- Offer Profile

- Since the company was founded in 1970, UNTHA has been fulfilling its promise to be "The reliable brand", meaning that we do everything we can to be more reliable than other providers. This applies to all UNTHA products and services. For our customers, this means that choosing an UNTHA system was the best decision they could make.

Industrial Shredders

LR520

- Compact and reliable shredding of small residual timber volumes

We designed the LR520 based on the requirements of small companies. This wood shredder is therefore especially compact, reliable and very energy-efficient. The simple and thus low maintenance technology and the extremely small footprint (<1 m²) enable you to efficiently recycle your residual timber. The LR520 is best suited for companies that have a residual timber volume of up to 3 m³ per week.

The wood shredder's reliability comes from its sturdy steel construction and its proven technology. The pusher-free design has a pull-in mechanism and therefore very few moving parts. This reduces maintenance costs to a minimum. The gear damper cushions strong blows during the shredding process and ensures the machine's quiet operation. In addition, the LR520 features a mechanism that detects foreign objects and automatically shuts down the shredder. This prevents damage to the cutting unit.Energy efficiency plays a big role in the LR520. The proven cutting system can easily shred residual timber and only requires a drive capacity of 11 kW. When it idles for more than 3 minutes, the machine shuts down automatically. This saves energy and simultaneously reduces operating costs.

The LR520 produces high-quality granulate that is well suited for thermal utilisation or briquetting. Each of our wood shredders is customized to your needs. The machines can also be equipped with a metal separator, a conveyor system or a customized hopper. We offer comprehensive solutions from one source!

Take advantage of the 3-year carefree warranty when buying an UNTHA wood shredder *

We are convinced of the reliability and quality of our products and are willing to prove it. In fact, we are the only manufacturer offering this special form of security!

Your advantages at a glance

- Small footprint

- Proven technology

- Energy-efficient

- Homogeneous chip size

LR520 applications:- Hard and soft wood

- OSB

- Chip boards

- MDF

- Veneer

Technical data:- Power [kW]: 11 | (18 hp)

- Cutting chamber width [mm]: 514 | (20 in)

- Perforated screen Ø [mm]: 12 - 25

- Ø Rotor [mm]: 248 | (10 in)

- Charging hole [mm]: 516 x 830

- Rotor speed [rpm]: 85

- Weight [t]: 0,85

- Required extraction speed [m/s]: 22

- Noise level pressure LPA1m [db (A)]: 82

LR630

-

Great technology in combination with high reliability at a fair price

The LR630 is a very sturdy wood shredder that is convincing thanks to its technology and expertise. The machine is designed for a long service life and energy efficiency and can be optimally adjusted to your needs. The LR630 is best suited for companies that have a residual timber volume of up to 7 m³ per week.

The LR630 is completely focused on making your work day easier and is one of the most popular models among carpenters. Thanks to its offset rotor bearing, proven and reliable gear damping and special cutting tools, this wood shredder is very low maintenance and has a long service life. This frees up time for what is really important in your company!

The well-designed machine is equipped with a horizontal pusher. The hydraulics aggregate has been placed in the machine housing to save space, where it is also protected from dust and dirt. To protect the wood shredder from possible cutting unit damage, the LR630 is equipped with an automatic foreign objects detection mechanism including automatic shutdown. Added to this is an automatic reverse that prevents motor overload.

Energy efficiency is an important characteristic of the LR630. The proven cutting system ensures the efficient and reliable shredding of your residual timber. The LR630 is available starting with a drive capacity of 11 kW. When it idles for more than 3 minutes, the machine shuts down automatically. This saves energy and simultaneously reduces operating costs.

The LR630 produces high-quality wood chips for briquetting or thermal utilisation in wood chip furnaces. Each of our wood shredders is customized to your needs. The machines can also be equipped with a metal separator, a conveyor system or a customized hopper. We offer comprehensive solutions from one source!

Take advantage of the 3-year carefree warranty when buying an UNTHA wood shredderWe are convinced of the reliability and quality of our products and are willing to prove it. In fact, we are the only manufacturer offering this special form of security!

Your advantages at a glance

- High performance at a reasonable price

- Sturdy and reliable

- Energy-efficient

- Proven cutting system

LR630 applications:- Solid wood

- Chipboard

- Veneer

- MDF boards

- Cardboard

Technical data:- Power [kW]: 11/15/18,5 | (up to 30 hp)

- Hydraulic power [kW]: 0,75

- Cutting chamber width [mm]: 624 | (25 in)

- Perforated screen Ø [mm]: 15 - 30

- Ø Rotor [mm]: 248

- Extraction connector Ø [mm]: 160

- Charging hole [mm]: 624 x 792

- Rotor speed [rpm]: 98

- Weight [t]: 1,3

- Required extraction speed [m/s]: 28

- Noise level pressure LPA1m [db (A)]: 82

- L x B x H [mm]: 1.220 x 1.740 x 1.670

LR700

-

Compact and universally applicable wood shredder

The LR700 combines the need for great flexibility with a very compact design. The wood shredder is suitable for companies that want to process up to 12 m³ of residual timber per week. The LR700 single-shaft shredder can be customized depending on what your company needs.

The LR700 is a single-shaft shredder designed for medium throughput and long operating hours. Due to its sophisticated design and swivelling pusher it has a very small footprint. Thanks to the offset rotor bearing, the gear damping and the reliable cutting system, the shredder is very low maintenance and has a long service life. In the event that foreign objects are pushed into the shredder, the smart drive control automatically shuts down the motor. In addition, the shredder is equipped with an automatic reverse to prevent motor overload.

Energy-efficient technology is particularly important for machines designed for more operating hours. This is why the LR700 features the reliable and very efficient cutting system that has been tried and tested a thousand times over. It will shred your residual timber very energy-efficiently even with a low drive capacity. In addition, the motor shuts down automatically if no wood is fed into the machine for more than 3 minutes. This saves energy and simultaneously reduces operating costs.

The LR700 produces high-quality granulate, which is well suited for briquetting or thermal utilisation in wood chip furnaces. Each of our wood shredders is customized to your needs. The machines can also be equipped with a metal separator, a conveyor system or a customized hopper. We offer comprehensive solutions from one source!

Take advantage of the 3-year carefree warranty when buying an UNTHA wood shredder *

We are convinced of the reliability and quality of our products and are willing to prove it. In fact, we are the only manufacturer offering this special form of security!

Your advantages at a glance

- Universally applicable

- Compact design

- Field proven cutting system

- Homogeneous chips

Applications:- Solid wood

- Chipboard

- Veneer

- MDF boards

- Cardboard

- Pallets

- Bark

Technical data:- Power [kW]: 18,5/22 | (up to 35 hp)

- Hydraulic power [kW]: 1,1

- Cutting chamber width [mm]: 700 | (27 in)

- Perforated screen Ø [mm]: 15 - 40

- Extraction connector Ø [mm]: 200

- Charging hole [mm]: 700 x 1.065

- Rotor speed [rpm]: 98

- Weight [t]: 1,8

- Required extraction speed [m/s]: 28

- Noise level pressure LPA1m [db (A)]: 82

- L x B x H [mm]: 1.306 x 1.712 x 1.630

LR1000/1400

-

The reliable wood shredder for pallets and large, bulky wooden pieces

We offer reliable and customised complete solutions for the shredding of pallets, packaging wood and production waste. The LR1000/1400 is fully adaptable to your application situation and is suitable for businesses with a wood waste volume of 12 m³ per week. Thanks to its size the shredder is ideal for pallets and bulky wooden pieces. Metal parts such as nails, screws, clamps or metal fittings are not a problem for the cutting system.

The high throughput capacity of the LR1000/1400 is a result of the powerful motors and the performance-oriented machine configuration. The configuration with a long rotor, a large perforated screen surface and an optimised cutting unit design gives you the capacity you need in your operation. High performance requires reliable machine operation which we ensure with a full range of high-quality technological components.

Thanks to the rotor's special mounting, dust-protected bearings, a proven transmission damper and special cutting tools, the wood shredder is also very low maintenance and has a long service life. In the event that foreign objects are pulled into the shredder, the smart drive control automatically shuts down the motor. In addition, the shredder has been equipped with an automatic reverse to prevent motor overload.

Energy-efficient technology is particularly important for machines that run continuously. For this reason, the LR1000/1400 uses cutting tools with a specific blade design that shred using very little energy. In addition, the motor shuts down automatically if no material is fed into the machine for more than 3 minutes. This saves energy and lowers your operating costs at the same time.

The LR1000/1400 produces a high quality granulate for immediate use in wood chip heating systems or briquett-generation using peripheral systems that can be connected if needed such as metal separators or pipe magnets that we can customise to your needs. As the hopper design is adapted to your individual requirements, loading may be done either by wheel loader, forklift, grabber or even manually.

Take advantage of the 3-year carefree warranty when you buy an UNTHA wood shredder *

We are convinced of the reliability and quality of our products and are willing to prove it. In fact, we are the only manufacturer offering this special form of security!

Your advantages at a glance

- High capacity

- Very reliable

- LR technology package

- Homogeneous wood chip quality

LR1000/1400 applications:- Pallets

- Solid timber

- Chip boards

- Sawmill waste (wet or dry)

- Wood residue

- Cap timber

- Veneer, MDF boards

- Cardboard (mixed with wood)

- Bark

Technical data LR1000/1400:- Power [kW]: 37 | (up to 60 hp)

- Hydraulic power [kW]: 1,5

- screw conveyor [kW]: 0,55

- Cutting chamber width [mm]: - 1.400 | (39/55 in)

- Perforated screen Ø [mm]: 15 - 40

- Ø Rotor [mm]: 300

- Extraction connector Ø [mm]: 250

- Charging hole [mm]: 1.000 x 1.050/1.600

- Rotor speed [rpm]: 98

- No. of indexable inserts [units]: 27/54

- Weight [t]: 2,4 - 2,7

- Required extraction speed [m/s]: 28

- Noise level pressure LPA1m [db (A)]: ~ 82

- L x B x H [mm]: 2.010 x 1.704 x 1630

Technical data LR1000/1400:- Power [kW]: 37 | (up to 60 hp)

- Hydraulic power [kW]: 1,5

- screw conveyor [kW]: 0,55

- Cutting chamber width [mm]: bis 1.400 | (39/55 in)

- Perforated screen Ø [mm]: 15 - 40

- Ø Rotor [mm]: 300

- Extraction connector Ø [mm]: 250

- Charging hole [mm]: 1.400 x 1.050/1.600

- Rotor speed [rpm]: 98

- No. of indexable inserts [units]: 38/76

- Weight [t]: 2,8 - 3,5

- Required extraction speed [m/s]: 28

- Noise level pressure LPA1m [db (A)]: ~ 82

- L x B x H [mm]: 2.406 x 1.704 x 1.645

RS30/40 CUTTING SYSTEM

-

High reliability for many years to come

The reliable and very sturdy RS30 and RS40 shredders have been tested and proven over several decades and are used particularly for processing long solid timber pieces. The wood chippers can be operated as stand-alone solutions or integrated into complex systems where they tend to be a favourite thanks to their very compact design. They are characterized by their high availability and unique productivity.

The high reliability of this series is a result of the machine's rugged cast-iron frame design and the sturdy cutting unit. The low-speed, 4-shaft shredders are not sensitive to foreign objects and are very low maintenance. Thanks to the pull-in mechanism the shredder does not need a hydraulic pusher system, which further reduces the need for maintenance. The low speed of the cutting shafts ensures low noise and dust emissions in your operations.

The machines are particularly productive thanks to the high torque in combination with a large perforated screen surface and are a favourite for multi-shift operations. In the event that foreign objects are pulled in, the shredder automatically shuts down thereby preventing greater damage to the cutting unit. The shredder is additionally equipped with an automatic reverse to prevent motor overload.

Take advantage of the 3-year carefree warranty when buying an UNTHA wood shredder*We are convinced of the reliability and quality of our products and are willing to prove it. In fact, we are the only manufacturer offering this special form of security!

Your advantages at a glance

- Heavy duty construction

- Small footprint

- Very reliable and low maintenance

- Low noise and dust

RS30/40 applications:- Solid timber (long pieces, splinters)

- Sawmill waste

- Cap timber

- Trim pieces

- Veneer

- Cardboard/paper (mixed with wood)

- Softwood bark

Technical data RS30/40:- Power [kW]: 22 | (up to 60 hp)

- Cutting chamber width [mm]: 450/750/960 | (18/30/38 in)

- Perforated screen Ø [mm]: 15 - 40

- Weight [t]: 1,1

- Cutting chamber [mm]: 450 x 560

- Speed main shafts [rpm]: 23

- Speed secondary shafts [rpm]: 34

- Noise level pressure LPA1m [db (A)]: 80

- L x B x H [mm]: 1.250 x 1.280 x 1.900

Technical data RS30/40:- Power [kW]: 37 | (up to 60 hp)

- Cutting chamber width [mm]: 450/750/960 | (18/30/38 in)

- Perforated screen Ø [mm]: 15 - 40

- Weight [t]: 2,4

- Cutting chamber [mm]: 960 x 700

- Speed main shafts [rpm]: 23

- Speed secondary shafts [rpm]: 34

- Noise level pressure LPA1m [db (A)]: 80

- L x B x H [mm]: 2.010 x 1.415 x 1.190

RS30/40 SHREDDING SYSTEM

-

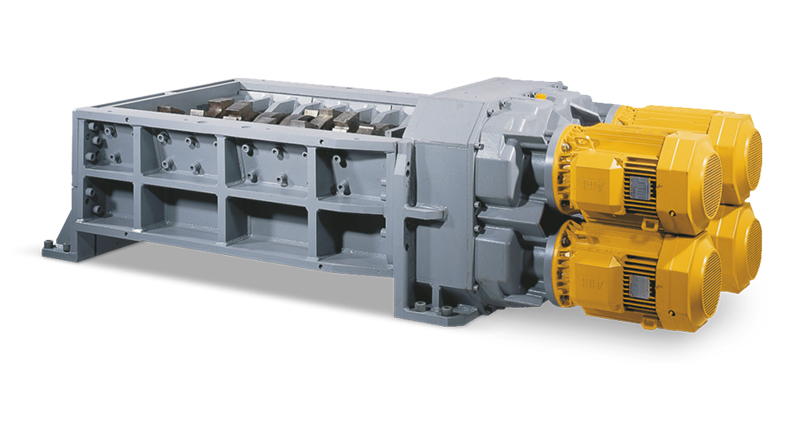

Shredder for recycling applications and data destruction

The reliable and heavy duty UNTHA 4-shaft RS30 and RS40 series shredders have been tested and proven over several decades and were specifically designed for a broad application range. The shredding machines can be operated as stand-alone solutions or integrated into complex systems where they tend to be a favourite thanks to their very compact design.

The high reliability of the small RS series is a result of the machine's rugged cast-iron frame design and the sturdy cutting unit. The low-speed, 4-shaft shredders are not sensitive to foreign objects and are very low maintenance. Thanks to the pull-in mechanism the shredder does not need a hydraulic pusher system, which further reduces the need for maintenance. The low speed of the cutting shafts ensures low noise and dust emissions in your operations.

The machines are particularly productive thanks to the high torque in combination with a large perforated screen surface and are a favourite for multi-shift operations. In the event that foreign objects are pulled in, the shredder automatically shuts down thereby preventing greater damage to the cutting unit. The shredder is additionally equipped with an automatic reverse to prevent motor overload.

A maintenance-free sealing system prevents dust and dirt from entering the bearings and gears. A central lubrication system provides lubrication for all essential bearings thereby ensuring a long service life.

The machines can also be equipped with additional separating and conveyor technology, customized hoppers and substructures and control expansions. We offer comprehensive solutions from one source!

Your advantages at a glance

- Rugged and compact construction

- High availability and process stability

- High resistance to foreign objects

- Low maintenance

Small RS series applications:- Files

- Dashboards

- Automobile interior lining

- Plastic films

- Rubber waste

- Cardboard boxes

- Cardboard tubes

- Plastic drums

- Plastic containers

- Leather

- Metal shavings

- Paper

- Plastic bottles

- Production waste

- Foam board

- Punching scrap

- Car bumpers

- Aseptic packaging

- Textiles

- Packing materials

Technical data RS30/40:- Power [kW]: 11/15/22 | (up to 60 hp)

- Cutting chamber width [mm]: 450 | (18/30/39 in)

- Perforated screen Ø [mm]: 15 - 40

- Weight [t]: 2

- Cutting chamber [mm]: 450 x 600

- Speed main shafts [rpm]: 23

- Speed secondary shafts [rpm]: 34

- L x B x H [mm]: 1.500 x 1.210 x 1.810

Technical data RS30/40:- Power [kW]: 33/37/44 | (up to 60 hp)

- Cutting chamber width [mm]: 750/1000 | (18/30/39 in)

- Perforated screen Ø [mm]: 15 - 40

- Weight [t]: 3,3 - 3,6

- Cutting chamber [mm]: 750/1.000 x 700

- Speed main shafts [rpm]: 24

- Speed secondary shafts [rpm]: 32

- L x B x H [mm]: 2.255 x 1.350 x 1810

RS50/60/100

-

Industrial shredders for difficult recycling applications

This industrial shredder has been tried and tested under difficult conditions is characterized by very high reliability, ability to handle non-shreddable extraneous materials as well as a very broad application range. Its sturdy design and the strong, resistant cutting unit is particularly well suited for continuous multi-shift operations.

The medium-sized RS-class shines especially in difficult recycling applications. Thanks to the modular design and the various cutting unit configurations these shredding machines are particularly flexible in their use. Moreover, it is possible to adjust speed, torque, sealings, cutting unit openings and perforated screens exactly to your requirements. This ensures highest flexibility with maximum reliability.

In contrast to high-speed systems, these slow-speed industrial shredders are particularly resistant to foreign objects. If a cutting disc detects a foreign object, the machine stops immediately. This prevents damage to the cutting unit. In addition, the drive permits frequent reversing, which is particularly beneficial when shredding problematic materials. The integrated perforated screen quick replacement system that comes standard permits the quick and efficient replacement of the perforated screen.

The shredding machines can also be equipped with additional separating and conveyor technology, customized hoppers and substructures and control expansions. We offer comprehensive solutions from one source!

- For particularly difficult applications

- Very compact and rugged design

- High availability and process stability

- Low noise and dust emissions

Technical data RS50/60/100:- Power [kW]: 44/50/60 | (up to 180 hp)

- Cutting chamber width [mm]: - 1.500 | (up to 59 in)

- Perforated screen Ø [mm]: 15 - 40

- Weight [t]: 2,6 - 3,2

- Cutting chamber [mm]: 750/960 x 700

- Speed main shafts [rpm]: 21 - 29

- Speed secondary shafts [rpm]: 32 - 43

- L x B x H [mm]: 1.050 x 1.040 x 1.420

Technical data RS50/60/100:- Power [kW]: 60/74 | (up to 180 hp)

- Cutting chamber width [mm]: - 1.500 | (up to 59 in)

- Perforated screen Ø [mm]: 15 - 100

- Weight [t]: 4 - 5,3

- Cutting chamber [mm]: 960 / 1.200 / 1.440 x 860

- Speed main shafts [rpm]: 17 - 21

- Speed secondary shafts [rpm]: 21 - 25

- L x B x H [mm]: 1.250 x 1.340 x 1.520

Technical data RS50/60/100:- Power [kW]: 100/110/150 | (up to 180 hp)

- Cutting chamber width [mm]: - 1.500 | (up to 59 in)

- Perforated screen Ø [mm]: 30 - 100

- Weight [t]: 9 - 12

- Cutting chamber [mm]: 1.200/1.500 x 1.020

- Speed main shafts [rpm]: 17 - 28

- Speed secondary shafts [rpm]: 17 - 28

- L x B x H [mm]: 1.600 x 1.520 x 1.520

LRK700/1000/1400

-

Reliable shredder for individual plastic applications

Customers like to use the reliable and sturdy LRK700, 1000 and 1400 plastic shredders in the plastic processing industry for re-granulation, inhouse recycling and volume reduction.Similar to all UNTHA shredders, the LRK plastic shredders can be used as a stand-alone solution or integrated into complex systems. High throughput performance, high availability and a precisely defined end product guarantee high economic efficiency for the user.

The cutting units can be easily and quickly replaced, thereby reducing the shredding machine's downtimes to a minimum. The rugged swivelling pusher with its maintenance-free guide is moved by two hydraulic cylinders, which prevents jamming and thus further increases the machine's availability

We equip our plastic shredders with a rotor cooling system for materials with a low melting point. This makes them particularly effective with regard to throughput performance.

Your advantages at a glance

- Mature technology

- Reliable, long service life

- Low maintenance

- Flexible utilisationLRK700/1000/1400 applications:

- Dashboards

- Automobile interior lining

- Plastic films

- Plastic film roles

- Cardboard

- Plastic drums

- Plastic containers

- Clumps

- Plastic tubes

- Rubbish bins

- Production waste

- Foam

- Car bumpers

- Textiles

- Packing materials

- and many more.

Technical data LRK700

- Power [kW]: 18,5

- Hydraulic power [kW]: 1,1

- Screw conveyor [kW]: 0,55

- Cutting chamber width [mm]: 700

- Perforated screen Ø [mm]: 15 - 40

- Ø Rotor [mm]: 300

- Extraction connector Ø [mm]: 250

- Charging hole [mm]: 700 x 1.065

- Rotor speed [rpm]: 98

- Weight [t]: 1,8

- Required extraction speed [m/s]: 28

- L x B x H [mm]: 1.310 x 1.710 x 1.630

Technical data LRK 1000- Power [kW]: 22/30/2 x 22

- Hydraulic power [kW]: 1,5

- Screw conveyor [kW]: 0,55

- Cutting chamber width [mm]: 1.000

- Perforated screen Ø [mm]: 15 - 40

- Ø Rotor [mm]: 300

- Extraction connector Ø [mm]: 250

- Charging hole [mm]: 1.000 x 1.050

- Rotor speed [rpm]: 98

- Weight [t]: 3 - 3,4

- Required extraction speed [m/s]: 28

- L x B x H [mm]: 2.010 x 1.645 x 1.704

Technical data LRK 1400- Power [kW]: 30/2 x 22

- Hydraulic power [kW]: 1,5

- Screw conveyor [kW]: 0,55

- Cutting chamber width [mm]: 1.400

- Perforated screen Ø [mm]: 15 - 40

- Ø Rotor [mm]: 300

- Extraction connector Ø [mm]: 250

- Charging hole [mm]: 1.400 x 1.050

- Rotor speed [rpm]: 98

- Weight [t]: 3,5 - 3,8

- Required extraction speed [m/s]: 28

- L x B x H [mm]: 2.406 x 1.645 x 1.704

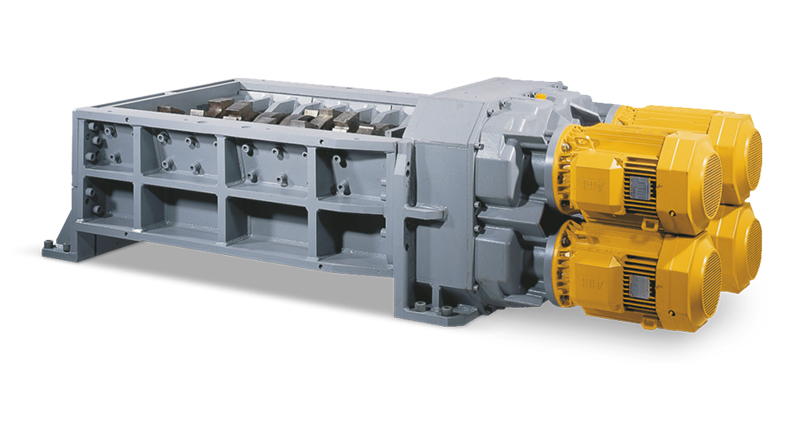

RS150

-

The smart power package for exceptional requirements

The RS150 is the largest UNTHA heavy duty four-shaft shredder and has been developed for especially difficult applications where a high throughput performance, high availability and low maintenance cost are all required.

The highlight of this unique innovation is the newly designed UNTHA Eco Drive. The dynamic and energy-efficient drive concept ensures that the cutting inserts are stopped immediately if foreign objects are pushed in so as to prevent the cutting tools from being damaged. Moreover, this drive permits frequent reversal which is particularly necessary when shredding difficult materials.

The throughput performance can always be optimally configured for the material to be shredded with the variable speed setting option for the cutting shafts. In contrast to high-speed systems (asynchronous motors), these machines do not require wearing parts such as couplings, belts or shear pins, which reduces the machine's vulnerability.

The large RS series can also be equipped with additional separating and conveyor technology, customized hoppers and substructures and control expansions. We offer comprehensive solutions from one source!

- For particularly difficult applications

- Low maintenance and high availability

- Low operating costs

Large RS series applications:- FE-containing metals

- FE-free metal scrap

- Electronic scrap

- Cable

- Paper and cardboard

- Plastics

- Truck and passenger car tires

- Hazardous waste

- Spring Mattresses

- Ragger Tails

Technical data RS150:- Power [kW]: 4 x 78 | (up to 420 hp)

- Cutting chamber width [mm]: ~ 1.500 | (59 in)

- Perforated screen Ø [mm]: 50 - 100

- Charging hole [mm]: 1.500 x 1.260

- Weight [t]: 21

- Speed main shafts [rpm]: 15 - 30

- Speed secondary shafts [rpm]: 17 - 34

- L x B x H [mm]: 4.195 x 2.500 x 4.160

Technical data RS150:- Power [kW]: 4 x 45 | (up to 420 hp)

- Cutting chamber width [mm]: - 1.500 | (59 in)

- Perforated screen Ø [mm]: 50 - 100

- Charging hole [mm]: 1.500 x 1.260

- Weight [t]: ~ 22

- Speed main shafts [rpm]: 25

- Speed secondary shafts [rpm]: 28

- L x B x H [mm]: 4.195 x 2.500 x 4.160

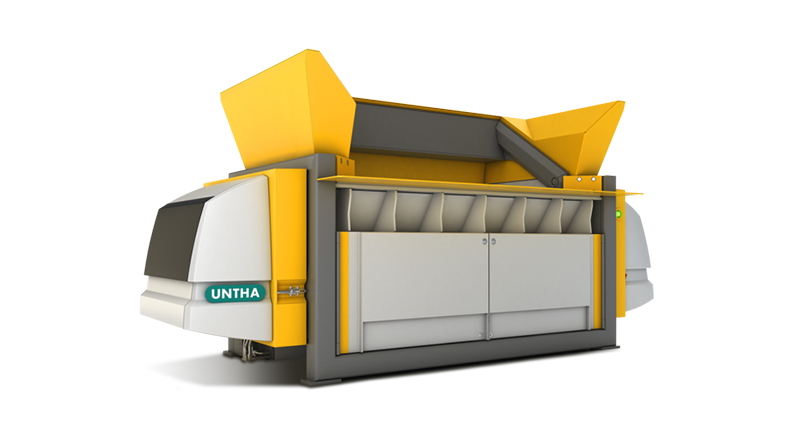

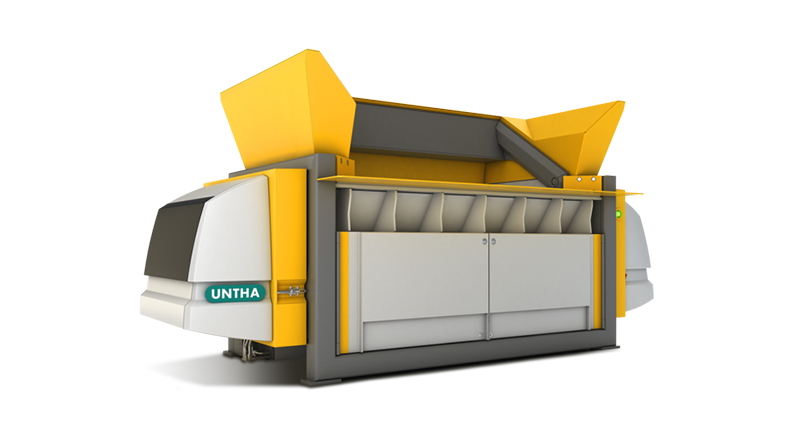

XR2000/3000

-

Flexible waste shredder for all kinds of waste streams

The XR class is a high-performance solid waste shredder for the size reduction of different waste streams like C&I waste, MSW, bulky waste, pulper ropes, rolled goods, carpets or wood waste. The slow speed shredder is often used as a pre-shredder / primary shredder in a comprehensive system or simply as a single-pass shredding concept to produce alternative fuels. The robust design enables even untreated material containing unshreddable items to be processed in one pass. These items can be removed quickly and easily using the impurity removal system, which keeps downtime to a minimum.

Customized slow speed shredding solutions: MSW shredder, C&I shredder or waste shredder for different material

To fulfill your individual requirements, the XR class is available with a ripper, cutter or X-cutter system. The combination with our patented XR screen bars or different-size screen systems makes a fraction size from 400 to 30 mm possible. The final throughput will depend on the type of material and the screen diameter and ranges from 10 t/h to 70 t/h.

The high torque and the machine’s perfectly aligned cutting system enable the material to be fed directly into the machine without pre-shredding. A load-dependent speed control ensures a constant throughput rate.

Throughput rates you can expect by single-pass processing of different materials:

- Commercial and industrial (C&I) waste: 25 t/h < 80 mm

- Municipal solid waste (MSW): 70 t/h < 300 mm

- Bulky waste: 30 t/h < 300 mm

- Waste wood: 45 t/h < 100 mm

Low operating costs

Minimal operating costs paired with maximum performance make this waste shredder a strong partner that stands out for its forward-thinking technology, such as the UNTHA Eco Drive concept that lowers energy consumption by 75% compared to standard electro-hydraulic drive options.

State-of-the-art synchronous motors achieve maximum efficiency, making the UNTHA Eco Drive one of the most energy-efficient drive systems on the market. In addition, maintenance costs may be reduced to a minimum as the unit is free from pulleys, hydraulic pumps and shaft stubs. Where higher throughputs – and therefore also higher rotor speeds – are required, there is the option of integrating a safety coupling that will separate the rotor from the drive if a foreign object is detected.

All rotors are wear-protected thanks to welded Hardox plates, making them particularly resistant against abrasive materials. Our experienced project engineers are at your disposal to assist with the planning and implementation of your project.

- Throughput up to 70 t/h

- UNTHA Eco Drive for very low operating costs

- Sturdy machine design

- Easy to maintain and service

XR class applications:- Commercial and industrial waste (C&I)

- Household waste (MSW)

- Construction & demolition waste (C&D)

- Woody C&D

- Bulky waste

- Wood waste

- Scrap wood

- Compressed plastic bales

Technical data XR2000/3000:- Power [kW]: 65 - 264 | (up to 360 hp)

- Hydraulic power [kW]: 7,5

- Cutting chamber width [mm]: 1960 | (77/116 in)

- Ø Rotor [mm]: 1.000

- Rotor speed [rpm]: 0 - 35

- Weight [t]: ~ 21

- Throughput* [t/h]: ~ 20

- Remark: *Depends on the type of material and perforated screen diameter

Technical data XR2000/3000:- Power [kW]: 65 - 264 | (up to 360 hp)

- Hydraulic power [kW]: 3,0

- Cutting chamber width [mm]: 1960 | (77/116 in)

- Ø Rotor [mm]: 1.000

- Rotor speed [rpm]: 0 - 22

- Weight [t]: ~ 20

- Throughput* [t/h]: ~ 50

- Remark: *Depends on the type of material and perforated screen diameter

Technical data XR2000/3000:

- Power [kW]: 65 - 264 | (up to 360 hp)

- Hydraulic power [kW]: 7,5

- Cutting chamber width [mm]: 2960 | (77/116 in)

- Ø Rotor [mm]: 1.000

- Rotor speed [rpm]: 0 - 35

- Weight [t]: ~ 24

- Throughput* [t/h]: ~ 25

- Remark: *Depends on the type of material and perforated screen diameter

Technical data XR2000/3000:- Power [kW]: 65 - 264 | (up to 360 hp)

- Hydraulic power [kW]: 3,0

- Cutting chamber width [mm]: 1.960/2.960 | (77/116 in)

- Ø Rotor [mm]: 1.000

- Rotor speed [rpm]: 0 - 22

- Weight [t]: ~ 23

- Throughput* [t/h]: ~ 70

- Remark: *Depends on the type of material and perforated screen diameter

XR mobil-e

-

Mobile electromechanical shredding system for efficient processing of waste and

waste wood

The new XR3000 mobil-e is a revolutionary machine concept in mobile waste shredding. It capitalises on many benefits of an electromechanical drive without having to forego the advantages of a mobile machine. This gives you maximum efficiency and flexibility.

Just like all our XR products, the XR mobil-e is also equipped with the energy-efficient UNTHA Eco Drive. This insures you that your operating costs will be minimised and that material quality will be maximised. The key feature: Unlike diesel operated and hence energy-guzzling, noisy mobile machines that are harmful to the environment, the XR mobil-e shreds only electrically. For the shredding process the XR mobil-e is connected to the power supply with a hands-on quick fastener. Thus your employees and your neighbours as well as the environment benefit from this feature in addition to the economic advantages that it brings.

Mobility is ensured through a reliable crawler-type undercarriage in combination with a small petrol-powered engine. The XR mobil-e can be easily moved to any spot via remote control. With an extensive range of interchangeable screens and cutters, the shredder can be configured according to the customer’s output specification. For example, a consistent 30 mm particle or a 400 mm particle size are both achievable, as is anything in between. This means the XR mobil-e can shred bulky, MSW, C&I, C&D or wood waste with ease, to produce a homogenous alternative fuel for the waste to energy, cement, gasification or biomass markets. In addition, a height-adjustable discharge conveyor belt and an optionally available magnetic separator give you everything you need for an efficiently operating mobile shredding system.

Plug - Shred - MoveRelocate this mobile waste shredder to different indoor and outdoor locations around your site and simply re-connect it to the power supply with the quick fastener!

Your advantages at a glance

- Mobile shredding concept with electrical drive

- Sturdy design with high resistance to foreign objects

- High material quality with high throughput performance

- Low maintenance expenditures

- Low noise emissions

XR3000 mobil-e applications:- Industrial waste

- Household and commercial waste

- Wood waste

- Scrap wood (e.g.: construction timber)

- Plastic bales

Technical data XR3000C mobil-e:- Power [kW]: 113 - 264 | (up to 360 hp)

- Hydraulic power [kW]: 11

- Cutting chamber width [mm]: 2.960 | (116 in)

- Ø Rotor [mm]: 1.000

- Rotor speed [rpm]: 0 - 35

- Weight [t]: ~ 37

- Throughput* [t/h]: ~ 40*

- Remark: *Depends on the type of material and perforated screen diameter

Technical data XR3000R mobil-e:- Power [kW]: 113 - 264 | (up to 360 hp)

- Hydraulic power [kW]: 11

- Cutting chamber width [mm]: 1.960/2.960 | (116 in)

- Ø Rotor [mm]: 1.000

- Rotor speed [rpm]: 0 - 22

- Weight [t]: ~ 36

- Throughput* [t/h]: ~ 70*

- Remark: *Depends on the type of material and perforated screen diameter

S25

-

Compact shredding system for reliable volume reduction

The S25 is a very compact shredder, which is well suited for continuous operation thanks to its robust design in combination with a foreign object-resistant cutting unit. The S25 is also optionally available as a "plug and shred" option. This gives you the utmost flexibility.

The S25 is a small, very powerful rotary shear that is used for a great number of different applications. The low-noise, 2-shaft shredder is equipped with an energy-efficient 7.5 kW drive motor and can be easily customized to your needs thanks to its variety of versions.

The shredding machine is designed for continuous operation in a multi-shift environment. The special sealing of bearings and gearbox, of the internal wear plates and the wear-resistant cutting unit make it particularly low maintenance and ensure very high process stability. Thanks to its compact design the machine requires little space and can be easily integrated into existing systems.

The S25 is available in a mobile version with substructure, control and a 240 l discharge bin as a "comprehensive solution". Just set up, plug in and shred. The machine can be optionally equipped with a conveyor system for feeding and material discharge.

Our experienced product managers will be happy to help you plan and implement your project.

- Compact and sturdy design

- Low wear and tear on parts and foreign object-resistant cutting unit

- Low noise and low maintenance

- Also available as a "plug and shred" option

S25 applications:- Shavings

- Punching scrap

- High-pressure die cast parts and metal and plastic containers

- Light wood waste

- Wooden boxes and fruit crates

- Canisters

- Tin cans

- Medical waste

S40

-

For continuous operation with high throughput performance particularly for

organic waste

The S40 is a rugged shredder with a particularly high throughput performance. Thanks to its special design this shredding machine is particularly well suited for biological and biogenic waste. Special sealings protect critical components from aggressive plant and food acids. Furthermore, the uncomplicated machine technology keeps your maintenance expenditures to a minimum.

The S40 is a very efficient 2-shaft shredder that is perfectly designed for orgaic waste and their specific characteristics. The precise cutting unit in connection with a stripping system ensure exact cutting and prevents jamming.

These shredders were equipped with a special mechanical seal that protects the shaft bearings and the gears from dirt and acids. This extends the service life and reduces maintenance expenditures. The S40's low noise and dust emissions thanks to the low speed of both shafts provides an additional advantage.

The two-shaft shredder can be optimally adjusted to your operating situation with various cutting unit widths, motors and many other technical options. We also offer comprehensive solutions from one source!

- Specifically for organic waste

- High throughput performance

- Compact and robust design

- Very low noise and low maintenance

S40 applications:- Organic waste

- Green waste

- organic materials such as slaughterhouse waste of poultry, pig and cattle fattening

- Foodstuffs with and without packaging

- Further applications of the S40

S120

-

Reliable pre-shredder for difficult applications

The S120 is one of the most innovative pre-shredders in its class. A sophisticated cutting strength distribution system ensures that the cutting tooth briefly receives up to 70% more cutting strength for materials with highly variable cutting strength requirements (e.g. thick-walled metal pieces). Together with its high throughput performance, high availability and low maintenance requirements, this shredder guarantees an economically efficient recycling of your material.The S120 is a rotary shear shredder that is often used as pre-shredder for difficult applications. Apart from its very resistant and sophisticated cutting system and flexible drive concept, the shredder is also convincing thanks to its high throughput performance. By linking four motors, the system reaches a high torque of max. 2 x 35,000 Nm. When needed, this torque is distributed to the respective cutting tooth at peak moments (see cutting strength distribution system).

This rotary shear is also characterized by a particularly high availability. This machine is particularly low maintenance thanks to special bearing and gearbox sealings, an integrated cutting system protection and an optionally available shaft ventilation.

In the field, this machine is connected with an UNTHA 4-shaft shredder downstream to achieve a homogeneous, separable and also smaller final fraction.

The combination of both machines ensures high process stability and guarantees economically efficient operation.

- Very sturdy and sophisticated cutting system

- High throughput performance with high availability

- Flexible drive system

- Low maintenance

S120 applications:- Metal sprues and housings

- Aluminum profiles

- Metal drums

- Electronic scrap

- Electrical devices

- Household devices

- Tires

- Paper waste

Used Shredders

QR1400

-

Your advantages at a glance

- Hydraulic multi-functional flap

- Customised cutting systems

- Fail-safe power train

- Maintenance-free pusher system

- Robust machine body

UNTHA QR1400 used

The ideal machine for shredding plastics and residual timber (pallets)

with high throughputs at low life running costs- Rotor driving power (kW): 1x55

- Driving power hydraulic (kW): 2,2

- Rotor Ø [mm]: 450

- Cutting chamber dimensions (mm) 1.400 x 2.010

- No. of cutting rows: 3

- No. of cutters: 114

- Size indexable insert (mm): 34 x 34

- Rotor speed (min-1): ca. 100

- Screen diameter Ø (mm): 30

- Model number: QR1400

- Hours: 131

Model:- Mechanically swiveling perforated screen

- Rotor in profiled design

- Integrated transmission oil cooling

- Spring preloaded detent coupling

LR1400

-

Your advantages at a glance

- High throughput capacity

- Very reliable

- LR technology package included

- Homogeneous wood chip quality

Used and reconditioned RS50 Specification:

LR1400 wood shredder - overhauled

The LR1400 is fully adaptable to your application situation and is suitable for businesses with a wood waste volume of 12 m³ per week.- Rotor driving power (kW): 1 x 30

- Driving power hydraulic (kW): 1,5

- Cutting chamber dimensions (mm) 1.400 x 1.600

- No. of cutting rows: 2

- No. of cutters: 76

- Screen diameter Ø (mm) 25

- Construction year 04/2018

Specials:- 45° Machine housing for larger filling opening

- Special swing gate for pallet shredding

- Cabinet and control

Applications/div>

Residual timber utilization

-

Our reliable industrial wood shredders and wood grinders ensure the production of a homogeneous granulate. This can be used for your in-house wood chip furnace, biogas plant, biomass co-generation plant and the production of wood briquettes. And this reduction in size also reduces your disposal, transport and storage costs. Regardless of how you are planning to use the wood chips, we will configure the wood grinder or chipper for woodworking scrap exactly according to your needs.

We offer a large selection of longevity wood shredders for carpenters, joineries and the wood processing industries, with various working widths, rotor diameters and drive capacities. The wood waste grinders can shred all mixed woodworking waste such as offcuts, veneers, pallets, solid timber, particleboards and MDF boards. The possible granulate sizes usually range from 12 to 80 mm. Regardless of whether you need a compact, small wood shredder or have specific needs with a conveyer system, we will always find the right wood recycling equipment for you!

Metal-free wood chips

All our industrial wood shredders produce a high quality granulate for immediate use in wood chip heating systems or the production of briquettes. Metal parts such as nails, screws, clamps or metal fittings are no problem for the cutting system: The metal is shredded together with the waste wood and can easily be removed by an additional metal separation system or a pipe magnet.3-year carefree warranty

Capitalize on our reliability! We provide a 3-year or 2,000-hours carefree warranty on all our UNTHA wood shredders, depending on which value is reached first.The first choice in wood shredders

We have been designing and manufacturing industrial shredders for residual and waste wood for over 40 years. More than 2,000 customers trust in an overall solution by UNTHA when it comes to wood waste shredding. We are happy to organise a visit to a reference facility in your area or a free trial with our wood waste size reduction equipment in our test centre. An excerpt of our successfully realized projects can be found in our reference book wood:

Refuse Derived Fuels (RDF)

-

Our alternative fuels shredders enable you to optimally recycle waste into substitute fuels and ensure high quality by producing a homogeneous granulate free of foreign objects.

Co-processing of industrial waste in cement kiln

The goal of recycling is to use the valuable energy contained in the waste and to substitute the use of fossil fuels. During the recycling process the portions with a high calorific value are separated from the commercial and industrial waste and turned into a marketable product. Depending on the calorific value and the granular size, these fuels are used in fluidised bed combustion, cement plants and substitute fuel power plants.

The waste undergoes a single-phase or multi-phase recycling process to separate the fractions with a high calorific value from household waste, bulky waste, industrial waste, commercial waste and sorting residue. This process may consist of the following steps:

Single-phase recycling process:

- Shredding

- Separation of ferrous and non-ferrous materials

Two-phase recycling process:

- Pre-shredding

- Sifting process

- Air separation

- Separation of ferrous and non-ferrous materials

- Ballistic separation

- Separation of heavy materials

- Optical sorting

- Re-shredding

We are world leaders in this complex field of substitute fuel recycling. Regardless of whether you require single-phase or multi-phase shredding, we offer an economic and, first and foremost, reliable solution!

Utilization areas and fraction sizes of substitute fuels

- Pre-shredded waste < 400 mm: The shredded material

is particularly suitable for material recovery facilities (MRF)

- Pre-shredded waste < 150 mm: This fraction size is

suitable for co-generation power plants with grate firing, refuse

combustion plants, material recovery facilities (MRF) and mechanical

biological treatment. The untreated residential waste reaches an

approximate calorific value of approximately 9-11 MJ/kg

- Substitute fuel < 80 mm: for co-incineration use in

cement plant calciners, fluidised bed combustion and power plants for

energy recovery. The resulting calorific value of this fraction is

approximately 15-18 MJ/kg

- Substitute fuel < 30 mm (SRF): Ideally suited for the injection furnace in cement plants and substitute fuel power plants. The secondary fuels in the mixture for the co-incineration in cement rotary kilns must have a calorific value of at least 18-22 MJ/kg

Waste processing

-

Our industrial waste shredders are well suited for 1-step or 2-step waste recycling and shred the material down to a fraction size of 400 to 30 mm. We offer powerful and versatile waste shredders for the volume reduction of different waste streams such as C&I waste, municipal solid waste (MSW), commingled waste, bulky waste and waste wood. The XR waste shredder can be individually tailored to the needs of waste disposal and recycling companies that require single-pass processing of household, industrial and commercial waste into alternative fuels (RDF/SRF).

A mechanical-biological waste recycling is usually performed when processing household or commercial waste similar to household waste. The goal of this treatment is to generate a landfill-suited waste material by separating waste fractions with a high calorific value, valuable resources as well as foreign objects.

We understand the tough requirements that the shredding technology of a mechanical-biological waste recycling system faces. With our newly engineered waste shredder we are able to offer the ideal product that meets these tough requirements for both low operating costs and high availability.

Overview of the different technologies for mechanical-biological waste processing

- Mechanical-biological waste treatment: In this

process, the waste is mechanically separated from the metals and the

fractions with high calorific value are sifted out. The subsequent

biological treatment occurs in the form of a decomposition or

fermentation process. The end product can be deposited in a landfill due

to its low biological activity.

- Mechanical-biological stabilisation: The

mechanical-biological stabilisation is different from the

mechanical-biological waste treatment because in addition to the

biological treatment, the fractions with a high calorific value are

recycled into substitute fuels.

- Mechanical-physical stabilisation: This process generates substitute fuel through a mechanical and physical sorting process (e.g.: separation of materials containing iron from materials not containing iron) using a multi-phase recycling process. The substitute fuel is usually processed into pellets or fluff.

- Mechanical-biological waste treatment: In this

process, the waste is mechanically separated from the metals and the

fractions with high calorific value are sifted out. The subsequent

biological treatment occurs in the form of a decomposition or

fermentation process. The end product can be deposited in a landfill due

to its low biological activity.

File, data and material destruction

-

Our hard drive shredders and industrial paper shredders reliably protect your sensitive and confidential data from the prying eyes of third parties. We guarantee a secure and uncompromised destruction of your data pursuant to the most recent DIN 66399 standard.

We offer customized shredding solutions depending on the required protection class, security level and type of data to be processed. Our robust hard drive shredders and industrial paper shredders have been tested and proven over several decades and excel where other traditional shredding systems cannot.

The independent certification centre DEKRA confirmed in an expert report that our 4-shaft shredding machines easily meet the new security standard DIN 66399-2 (destruction systems for files and data carriers).

Waste wood recycling

-

Waste wood is a precious resource that is available in large volumes and may be used either for material recycling or energy production, depending on the quality grade. The rising cost of waste material disposal and a growing consciousness for the environment also contribute to the increasing importance of waste wood recycling. The term “waste wood” includes all woods and wood-based materials that have come to the end of their product lifespan and are thus considered waste.

We offer you innovative, highly economical single-step shredding concepts for the recovery of your waste wood, upon request also with metal separation. Units are available as stationary or mobile versions. Low operating costs, extremely low fines and foreign object protection paired with high performance are the key factors in the success of UNTHA waste wood shredders. Minimised dust and noise levels benefit your employees, your neighbours – and ultimately also the environment!

Processed for thermal utilisation or recycling

During the recovery process, the waste wood is shredded and separated from foreign matter such as metal parts. The resulting wood chips are either recycled or utilised for energy production, depending on their classification grade. Recycled waste wood is often used as raw material for the production of chipboard or other wood-based materials. In case of thermal utilisation, the wood chips are used as high-grade fuel in biomass or thermal power stations.

We offer reliable shredders with a throughput of up to 40 t/h for waste wood recovery. Our units are suitable for a wide range of applications.

Plastic materials

-

As a renowned manufacturer of reliable plastic shredders, we offer special machines for in-house recycling and for heavily contaminated post-consumer waste.

Due to its format, components and characteristics, plastic is a very versatile material that is primarily used in industrial mass production. The resulting plastic waste can be recycled by shredding and washing the material, before generating a reusable, recycled granulate. Shredded plastic waste can also be used for energy generation.

Our plastic shredders were developed specifically for the processing of these components. They deal effortlessly with all kinds of plastics, ranging from foils, lumps, profiles, fibres, ribbons, PET bottles and hollow parts to post-consumer and production waste. Thanks to a range of different cutting systems, rotor diameters and shapes as well as different blade sizes, the shredders are suitable for thermoplastics, duroplastics and elastomers and may be customised to suit your individual requirements.

Impressive references

Take a look at our current reference book "Plastics" and get an impression of how companies around the world use our shredders successfully:

Metals

-

Regardless of whether your metal waste comes from the metal-processing industry, automotive industry, electronics industry, waste industry or commercial production, we will always offer you the right shredding system for recycling your valuable resources!

Metals are important raw materials for the industry and can be repeatedly returned to the recovered resource cycle with very little loss. The recycling of metals saves valuable raw materials and energy as opposed to the new processing of ores.

Our sturdy industrial metal shredders have been tried and tested a thousand times over, reliably and efficiently shred light metals such as aluminium, magnesium, Al-Mg alloys, copper or nickel, as well as harder metals such as iron, zirconium, titanium and sheet steel.

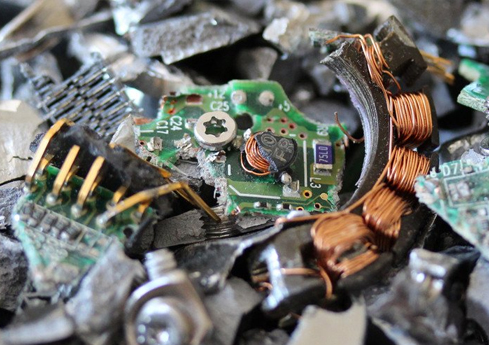

Electronic scrap

-

Our customized e-scrap shredders enable you to process electronic scrap in your recycling facility and they align perfectly with your recycling system. The granulate size is adjusted in such a fashion that metals and non-metals can be separated and recycled as completely as possible.

More than 40 million tons of electrical and electronic scrap are generated annually – and the trend is growing dramatically! Recycling electronic devices is not just beneficial for environmental reasons. This scrap, as a rule, contains many precious metals that are recovered during the recycling process. To ensure a high yield during the recovery process, the shredding step should generate only a very low amount of fine particles.

E-scrap shredders that meet your needs

Our reliable 4-shaft shredders are particularly suited for processing e-waste. Their low speed ensures that printed circuit boards and old devices are carefully shredded with low emissions. The recycled material is ideally suited for e-scrap recycling machines and subsequently for cutting facilities where precious metals are separated from impurities.Seeing is believing: Reference visit or free trial in our test centre

We have been designing and manufacturing industrial shredders for recycling applications for over 40 years. Customers trust in an overall solution by UNTHA when it comes to shred e-scrap. We are happy to organise a visit to a reference facility in your area or a free trial with our e-scrap shredders / circuit board shredders in our test centre.

Paper and cardboard

-

We offer customized solutions for shredding paper and cardboard. Our experienced technicians optimally configure the shredding system to meet your needs and thus ensure a perfect shredding result.

Paper, cardboard and pasteboard are valuable raw materials that play an important role in recycling and in the waste processing industry. The easy recyclability of cellulose permits the economically efficient and environmentally friendly reuse of paper. Before shredding, the material is sorted based on its prior use, foreign objects are removed and only then is the material shredded.

Hospital waste

-

Our hazardous waste shredders are perfectly suited for the chemically aggressive material in your hospital waste. After the shredding process, the material can be optimally utilised thermally or disposed of together with municipal solid waste once it has been sterilised. The shredding is so effective that the granulate does not give any indications of the source material.

Hospital waste consists of very different types of waste and requires special treatment during disposal due to the presence of infectious and highly contaminated materials. Depending on the waste type or classification, the hospital itself might need to specially treat the waste or store it in dedicated plastic containers or drums on-site.

Our hazardous waste shredders have been tested and proven multiple times for shredding medical waste or tough materials like oil filters. Our customers particularly value the high operating reliability, low emissions and easy maintenance. The shredded material can, thanks to subsequent sterilisation, be used either as a substitute fuel or disposed of together with municipal solid waste.

When it comes to hazardous waste shredding you can profit from our experience. More than 100 customers trust in our hazardous waste shredders worldwide.

Organic waste

-

Our shredding solutions process biological and biogenic waste to generate an optimal substrate for further utilisation in your biogas plant or in your disposal business. The application area ranges from green or garden waste to food waste and expired goods including packaging to slaughterhouse waste.

Non-homogeneous or organic waste in pieces including packaging must be shredded to prepare it optimally for fermentation. Our low-speed organic waste shredding solutions are ideally suited for this application. These two-shaft shredders ensure reliable processing and guarantee a pumpable fermentation substrate. Thanks to the special equipment, efficient cutting unit and sturdy machine construction, these shredders are very reliable and have a long service life!

Pulper ropes

-

In addition to a homogenised granulate of your residual products, our customized shredding systems guarantee an optimal pre-product for further recycling or thermal utilisation in your plants.

Our customised shredding systems not only turn your waste materials into a homogeneous granulate, but also provide an ideal pre-product for further processing and/or thermal recovery within your plant.

Pulper ropes are waste products from the paper industry. They are created when waste paper is recycled in the pulper and absorb impurities such as plastics, small metal parts, foils and non-soluble paper. But what is the best way of recycling these waste products?

Processing them into alternative fuels has proved to be the most effective way of recycling pulper ropes and paper production rejects. This yields two marketable materials: metal as well as high-calorific alternative fuels for energy production.

UNTHA offers a cost-efficient, single-phase shredding system. Benefit from the following advantages:

- Compact shredders, material handling and metal separation units require little space

- Low operating costs thanks to single-phase processing concept

- Perfectly processed material streams (alternative fuel and metal)

Tried-and-tested processing concept

The ropes are fed directly into the hopper via a material handler. The cutting unit shreds the material to a pre-defined size and the granulate is removed by a discharge conveyor. An overbelt magnet removes all metal parts from the material stream, resulting in a metal content with few impurities and a high-calorific alternative fuel. For this single-phase processing method, we offer a 1-shaft shredder in the XR class and a 4-shaft shredder in the RS class.

Miscellaneous

-

You did not find your material or application case in our overview? No problem – our application engineers are known for their ability to provide solutions for even the most complex customer requirements. Let us know what material you need to shred or what type of application you need by completing our product enquiry form or make an appointment with theUNTHA tesr centre. We will be happy to help you test your material in our test centre under real-life conditions.

We look forward to coming up with a solution!