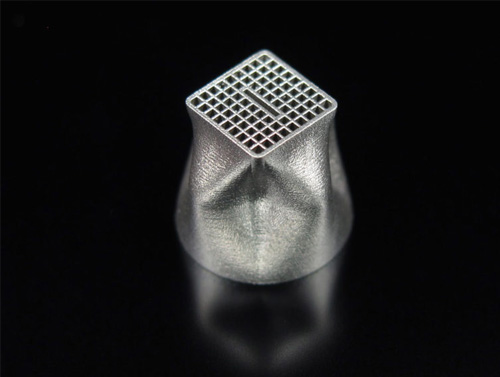

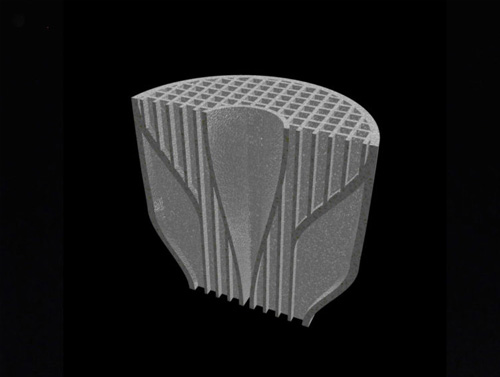

Case study lattice structures

- Complex 3D lattice structures – Micro Laser Sintering

enables maximum functionality by minimum material use

Lattice structures are used to save weight without sacrificing stability of parts. Furthermore these structures can also realize functions like shielding, guiding or separating fluids in medical devices, reactors, heat exchangers, fuel cells and other microfluidic applications.

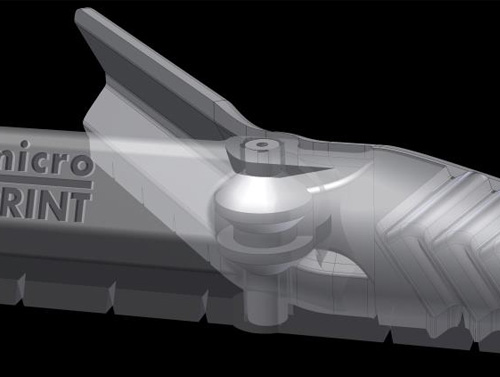

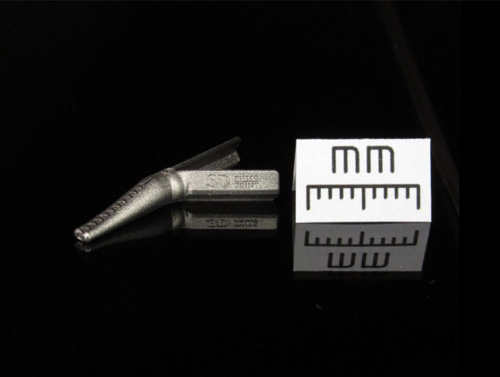

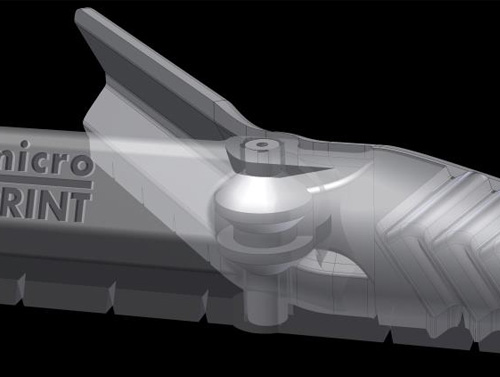

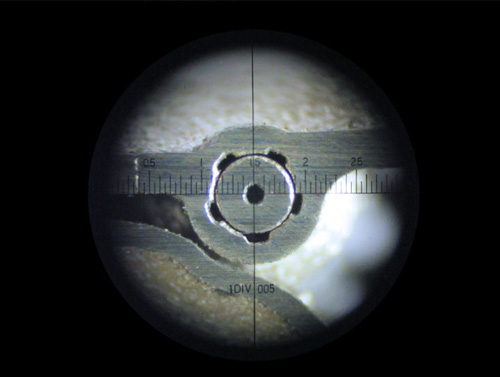

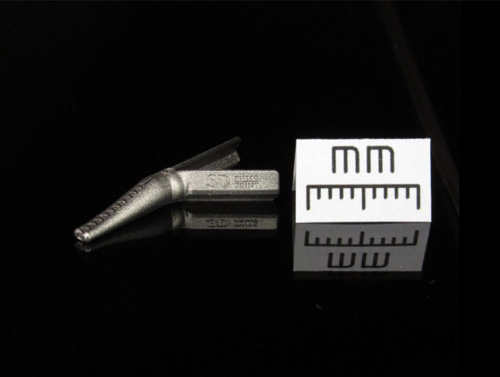

Case study grabber

- Cost reduction by saving assembling – Functional module

built at-once by Micro Laser Sintering

Grabbers or manipulators are used in numerous branches from medical technology to aerospace. Using conventional technologies such a grabber has to be assembled at least of four single pieces. The smaller the parts become, the more difficult the secure assembling of the tiny components is.

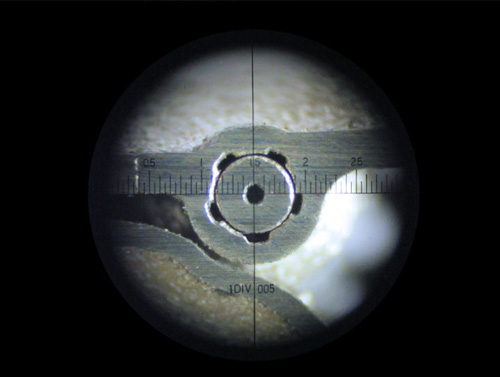

Case study watch

- Micro Laser Sintering for highest quality standards – The

future at your wrist

The watch manufacturing has in Europe a century old tradition and is the epitome of elegance, quality and precision. The production of precise serial components is carried out under the highest quality standards. Existing technologies for micro-machining already encounter the limits of feasibility. An additional individualization is only possible under enormous costs.

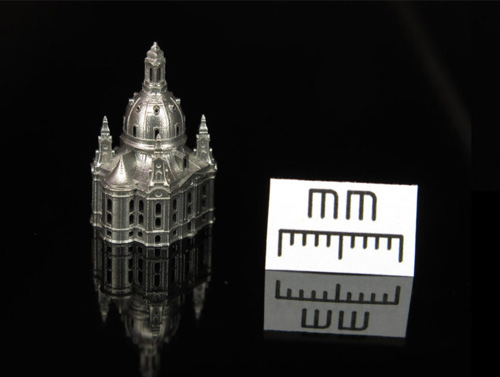

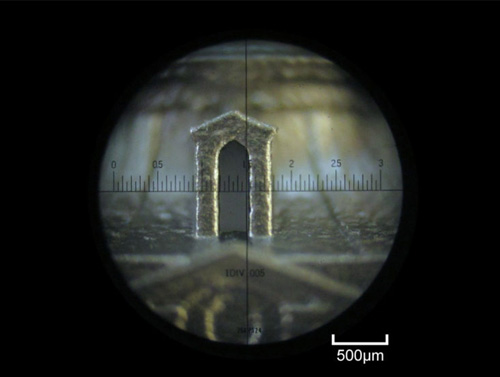

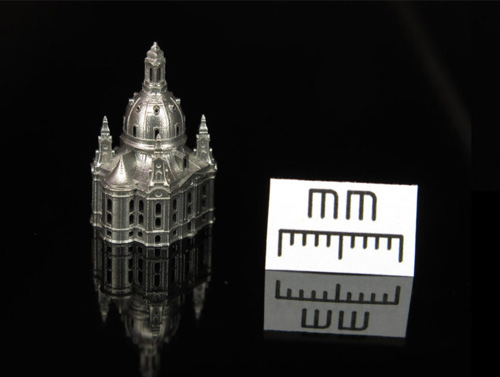

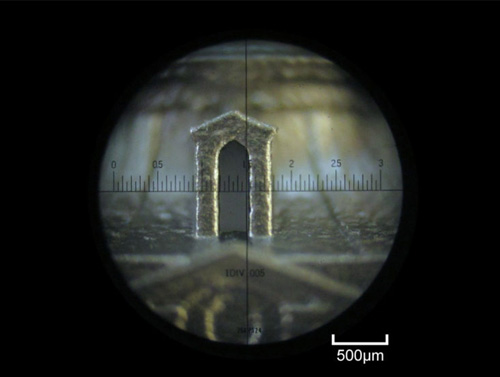

Case study Frauenkirche

- Miniaturization with highest complexity – Scaled

architectural models

The Frauenkirche located in Dresden (Germany) is a landmark of the city. Built in the 18th century and destroyed in the World War II, it was faithful reconstructed almost 60 years later. This war memorial became a symbol of peace and reconciliation. A miniature model of the building transmits the message to the world and illustrates the high accuracy of Micro Laser Sintering.

Example: Miniature model of the Frauenkirche located in Dresden (Germany); scale 1:6100; height 16.6 mm; material 1.4404 (316L)

Services

-

You have the application, we do have the experience with Micro Laser Sintering. With our engineering services we make your parts 3D printable.

With years of experience we help you to select the right parts, optimize their design and make sure, you will receive your first 3D printed micro metal part. Understanding the purposes of your application by a functional analysis is the basis for a successful start. Thus we find the best conceptual design. Afterwards we will prove feasibility by manufacturing your designs. To finally have the part in your own hand is very convincing.

Our design rules and knowledge transfer will enable you to optimize the part design on your own. This way you can take advantage of our technology for series production as well as for prototypes or individualized parts.

LetÂs discuss your ideas, we will find a solution together!

3D Printing enables new solutions. Undercuts, customized or even individualized parts, lightweight design, assemblies in one piece quickly available without the need for additional tooling  3D MicroPrint GmbH has opened these amazing advantages to the world of micro parts.

Benefit from the advantages of additive manufacturing

- Function-oriented design of parts

- Combination and integration of multiple functions

- Lightweight-design saves material

- Print an assembly in one piece

- Immediate manufacturing without additional tools

- Fast time-to-market

Parts

- 3D MicroPrint GmbH provides the complete solution chain

for the production of precisely printed metal parts. Experience high

precision in 3D printing.

The production of printed micro metal parts with fine details, smooth surface finish and high precision is the key competence of 3D MicroPrint GmbH. With our technology Micro Laser Sintering we supply a cost-effective, material-efficient and economical manufacturing of customized parts, prototypes up to series production of micro metal parts, including all advantages of 3D printing.

We offer several materials such as several stainless steels or high melting materials like Molybdenum or Tungsten. Do not hesitate to ask us for your specifically tailored material. Also post processing like electrical discharge machining (EDM), blasting, plasma polishing and others are available.Typical industries

- Medical Industry

- Automotive

- Aerospace

- Semiconductor and MEMS

- Energy and chemical

- Jewelry and watches

Machines exlusively sold through 3D-Micromac AG

-

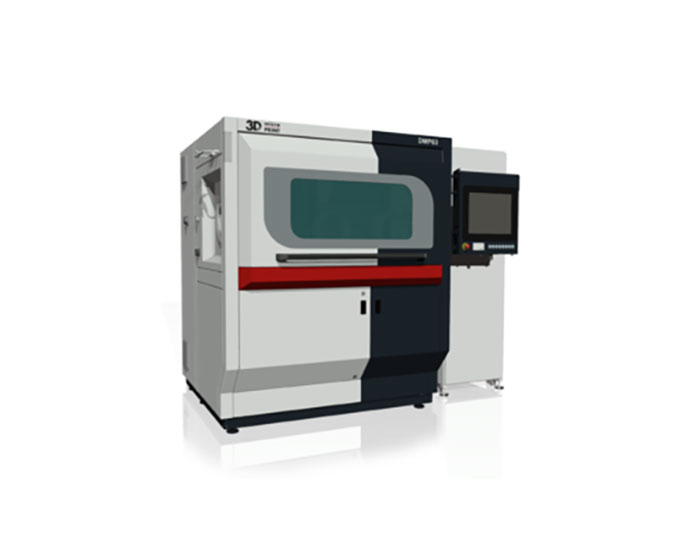

3D MicroPrint’ s machines deliver best results in terms of detail resolution, accuracy and surface finish for 3D printed micro metal parts by micro laser sintering.

Our solutions merge the abilities of micro manufacturing with the advantages of 3D printing for the first time. Inspired by and made for Industry and R&D our machines satisfy a big bandwidth of user requirements. Low running costs, availability of industrial standards like zero-point clamping system, inert gas atmosphere including gas cleaning and remote service support ensure best technical and commercial results.

If you have special requirements we are happy to tailor your solution.Our machines are exlusively sold through the 3D-Micromac AG

DMP70 series

-

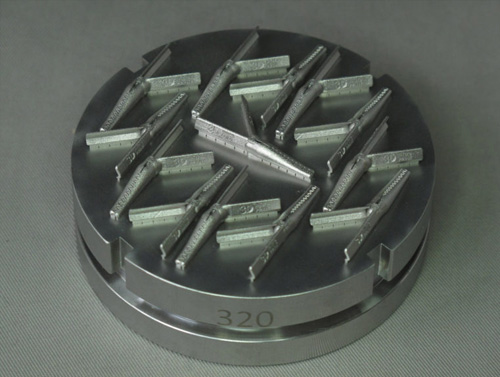

The DMP70 series is the current machine generation for Micro Laser Sintering. Based on the industry proven quality of the DMP63 we have enhanced the system further.

Main specifications:- Infrared Fiber Laser 50 Watt

- Laser spot size ≤ 30 µm

- Building platform □ 60 mm

- Max build height 30 mm

- Layer thickness 1 µm to 5 µm

- Purified Argon atmosphere

- Gas tight design – low running cost

- Air locks and rapid transfer ports

- Zero-point clamping system

- Reduced footprint, weight and costs

- CE and UL conformity available

- Pneumatic shock absorber for rough environments

- Optimized machine design for reduced material loss – important for precious metals

DMP60 series

- The DMP60 series is the current machine generation for

Micro Laser Sintering.

Requirements from industry and universities have helped us to develop this enhanced system.

Choose the one that fits your needs best:

DMP60: The cost efficient machine for R&D and Universities. It processes nonreactive materials only.

DMP63: The most common of our machines. It serves the highest productivity for nonreactive and reactive materials. Included is a zero-point clamping system for easy post processing with highest accuracy based on industrial standards. Also with a high power laser option available for processing of high-melting materials.

DMP64: If you need superior detail resolution < 15 µm, the DMP64 is the right choice. It sets the pace with best detail resolution, accuracy and surface finish. It is also equipped with a zero-point clamping system and processes reactive materials too.

Main specifications:- Infrared Fiber Laser

- Layer thickness 1 µm to 5 µm

- Inert Argon atmosphere

- Air locks and Rapid Transfer Ports

- Processing of highly reactive materials

Material

Material

- The powder materials are tailored to satisfy the requirements of Micro Laser Sintering. We use powder with particle sizes smaller 5 µm to achieve a very good detail resolution. Together with selected partners from Industry and Universities we develop these high tech powders.