- Offer Profile

- Milacron is a global leader in the manufacture, distribution and service of highly engineered and customized systems within the $27 billion plastic technology and processing industry. We are the only global company with a full-line product portfolio that includes injection molding and extrusion equipment. We maintain strong market positions across these products, as well as leading positions in process control systems, maintenance, repair and operating (“MRO”) supplies for plastic processing equipment. Our strategy is to deliver highly customized equipment, components and service to our customers throughout the lifecycle of their plastic processing technology systems.

Plastic processing machines

-

Our focus is on a product offering that is all-encompassing. No one else in the plastic processing industry has you covered as completely as Milacron. We’re committed to what our customers need: a one-stop shop, focused on providing excellence in pellet-to-part solutions.

Milacron technologies manufacture technical automotive parts, big and small, with a focus on keeping parts high-strength, low-weight, fuel efficient, and durable.

Plastics processors, around the world, rely on Milacron extrusion systems to produce materials that fit today’s construction industry requirements, including lighter-weight components made with recycled materials. Milacron’s injection molding, structural foam, and web gas assist systems offer the ability to create innovative, durable, weather resistant, and easily maintained components for construction applications.

We provide high-quality injection molding technology for extruded wood and natural fiber composites. Our systems and processing technologies create construction equipment that is durable and long-lasting. Our innovative machines help the construction industry increase production rates and decrease labor costs.

Milacron’s latest technologies, in rapid product development cycles, meet the demand for superior part quality, precision, and ever-smaller parts, with ever-shorter life-cycles, at ever-lower costs.

INJECTION MOLDING MACHINES

All Electric

-

Explore Milacron’s industry leading selection of injection molding machines. A vast selection of machines all focused on performance.

From 6 to 6,000 ton clamp capacities, Milacron offers you the widest range of injection molding machines. Choose from all-electric, servo or hydraulic machines with a full range of plastics processing technologies, including multi-component and co-injection.

Milacron’s all-electric injection molding machine technology provides faster cycles and clean, quiet, energy-saving machines. They deliver increased productivity and reduced energy consumption compared to equivalent hydraulic machines.

POWERPAK

-

A New Standard in High-Performance Electric Technology

PowerPAK all-electric injection molding machines provide an increase in tonnage over similar models. With energy savings of 50-60% over similar machines, Milacron’s PowerPAK offers environmentally sound equipment that provides speed and repeatability, cleanliness, and highest part productivity, quality and profitability.

Configured precisely to production requirements and applications, PowerPAK allows customers to combine a large range of clamp and injection units. With a high speed, ultra-precision rack-and-pinion clamp, low inertia motors that increase response, and higher performing components than other packing machines on the market, PowerPAK gives you a competitive advantage in the market while reducing your operational costs.

ROBOSHOT

-

The Next Generation of Artificial Intelligence in Injection Molding Machines

High Precision Electric Injection Molding

Roboshot is the next generation of Artificial Intelligence (AI) in injection molding machines, with higher precision and reliable molding capabilities than ever before. Engineered for greater rigidity, Roboshot’s proven performance makes it the perfect solution for cleanrooms and other molding environments that demand precise process control, high speed injection and consistent repeatability.

Servo

-

Milacron’s servo injection molding machines offers energy efficiency, reliability, precision, and product versatility. The reduced energy use reduces the heat load on the factory and reduces maintenance and operational costs over the life of the machine.

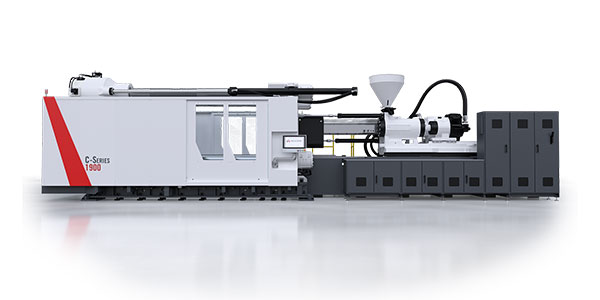

C-SERIES

-

Introducing the next generation of Milacron Innovation. The C-Series expands on Milacron’s leading big machine technology through a large-tonnage two-platen press powered by an energy efficient servo-motor hydraulic system, geared towards versatility, and designed to exceed the demands of global automotive, appliance, pallet, and other large molded parts. Powered and driven by the energy-efficient and highly reliable Fanuc servo motor power pack, the C-Series’ enhanced machine specifications and performance offer improved reliability, higher max mold weights, faster clamp speeds, and a compact footprint. The C-Series is a true global machine in design, performance, and reliability.

C-SERIES: STANDARD FEATURES- Advanced 2 Platen Technology powered by energy efficient servo motor hydraulic system

- Enhanced reliability driven by a proven Fanuc AC servo motor and drive package

- Direct control of pressure and flow via internal gear pumps

- Multiple servo motor system for independent operation of eject and core pull

- Improved layout of manifolds and hoses on non-operator side

- Monitored shut off valve to pump suction lines

- And More...

MAGNA TOGGLE

-

A New Standard in Toggle Technology

Combining the advantage of a precise and accurate toggle mechanism with advanced user-friendly controls, the Magna T Servo is a high-value injection molding machine. Reduced heat generation results in longer life for the hydraulic components and enhanced oil life, while the head load on the factory floor and cooling water consumption is reduced. Magna T Servo offers energy efficiency while providing outstanding repeatability, increased accuracy and precision.

The Magna T Servo has a quiet gear pump resulting in substantial noise reduction. Its toggle mechanism is optimized for fast cycling and reduced platen deflection and its servo motor design has increased reliability, lower maintenance costs, all while reducing energy consumption, lowering operating costs.

The Magna T Servo sets a new standard in toggle technology providing the highest performance, versatility, precision, durability, consistency, and productivity.

MAGNA VERTICAL

-

Magna V vertical clamp machines bring you every advantage for insert molding, making it easy to combine two materials and reduce assembly costs. From encapsulation of delicate electronic parts to over molding of plastic on metal for diverse automotive applications, Magna V also offers a reduction in post-molding operations, saving time and money.

Milacron’s Magna V machines can be configured for every possible insert molding application by combining a wide range of clamp, table and injection unit configurations. Vertical clamps with horizontal tables let gravity gently and easily do the work of holding single or multiple inserts. Open clamp designs with rotary and shuttle tables give the advantage of working with multiple molds and simultaneous operations including pre-molding, injection and post-molding operation. Simultaneous operations are easily automated for consistent quality, high productivity and high profitability.

MAXIMA PERFORMANCE

-

Enhanced performance, speed, reliability, precision, versatility and user-friendliness

Introducing the new Maxima Performance Series, which builds upon the highly successful Maxima platform. The Maxima Performance Series addresses the market demand for higher performance, precision and flexibility. This enhanced platform delivers faster cycle times, wider platens, a precision greaseless clamp guided on linear bearings and integrated auxiliary capability.

Maxima Servo is one of Milacron’s most energy-efficient machines. The servo-hydraulic machine provides up to 70% energy savings over similar machines, with a reduction in molding costs, maintenance costs and heat load on the factory floor.

Q-SERIES

-

Milacron’s Q-Series is the latest globally available servo-hydraulic injection molding machine. With a tonnage range of 55 to 610 (500-5.500 KN), the Q-Series is built to perform in wide array of applications and configurations. Based on Milacron’s highly touted, reliable and in-demand Magna Toggle and F-Series machine lines, the Q-Series is a true culmination of high efficiency, consistency and globally engineered technology.

Q-Series has been designed to fit the high expectations of toggle performance while providing an extraordinary value. Leveraging the use of a servo motors in combination with hydraulic components the Q-Series provides exceptional repeatability while offering up energy savings. The clamp kinematics provide enhanced velocities while delivering a smooth and accurate operation. The clamp design provides for better tonnage linearity allowing minimum tonnage to go lower than previous toggle designs. The servo motor and hydraulic systems combine to provide power when it is needed, using less power when it is not. The eco-friendly design generates savings in electrical power consumption, cooling requirements, and lower maintenance cost.

EXTRUSION MACHINES

-

Our single and twin screw extrusion machines excel in producing sheet, pellets, PVC pipe, window profiles, vinyl siding, and profiles of wood and natural fiber plastic composites. We can help with challenging projects that require complex system solutions for thermal sensitive compounds to complex shapes or precision extrusions.

Milacron both designs and builds full extrusion systems in house, maintaining complete control of your precise equipment needs. From extruders, to new and rebuilt extrusion barrels and screws, to pipe heads, dies and downstream equipment, you get powerful, reliable solutions that meet your unique needs. Milacron’s demonstration and development laboratories have made a science of optimizing processing via natural compression. This creates a highly customizable approach for our customers: one that increases productivity, output and accuracy, while reducing costs.

CONICAL TWIN SCREW TC SERIES

-

Compact Designs Optimize Processing via Natural Compression

The Milacron TC Conical Twin Screw system has a wide range of options for every application requirement:

- Customized screw designs matched specifically to the customer process requirements for optimal performance.

- Feeding systems to meet process performance requirements: gravity, doser, crammer, single and multi-component gravimetric.

- Screw core temperature regulation options.

- Barrel cooling system: water, HTF, air

- Variety of drive and motor systems available including AC vector, brushless DC and DC.

- Advanced materials of construction, including tungsten coated screws and tungsten clad barrels for maximum wear protection and the lowest possible life cycle costs.

PARALLEL TWIN SCREW TP SERIES

-

For High Output with Gentle Plastification

Milacron’s TP Series of Parallel Twin Screw Extruders is designed for greater output, superior performance and higher profits.

- The strongest and most reliable gear box available on the market today.

- Ideal for heat and shear sensitive materials.

- High surface area, low shear screw designs for efficient heat transfer.

- Positive displacement pumping characteristics.

- Narrow residence time produces optimal melt condition.

CANTERBURY AND GENCA

-

- Canterbury custom service

- Extrusion screws and barrels

- Extrusion tooling

- Injection screws, barrels and valves

FIELD SERVICES

-

Each of our field service engineers has many years of experience in every facet of the extrusion process, having trained and worked with some of the world’s leading extrusion equipment manufacturers. We offer on-site field services for borescope alignment, PM inspections, barrel and feed screw measurement, as well as many other services you may require. Milacron Extrusion’s work is guaranteed. References from our customers can be provided at any time.

∙ Barrel Alignment

∙ Feed Screw Measuring

∙ Barrel Measuring

∙ Troubleshooting

∙ Preventative Maintenance

SCREWS AND BARRELS

-

Milacron Extrusion sells new feed screws with a variety of options available. Feed screws are typically made of 4140 steel, polished, and hard faced with either Colmonoy 56 or 83. They can also be chrome plated or surface treated with a carbide encapsulation for more abrasive or demanding applications. In addition we offer several design options such as conventional or barrier, with mixing options such as straight Maddock, spiral Maddock, and Pineapple. We are capable of handling requests of any size, application, and complexity.

AUXILIARY EQUIPMENT

-

The New, Integrated Automation Solution

Milacron is the leading supplier of plastic processing auxiliary equipment. Our plastic auxiliary equipment consists of several complementary components, such as material management, quick mold changes, reclamation, heat transfer, robots and conveyors.

CONVEYORS

-

Milacron's conveyor equipment allows you to quickly and efficiently prepare parts for shipment.

The plastics-processing conveyor equipment from Milacron allows you to quickly and efficiently prepare parts for shipment.Our conveyor systems move parts to different process stages and automatically remove runners and boxing parts for delivery. Automatically move parts to where they are needed with conveyors, separators and automatic box filling systems. You will minimize the amount of time and the number of people it takes to handle and package molded plastic parts.

Our plastic processing conveyor machines will reduce your labor costs while increasing the timely delivery of parts for your plastic processing plant.

- AK SERIES

- AF SERIES

HEAT TRANSFER

-

Milacron specializes in precision temperature control for process heating and transfer systems. When it comes to productivity and profitability, maintaining the required temperature for your machinery results in ultimate performance.

We offer cooling towers, pump stations, central chillers, portable chillers, mold temperature controllers, and hot runner controllers with VNC Integration Capability. All designed for efficient heat removal and proper mold cooling. Beyond these heat exchange and transfer systems, Milacron Plastics provides custom temperature solutions to meet your process requirements and goals for energy savings.

MATERIAL HANDLING

-

The plastics processing industry has its own unique set of demands, from quality requirements to increasing production outputs.

At Milacron Plastics, we offer customized material handling systems that match your needs. To stay ahead in your industry, it’s important to have material management support from products, installation, system design, technical support and customer service. To accommodate purchases of bulk materials, you will want ample storage along with a material management system flexible and reliable enough to handle your needs. That’s where we come in.

Our advanced designs and high-quality material management equipment allows for a manufacturing process that is reliable, quick and cost-efficient. From bulk storage, surge bins, vacuum loading systems, color feeders and loaders and dryers, our material management systems provide the speed and efficiency you demand. Milacron Plastics’ material management equipment and systems are specifically engineered and designed to save you time, streamline production and reduce operating costs.

QUICK MOLD CHANGES

-

Milacron’s lineup of quick mold change solutions includes a full line of mold handling products. We have a solution to solve your quick mold change application needs. From hydraulic and magnetic mold clamps, mold change tables, mold storage rack system, to quick connect multi coupling systems for water, pneumatic, hydraulic, and electrical mold connections. Our equipment is engineered and built to the highest industry standards, so you can expect the equipment to withstand rigorous daily use.

• Hydraulic Mold Clamps

• Magnetic Mold Clamps

• Mold Racks

• Mold Tables

• Mold Transfer Stations

• Mold Up-enders

• Quick Connectors – Multi-coupling

RECLAMATION

-

Reusing plastic materials to furthers industrial processing results by lower production costs, lower environmental impact on manufacturing operations, and opportunities for new product innovations through technologies such as co-injection and mono-sandwich processes.

Milacron’s line of reclamation products includes our Low RPM Sprue / Runner Granulator Series, Small Part Robotic Fed Granulators, Mid-Range Beside-the-Press Granulators, and Central Granulators / Shredders equipped with Blower Evacuation Systems and Fine / Dust Filtration, as well as Clean Air Bags and Electrostatic Oil Cleaners.

• Clean Air Bags

• Electrostatic Oil Cleaners

• Granulators

• Shredders

ROBOTS

-

Milacron is a leading supplier of industrial robotic systems to the plastics processing industry. We provide a series of robotic solutions for many different applications, such as in mold decorating, palletizing, insert loading, de-gating of runners, trimming of parts, vision inspection and much more. Today’s plastics industry requires versatility, ease of operation, and product up-time. Milacron provides a portfolio of robotic solutions built with superior manufacturing techniques, innovative engineering / design and continuous improvement to keep up with the demands of our customer base.

Our line of robotic solutions span a diverse range of applications from pneumatic sprue pickers, servo sprue pickers for parts / runner separation, 3 axis and 5 axis servo traversing robotic systems, up to 6 Axis Articulating robotic cells with complete integration between the processing machinery and the robotic cell.