- Offer Profile

-

With a patent registered in 1956, we revolutionized the design of knife gate valves forever. The engineer’s name: Joseph Wey. The Original Wey Design and the Wey brand were born.

Wey products and solutions have been conquering the world ever since, and today stand for performance, reliability, quality and cost-effective solutions for knife gate and butterfly valves as well as water control gates.

VALVES FOR HIGHEST DEMANDS

- High performance valves are our specialty. Thanks to decades of engineering experience and in-house production with an outstanding manufacturing expertise, we offer a wide range of products for demanding applications.

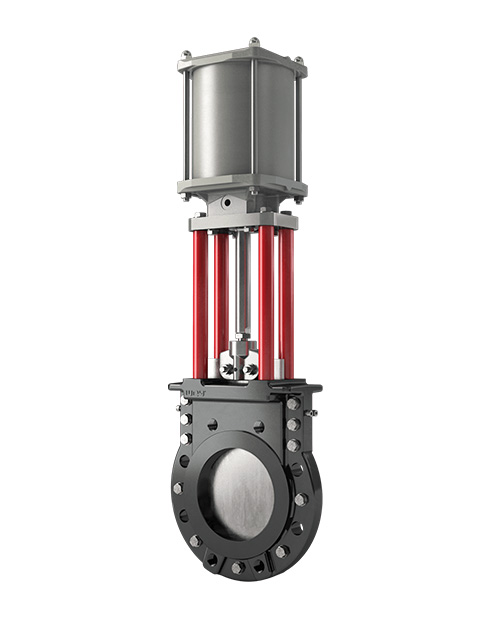

KNIFE GATE VALVES

- Equipped with the unique Wey sealing system, our knife gate valves are suitable for the most demanding of applications. They can handle a variety of differential pressure scenarios and abrasive and corrosive materials, not to mention extreme temperatures. They are available in different materials and come with multiple options.

VN SERIES

-

Nominal sizes: 50 – 1400 mm

Material: Stainless steel, Cast iron, Special material

Pressure rating: 0 – 10 barThe VN series combines all the properties of a knife gate valve in an inexpensive semi-lug flange design, in order to meet the most common market requirements. With this series, we guarantee the greatest possible functional and operational safety, in an easy-to-maintain, optimized design. We guarantee a 100 % bidirectional bubble-tight shut off over the entire pressure range. For many applications this results in a balanced cost-benefit ratio in terms of investment and maintenance.

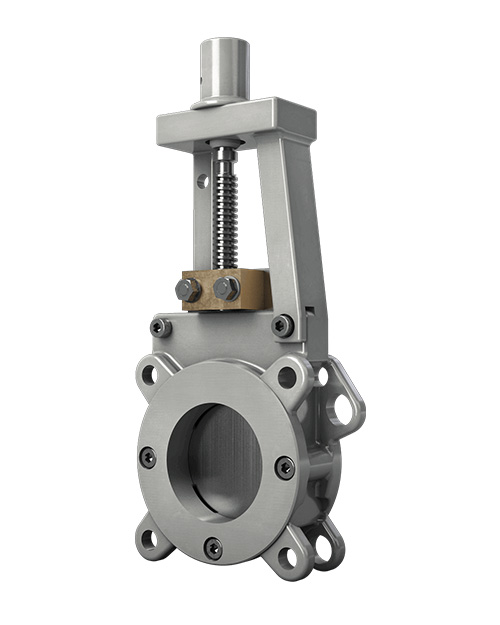

VS SERIES

-

Nominal sizes: 50 – 900 mm

Material: Stainless steel, Special material

Pressure rating: 0 – 10 barThe appeal of the VS series lies in its ingenious semi-lug design. The lightweight construction of this knife gate valve, which is available in stainless steel, makes it very cost-effective. Nonetheless, it gives our customers the highest level of reliability and durability in use. This is also because – like all Wey products – it can be repacked at any time and ensures zero leakage while in use.

VG SERIES

-

Nominal sizes: 150 – 200 mm

Material: Cast iron

Pressure rating: 0 – 4 barWey VG knife gate valves are products with a special flange. They were specifically developed for biogas applications in agriculture, since standard DIN gate valves for industrial pipelines are not compatible. The VG is available exclusively in cast iron, and only in the nominal sizes DN 150 and DN 200.

VL SERIES

-

Nominal sizes: 50 – 900 mm

Material: Stainless steel, Special material

Pressure rating: 0 – 10 barWith the optimized lug design of our VL Series, we give you the best of both worlds. It unites cost-saving design and the highest possible performance. Made of stainless steel as standard, it is often used in corrosive applications and, thanks to its 100% bidirectional bubble-tight shut off, offers the best possible customer confidence and satisfaction.

VM SERIES

-

Nominal sizes: 50 – 650 mm

Material: Ductile iron

Pressure rating: 0 – 10 barThe VM knife gate valve is manufactured according to high quality standards, combining a robust design with proven technical features not found in conventional knife gate valves. Thanks to the original, integrated Wey design, it guarantees the best-possible performance and, of course, absolute zero leakage in demanding applications.

MF SERIES

-

Nominal sizes: 50 – 2000 mm

Material: Cast iron, Ductile iron

Pressure rating: 0 – 10 barThe MF is a universally applicable knife gate valve with a central flange design that will just about satisfy the customer's every need. As well as featuring the integrated Wey sealing system, the robust, modular design of the series is particularly advantageous. Choose from a variety of materials, add-on parts, and actuator options across the entire nominal size range. A true all-rounder.

MG SERIES

-

Nominal sizes: 50 – 600 mm

Material: Stainless steel, Ductile iron, Special material

Pressure rating: 0 – 16 barKnife gate valves with an EN 558/ISO 5752 20 series face to face often quickly reach their pressure limit values of 10 bar – but not our MG series. For the same face to face, it is generally designed for pressures of up to 16 bar. Of course, we retained the many design features that have always set the Wey knife gate valve apart from the competition.

MH SERIES

-

Nominal sizes: 100 – 400 mm

Material: Stainless steel, Ductile iron, Special material

Pressure rating: 0 – 25 barThe MH series is designed for extremely high pressures in particularly demanding applications. The original Wey design ensures optimal sealing in the seat and is 100% bubble-tight, regardless of pressure, medium, or on/off cycle.

W SERIES

-

Nominal sizes: 50 – 1200 mm

Material: Stainless steel, Carbon steel, Cast tin-bronze , Cast aluminum-bronze

Pressure rating: 0 – 50 barWhether an application is referred to as “severe service”, “high performance”, or “heavy duty”, we have overcome the corresponding challenges with our Wey design. We pushed it to the limit, and the result is the W series. It offers the greatest flexibility, including for the range of nominal sizes, materials, and pressures. It opens up an incredible scope of application. With the W series, we guarantee that we will outperform the competition, no matter what the situation.

DB SERIES

-

Nominal sizes: 80 – 750 mm

Material: Stainless steel, Special material

Pressure rating: 0 – 10 barThe “double block and bleed” knife gate valve was specially developed for applications using hazardous media. The DB model is a single valve with two seat areas. In the closed position, these provide a seal against pressure from both ends of the valve, and there purge ports to flush the cavity between the seat areas. The DB model thus makes complex and costly multiple valve systems redundant. In spite of these cost benefits, it offers zero leakage protection in difficult applications.

DP SERIES

-

Nominal sizes: 50 – 400 mm

Material: Stainless steel, Cast iron, Ductile iron, Cast steel, Special material

Pressure rating: 0 – 25 barWith its special O-Port gate design, the DP model is suitable for the most difficult applications involving solids. Due to its unique design, it can easily cut through a medium column holding solids. The integrated transverse seal sets the DP model apart from conventional O-Port gate valves, guaranteeing maximum performance and zero leakage.

HD SERIES

-

Nominal sizes: 80 – 400 mm

Material: Stainless steel, Cast steel

Pressure rating: 0 – 100 barThe HD series is an extraordinary development of the Wey knife gate valve for operation up to a maximum pressure of 100 bar. The ingenious design ensures that the pressure of the medium creates an automatic sealing effect inside the seat area. The special bonnet design also allows media containing solids to be flushed out – and, of course, it is completely airtight. This makes the HD series ideal for the most difficult applications.

HSI SERIES

-

Nominal sizes: 65 – 400 mm

Material: Stainless steel

Pressure rating: 0 – 16 barThe HSI knife gate valve was specially developed for use in pipelines at risk of dust explosions, to prevent explosions from spreading beyond the valve installation point. With a closing time of 23 milliseconds, it makes a significant contribution to protecting human life at work, as well as systems with explosive gas and dust mixtures.

TI3 SERIES

-

Nominal sizes: 80 mm

Material: Stainless steel

Pressure rating: 0 – 10 barThe TI3 model really is a unique design. It is designed for shut-off isolation of differential pressure level sensing. Unlike other transmitter isolating valves, which are only adapted from standard knife gate valves, the TI3 model was developed for the sole purpose of isolating the transmitter. The TI3 uses standard 1/2" socket drive.

VK SERIES

-

Nominal sizes: 200 – 1000 mm

Material: Stainless steel, Cast iron, Special material

Pressure rating: 0 – 2.5 barThanks to its square shape, the VK knife gate valve increases the range of possible ways you can use the round Wey knife gate valve, with its well-known advantages. This is the best solution for achieving absolute zero leakage shut off, even when using rectangular or square flange connections.

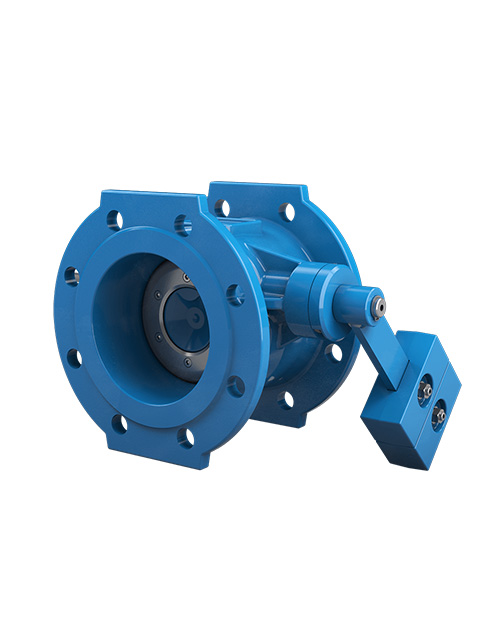

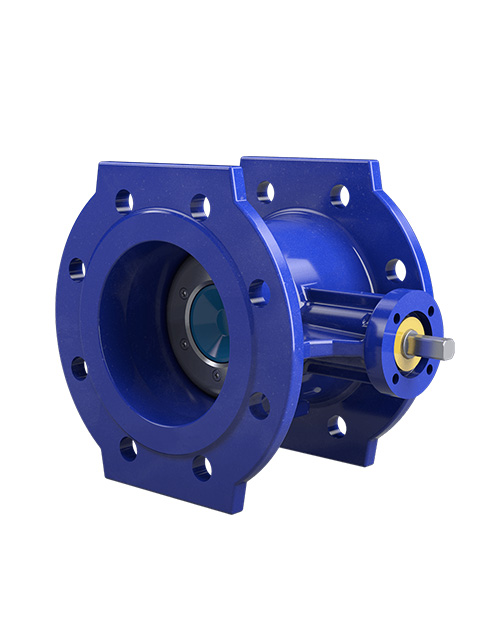

BUTTERFLY VALVES

TW20

-

Design: Centric butterfly valve

Case shape: Wafer type body

Nominal sizes: 25 – 1200 mmThe TW20 series responds to the demand for butterfly valves designed in accordance with ISO PN10/16 standards. The combination of its design, materials, and state-of-the-art manufacturing technology means we can offer a tremendously reliable product at extremely competitive prices.

TL20

-

Design: Centric butterfly valve

Case shape: Lug type body

Nominal sizes: 25 – 1000 mmOur TL20 butterfly valve was designed for general industrial applications. Due to its lug flange design, it can serve as a complete and cost-effective replacement for double flange valves. It offers significant benefits in systems where a line must occasionally be isolated.

TF20

-

Design: Centric butterfly valve

Case shape: Double flange body

Nominal sizes: 80 – 1600 mmThe TF20 butterfly valve comes with short face to face double flange design and is suitable for the most common standards (DIN, ANSI, BS). Thanks to its design and great strength, it is suitable for all applications requiring the use of a double flange valve, such as installation at the line end.

TF13

-

Design: Centric butterfly valve

Case shape: Double flange body

Nominal sizes: 40 – 1200 mmThe TF13 butterfly valve comes with a wide face to face double flange and is suitable for the a variety of different standards (DIN, ANSI, BS). Thanks to its design and great strength, it is suitable for all applications requiring the use of a double flange valve, such as installation at the line end.

RSK

-

Design: Check valve

Case shape: Double flange body

Nominal sizes: 65 – 300 mmOur RSK check valve is our comprehensive answer to today’s demanding requirements. We have paid special attention to the robust design. The main difference compared to conventional check valves is that the valve disc and lever are not inside the body, but inside the cover, making it very user-friendly. Moreover, once the cover is removed, the valve body is fully exposed for any kind of inspection, even when it’s still installed in the system.

TK01

-

Design: Check valve

Case shape: Double flange body

Nominal sizes: 150 – 400 mmThe TK01 is an eccentric, non-return check valve manufactured in accordance with DIN face to face length EN 558/ISO 5752 series 14. When the butterfly valve opens and closes, the eccentrically mounted valve disc swings in and out at an optimal angle. Unlike conventional check valves, the TK is very free-moving and opens with minimal differential pressure. This is because the contact pressure in the seal seating has been optimized. Thanks to its robust, careful design, the TK has proven itself on the market over the course of decades.

TZ01

-

Design: Double eccentric butterfly valve

Case shape: Double flange body

Nominal sizes: 100 – 400 mmThe TZ01 is our double eccentric butterfly valve. The specially developed dynamic seal is self-pressing and adapts to system pressure. Only as much system pressure is generated from the seal on the seat as is necessary for the drip-tight seal, due to the respective operating pressure at the time. This results in a minimal amount of torque required for actuation. The special shape of the seal means the direction of pressure can come from both sides.

CONTROL GATES

SLUICE GATE

-

Design: Sluice gate

Width: 200 – 5000 mm

Head of water: 0 – 15 mOur type 2, 3, and 4 sluice gates are all based on the same well thought-out design principle. Every one of our sluice gates is custom-made with great care. Thanks to the circumferential transverse seal and double scraper, our sluice gates are much tighter than the standard prescribes – and are tight in both flow directions.

PIT SLUICE GATE

-

Design: Sluice gate

Width: 150 – 500 mm

Head of water: 0 – 5 mOur made-to-measure pit sluice gates with their round bottom profile are perfectly suited to round shafts or sludge collectors. The frame structure can either be concreted in or doweled, and is sealed on four sides in both flow directions.

HAND STOP

-

Design: Sluice gate

Width: 100 – 1200 mm

Head of water: 0.15 – 1.20 mHand stops are mainly used temporarily, for inspection procedures. That is why they can only be operated with a handle. Our hand stops are made to measure from high-quality stainless steel for each order, and are tighter than the standard prescribes. They are also bidirectional in both flow directions.

STOP LOG

-

Design: Stop log

Width: 500 – 6400 mm

Head of water: 0.15 – 6 mFor temporarily or variably blocking sewers, our range includes aluminum stop logs. We custom-make the installation frames for the logs with pressing devices from high-quality stainless steel. Our stop logs seal on 3 sides in both flow directions.

STOP GATE

-

Design: Stop gate

Width: 1000 – 5000 mm

Head of water: 0.15 – 4 mOur stop gates are made of high-quality stainless steel, making them ideal for permanent isolation. We make these to measure. Our stop gates seal on 3 sides in both flow directions, which actually exceeds what the standard prescribes. Stop gates are provided without actuators and require hoisting gear for on-site operation.

VALVES FOR EVERY APPLICATION

- We’re at home in an extremely wide variety of industries and are familiar with their specific requirements. Whether we’re working in water treatment, general process industries, mining or power plant construction, we meet the highest demands and can draw on extensive experience in each of the diverse areas of application. We don’t think in terms of prefabricated products; instead, we always look for the best possible solution. Because we’re not completely satisfied unless you are.

RENEWABLE ENERGY

- Biogas plants are complex processing systems built from many different components. Each of these components is subjected to the highest demands. In this context, knife gate valves must be completely bubble-tight. This is true for all the raw materials needed to produce alternative energies, whether food, leftover food, manure, untreated wastewater, or agricultural waste. The unique design reliably guarantees both zero leakage in the seat area and towards the atmosphere. This makes our knife gate valves the perfect solution for biogas plants, as they have been for decades.

MINING

- One of the most difficult pumped media to deal with in mining is abrasive slurry. It often contains toxic chemicals that are extremely hazardous to people and the environment. It has a sandpaper-like effect and moves at high speed. This slurry is transported through various process steps, before being finally stored in tailing ponds. Knife gate valves used in these applications must therefore remain absolutely bubble-tight, even under extreme conditions – without interruption in either direction and with a long operational life-cycle. This is because the intervals between maintenance are very long – a challenge that we gladly accept and more than meet.

CHEMICAL AND PETROCHEMICAL INDUSTRYs

- Conventional knife gate valves are not usually suitable for use in the chemical and petrochemical industries. They leak in the bore area, get jammed, and are not bubble-tight. However, our knife gate valves come with a unique sealing system and flow-optimized body contours. This design guarantees, firstly, the highest level of reliability when opening and closing the valve and, secondly, absolute zero leakage in both flow directions. Thanks to the possibility of repacking, leakage to the atmosphere can be eliminated directly on site and under full pressure. Without having to remove the knife gate valve or power down the system.

FLOOD PROTECTION

For decades, our products have been used in many different ways in water management and flood protection. For such applications, we not only manufacture well-engineered series products, but also make custom products to meet customers’ requirements. Our products are cost-effective and sustainable and often operate independently of external energy sources.

INFRASTRUCTURE

- Wey sluice gates are the first choice for infrastructure projects. They are versatile and flexible. This means that they can be designed individually for every application. Their potential uses range from collecting and storing water in sewage reservoirs, through applications in highway drainage systems, to use in construction pits. They are also widely employed in flood protection and water management.

POWER GENERATION

The demands placed on components in power plant applications are high. This is particularly true of the valves used to reliably isolate shutoff applications. Our knife gate valves are designed for just such extreme conditions. Their excellent reputation is due to their robust, easy-to-maintain design – whether for flue ash in the pumping system, static media columns in the ash hopper, or in the coal washing or flue gas cleaning plant. Wey knife gate valves are the best choice, because they are designed for the most challenging applications.

FOOD AND BEVERAGE INDUSTRY

-

Standards in the food and beverage industry are very high: High work cycles, strict hygiene requirements, and trouble-free operation are a must. Our many years of experience have enabled us to launch numerous special applications in recent years, for cocoa powder, potato starch, dairy products, and sugar production – as solutions and as a step towards a promising future.

OIL AND GAS PRODUCTION

- Our knife gate valves are also widely used in the oil and gas industry. Their unique design has made them our customers’ first choice for decades. We have used our acquired experience to continuously improve our products. That means we can keep production capacities high and maintenance costs low – for oil and gas production, on dry land and on rigs.

PULP AND PAPER INDUSTRY

Wey knife gate valves are ideally suited to the pulp and paper industry, where fibrous media in the pipelines cause frequent problems. Conventional designs featuring a stuffing box and dead angles in the body are not a viable solution. Whether for washing systems, storage tanks, or cyclone applications, our unique design offers leak-free, bidirectional seat tightness. The minimal chest area and contoured flush ports in the body prevent jamming, because no material builds up. This guarantees smooth operation and low maintenance costs.

WATER TREATMENT

- We have been at home in wastewater treatment for almost 50 years – all over the world. It's all thanks to our knife gate valves. With their unique features, they stand out where other valves fall short. They guarantee, firstly, the highest level of reliability when opening and closing the valve and, secondly, absolute zero leakage in both flow directions. This is a huge advantage at installation sites where valves cannot be serviced regularly. And that's not all: When it comes to the total cost over the years of operating a wastewater treatment plant or pumping station, Wey valves are unbeatable.

CEMENT INDUSTRY

- Cement is produced using a very specific chemical process from calcium, silicone, aluminum, iron, and other components. Conventional knife gate valves are usually unsuitable for mixtures like these. The unique design of our products guarantees absolute zero leakage in both flow directions. Any leaks that do occur can be resealed directly on site and under full pressure, without having to remove the knife gate valve or power down the system.s