- Offer Profile

... is the world’s leading supplier of machinery for woven plastic packaging production, plastics recycling and refinement.

For 50 years we have been producing machinery for sacks, packaging fabrics and technical textiles made of plastic tapes. The portfolio of the textile packaging division ranges from tape extrusion lines, winders and circular looms to machines for coating, printing, and sack conversion.

In addition, we look back at more than 30 years of experience in the development and production of plastics recycling machinery. The product portfolio of Starlinger’s recycling technology and viscotec divisions comprises machinery solutions for the recycling and refinement of plastics such as PE, PP, PA, PS, BOPP and (food grade) PET.

Packaging

-

Woven plastic packaging is without doubt one of the most sustainable packaging solutions worldwide.

And much sought after – global demand is increasing by 4 % each year – more than for any other type of industrial packaging.

Starlinger supplies all machines for the production of a wide range of woven sacks made of polypropylene and PET – even from recycled material. This is a first step towards a circular economy. With our "Circular Packaging" concept for woven plastic packaging we offer a closed product loop and contribute to an efficient and resource-conserving use of plastics. Tape extrusion

-

This is where the sack production process begins.

Our portfolio of extrusion lines and associated components offers sophisticated technology with an optimum price-performance ratio, easy operation and maintenance, as well as high line speed – also for the material-saving production of light tapes.

starEX 1200 eqo

-

The starEX 1200eqo is specially designed to extrude PP or HDPE/LLDPE tapes for high-performance applications at premium quality and lowest cost. The tapes are used for producing woven bags, FIBC fabrics, and in various other technical applications. The eqoSTRETCH system provides best tape quality at lowest possible energy consumption. The optional Starlinger eqoCLEAN filter system allows to produce tapes with a high rPP or CaCO3 content.

- high-end tape extrusion technology

- highly productive

- resource-saving state-of-the-art design

- versatile use

- high economic efficiency

- low energy consumption

- Production speed up to 600 m/min*

- Melting capacity up to 1000 kg/h**

- Processing of recycled PP

- Processing of HDPE and LLDPE***

- High-quality lightweight tapes

- FIBC tape production with higher line speeds

- Energy recuperation system

- Change from standard to automatic die possible without replacement of die

- Energy-saving eqoSTRETCH stretching unit

- Optimized energy consumption

starEX 1600 S/ES/eqo

-

Our top model in the area of tape extrusion.

The starEX 1600 is specially designed to extrude PP or HDPE/LLDPE tapes for high-performance applications at premium quality and lowest cost. The tapes are mainly used for producing woven bags, FIBC fabrics and in various other technical applications. In combination with the Starlinger eqoCLEAN filter tapes with a high content of rPP or CaCO3 can be produced.

- outstanding tape extrusion technology

- highly productive

- resource-saving state-of-the-art design

- versatile use

- high economic efficiency

- high contents of recycled PP and CaCO3

- Production speed up to 550 m/min*

- Melting capacity up to 1000 kg/h**

- Processing of HDPE and LLDPE***

- High-quality lightweight tapes

- High tenacity tapes

- Energy recuperation system

- Change from standard to automatic die possible without replacement of die

- Customized machine versions

- Modular design

- Energy-saving eqoSTRETCH stretching unit

- Optimized energy consumption

Tape winders

- Starlinger precision cross winders are made for teamwork:

They reveal their technological advantages especially when it comes to weaving and fabric quality. As an option, the filTRONIC system – with meter counter and bobbin change signal for each winding head – allows to set the exact running length on the bobbin.

stacoTAPE 200XE

-

Precision cross winder designed to produce optimum bobbin packages for circular looms. Starlinger stacoTAPE 200XE winders combine the know-how of winding and circular weaving experts to ensure highest production efficiency and outstanding fabric quality.

- high-speed precision tape winder

- worldwide proven XE technology

- the ultimate bobbin packages for circular weaving

- production monitoring

- lowest energy consumption

- Production speed of 550 m per minute

- Patented multi-stage precision winding

- Central winding tension setting

- Winding of tapes up to 6 mm wide

- Large bobbin packages with up to 180 mm diameter

- Winder monitoring system filTRONIC

- easyDOFFING for easy, ergonomic handling

- Hose guide for compressed air hose

linTAPE

-

The linTAPE precision winders offer cost-efficient winder technology for the production of perfectly wound high-quality bobbins. High-efficiency drives and frequency converters, as well as low maintenance and raw material usage help to reduce production costs and CO2 emissions in modern woven sack plants. The semi-automatic easyDOFFING system facilitates safe and easy operation.

- patented variable traverse system

- state-of-the-art frequency converter technology

- lowest energy consumption

- new graphical HMI

- ultimate beveled-edge bobbin packages

- simple maintenance

- Easier handling with semi-automatic easyDOFFING

- Lubrication-free traverse system

- Newest frequency converter technology with PLUG & PLAY function

- Specially developed high-efficiency drives

- New HMI (Human Machine Interface) for easy operation with remote control and fault tracking system

- Central setting of the winding tension

- High safety standards and CE certification

- Simple maintenance

- Reduced waste

- Higher efficiency on looms

twinTAPE+

-

Maximum bobbin changeover reliability, low maintenance and no greasing – twinTAPE+ automatic precision winders are top-scale regarding efficiency, robustness and operator-friendliness. Designed to improve productivity, fabric quality and working conditions in a modern woven sack plant, they ensure precise winding and perfect bobbin packages. For PP, HDPE and PET tapes.

- perfected bobbin changeover technology

- state-of-the-art

- frequency converter technology

- new graphical HMI

- variable traverse system

- simple maintenance

- Excellent changeover reliability (> 99.8 %)

- Lubrication-free traverse system

- Newest frequency converter technology with PLUG & PLAY function

- Specially developed high-efficiency drives

- New HMI (Human Machine Interface) for easy operation with remote control and fault tracking system

- Central setting of the winding tension

- High safety standards and CE certification

- Simple maintenance

- Reduced labour costs

- Reduced waste

- Higher efficiency on looms

- Noise reduced

Circular looms

-

They produce the tape fabric which all types of bags, big bags, tarpaulins or agrotextiles are made of.

In their development we consider everything to make high-tech weaving cost-efficient. By using the latest technologies and processes, we ensure maximum precision, user-friendliness and productivity so that you can produce eco-friendly packaging of the highest quality – and at competitive prices.

Because investments in technologically sophisticated systems pay off in the long term: Due to less raw material requirements and less production waste, reduced energy consumption, minimized machine downtimes and lower personnel requirements, our looms do not only achieve the lowest production costs per square meter, but also highest sustainability for you.

FX

Circular Loom FX 6.0

-

The innovative FX 6.0 is a 6-shuttle circular loom that targets all aspects of cost-efficient high-tech weaving. It is especially userfriendly and ensures precise and gentle production of high quality fabric – even with lightweight tapes. With an IQ of 350 the FX 6.0 sets new standards in its field.

- next generation of high-speed circular looms

- worldwide proven Starlinger technology

- Indicatorof Quality (IQ)

- for lightweight and heavy fabriC

- warp break detecting system

- high economic efficiency

- Indicator of Quality (IQ) of 350 *

- Optimised weaving technology

- Production speed up to 1200 ppm **

- High efficiency > 90 % **

- Fabric width tolerance ± 4mm **

- Wear and tear resistant

- Sensor for weft tape end

- Warp break detection system

- Outstanding fabric quality from 50 to 140 g/m2

- Weft tape width up to 6 mm ***

- Oil-free fabric for high coating adhesion and food-safe packaging ***

- Large warp and weft tape packages

- Energy-saving AC drives

* running meters on fabric roll divided by number of warp breaks

** based on AD*STAR® quality standard

*** depending on tape quality, reed version, fabric width and densityalso available:

- CIRCULAR LOOM FX 6.0 L

Circular Loom FXa 6.0

-

The FXa 6.0 combines proven technology with innovative design for precise and gentle production of high quality fabric with optimized energy use. With an IQ of 350 the FXa 6.0 continues to lead by example: 1 warp break every 350 meters on average results not only in outstanding fabric quality but also less machine downtime and operator work.

- next generation of high-speed circular looms

- worldwide proven Starlinger technology

- Indicator of Quality (IQ)

- for light to medium-weight fabric

- warp break detecting system

- high economic efficiency

- Indicator of Quality (IQ) of 350*

- Optimised weaving technology

- Production speed up to 1200 ppm**

- High efficiency > 90 %**

- Fabric width tolerance ± 4mm**

- Wear and tear resistant

- Sensor for weft tape end

- Warp break detection system

- Outstanding fabric quality from 45 to 140 g/m²

- Weft tape width up to 6 mm***

- Oil-free fabric for high coating adhesion and food-safe products***

- Large warp and weft tape packages

- Energy-saving AC drives

* running meters on fabric roll divided by number of warp breaks

** based on AD*STAR® quality standard

*** depending on tape quality, reed version, fabric width and density

Circular Loom FX 6.1

-

The FX 6.1 circular loom offers high-speed weaving of tubular, flat and also heavy duty fabrics in perfect production quality. This model of the FX circular loom series is designed for weaving fabric out of PP, HDPE and PET tapes and achieves an IQ (Indicator of Quality) unmatched by comparable looms. The newly constructed reed does not require lubrication, allowing the production of fabrics for food packaging.

- state-of-the-art 6-shuttle circular loom

- for weaving of flat/heavy-duty fabrics

- maximum productivity and reliability

- low maintanance requirements

- swift ROI

- Production speed grommet band version up

to 920 ppm*, heddle wire version 850 ppm* - Low fabric width variations ± 7mm

- High efficiency > 85 %**

- Working width, doubleflat: 800 - 1250 mm

- Outstanding fabric quality:

- FX 6.1 – from 50 to 140 g/m2

- FX 6.1 HD – from 55 to 220 g/m2* (260 g/m2***)

- Weft tape width up to 6 mm

- Large warp (up to 180 mm) and weft (up to 120 mm) tape packages

- Increased lifetime of machine parts

- Energy-saving components / 6 kW*

- Oil-free reed, new shuttle design

- Reduced noise level

- Significant material savings

* depending on tape quality, fabric width and density

** grommet band version

*** grommet band version

Circular Loom FX 8.0

-

The FX 8.0 circular loom offers high-speed weaving of heavy-duty tubular and flat fabrics out of PP, HDPE and PET tapes. This 8-shuttle model of the FX circular loom series is designed to achieve perfect production quality and reaches an IQ (Indicator of Quality) unmatched by comparable looms. The newly constructed reed does not require lubrication, allowing the production of woven sacks for food packaging.

- state-of-the-art 8-shuttle circular loom

- for weaving of heavy-duty fabrics

- fast and efficient production with lowest energy consumption

- excellent fabric quality

- high economic efficiency

- versatile use

- Production speed of up to 850 ppm*

- Low fabric width variations ± 7mm

- High efficiency > 70 %

- Outstanding fabric quality:

- FX 8.0 – from 50 to 140 g/m2*

- FX 8.0 HD – from 55 to 220 g/m2 (260 g/m2)**

- Weft tape width up to 6 mm

- Large warp (up to 180 mm) and weft (up to 120 mm) tape packages

- Increased lifetime of machine parts

- Energy-saving components / 7 kW*

- Oil-free reed, new shuttle design

- Reduced noise level

- Significant material savings

* depending on tape quality, fabric width and density

** on special request

Circular loom FX 10.0

-

Heavy-duty weaving on a new level: The innovative reed design and enhanced key parts of the FX 10.0 ensure highest fabric quality and efficiency. The 10-shuttle loom produces endless tubular or flat fabric for heavy-duty applications such as big bags (FIBCs), tarpaulins, geotextiles and agrotextiles out of PP or HDPE and PET tapes. With a gentle, material-protecting weaving process the FX 10.0 achieves an IQ (Indicator of Quality) never seen before on an FIBC loom.

Advantages FX 10.0- Production speed up to 850 ppm*

- Low fabric width variations ± 5mm

- High efficiency > 70%

- Outstanding fabric quality from 55 to 220 g/m2 (260 g/m2)*

- Weft tape width up to 6 mm

- Large warp and weft tape packages

- Increased lifetime of machine parts

- Energy-saving components / 7.5 kW*

- Oil free reed and shuttle design

- Reduced noise level

- Significant material savings

* depending on tape quality, fabric width and density

RX

RX 6.0 pro

-

With the next generation of the RX series, Starlinger puts the focus on longer part lifetime and operator friendliness. Featuring energy-saving AC drives and long-life materials for wear and tear parts, the RX 6.0 pro is easy to operate and ensures efficient production of high quality fabric while saving energy and resources.

- world wide proven Starlinger technology

- operator-friendly

- longer lifetime of parts

- outstanding fabric quality

- for lightweight and heavy fabric

- high economic efficiency

- Production speed up to 1140 ppm*

- High efficiency > 90%

- Wear and tear resistant

- Outstanding fabric quality from

50 to 140 g/m2*,

140 to 200 g/m2* with heavy duty version - Weft tape width up to 6 mm

- Oil-free fabric for high coating adhesion and food-safe products*

- Large warp and weft tape packages

- Energy-saving AC drives

* depending on tape quality, reed version, fabric width and density

- Also Avalaible: Circular Loom RX 6.0 L pro

Circular Loom RX 6.1 pro

-

With the next generation of the RX series, Starlinger puts the focus on longer part lifetime and operator friendliness. The middle-size 6-shuttle loom RX 6.1 pro features energy-saving AC drives and long-life materials for wear and tear parts, is easy to operate, and ensures efficient production of high quality fabric even with lightweight tapes.

- worldwide proven Starlinger technology

- operator-friendly

- longer lifetime of parts

- outstanding fabric quality

- for lightweight and heavy fabric

- high economic efficiency

- Production speed up to 920 ppm*

- High efficiency > 85%

- Wear and tear resistant

- Outstanding fabric quality from

- 50 to 140 g/m2*

- 140 to 200 g/m2* with heavy duty version

- Weft tape width up to 6 mm

- Oil-free fabric for high coating adhesion

and food-safe products* - Large warp and weft tape packages

- Energy-saving AC drives

- Low fabric width variations ± 5mm

Circular Loom RX 8.1 pro

-

With the introduction of the RX 8.1 pro circular loom, the highly successful RX series now covers the entire production range in terms of fabric width. This model produces endless tubular or flat fabric from PP, HDPE and PET tapes for big bags (FIBCs), tarpaulins, geotextiles and agrotextiles. The specially constructed reed does not require lubrication, allowing the production of fabrics for food packaging.

- state-of-the-art 8-shuttle circular loom

- for lightweight fabric

- oil-free reed and shuttle design

- worldwide proven Starlinger technology

- High economic efficiency

- swift ROI

- Production speed up to 800 ppm*

- High efficiency > 70%

- Increased lifetime of machine parts

- Outstanding fabric quality from

50 to 140 g/m²; 140 to 200 g/m²**

with heavy-duty version - Weft tape width up to 6 mm

- Oil-free reed and shuttle design

- Large warp and weft tape packages

- Energy-saving components

- Reduced noise level

* depending on tape quality, fabric width and density

** special versions on request

Circular Loom RX 8.2 pro

-

It’s simple maths: The product of the most successful heavy-duty circular loom on the market multiplied by the latest technology equals the RX 8.2 pro. The upgraded 8-shuttle loom produces endless tubular or flat fabric for heavy-duty applications such as big bags (FIBCs), tarpaulins, geotextiles and agrotextiles from PP, HDPE and PET tapes and achieves an IQ (Indicator of Quality) unmatched by comparable looms.

- next generation of heavy duty weaving

- high speed

- worldwide proven Starlinger technology

- outstanding fabric quality

- high economic efficiency

- swift ROI

- Production speed up to 800 ppm*

- High efficiency > 70%

- Increased lifetime of machine parts

- Outstanding fabric quality from 50 to 220 g/m² (260 g/m²)*

- Weft tape width up to 6 mm

- Oil-free reed and shuttle design

- Large warp and weft tape packages

- Energy-saving components / 7.5 kW*

- Reduced noise level

Coating

-

Your sacks need to provide good protection against moisture and dust and/or have an attractive print?

No problem at all – with the right coating or lamination. The coating lines of our lamiTEC series offer uniform coating with excellent adhesion properties. For designs with special visual appeal it is possible to laminate printed BOPP films to the fabric. For tubular and flat fabrics made of PP, HDPE or PET.

Coating Line lamiTEC MX+, LX, CX

-

The lamiTEC series represents a new league of high-level coating lines. They combine newly designed technical features to coat and laminate endless tubular or flat fabric.

The main areas of application comprise the production of coated/laminated bags and technical fabrics woven from PP or HDPE tapes.- state-of-the-art coating and co-extrusion technology

- new ergonomic and compact design

- highly efficient inline lamination

- Automatic roll change at speeds up to 220 m/min*

- Line speed of 250 up to 280 m/min*

- Higher extruder output of newly designed main and co-extruder

- of more than 500 kg/h* in total

- Edge trimming for coloured and transparent overcoating

- Modular machine concept

- Operator-friendly construction

* Depending on machine type, fabric and roll quality

Printing machines

- Successful product presentation must be eyecatching  our printing machines achieve just that! State-of-the-art flexographic printing makes your woven sacks unique. This way, you can successfully set your product apart from the competitors and market it even better. With unique flexibility, best graphical resolution, and highest operator friendliness the Starlinger rollFLEX and dynaFLEX printing lines are leading in their field.

Printing Line dynaFLEX DX evo

-

The next-generation dynaFLEX DX evo is a roll-to-roll printing machine for coated and uncoated tubular fabric. It combines flexibility and quality at the highest level. The well-proven stack-type construction guarantees highest reliability combined with a space-saving layout. The redesigned colour decks are wider and easier to access, making line operation more comfortable and start-up faster. An extended format range and fast roll-change improve flexibility significantly.

- for perfect flexographic printing results

- no change of printing cylinders

- outstanding flexibility for different sack lengths

- compact design

- easy operation

- highest operator convenience

- faster start-up

- unique in its field

- One fixed printing cylinder per color deck. No storage, no maintenance – and no

purchase costs for additional printing cylinders - Wider and more robust color decks with improved accessibility, including lighting

and splash guards - Improved color-saving doctor blade system

- Perfect process printing (coated fabric)

- 180 m/min production capacity

- Infinitely variable repeat length

- Dynamic and flexible printing concept

- Worldwide proven direct drive technology – now with uniform design

- High efficiency and minimum waste due to semi-automatic roll change

- Very operator-friendly and easy to handle

Printing Line rollFLEX PX

-

The rollFLEX PX is a roll-to-roll printing machine for coated and uncoated tubular PP tape fabric. It combines highest levels of productivity and quality with easy handling and low maintenance.

- high-speed flexographic printing

- chambered doctoR blade system

- printing on fabric with highest graphical resolution

- high economic efficiency

- Production speed 250 m/min

- 6-colour stack-type printing on both sides

- Production speed of 250 meters per minute*

- Maintenance-free direct drive technology

- Standard semi-automatic roll change

- Gearless drive system

- Roll diameter of 1.5 meters

- Process printing

- Lifting support for change of printing cylinders

- Operator-friendly

* Depending on stereo material, ink and fabric quality, viscosity and drying

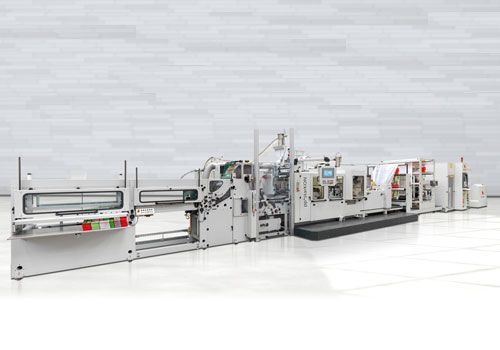

Conversion lines

-

Whether sewn or welded – our conversion lines produce the sack you need.

And not only with high speed and superior quality, but also with lowest energy consumption and minimum production waste – the priority is clearly sustainable and efficient production.Choose from various production methods, sack formats and closures: From welded 5 kg sacks with handles for construction materials in DIY stores to sewn 50 kg sacks with easy-open closure for animal feed – we have a sack for every purpose.

Conversion Line ad*starKON AX / AX+

-

Well-proven conversion technology for economic and efficient block bottom valve bag production. ad*starKON AX / AX+ conversion lines ensure cost-effective manufacturing without any compromise in performance and quality.

- new-generation high-speed valve bottomer

- compact design

- continuous bag forming

- high-precision bottom geometry

- Super-fast format change

- worldwide patented technology features

- cost-effective bag production

- Worldwide patented technology features

- Production of standard, 2-ply, open mouth, pocket valve AD*STAR® sacks, AD*STAR® *carry sacks with handles and BOPP laminated AD*STAR® sacks

- High precision bottom geometry through fabric width monitoring system

- Tempering/preheating of the patch and valve material

- Super-fast format change

- Adjustment of valve and cover patches during production

- Self-documenting graphical user interface

- Sensors at strategic process points

- Fabric roll monitoring system

- Easy changeover to microSTAR perforation

- Compact design

- Extended sack format range

Conversion Line ad*starKON SX+ / SXneo

-

Performance excellence through outstanding production speed paired with well-proven efficiency and unmatchable flexibility, giving converters a technological head-start in block bottom sack conversion.

- increased output

- new generation high-speed valve bottomer

- compact design

- High operator convenience

- continuous bag forming

- high-precision bottom geometry

- super-fast format change

- virtually non-stop production

- worldwide patented technology features

- synergy of SX and HX technologies

- Worldwide patented technology features

- Increased output per m² machine footprint

- Extended bag format range

- Synergy of SX and HX technologies

- Highest operator convenience

- Production of standard, 2-ply, open mouth, pocket valve AD*STAR® bags,

AD*STAR® *carry bags with handles, BOPP laminated AD*STAR® bags,

AD*STAR® *grip bags and AD*STAR® bags with high content of rPP/CaCO3 - High precision bottom geometry

- Super-fast format change

- Adjustment of valve and cover patches during production via user interface

- Easy changeover to microSTAR perforation

- Compact design

- Reduced number of chains, belts, gear wheels and gear boxes

- Interface for production monitoring systems such as GRAFiT

- Convenient diagnostics system

Conversion Line ad*starKON HX

-

In a league of its own: Featuring revolutionary concepts like iMOVE and other intelligent functions, the ad*starKON HX conversion line produces AD*STAR® sacks in a precise, high-speed production process with minimum waste and highest efficiency.

- revolutionary conversion concept

- operator-friendly

- valve and cover patch adjustment

- high-precision bottom geometry

- intelligent output optimization

- virtually non-stop production

- worldwide patented technology features

- Production speed of up to 140 bags/min

- iMOVE – intelligent output optimization

- Wider format range than ever before

- Easy bag handling due to dual stacking unit with two conveyor belts

- Significantly reduced energy consumption per bag

- Ergonomic 15” touch screen display

- Fabric roll monitoring system

- Easy changeover to microSTAR+ perforation

- Production of standard, 2-ply, and open mouth AD*STAR® bags,

AD*STAR® *carry bags with handles, AD*STAR® *easy bags with

easy-open feature, BOPP-laminated AD*STAR® bags and AD*STAR® *grip bags - Interface for production monitoring systems such as GRAFiT

- Convenient diagnostics system

Conversion Line multiKONservo

-

The multiKONservo is the next generation of Starlinger’s conversion lines for cutting, sewing, and stacking various different types of sacks. Using operator-friendly servo technology, it converts coated or uncoated, printed or unprinted endless tubular PP or HDPE fabric with or without gussets and/or liner in a continuous process.

- next generation high-speed sewing line

- fully automatic cutting and fabric-saving operation

- servo drive technology

- low wear and tear

- designed for operator convenience

- Servo drive technology – ensures reduced wear and highest operator convenience

- Operating speed up to 55 sacks per minute*

- Fabric-saving bottom folding process

- Precise fabric-saving cutting process

- Various closure types, including e.g. easy-open feature for consumer applications

- Production of transparent and OPP laminated sacks

- Fast top-feed sewing machine

- Modular design

* Based on sack size 500 x 1000 mm (uncoated) and and depending on quality of fabric and fabric roll

Conversion Line multiKON KXservo

-

The multiKON KXservo is the next generation of Starlinger’s high-performance IC*STAR® conversion lines. With a strong focus on operator convenience it converts coated, uncoated, OPP laminated, printed and unprinted endless tubular PP fabric in a continuous, fabric-saving process. The produced high-quality IC*STAR® sacks can be with or without gusset and/or liner and feature low fabric weight and high closure strength.

- next generation high-speed hot-air sealing line

- for coated and uncoated endless tubular fabric

- IC*STAR® technology

- with/without gusset and liner

- easy-open closure

- servo drive technology

- focus on operator convenience

- low wear and tear

- Servo drive technology – ensures reduced wear and highest operator convenience

- Hot-air sealing unit sealTEC

- Very high closure strength

- Increased output of up to 60 sacks per minute*

- Fabric weight reduction

- Bottom folding no longer required – significant fabric savings

- Precise cutting length for fabricsaving operation

- Production of transparent and OPP-laminated sacks

- Modular design

- Precise cutting length for gentle fabric handling

* Based on sack size 500 x 1000 mm (coated) when welding, and depending on quality of fabric and fabric roll

Recycling for woven sacks made of PP, PE and PET

-

New from old.

From big bag to big bag

Not only PET bottles, also woven plastic sacks constitute a valuable secundary resource. Woven sack production scrap is ideal for recycling – be it start-up lumps and endless tapes from the extrusion process, residual tapes on bobbins or tangled tapes from weaving, or printed and coated rejects from sack conversion. This way, you can make the most of your production scrap and at the same time reduce the costs for raw material consumption and waste handling, storing and disposal. Our recoSTAR lines designed for recycling woven sacks process contaminated, humid and heavily printed sack waste and turn it into high-quality pellets that can be reused in woven sack production.A closed packaging loop for woven sacks is no longer out of question. With the "Circular Packaging" concept for big bags, Starlinger customers are among the pioneers in this field. The main challenges: Big bags are produced in various designs and material compositions, and there are hardly any functioning collection schemes for them (until now). The more the principles of Design for Recycling (DfR) are applied in big bag production, and the more big bags are collected and recycled after their use, the greater the benefit for the environment – and, ultimately, for us.

Recycling Line recoSTAR universal TX

-

State-of-the-art recycling technology with extended functionality and innovative process adaption through the ACTIVE shredder. Designed for recyling films, fibers and filaments, nonwovens, tapes, fabrics, as well as solid lumps, start-up scrap, injection moulding parts, and any type of regrind, it processes materials such as PE, PP, PS, PA, PLA, and others.

With the ACTIVE shredder, the recoSTAR universal recycling line is the most efficient solution for processing in-house scrap from woven bag production.- for in-house production scrap

- integrated ACTIVE shredder

- "Smooth Cut" Technology for efficient cutting

- robust and high-performance design

- easy accessibility and fast maintenance

- ACTIVE shredder mit "smooth cut" technology

- Load-controlled dosing screw

- User-friendly design of the control panel

- Consistent high pellet quality

Recycling

-

Starlinger recycling technology offers pioneering solutions for converting used plastics and plastic production scrap into an economically and ecologically significant resource.

Films, PET flakes, fibers, nonwovens or woven bags: We supply state-of-the-art plastics recycling systems that transform post-industrial and post-consumer waste into a valuable secondary raw material. Sustainability concerns everyone – and requires visionaries. With our machines you become part of the ever-growing circular economy.

Recycling line recoSTAR PET

-

This product line is available in three different versions. All systems are equipped with FIFO pre-drying and single-screw extrusion and differ in terms of IV increase and VOC reduction. All versions are approved for the production of food-contact PET regranulate.

High-end bottle-to-bottle recycling line for the recycling of post-consumer bottle flakes after the washing process. The end product is melt-filtrated, uniform granulate of highest purity with lowest VOCs.

FIFO pre-drying of the PET bottle flakes ensures optimal preparation for subsequent extrusion. Single-stage drying with hot, dessicant air according to the First-In First-Out principle.

Single-screw extrusion with short melt phase. The melt pump increases the overall output, stabilizes the melt pressure and ensures a stable process and consistent melt quality.

Highest energy efficiency is ensured by various design features. Energy recovery is available for the pre-heater of the SSP and the final pellets. Alternative energy sources such as natural gas or steam can be used as a cost-friendly alternative for heating.

Compact design: The set-up of the recycling line is flexible, the most popular options are L, U, or line layout. Each layout option utilizes minimal footprint while maintaining access to relevant operation and maintenance points.- for post-consumer PET bottle flakes

- FIFO pre-drying, single-screw extrusion

- FIFO Solid-State Polycondensation (SSP)

- high-end bottle-to-bottle recycling

- automatic food-grade quality monitoring

- approved by multinational beverage brand owners

- Outstanding food-contact decontamination

- Adjustable IV increase

- FIFO procedure ensures uniform treatment

- Low energy consumption

- Small machine footprint

- Convenient operation and maintenance

Recycling line recoSTAR dynamic

-

State-of-the-art recycling technology with extended functionalities such as SMART feeder and dynamic automation package. Designed for processing film, fibres, thermoplastic in-house production scrap and washed post-consumer waste from materials such as PE, PP, PET, PES, PA, PLA, PS, PPS as well as foamed products. The most efficient solution for hygroscopic and wet materials.

The wear-resistant extruders are designed and manufactured in-house. The optional degassing extruder purifies the melt from volatile contaminants and monomers. Highly printed, very humid or organically contaminated input material requires the C-VAC module, hygroscopic input material the H-VAC module.

A melt filter continuously removes solid contaminants. The optional backflushing function reduces costs for filter screens and operator intervention. In case of higher contamination, a power backflush or continuous melt filter is recommended.

The pelletising system is chosen with regard to polymer type and preferred pellet shape. In case of an automatic strand pelletiser, broken strands are automatically inserted into the strand pelletiser without operator interference. Alternatively, manual strand, water ring, or underwater pelletisers are available.

- for post-consumer waste and production scrap

- wide range of applications

- inline recycling

- superior functionality with SMART feeder

- dynamic automation package For higher output

- increased energy efficiency

Recycling line recoSTAR universal

-

State-of-the-art recycling technology with extended functionality and innovative process adaption through the ACTIVE shredder. Designed for processing films, fibres and filaments, nonwovens, tapes, fabrics, as well as solid lumps, start-up scrap, injection moulding parts, and any type of regrind; from materials such as PE, PP, PS, PA, PES, PET, PPS, PLA, and others.

The optional degassing extruder purifies the melt from volatile contamination and monomers. High-vacuum degassing for hygroscopic polymers is optionally available. Wear-resistant extruder design.

A variety of melt filters for removing solid contaminants is available. The optional backflushing reduces costs for filter screens and operator intervention. In case of higher contamination a power backflush or continuous filter is recommended.

The water ring pelletiser ensures exact cutting for high pellet quality and low operating costs. Alternatively, a strand, automatic strand, or underwater pelletiser can be used. The remote control panel at the pelletizer allows starting/stopping of the line also from this position.

- for production and post-industrial scrap

- integrated ACTIVE shredder for hard-to-grind materials

- innovative process adaption

- fast material changeover

- easy maintenance

- high-performance design

Recycling line recoSTAR direct

-

State-of-the-art recycling technology for the cost-effective processing of regrind with high bulk density (> 300 g/l): production and post-industrial scrap from materials such as PE, PP, PS, PA and PLA.

The direct feeding of the input material is done by a feeding screw mounted on top of the extruder. Additional dosing of masterbatches or additives is possible.

The user-friendly touch-screen allows simple operation with RFID chip-controlled user levels, alarm history, recipe management, maintenance control, etc. Screenshots can be downloaded via USB-port.

A variety of different melt filters for dirt particle removal are available. The optional backflushing reduces costs for filter screens and operator intervention. For higher contamination, a power backflush or continuous rotation filter is recommended.

The patented water ring pelletiser ensures exact cutting for increased pellet quality and reduced wear of knives. Alternatively, strand, automatic strand, or under-water pelletisers can be used.

The produced uniform high-quality pellets have flow characteristics like virgin resin and can be reused up to 100 % in the same application or upcycled for other uses.- for production and post-industrial scrap

- regrind with high bulk density

- wide range of thermoplastics

- space and energy saving

- one-button start/stop

- cost-effective recycling solution