- Offer Profile

- Almatec Maschinenbau GmbH is a premium manufacturer of air-operated double-diaphragm (AODD) pumps and a company which has successfully combined a worldwide presence with proximity to the end-user. Permanent product innovations and improvements have resulted in a large range of products and the opening up of new markets. Our extensive product range offers sophisticated and economical solutions for all of your applications.

Almatec® pumps

- Almatec® pumps meet or exceed industry quality requirements and incorporate the standard-setting features and benefits our customers have come to demand: a solid design, safe ring-tightening structure, the energy-efficient PERSWING P® air control system, cutting-edge diaphragms and best-in-class materials.

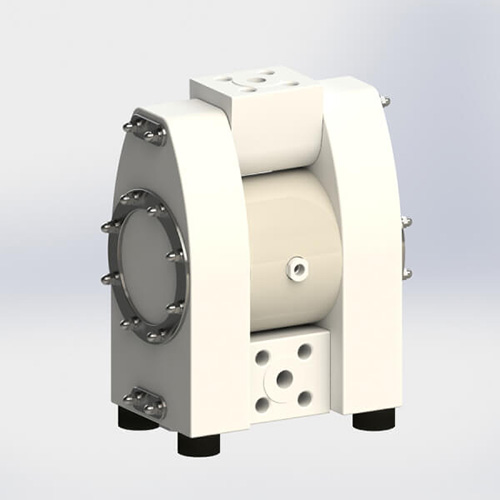

Almatec Plastic AODD Pumps with Solid Design

- An important design element for Almatec air-operated double-diaphragm (AODD) pumps is a solid-block construction, which is necessary to support the weight of an oscillating pump. With this design, the individual components can be designed so that the required wall thicknesses are arranged where needed. The high-static mass leads to a smooth operation and eliminates the need for unnecessary external metal parts that otherwise would be used for reinforcement. The mechanical machining of a solid plastic block is also economical thanks to modern CNC technology that enables tight tolerances to be achieved. In all Almatec plastic pumps, only German-produced virgin PE and PTFE is used.

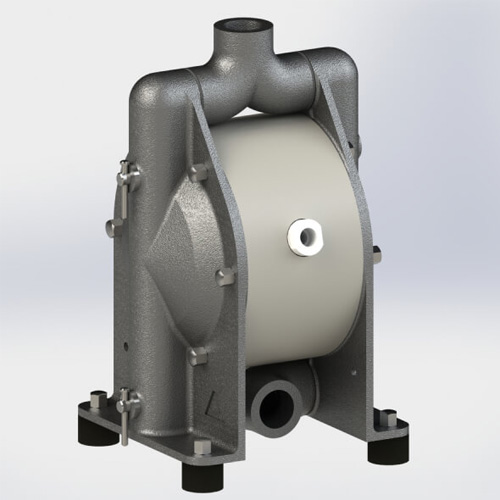

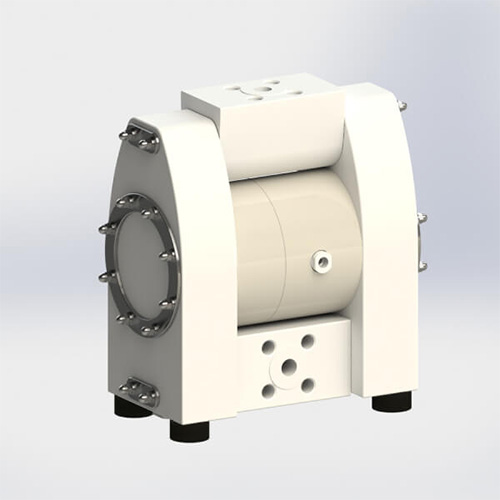

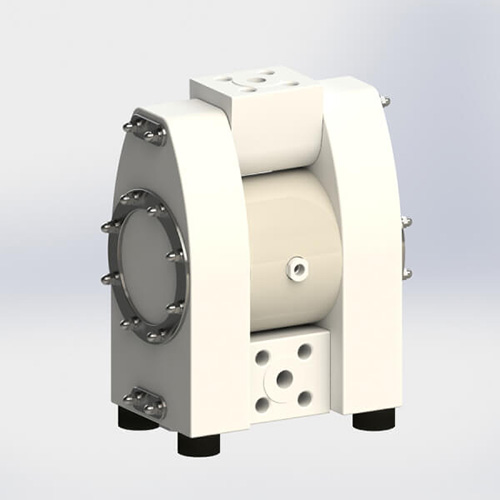

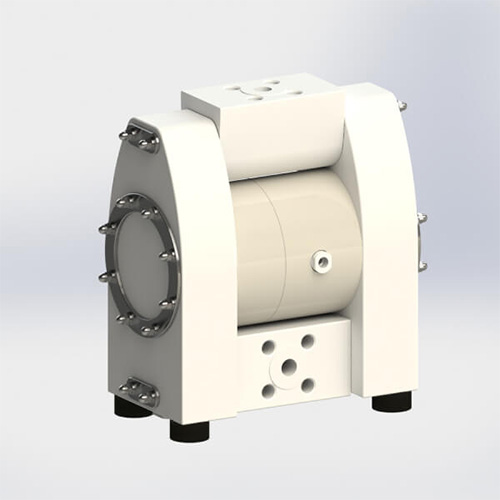

Almatec E-Series

-

State-Of-The-Art Plastic AODD Pumps

The development of the E-Series was based on the extensive experiences with the proven pump models. The solid design with distinctive wall thicknesses, the flange connection capability, the ring tightening structure and more construction features are responsible to meet the customer demands of safety, quality and reliability. Six pump sizes available with optional equipments cover most applications in the market. Pulsation dampeners are available as screw-on and flanged models.

Features at a Glance

- Air-operated diaphragm pumps in solid design

- Housing made of PE or PTFE, both also available in a conductive version

- Interchangeability to the previous A-Series

- Six sizes from DN 8 to DN 50

- Max. capacities of 0.9 to 35 m³/h

- Increased pump safety due to innovative ring-tightening structure

- Compared to the previous A-Series, increased capacity and decreased air consumption thanks to an optimized flow pattern, decreased noise level

- Models available with ATEX, EC1935/2004, FDA, USP Class VI approval

- Exterior free of metal

- Optimized diaphragm fixing

- Different possible port configurations

- Ball or cylinder check valves with identical interior design

- Maintenance and lubrication-free air control system PERSWING P® without dead center

- Composite diaphragms with integrated metal core, no diaphragm discs

- Proof against dry running and overloading, self-priming, insensitive to solids

- Gentle displacement

- Can be infinitely controlled via the air volume

- No drives, no rotating parts, no shaft seal

- Unattended operation with long service life

- Easy to start up

- Integrated muffler

- Recessed tie rods

- Low noise levels

- Optional features meeting requirements, such as:

- Screw-on or flanged pulsation damper

- Draining system

- Barrier chamber system

- Diaphragm monitoring

- Stroke counter

- Flange connection

- Transport cart

Almatec CXM Series

-

AODD Pumps for Low- to Middle-Duty Applications

Almatec® CXM Series Air-Operated Double-Diaphragm (AODD) Pumps are general-purpose pumps designed for low- to medium-duty applications and to operate as drum pumps.

Thanks to the pump’s modular design, CXM Series is available with seven different product connections – four sizes with NPT connections and three sizes with BSP connections. The NPT pump sizes 10, 20, 50 and 130 can be changed by rotating the center block. The product connections of the BSP pumps sizes 25, 55 and 135 are located on the face side of the pump. This wide range of product connections allows a precise adjustment of the pump to the specific application.

Features at a Glance

- Flow optimizations in the product channels ensure high performance and gentle pumping

- Can be easily be converted from ball to cylinder valves, and vice versa

- Machined PE conductive construction with ATEX and FDA conformity

- Self-priming and dry running

- Simple and compact, space-saving design for easier maneuverability

- Suction-lift capabilities that allow containers to be emptied to the very last drop

- Maintenance-free PERSWING P® air control system without dead center

Metal AODD Pumps

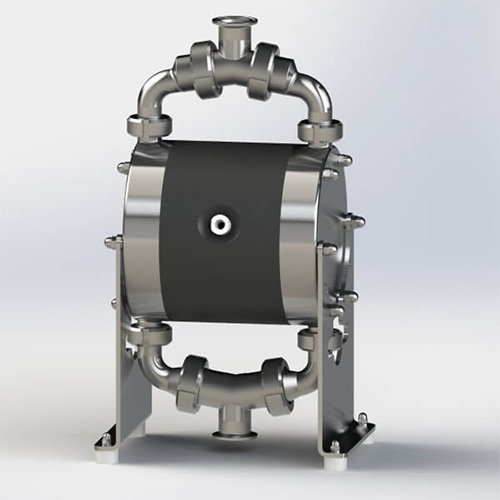

Almatec CHEMICOR Series

-

Stainless-Steel AODD Pumps

When developing Almatec® CHEMICOR Series Stainless-Steel Air-Operated Double-Diaphragm (AODD) Pumps, special attention was paid to the shape of the product chambers. The result is a pump design that offers soft changes in direction, smooth flows and no dead corners. The pump image shows a model with optional draining system.

CHEMICOR Series pumps are manufactured from stainless steel 1.4408/SS316 (G-X 6 CrNiMo 18 10), which is a cast steel that is resistant to corrosion and acids, and is frequently used for fittings and pump casings because of its good general chemical stability. This material in a precision lost-wax casting is used for the wetted housing parts of the CHEMICOR Series. The lost-wax process is a complex casting process yielding a smooth and dense surface with increased resistance to corrosion.

Features at a Glance

- Three sizes: AD 20, AD 32, AD 50

- Max. capacities 4.5 / 9 / 24 m3 /h (19 / 38 /105 gpm)

- Wetted housing parts made of stainless-steel precision casting 1.4408

- Special shape of the product chambers

- Pump casing with only two joint faces

- Freely turnable suction and discharge ports

- No drives, rotating parts or shaft seals

- Ball valves for liquids containing solids

- Maintenance-free PERSWING P® air control system without dead center

- Composite diaphragms with integrated metal core and no diaphragm discs

- Self-priming and dry running

- Gentle displacement

- Can be infinitely controlled via the air volume

- Unattended operation with long service life

- Compact design

- Easy to startup

- Integrated muffler

- Models available with FDA, USP Class VI, EC1935/2004, ATEX approval

- Optional equipment available

Almatec Specialty Pumps - AODD Pumps for Special Applications

- In addition to standard plastic and metal air-operated double-diaphragm (AODD) pumps, Almatec® also offers AODD pumps specifically designed to meet the requirements of special applications, including biopharma (BIOCOR Series), semiconductor (FUTUR Series), high-pressure (filter press feeding, AHD Series), as well as food and beverage (MM Series).

BIOCOR Series

-

AODD Stainless-Steel Pumps for Sterile Applications

Almatec® BIOCOR Series Air-Operated Double-Diaphragm (AODD) Pumps have been specifically designed for critical sterile applications within the pharmaceutical, biotech and food industries. BIOCOR Series pumps are EHEDG certified and conform to EC1935/2004, FDA, USP Class VI and ATEX requirements. The special design of the fluid path enables the CIP and SIP capability.

All of the housing parts on the BIOCOR Series pump contain no horizontal areas, a critical consideration for sterile applications. Available with a 1.4435/316L polished stainless-steel wetted path, BIOCOR Series pumps provide superior containment and utilize four ball-lifting magnets that can be attached to the pump housing from the outside at the location of the four ball valves (available for B20 and B32 models only). With the use of magnets, the ball valves can be lifted from their seats, allowing the pump to be drained entirely without needing to be disassembled or removed from the application.

Features at a Glance

- Engineered in accordance to the essential specifications (EHEDG, FDA, CLASS VI, etc.)

- Unique integrated cleaning system

- Clean-in-place (CIP) and sanitize-in-place (SIP) capabilities

- ATEX conformity

- Wetted materials made of 1.4435/SS316L (Basel Standard II) to ≤ 0.4 µm (15.75 µin)

- Sterile design with no horizontal areas

- Smooth diaphragms without disc and seals

- Diaphragms, ball valves and O-rings made of PTFE or EPDM (FDA conform)

- Maintenance-free PERSWING P® air control system without dead spot

- Gentle displacement

- No drives, no rotating parts, no shaft seals within the fluid

- Short-term temperature range up to 130°C (266°F)

- Easy startup, step-less control via the air volume and pressure

- Self-priming and dry running

- Suction and discharge ports suitable for different sanitary standards

In Compliance with Hygienics Standards

Aseptic pumps of the BIOCOR Series are built in compliance with the corresponding hygienics standards (EHEDG, FDA, Class VI, etc.). The special design with the integrated cleaning-system enables clean-in-place (CIP) and SIP sanitize-in-place (SIP) capability. In addition, the pumps are conform to ATEX. For the EHEDG confirmation every BIOCOR pump is equipped with a diaphragm sensor (code D1).

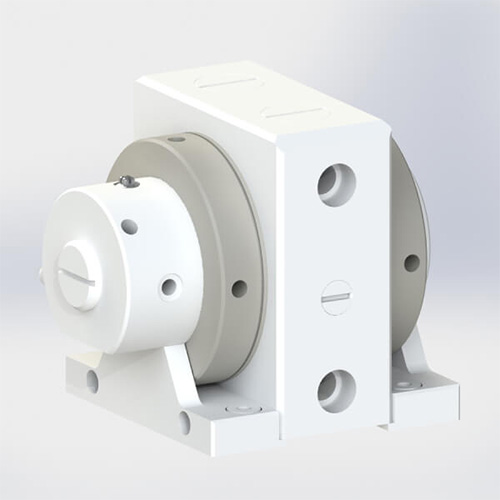

Almatec FUTUR Series

-

AODD Pumps for the Semiconductor Industry

Since 1984, Almatec® has been manufacturing a variety of specialty pumps for supplying and circulating chemicals in the semiconductor industry. With its straight-through flow pattern technology, the Almatec FUTUR Series Air-Operated Double-Diaphragm (AODD) Pump is ideally suited for the special requirements of these applications.

FUTUR Series pumps are self-priming and dry run capable, and feature a compact, simple design with few parts. FUTUR Series pumps have housing parts machined from solid blocks for long-life performance, and are cleaned, assembled and tested in a cleanroom line. For every pump size and material option, the appropriate pulsation damper is available.

The FUTUR is currently available in four materials:

- Four sizes made of PTFE/PE for acids and caustics up to 130°C (266°F) (FUTUR T model)

- Two sizes made of PTFE for hot applications with acids and caustics up to 200°C (392°F) (FUTUR H model)

- Two sizes made of PE for slurries (FUTUR E models)

- Two sizes made of SS316L for solvents (FUTUR S and SH models)

Features at a Glance- Four material versions (T/H/E/S) for different applications

- All plastic models contain no metal

- Temperature range up to 200ºC (392ºF)

- Patented, contactless cascade sealing between the product chambers

- No O-ring sealing in wetted areas

- Straight-through flow pattern, only one wetted housing part

- Maintenance-free PERSWING P® air control system

- Internal air flow

- Diaphragms without plates and gaskets, optimized diaphragm geometry

- Cylinder valves with surface sealing

- Easy to dismantle and assemble

- No elements to fix, including tie rods, nuts, or clamps

- Separate pulsation damper available for all materials and sizes

- Diaphragm and/or stroke sensors can be retrofitted easily

- Low noise level

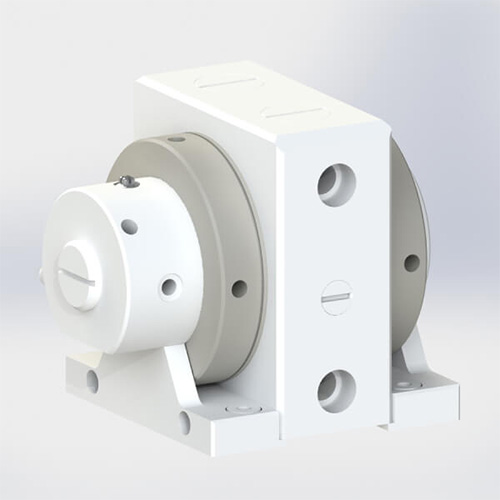

Almatec AHD and AHS Series

-

AODD Pumps for High-Pressure Applications

Almatec® AHD and AHS Series Air-Operated Double-Diaphragm (AODD) Pumps have been specially designed to provide a safe operation in high-pressure applications up to 15 bar (218 psig). A typical application of these pumps is filter press feeding

AHD Series pumps utilize an internal pressure booster while featuring the well-known Almatec ring-tightening structure. The “D” in AHD stands for Duplex, which means the reinforcement of the drive pressure is more than 2:1 by the internal pressure boosting stage. The maximum drive pressure of 7 bar (100 psig) allows the AHD to build up discharge pressures up to 15 bar (218 psig). AHD Series pumps are available in three sizes (AHD 15, 25 and 40) with maximum capacities of 4, 10 and 20 m3 /h (17, 44 and 87 gpm).

The AHS Series pump, which does not include an internal pressure booster, features an extremely rugged housing making it suitable for higher discharge pressures. The “S” in AHS stands from Simplex, meaning the drive pressure is transferred to the medium in a ration of 1:1. This makes the AHS Series ideal for a wide variety of applications under heavy load conditions – from low discharge pressures to high-pressure applications up to 15 bar (218 psig). Due to the 1:1 ratio of the drive/discharge pressure, the corresponding air pressure has to be supplied from the compressor itself or an external pressure booster, also offered by Almatec. AHS pumps are available in two sizes (AHS 15 and 25).

Users who need a high discharge pressure of 15 bar (218 psig) – no matter whether it is with an AHD pump with internal pressure transmission or an AHS pump that achieves the discharge pressure by means of an external booster – can do so with peace of mind that the pump has been specially designed for such pressure ranges and does not have to be held together by external reinforcements.

Features at a Glance

- Corrosion-proof and wear-resistant housing in solid design made of polyethylene for heavy-duty applications

- Double-acting principle of operation

- High pump safety due to innovative ring-tightening structure

- Automatic pressure/volume adjustment for filter press feeding

- No control or safety elements required for dry running, over pressure and speed control

- Safe operation over the entire range of capacity without over pressure risk

- No drives, rotating parts or shaft seals

- Self-priming and dry run capable

- Easy startup

- Gentle displacement by compressible drive medium

- Compact dimensions

- Specially developed heavy-duty diaphragms for long service life

- Integrated muffler

- Horizontal or vertical position for suction and discharge ports

- Maintenance-free PERSWING P® air control system without dead center

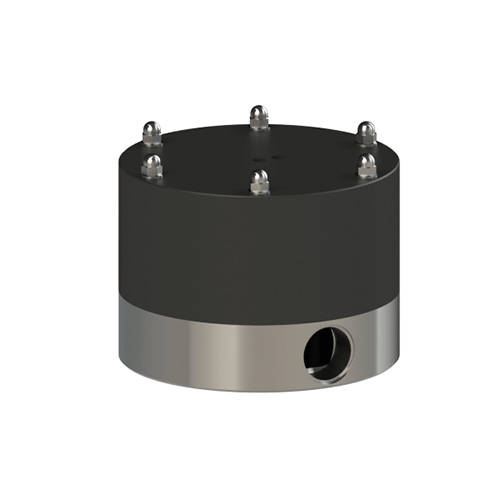

Almatec Active Pulsation Damper – For a Uniform Flow

-

Due to their design, pumps with oscillating action produce a pulsating flow. While the double-acting design of the Almatec® E-Series pump with a direct pneumatic drive already greatly reduces pulsation, a self-regulating pulsation damper must be installed on the delivery side of the pump in order to obtain a virtually uniform flow.

The dampers are self-regulating. Like in Almatec pumps, the diaphragm merely serves as a barrier between the product and the air chamber and is, therefore, always without pressure. If the pressure on the product side drops due to changes in the operating conditions, the pressure on the other side of the diaphragm will decline accordingly. As soon as the pressure on the product side rises, the pressure on the other side will increase as well. This automatic adjustment optimizes the diaphragm setting and ensures a consistently good damping effect.

Almatec Screw-On Dampers

-

Easy and Effective

Almatec® screw-on pulsation dampers represent the latest generation of active pulsation dampers and can be simply screwed onto the pump. Additional connecting elements are not required. Screw-on pulsation dampers are available for E-Series and FUTUR Series pumps.

The E-Series ET damper is also available in a flange version. Appropriate size pulsation dampers are available for every pump. The wetted material is PE or PTFE (both also conductive). Damper heads are made of polyamide or PE conductive. As with Almatec pumps, the recessed housing bolts are tightened against a ring. The exterior is completely free of metal.

The FUTUR Series damper model D is also available in a stainless-steel version for the FUTUR S Series pumps.

Almatec Inline Dampers

-

The Solution for the Stainless-Steel Pumps

The AT Series inline pulsation damper will be used for CHEMICOR Series pumps and the P Series damper will be used for BIOCOR Series pumps. The wetted material of the housing is SS316 and the non-wetted damper head is made of PE conductive (ATEX).

OUR MARKETS

-

All Almatec® AODD pumps meet or exceed industry quality requirements and incorporate the standard-setting features and benefits our customers have come to demand.

CHEMICAL PROCESS

-

OUTSTANDING CHEMICAL CHARACTERISTICS

SOLVING THE CHALLENGES INHERENT IN ALL YOUR CRITICAL CHEMICAL-TRANSFER APPLICATIONS.

Almatec® AODD pumps excel in a variety of critical applications in the chemical industry (including the pharmaceutical industry). Their outstanding design characteristics – safety, quality, reliability, solid construction, self-priming and dry-operation capabilities, etc. – play a pivotal role in the transfer of media that often exhibit corrosive, hazardous, toxic, or explosive properties, including acids, bases, solvents, and chemical mixtures. E-Series plastic pumps are available with PE (abrasion resistant) and PTFE (almost universally chemically resistant) material options, as well as ATEX-compliant conductive versions, to cover a wide range of chemical applications.

SEMICONDUCTOR/SOLAR

-

OPTIMIZING YOUR PRODUCTION PROCESS

ADVANCED ENGINEERED SOLUTIONS THAT COME FROM DECADES OF EXPERIENCE AND INNOVATION IN THE SEMICONDUCTOR/SOLAR INDUSTRY.

The supply, circulation and filtration of high-purity chemicals, as well as the transfer of abrasive slurries and solvents, are typical applications found in the semiconductor industry. These operations place very high demands on pumps, especially plastic pumps, because of the high-temperature ranges often associated with these applications.

The completely metal-free Almatec® FUTUR Series pump offers numerous design features that enable it to overcome the many challenges inherent in the production of semiconductors while providing a pure and safe operation. Thanks to these design features and benefits, FUTUR Series pumps are well suited to successfully handle high-purity chemicals, including H2SO4, HCl, HNO3, H3PO4, HF and H2O2.

The value of the solar or photovoltaic industry in the world economy is increasing rapidly due to the growing importance of renewable energies. The Almatec E-SERIES air-operated diaphragm pumps, which do not use any metal on their exterior, are considered to be especially well suited for use in the manufacture of silicon solar cells (wafers) in particular. Possible areas of application in this industry include using pumps made of abrasion-resistant polyethylene for the pumping of slurry before and after the silicon sawing process, as well as chemical treatment of the wafers (using pumps made of PTFE).

CERAMIC

-

ABRASION RESISTANT AND SOLID CONSTRUCTION

ROUGH AND RUGGED SOLUTIONS MANUFACTURED FROM WEAR-RESISTANT MATERIAL.

In the ceramic industry, pumps are needed to transport a variety of liquids such as sludge and glazes. The pumps necessary for these applications must be manufactured with abrasion-resistant material. This is why the material in the solid Almatec® E-Series AODD pump, abrasion-resistant polyethylene (PE). Trials based on the sand-slurry method have confirmed that the abrasion resistance of the PE is seven times higher than that of polypropylene (PP) — which is often used as a material in pumps — and 1.6 times higher than that of steel. It is also more wear-resistant than, for example, cast iron or aluminum.

HYGIENIC

-

CLEAN SOLUTIONS

OFFERING THE EFFICIENCY, SAFETY AND CLEANLINESS NEEDED TO PUMP AN ARRAY OF PRODUCTS IN HYGIENIC APPLICATIONS.

Almatec® BIOCOR pumps have been specifically designed to meet and exceed the strictest international regulatory guidelines for the biopharma and food and beverage industries. These pumps comply with EHEDG, EC1935, ATEX, FDA and USP Class VI standards, and feature high surface quality, the ability to trace the materials used, as well as clean-in-place (CIP) and sanitize-in-place (SIP) capabilities.

PAINT & COATINGS

-

OPTIMIZING UPTIME PERFORMANCE

IDEAL CHOICE TO MAXIMUM YOUR PERFORMANCE, EFFICIENCY AND CONTAINMENT IN CRITICAL PRODUCTION APPLICATIONS .

Almatec® AODD pumps are ideally suited to excel in a wide range of applications in the paint and coatings market thanks to a variety of industry-leading features and benefits.

When speaking about specific applications, CHEMICOR Series metal pumps are ideally suited to transfer paint and varnish because they are ATEX compliant. For UV varnishes, Almatec E-Series pumps manufactured of conductive plastic are available. Due to the high pressures encountered in painting systems where there is only one pump as a central supply, the Almatec high-pressure pump in stainless steel (AH-S) is an ideal solution. When using these pumps, the time required to clean the pump when changing colors is just as low as the amount of cleaning agent needed for cleaning.

The process chemicals used in the surface technology industry – which range from highly concentrated acids and bases to abrasive slurries – place a heavy amount of strain on materials and equipment. Therefore, these unique applications require innovative Almatec pumps. These pumps include Almatec E-Series pumps, which are used to transfer etching agents as well as grinding and drilling emulsions. In addition, Almatec AHD/AHS Series high-pressure pumps are used in filter press applications to compact sludge for disposal purposes.

PULP & PAPER

-

MEETING ALL YOUR PULP AND PAPER CHALLENGES

DELIVERING SUPERIOR EFFICIENCY AND FLOW WHILE REDUCING ENVIRONMENTAL IMPACT.

In the paper and printing industries, AODD pumps are primarily used to transport glues and printing inks. In many cases, an average-sized pump manufactured from polyethylene (PE) can be used for a variety of glue applications. This includes the innovative Almatec® E-Series Pump.

When choosing a pump to transfer printing inks, Almatec pumps that feature a draining system offer numerous advantages. Because the colors must not be allowed to mix during a color change, the draining system allows the pump and pipeline to be emptied without disassembly. The draining system also allows the color to flow back into the supply container (saving money). In addition, this design feature also reduces the amount of cleaning agent and solvent required to clean the pump, thereby reducing the impact on the environment.

WATER TREATMENT

-

SATISFYING ALL YOUR WATER TREATMENT APPLICATION NEEDS

DESIGNED TO INTEGRATE PERFECTLY INTO YOUR WATER-TREATMENT PROCESS TO SIMPLIFY OPERATIONS AND MAXIMIZE OUTPUT IN THE MOST EFFICIENT MANNER POSSIBLE.

In industrial water treatment applications, Almatec® AODD pumps are ideally suited for a variety of tasks, including taking samples for analysis around the clock, wastewater neutralization and feeding filter presses with sludge. Almatec E-Series, CHEMICOR Series and CXM Series pumps are primarily used for sample taking and the proportioning of neutralization chemicals. Additionally, Almatec high-pressure pumps are primarily used for filter-press feeding thanks to the pumps' ability to operate over the entire range of flow rates without the risk of overpressure while automatically adjusting the pressure/quantity.

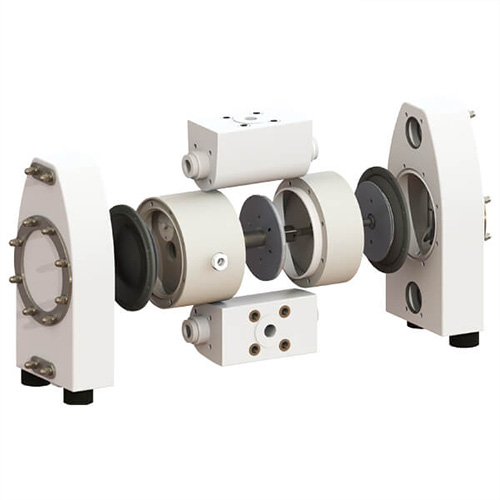

Air Operated Double Diaphragm Pump Technology

-

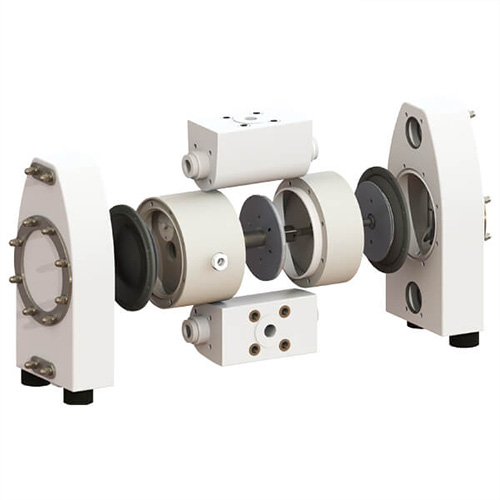

The basic configuration of an Almatec® air-operated double-diaphragm (AODD) pump consists of two external side housings with a center housing between them. Each of the side housings contain a product chamber separated from the center housing by a diaphragm, which are interconnected by a piston rod. Governed by an air control system, the diaphragms are alternately subjected to compressed air so that they move back and forth.

In the first figure, compressed air has forced the diaphragm on the left side of the pump towards the product chamber and displaced the liquid from that chamber through the open valve at the top of the discharge port. Liquid is simultaneously drawn in by the diaphragm on the right, thus refilling the second product chamber. When the end of the stroke is reached, it reverses automatically and the cycle is repeated in the opposite direction.

In the second figure, liquid is drawn in by the diaphragm on the left and displaced by the diaphragm on the right. The liquid is displaced and, thus, conveyed by the compressed air. The diaphragms merely serve as barriers and are not pressurized. This is a fact of decisive importance for the service life of the diaphragms.

STATE-OF-THE-ART

-

State-Of-The-Art AODD Pumps

Since our founding in 1984, Almatec® has been committed to defining "what's next" in state-of-the-art AODD pump technology by focusing on extensive product enhancements and innovations. Described below is the product development of our main pump lines.

MATERIALS

-

Solid-Body Design for Strength and Smooth Operation

An important construction element in Almatec® air-operated double-diaphragm (AODD) pumps is the solid-body design. Only a solid-plastic body can support the necessary weight for an oscillating pump. The individual components can be designed so that the required wall thicknesses is arranged where they are needed. The mechanical machining of a solid-plastic block is economical thanks to modern CNC technology, enabling tight tolerances to be achieved. The high-static mass leads to smooth operation and eliminates the need for unnecessary external metal parts that would otherwise be used for reinforcement. All Almatec pumps use only virgin PE and PTFE produced in Germany.

AIR CONTROL SYSTEM

-

Almatec’s Air Control System

The purpose of the pneumatic diaphragm pump air control system is to ensure automatic operation that is indirectly controlled by the movement of the diaphragms. Reaching its final point, the stroke reverses automatically and the cycle of medium being drawn in by one diaphragm and being displaced by the other is repeated by the opposite side of the pump.

The metal-free, pneumatically pilot-operated PERSWING P® Air Control System ensures accurate reversal of the main piston and is characterized by low noise levels. Only two moving parts ensure that there is absolutely no dead center. It does not require maintenance, operates without any lubrication and is engineered with no more than four different parts. The complete cartridge can be replaced easily. The PERSWING P® is a precision control system and, therefore, requires clean, oil-free compressed air to ensure its optimal function.

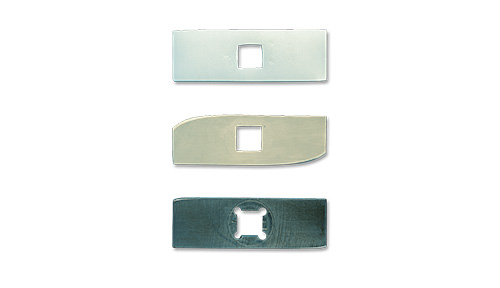

DIAPHRAGMS

-

Diaphragms used for Almatec AODD Pumps

The surface of an Almatec® diaphragm is smooth and not interrupted by any seals. Due to their integrated metal core, they do not require diaphragm discs that can frequently result in leaks and attract dirt. Produced in priming position, these diaphragms simplify assembly and almost completely eliminate the dead space on the air side since the inner side of the diaphragms rests against the central housing in the limit position, thus optimizing efficiency and reducing air consumption.

Since the medium is displaced and delivered by compressed air, the diaphragms merely serve as barriers and are not pressurized. This is a fact of decisive importance for the service life of the diaphragms.

Almatec diaphragms have always been designed from the "PTFE" point of view. This results in a diaphragm that has a large diameter and short stroke with low flexural load. This ensures uniform delivery regardless of the material used for the diaphragm's construction.