- Offer Profile

-

Gravotech is a global leader and pioneer in laser and rotary engraving. We offer unique turn-key solutions to our customers for business, academic, industrial, and many other applications. Always innovative, Gravotech strives to deliver a perfect engraving machine or software for you. Please see our product lines below or contact us today to discuss your business goals, and we will help you select the most appropriate solution. Need a custom product? Our engineering team is ready for any challenge.

Online machines

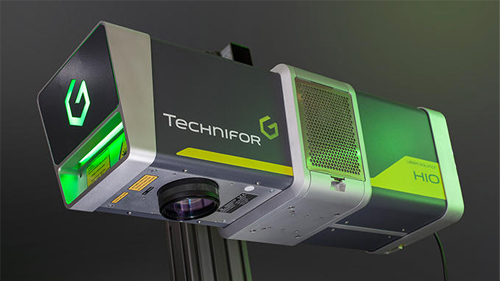

Laser Solution Fiber Series

-

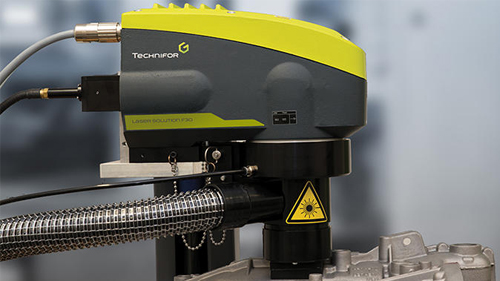

Complete Range of Integrable Fiber Laser Marking Solutions

Powerful and excellent quality, it performs accurate marking in very short cycles.

Ultra compact and robust, it is the fiber solution that is fully PPC (program-to-program communication) compatible and is easily integrated into any manufacturing process.

Technology

Laser source YB: Laser fiber, Class 4, wavelength: 1064 nm

Power range 20 - 30 - 50 W

Optical fiber length 3 m

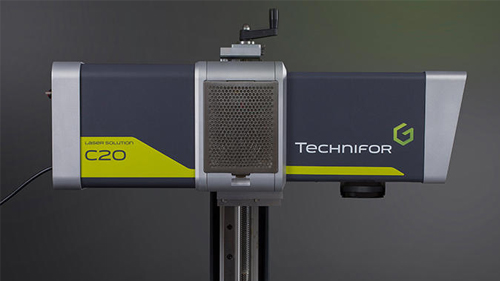

Laser Solution Hybrid Series

-

DPSS laser marking machine - Integrable range

With the highest peak power in the range, it provides contrasted marking on a range of materials.

The high-quality beam is particularly effective on plastics.

Its all-in-one design minimizes integration costs and facilitates its many uses.

Technology

Laser source DPSS: Laser Solid State, Class 4, wavelength: 1064 nm

Power range 6 - 10 - 20 - 40* W (* on request)

Fibre optic All-in-one system: integrated mechanics, electronics and software

Laser Solution Green Series

-

Green laser marking machine - Integrable range

This range uses the 532 nm wavelength to offer an ultra fine laser and very soft marking on parts.

From the most diverse plastics to the most reflective metals, it marks materials which usually react poorly or not at all to other infrared wavelengths while not altering the material itself.

Technology

Laser source YB: Green laser, Class 4, wavelength: 532 nm

Power range 5 - 10 W

Fiber optic length All-in-one system: integrated mechanics, electronics and software

Laser CO2 Series

-

Laser CO2 marking machine - Integrable range

Laser marking and coding on high-speed production lines.

High-speed, economic and easy to use traceability solution without the need for consumables

Technology

Laser source Laser CO2, Class 4, wavelength: 10 600 nm

Power range 20 - 30 W

Fiber optic All-in-one system: integrated mechanics, electronics and software

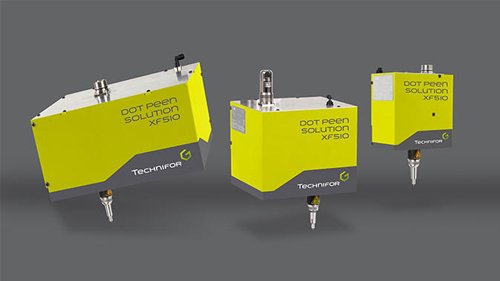

Pneumatic Dot Peen Solution XF510

-

Dot peen marking machine – Integratable range

Mark 100% of your parts during your production life cycle!

The fastest currently on the market, the XF510 dot peen marking machines offer permanent marking with no stress on your parts.

Designed to fit into the smallest spaces, they are ideally integrated in production lines where space and accessibility are a concern.

Technical characteristics

Dot peen Pneumatic

Compressed air supply Operating pressure 6 Bar (87.023 PSI) nominal, 6.5 Bar (94.275 PSI) maximum

Power supply 110-230 V AC - 50-60 Hz

Pneumatic power 120 VA

Operating temperature 5 - 45° C

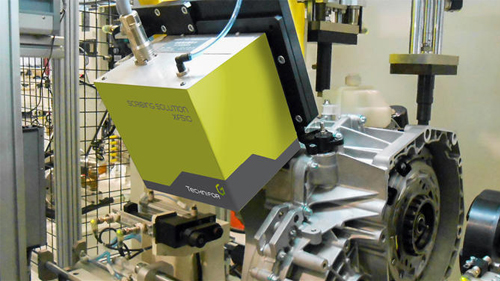

Electromagnetic Dot Peen Solution XF510

-

Dot peen marking machine - Integrable range

High-quality accurate marking without the need for compressed air.

Designed to meet the most demanding standards, these marking machines produce outstanding marking quality on all types of materials. The position and force of each impact are fully controllable.

This range is particularly adapted to the marking of 2D codes (Datamatrix, ECC200, UID, etc).

Technical charcateristics

Dot peen Electromagnetic

Power supply 110-230 V AC - 50-60 Hz

Power 360 W

Scribing Solution XF510 Scribing Machine

-

Scribe marking machine - Integrable range

Designed to combine deep marking and aesthetics, this range delivers direct marking on your parts while keeping noise to a minimum.

Quiet enough to meet the noise controls in the strictest standards, it is the industrial solution for marking metal parts, sheets, tubes, etc.

With an unrivaled scribing speed, the XF510r offers very high returns without the need for consumables. Ideal for 2D datamatrix codes.

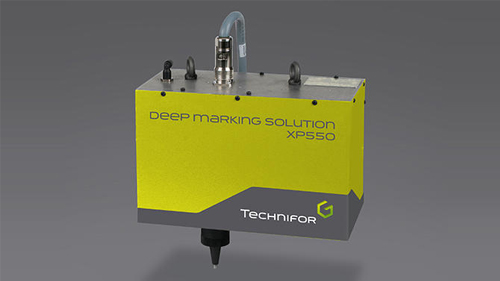

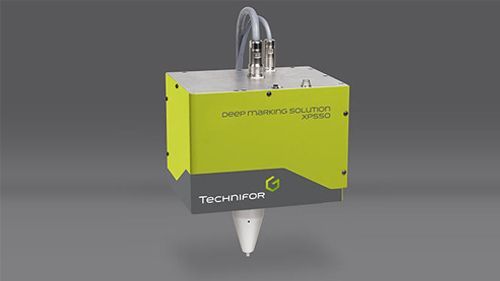

Deep Marking Solution XF530 - Deep marking

-

Deep dot peen marking machine - Integrable range

Equipped with an extremely powerful stylus, the XF530 micro-impacts to create durable tamper-proof marks on virtually any surface and any material.

A machine adapted to strict industrial applications, it is designed to allow accurate and very deep marking.

Available in a pneumatic or electromagnetic version.

Technical characteristics

Dot peen Pneumatic / Electromagnetic

Compressed air supply Operating pressure 6 Bar (87.023 PSI) nominal, 6.5 Bar (94.275 PSI) maximum

Power supply 110-230 V AC - 50-60 Hz

Power 120 VA 360 W

Operating temperature 5 - 45° C

VIN Marking Solution SV510 - VIN marking machine

-

Scribe marking machine - Integrable range

Powerful and fast, this machine provides non-tamperable deep mark with clear readability and in record time.

Industrial, it can be integrated into a production line or be used as a mobile station.

It is the V.I.N (Vehicle Identification Number) marking solution.

Technical characteristics

Technology Scribing

Compressed air supply Operating pressure 6 Bar (87.023 PSI) nominal, 6.5 Bar (94.275 PSI) maximum

Electrical supply 110-230 V AC - 50-60 Hz

Pneumatic supply 120 VA

Operating temperature 5 - 45° C

Offline machines

LW1 Laser Station

-

Enclosed column-based laser marking station - Station range

Easy to use and economic, this ready-to-mark station can be installed safely in an office or on a work table. Compact and quiet, it quickly identifies your small to medium series of parts.

The rigidity of the casing and frame combined with the high-performance mechanical and electric components, guarantee the station's long service life.

Technology

Laser source Available with all lasers in the Technifor range: Fiber, DPSS, Green, CO2

Class 1 enclosed station (closed door)

Dimensions (mm) L 650 x W 504 x H 549

Weight 50 Kg (excluding laser)

Part acceptance (mm) Up to 260mm Height

Safety Class 1 (closed door) - Full "Interlock" locking system

LW2 Laser Station

-

Enclosed column-based laser marking station - Station range

This station marks all types of data (serial numbers, 2D Data Matrix codes, references, logos, etc) on your small to medium series of parts and improves your productivity.

Optimum comfort and fast adjustment, it guarantees the professional and permanent marking of all your parts.

Technology

Laser source Available with all the lasers in the Technifor range: Fiber, DPSS, Green, CO2

Class 1 enclosed station (closed door)

Dimensions L 600 x W 622 x H 772

Weight 60 Kg (without laser)

Part acceptance (mm) up to 545 mm deep / 558 mm wide / 365* mm high (* depending on focal length)

Safety Certified Class 1 (closed door) - Full "Interlock" locking system - Door equipped with anti-pinch system sensors

IMPACT - Benchtop dot peen marking machines

-

Dot peen engraving and marking machine

Perform long-lasting and forgery-proof markings with speed and precision! The dot peen marking machines in the IMPACT range are capable of marking metal workpieces and plastic; they will fit easily into your work space.

The dot peen marking machines in the IMPACT range are available in two power source versions: pneumatic or electromagnetic, both areas of specialist expertise for Technifor.

The pneumatic marking machine offers industrial manufacturers high-speed operation and high marking frequency.

If your application calls for precision and consistency , the electromagnetic marking machines are more suitable. The electromagnetic version is particularly efficient for marking DataMatrix codes.

Dot Peen Solution XE320Cp Portable machine

-

Portable marking machine - Pneumatic dot peen

A compact, pneumatic dot peen marking machine providing permanent identification and traceability of your parts:- Ergonomic: compact, light and manoeuvrable, this portable machine is the ideal tool for marking heavy or large parts that are difficult to access. Designed for industrial marking, dot-peen solution has ergonomically curved handles, a bright LED light, as well as a trigger for the precise marking of your parts.

- Reliable: The Technifor XE320Cp is backed by decades of expertise and knowledge on marking and traceability requirements and standards.

- Attractive: A smart and intuitive total solution (USB, Ethernet, etc) available at an economical price

Technical characteristics

Dot peen Pneumatic

Power supply 110-230 VAC - 50-60 Hz

Power 120 VA

Compressed air supply air filter supplied

Air pressure 6 bars nominal ± 0.5 / 87 PSI

Operation mains

Operating temperature 5 à 45°

Standards "Machine" directive 98/37 EC

"Electromagnetic compatibility" directive 89/336 EEC

"Low voltage" directive 73/23 EEC

Manufactured ISO 9001 compliant

Dot Peen Solution XM700 Marking Machine

-

Portable marking machine - electromagnetic dot peen

A marking machine unique in its all-in-one design:- A single hand-held tool with touchscreen with no remote electronics, comes with optional battery belt for complete mobility

- Fast and powerful, the marks are permanent, deep and highly legiable

- Ergonomic, work can take place either horizontally or vertically

Technical charcateristics

Dot peen Electromagnetic

Power supply 110-240 VAC - 50-60 Hz

Operation battery: Li-ion - 1 kg / mains

Operating temperature 5 - 45°

Operating humidity up to 85%

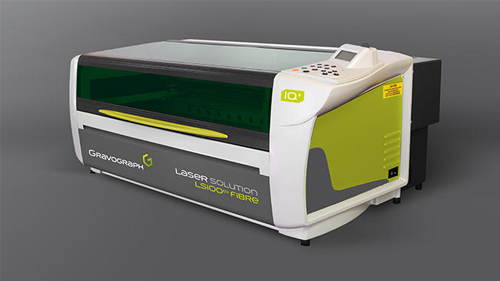

LS100 LS100Ex

-

Solutions laser CO2

The LS100 and LS100EX are rugged CO2 lasers and can be set up in a factory, workshop, office or retail outlet. Suitable for most marking, cutting and engraving applications including: trophies and awards, gifts, leather goods, acrylic, crystal and glassware, barcodes, data matrixes, photo, marking and rubber stamp production.

LS100 and LS100Ex technical characteristics

Dimensions (l, d, h) 775 x 725 x 450 mm / 1025 x 725 x 450 mm

Engraving area 460 x 305 mm / 610 x 305mm

Z axis travel 145 mm

Max. speed 2.54 m/s

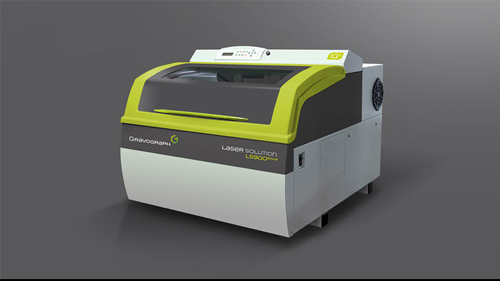

LS900

-

LS900: large format engraving solution

The LS900 is our large format engraving and cutting solution, perfect for reaching optimum productivity.

The engraving surface of this industrial laser measures 610x610mm'. It is ideal for marking or cutting of medium and large format media.

Laser

Source CO2 (10,6µm)

Power 35 - 40 - 60 - 80 Watt

LS100Ex Fiber and LS900 Fiber

-

The LS100Ex Fiber and LS900 Fiber are laser engraving solutions for metal and large surfaces.

They are perfect for engraving directly onto a range of metal parts and plates.

Fibre lasers

Power Range

LS100 Ex Fibre 20W or 30W

LS900 Fibre 30W or 50W

Engraving area

LS100Ex Fibre 610x305mm

LS900 Fibre 610x610mm

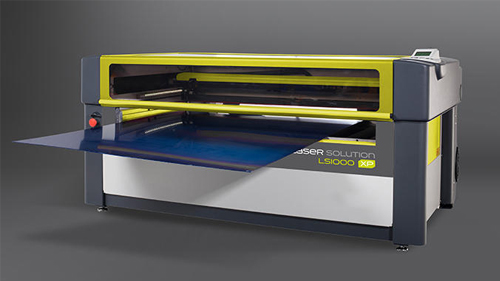

LS1000XP

-

The large format CO² laser solution for cutting and engraving.

The LS1000XP by Gravograph combines numerous innovation functions and features into one unique solution aiming to reduce production times.

The work speed (4 m/sec in raster mode), CO2 laser sources (from 60W to 150W), and choice of optics make the LS1000XP a high quality product that guarantees high productivity rates.

Power

A range of 60 to 150W CO2 laser sources are also available for very precise engraving jobs and the important job of cutting organic material.

Dual source LS900 EDGE, laser engraving and cutting of all materials

-

Dual source laser engraving and cutting machine

Diversify your business! The LS900 EDGE is the ideal combination for laser engraving and cutting multiple materials. Its two laser sources, CO2 and Fibre, make it highly flexible in use. Its large engraving area is suitable for piece production and short and medium-length job runs.

CO2 Laser and Fiber Laser

Technology CO2 et Fiber

Output CO2 : 40W

Fibre : 20W/30W/50W

Engraving area (mm) 610 x 610

Dimensions 945 x 1080 x 810

Maximum raster speed (m/s) 4

Z-axis travel (mm) 250

Weight (kg) 170

M10 compact machine, for the engraving of jewellery and small objects

-

Customisation solution

The M10 machine can engrave texts and logos on many articles.

Create personalised, original and unique gifts!

This customisation solution has been designed to fit perfectly into your shop, showroom or workshop.

Technical features

Marking area (mm) 70 x 60

Maximum object size (mm) 120 x 80 x 40

Speed (mm/s) 25

Marking technology Diamond engraving technology

Jewellery engraving: M10 Jewel

-

Inside and outside engraving solution for rings, wedding bands and bracelets.

The M10 Jewel solution includes the engraving machine, control software, accessories and user manual.

Technical specifications

Machine size 230 x 293 x 290 mm

Weight 6.5 kg

Inside engraving

Rings and bracelets: min - max width 1.5 - 20 mm

Rings: min - max diameter 12 - 25 mm

Bracelets: min - max diameter 45 - 80 mm

Outside engraving

Rings and bracelets: min - max width 1.5 - 20 mm

Rings: min - max diameter 13.5 - 25 mm

Bracelets: min - max diameter 50 - 80 mm

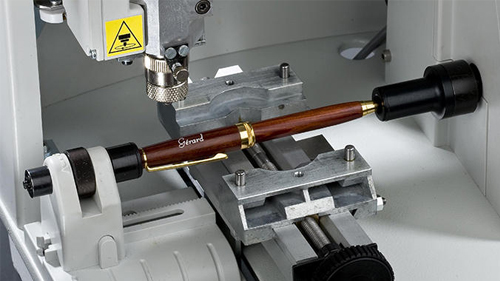

M20 Series: engraving for photos, plates and pens, etc.

-

The compact and versatile solution par excellence.

The M20 range covers all small signs, jewelry and personalization applications.

Check out the 4 versions of the most versatile compact engraving solutions- M20 PIX: engraving photos and texts on metal items

- M20: general engraving on all types of materials

- M20 PEN: includes a rotating device for engraving pens

- M20 JEWEL: includes a rotating device for engraving wedding bands

M40 and M40 ABC

-

Versatile mechanical engraving solutions

If you're looking for an optimized engraving area for professional plaques with numerous features and accessories, look no further! The M40, an innovative and ideal machine for engravers!

Technical specifications

M40 / M40 ABC

Machine dimensions 560 x 630 x 440 mm / 720 x 630 x 480 mm

Weight 19 kg / 21 kg

Engraving area 305 x 210 mm

Max. dimensions of engravable item X unlimited x 260 x 110 mm

M40 Gift

-

The ideal glass engraving machine for retail stores and gift shops

The M40 Gift is the ideal machine for engraving business gifts, souvenirs, jewelry, wedding presents or gifts for a newborn. It is designed with an integrated lubrication system for easy glass engraving.

Technical specifications

Engraving area 305 x 210 mm

Z axis 40 mm

Size of machine 730 x 540 x 340 mm

M20 ArtFoil™ Solution for hot stamping

-

Compact machine for hot stamping & embossing

Elegantly personalize leather goods, business cards, wood, cardboard and more with a beautiful colored metallic finish.

The M20 Artfoil is a complete, compact and transportable solution for hot stamping, foil embossing and engraving. Add dimensional embossing and texture to your marking with the adjustable pressure system. Controlled by Gravograph sofware, this machine can handle the most delicate and detailed foil designs.

Marking area 100 x 90 mm

Max. dimensions of item to mark 180 x 110 x 50mm

Z axis Spindle travel 30 mm

Machine dimensions 345 x 315 x 380 mm

IS200

-

An engraving machine that's as easy to use as a printer!

The IS200 is a adjustable machine for engraving small objects, sign plates and technical labels.

This machine benefits from a unique mechanical structure, providing a completely unrestricted working area, which makes it easy to attach oversized items to the machine for engraving.

IS200 and IS200TX technical specifications

X and Y axis

Engraving area covered in one pass: 80 x 225 mm

Flatness tolerance: 0.2 mm

Maximum clearance in X between columns: 300 mm

Maximum clearance in Y axis: unlimited

Z axis

Spindle travel : 75 mm

Spindle travel at bottom of vice: 48 mm

IS400

-

Progressive professional machine for A4 format work

This machine is most commonly used for signage, labeling and identification of industrial parts.

To get to know the IS400 better, here are its main technical characteristics:

X and Y axis

Engraving area 305 x 210 mm

Flatness tolerance 0.2 mm

Max. clearance in X axis between columns 370 mm

Max. clearance in Y axis unlimited

Z axis

Spindle travel 40 mm

Spindle travel at bottom of vice 120 mm

Spindle travel with clamping table 33 mm

Spindle Tool diameter 4.36 mm

Rotation speed 11 to 20 000 rpm

Direct current mechanical power 75 W

IS400 Volume

-

All types of marking!

A mechanical engraving machine, the IS400 Volume is the solution for engraving of large size objects.

Below you will find techical specifications for the IS400 Volume:

X and Y axes

Engraving area 305 x 210 mm

Flatness tolerance 0.2 mm

Max. clearance in X between columns 370 mm

Z axis

Spindle travel 40 mm

Spindle travel at bottom of vice 400 mm

Spindle Tool diameter 4.36 mm

Rotation speed 11 - 20 000 rpm

Direct current motorisation

IS6000XP - IS7000XP - IS8000XP

-

Robust, powerful and precise

Very fast paced, these machines meet industrial requirements (productivity, reliability and safety) with their motor options and automated tool changing system.

Make a good choice: get to know the characteristics of the IS6000 XP, IS7000 XP and IS8000 XP

X andY axes

IS6000 XP engraving area 610 x 410 mm

IS7000 XP engraving area 610 x 815 mm

IS8000 XP engraving area 610 x 1220 mm

Flatness tolerance 0.2 mm

Max. clearance in X between columns 880 mm

Max. clearance in Y unlimited

Z axis

Spindle traval 80 mm

Spindle clearance with clamping table 80 mm

Spindle clearance with vice 140 mm

Accessories

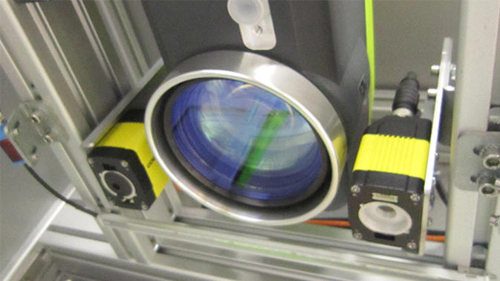

Vision Manager: Reading of Codes and Fonts, Verification and Saving

-

Accessories for laser marking machines

Manage your markings instantly!

Marking of 2D datamatrix codes or character fonts + industrial vision system automatic verification of marking + communication + data saving:

The Vision Manager offers complete traceability of your parts in a single cycle.

Camera InSight Cognex / High definition: 1280x1024

Lighting Many lighting options available, adapted to each application

Auto-focus integrated auto-focus system

Reading options- 1D code (barcodes)

- 2D code (datamatrix, QR code, etc)

- OCR font (OCR-A, OCR-B)

- All fonts: capacity to acquire the reading of all characters

Beam Protection Funnel - Class 1

-

Accessories for laser marking machines

Simplify production line integration with an integrable class 1 solution!

Minimum size, maximum safety, the beam protection funnel frees you from the costs and constraints of a class 1 station:- Compact

- Safe

- Reliable

Used on high-speed automotive production lines and in the very harsh environments of metalworking factories, this accessory has proven its effectiveness.

Safety Class 1 - safety systems preventing laser emission if the tunnel is not properly closed over the part

Suction Double-wall system with suction allowing the evacuation of smoke and dust

Compatible- Laser Solution F-Series

- Laser Workstation LW1

- Laser Workstation LW2

Fume Extractor

-

A range of extractors for the evacuation and filtration of fumes and particles generated during laser marking:

- Compact and universal

- Safe and Reliable

- Economical and robust

ES10 / ES30

Voltage 100 - 240 V

Dimensions (LxWxH) 350x470x580 mm / 350x470x700 mm

Weight 88.18 lbs or 40 kg / 123.46 lbs or 56 kg

Noise level 63 dBA / 71 dBA

Max. air flow 200 m³/hr / 360 m³/hr

Flow control no / yes

Activated carbon 13 L (12 kg) / 30 L (24 kg)

Power 140 W / 750 W

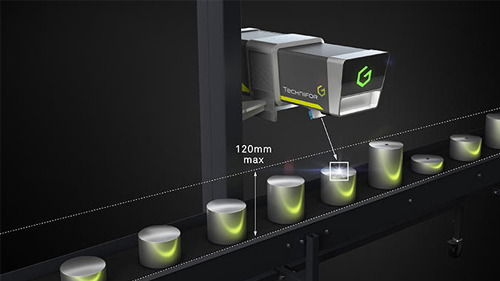

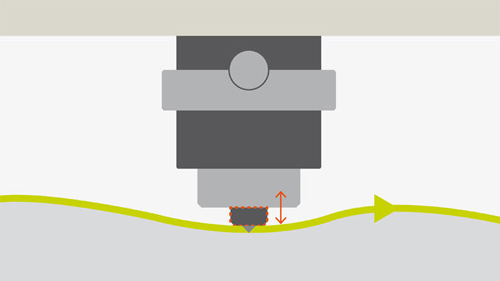

Auto-Focus

-

Accessories for laser marking machines

Are you unable to guarantee the size of your parts to the nearest millimeter? Technifor guarantees the precision of its markings.- This sensor measures the distance between the focus and the surface being marked and the laser system automatically adjusts its focus.

- The focusing is instantaneous with no waiting time.

- The auto-focus eliminates the need for costly mechanical systems and complex adjustments.

Link the marking of thousands of parts with uneven surfaces, the auto-focus takes care of it all!

Range up to 120mm (focal length 254)

Compatible- Laser Solution Fiber-Series

- Laser Solution Hybrid-Series

- Laser Solution Green-Series

- Laser Workstation LW1

- Laser Workstation LW2

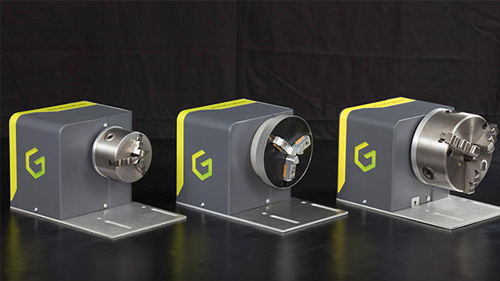

Rotary device

-

Part rotary device for round and circular parts

Rotary device for the laser marking of round and circular parts

The rotary device is a device facilitating the marking of cylindrical parts by turning them during the marking cycles.

This means you can easily mark your revolving parts on their top or on their circumference.

Available in 3 versions - RD1, RD2 and RDM- it can be used to mark all your parts, from small to large.

Integrated Readers for Reading Bar Codes and DataMatrix Codes

-

Industrial vision systems

Compact and efficient, these compact code readers combine ease of use with integration (1D and 2D codes).- Easy installation

- Flexible optics and lighting options to suit any application

- Identification and decoding of all types of codes in all usage conditions

- Industrial design for decoding DPM (direct party marking) codes

Laser cutting support accessories

-

Floating pin cutting table:

- Reduced backflash effect

- Quick and easy assembly

- Removable pins

- Suitable for XY lasers

Honeycomb cutting table:- Stainless steel frame

- Outstanding strength and durability

- Marked alignment rulers for quick and accurate positioning

- Reduced flashback effect

- Easily inserted and removed laser

- Covers the whole marking area

- Available for LS100-LS100Ex-LS900 and LS900XP lasers

Cylindrical attachment and pen attachment

-

Cylindrical attachments and pen attachments are ingenious accessories that add further capacities to your engraving machine and open up new business opportunities at a very small cost.

Based on their size, these accessories allow you to engrave cylindrical objects: pens, bottles, glasses and rings, etc.

Regulating noses

-

Ensure constant engraving depth, even on uneven surfaces

Gravograph brings you a huge range of noses, including:- Steel noses: the most commonly used noses (resistant and highly polished for minimum plate scratching)

- Vacuum noses: same as steel nose and can be linked to a swarf extractor

- Swivel and prismatic noses: for engraving on curved surfaces (steel or teflon)

- Teflon noses: for engraving on easily scratched surfaces such as metal

Chip collectors

-

Ensuring a clean and tidy working area

An essential accessory that ensures your machine stays clean and facilitates your engraving jobs.

Coupled with its vacuum nose, the Gravograph chip collector is an essential accessory for all your cutting and engraving tasks.

Gravograph chip collectors are easy to use and guarantee your working areas are always clean and tidy.

Our collectors are powered by our machines and stop between 2 engravings to limit noise.

Jig ranges

-

Gravograph brings you an extended range of vice jigs to secure all types of objects during engraving. Our jigs are compatible with all engraving machines.

Gravograph brings you an extensive range of jigs and clamping devices designed for our customers and alongside them, specially made for:- Flat engraving

- Jewelry engraving

- Gifts and tableware

- Specific applications

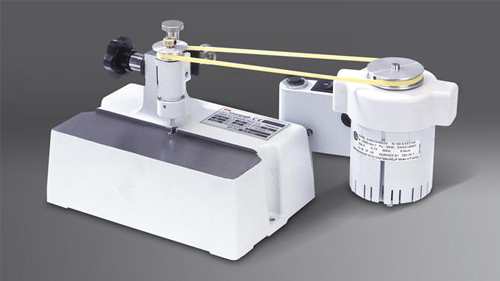

Bevelling machines

-

Bevelling machines are essential tools for showcasing your items and giving them the finish and quality sought by your customers.

The angle you choose also facilitates insertion of plates into the machine's support.

The bevelled edges created by our accessories bring clear added value to the products you've cut or engraved using Gravograph solutions.

This procedure allows you to differentiate your products and stand out against your competitors. For a small cost, you'll get a quick return on investment.

Softwares

Lasertrace

-

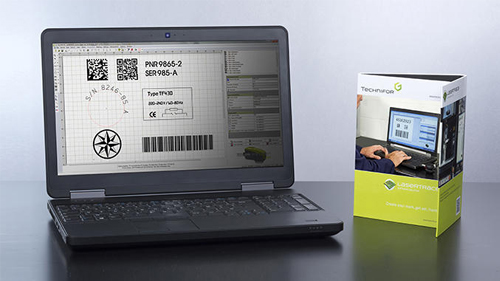

Marking and traceability software for laser marking machines

Mark in less than 5 clicks!

Developed by Technifor and dedicated to marking and traceability, the Lasertrace software is intuitive and simplifies the creation of your markings.

From the workshop to the automated production line, Lasertrace has all the features needed to facilitate the identification of your products.

Standard for delivery with every Technifor laser machine, Lasertrace offers all the responses to the standards and regulatory requirements.- Multilingual interface

- Direct access to the marking parameters

- Library of pre-settings sorted by material

- Compatible with multiple databases (ODBC, Excel and ASCII, etc)

Gravostyle™ - Laserstyle™

-

Unique software for mechanical and laser engraving machines

Gravograph by Gravotech designed unique engraving software Gravostyle™ and Laserstyle™ to run your laser machine. Whether you are a seasoned engraver or a beginner, we have a solution for you.

Gravostyle™ offers professional solutions for a variety of applications: from engraving on door plates to the design of measurement tools and the creation of photo gifts.

Control your laser machine with Laserstyle™ !

Laserstyle™ comes as standard with Gravostyle™ software from the Discovery module, but is also available separately.

Designed to work together with your 3rd party design software or as a standalone software solution. Also providing powerful engraving-specific features to improve your laser engraving productivity.

Gravotouch

-

Professional engraving at your fingertips!

Who said personalizing should be left to the experts? Gravotouch™ is an innovative, picture-driven software solution from the experts at Gravotech.

Now you can engrave anything using a touch screen. Our picture driven software is not only powerful, but also very user friendly!

Personalize like never before!

Engraving personal messages becomes fun and easy with GravoTouch:- Browse through the wide selection of fonts optimized for engraving

- GravoTouch offers a graphics and symbols library based on a wide variety of themes

- Import photos and edit them to get the best possible finish on your item.

- Feeling creative? Grab a pen and add your own handwritten message on the graphic tablet using Dedicace™ by Gravotech.

Applications

Traceability of Medical Devices

-

WHY YOU NEED TRACEABILITY OF MEDICAL DEVICES:

- Improve internal traceability by tracking and following-up on each instrument

- Identify and read each instrument throughout the sterilization process

- Benefit from a very simple and easy to use turnkey marking and reading solution

REQUIREMENTS:- Must have ability to mark many different parts:

- Large variety of shapes

- Different material characteristics (hardness, shine, etc)

- The need for permanent as well as resistant marking that can withstand the harsh sterilization processes

- Must be a compact, flexible and versatile solution

SOLUTION PROPOSED- Laser F-Series

Automotive, Motorcycles, and Bicycles

-

Direct and permanent marking (DPM) by laser, dot peen, and scribing

Technifor offers comprehensive solutions integrating marking and its automatic camera-based verification to track each part throughout its production process up to its maintenance.

Constructors and equipment manufacturers use Technifor solutions on their production and assembly lines, quality control stations, and maintenance centers for the identification, and traceability of all their parts:- Marking compliance with international standards

- Automation of marking and reading

- "Zero fault" guarantee: part numbers, batch traceability, time-stamping, and internal coding

Technifor is proud to manage international projects and integration projects around the world!

Marking and Engraving in the Oil and Gas Industries

-

In production, during maintenance, and on the operating sites: Technifor's solutions are suited to the marking and engraving of all the components intended for the oil and gas industry.

- unique markings resistant to external aggression

- simple and versatile solutions with a software interface dedicated to your application

Tubes, valves, beams, pumps, plates, tooling and site materials etc, our systems can be used to permanently identify all your parts even the heaviest and largest of them.

Robust, marking machines perform precise and fast engraving of text, logos, plan numbers, certification and time stamping, etc.

Our markers are easy to use and facilitate the identification of parts and materials during quality control and inventories.

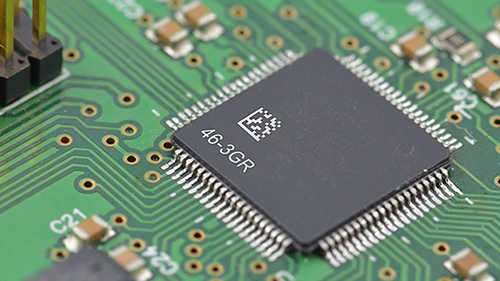

Marking of Electrical Components

-

Technifor offers fast and compact marking solutions for permanently identifying any electrical component:

detectors, printed circuits, component and semi-conductors, etc.- on the production line, for finishing machines, during quality control

- on the line side

- in a work shop

Easy to integrate and communicate within your environment, our machines identify your parts with variables (serial numbers, references, supplier numbers, etc), codes (DataMatrix, date and time, shift and factory etc) and marks (logos, symbols and diagrams etc).

Laser engraving and cutting on wood

-

GRAVOGRAPH HAS SOLUTIONS TAILORED TO YOUR APPLICATIONS

Gravograph, with our years of industry experience can meet and exceed your requirements when it comes to laser engraving on wood, laser machining or laser cutting on wood for all kinds of creations, ranging from models to prototypes as well as signage and decorative objects.

Both our laser engraving machines and mechanical engravers can produce the result you want according to your engravable item (size, type of wood, thickness etc).

Gravograph meets the needs of operators in the wood sector, primarily for the following applications:- Models: architecture and craft

- Engraving on wood for the creation of shop signs or outdoor signage

- Engraving or cutting of wood for decorative elements

- Art: inlays, marquetry

- Laser cutting or engraving of wooden toys

- Engraving and cutting of your packagings

SOLUTION PROPOSED

WOOD LASER ENGRAVING AND CUTTING MACHINES

Gravograph offers the latest laser engraving and cutting machines for wood as well as mechanical machines suitable for various types of wood.

Cutting and engraving on paper and cardboard

-

Thanks to laser engraving and cutting on paper and cardboard, personalisation really comes into its own! Add real value to your creation, by making it unique. Produce superb announcement, greetings cards, invitations and business cards; cut out and make bespoke packaging items with our laser cutting machines offering cardboard and paper capabilities.

Our engraving and cutting machines can meet your engraving and cutting needs allowing you to personalise paper and cardboard.

Gravograph offers solutions to your needs in the following- applications in particular:

- Announcements

- Business cards

- Invitations

- Packaging items: box cutting and dotted line perforation (facilitates folding)

- Greetings cards or cards for any occasion

- Decoration

- School/office supplies

- Sports awards

SOLUTION PROPOSED

MACHINES FOR CUTTING AND ENGRAVING ON PAPER AND CARDBOARD

An expert in laser and mechanical engraving and cutting solutions, Gravograph supports you in your projects.

Are you looking for a technology to carry out tasks involving paper or cardboard cutting? Gravograph offers laser engraving and cutting machines for paper and cardboard which are efficient as well as affordable.

Engraving and personalising glass and crystal

-

Working on glass calls for the highest performing tools, including faceted diamonds and CO2 laser technology. Gravograph's engraving machines offer the most effective technologies for engraving and personalising your champagne flutes, beer glasses, bottles and decanters, mirrors, windows signage, and so much more!

Achieve an impeccable result with the range of accessories that are compatible with our engraving machines. You can also extend the service life of your tools and improve the engraving result with the lubrication kit or achieve a perfect finish with our cold wax sticks, to add colour to your engravings!

Laser engraving roughens the worked surface, while diamond engraving hollows out the material to deliver a finer engraving while maintaining its transparency. Choose laser or mechanical technology according to the desired effect, your budget and your production needs.

PERSONALISING A GLASS PIECE

Delight your customers by offering them engraved glass gift items of superb quality. Fine, detailed and precise personalisation will be guaranteed for all types of items, including:- Perfume bottles

- Glasses (wine glass, whisky glass, champagne flute etc.)

- Bottles and decanters

- Tableware

- Photograph frames

- and so much more!

ENGRAVING A DECORATIVE SURFACE

Glass is a key element in the decoration of your stores. Boost your footfall by offering unique point-of-sale installations!- Easily engrave:

- Mirrors

- Showcases

- Display stands

- A variety of decorations…

SOLUTION PROPOSED

Gravograph offers a wide range of glass engraving machines, covering all customer applications and budgets, from the personalisation of event-based items to the marking of glass windows.

Galvo laser, gantry, or mechanical machine... find the solution best suited to your needs here.

Mechanical and laser engraving on stone

-

A message engraved into stone is an enduring one.

Be it an engraving of a photograph on slate, a personalised motif on a stone, a decorative marble plaque or a piece of jewellery worked from natural stone... Every one of these objects is possible with the help of a Gravograph engraver! But what dictates your choice between a laser engraving machine or a mechanical engraver?

THE CHOICE FOR PRECISION: LASER ENGRAVING

Laser engraving on stone produces a result similar to sandblasting or acid etching: a surface engraving that gives the impression that the stone has been bleached or abraded. The difference: stone engraving by laser does not require any consumables (such as stencil, acid, ink, etc) and produces instant results.

Laser engraving does not require the use of cutting tools and is therefore extremely fast and easy, without the need to hold the stone in place since lasering is a non-contact operation.

The laser beam impacts the surface of the mineral material being engraved to a depth of a few microns only. The finer the grain of the stone, the sharper and clearer the engraved mark! The best results are achieved with darker stones as they provide greater contrast. The most suitable materials are:- Slate

- Granite

- Marble

- Basalt

Laser technology is suitable for engraving and personalising small and large items. The very fine laser beam diameter allows high graphic resolution and the large engraving area allows for large size items to be lasered. It is ideal for:- Engraving photographs, drawing and designs on a stone boards

- Engraving on a stone, decorating a seashell

- Decorative engraving on marble (wall panel, floor covering, furniture etc.)

- Engraving on slate, personalisation for a coaster or serving mat

- Funerary engraving on plaques, headstones, urns etc.

MECHANICAL ENGRAVING MACHINE: GIVE DEPTH TO YOUR CREATIONS!

Mechanical engraving on stone gives a very different result compared to laser engraving. Laser engraving superficially ablates (or discolour) the surface of the stone, giving a ‘bleached’ effect, whilst mechanical engraving physically cuts in depth into the material.

The engraving of headstones can be accomplished with a Gravograph mechanical engraving machine. Once engraved, the message can then be painted or gilded (gold leaf).

Gravograph offers a wide choice of colouring products and paints to give the perfect finish to all your engravings!

The creation and personalisation of stone jewellery (precious stones, natural stone) is also possible with our machining units. Personalise your jewellery pieces in amber, jade etc... By changing their shape, giving free rein to your imagination.

Metal engraving with laser and CNC machine

-

Do you manufacture or machine metal parts and are you looking for a solution to engrave and permanently mark your products? Do you create metal labels or other metal signage products?

Do you manufacture or personalise metal giftware and jewellery?

Two technologies are available to you for an optimal result: laser engraving and mechanical engraving.

These marking processes produce excellent results both for engraving soft metal such as aluminium or brass, and for marking very hard alloys such as steel, stainless steel or iron. Precious metals can also be engraved.

Examples of metal engraving applications :- engraving of aluminium, stainless steel and brass plates ...

- manufacture of signage - both internal and external, small and large

- engraving of door plates, professional plates

SOLUTION PROPOSED

With Gravograph, you benefit from the know-how of a manufacturer with expertise in all engraving and cutting technologies.