EXTRUDEX

- Offer Profile

Quality to Highest Standards

Our experience, know-how and close contacts with customers, suppliers and leading research institutes make us a qualified provider of pipe, tube and profiled part manufacturing technologies for application sectors of all imaginable types. Always looking to improve and expand existing technologies, EXTRUDEX offers custom-designed solutions to even the toughest manufacturing problems.

The portfolio of machinery and systems provided by EXTRUDEX includes extruders in a wide variety of designs and sizes, extrusion tooling, downstream equipment and other components as well as turn-key lines, grinders, coating stations and sheathing stations.

Product Portfolio

EXTRUDERS

-

Our Strength: Custom-Designed Extrusion Solutions

EXTRUDEX extruders are used for a broad variety of products and applications:- Profiled parts

- Medical tubing, monolayer or up to 6 layers

- Sanitary and automotive piping, monolayer or up to 6 layers

- Mono- or multilayer corrugated pipe

- Cable jacketing

- Special applications

HELIBAR® single-screw extruders

-

with grooved intake zone, axially or helically grooved barrel and barrier screw with shearing and mixing sections.

Advantages:

HELIBAR® extruders provide substantial process advantages over smooth-barrel extruders including:- Higher specific throughput

- Improved melt pressure build-up

- Lower melt temperature for most resins

- Improved melt homogeneity

- Problem-free processing of wall-slipping resins

- Reduced wear

- Short residence time

- Higher overall operating efficiency and therefore improved economics

- The name HELIBAR® is a registered trademark owned by EXTRUDEX Kunststoffmaschinen GmbH. HELIBAR® is a patented technology.

EXTRUDEX Grooved-Barrel Extruders

-

EXTRUDEX extruders with grooved intake zones provide significant benefits including:

- High pressure build-up and high pressure stability

- High specific throughput rates

- High intake and output consistency

- These benefits are realized with all thermoplastic resins which are suited for solid-phase transport within grooves, i.e. which exhibit low "outer friction". Process-relevant components such as the screw and the grooved barrel are designed and/or optimized in accordance with the intended application at hand.

EXTRUDEX Smooth-Barrel Extruders

-

Smooth-barrel extruders for processing of rigid PVC, PC, PMMA + PEEK.

Smooth-barrel extruders are used for resins with high "outer friction" and resins with high shear sensitivity, e.g. rigid PVC, PC, PMMA, PEEK.

Their simplicity of design makes them versatile and well suited for wide-ranging applications.

EXTRUDEX smooth-barrel extruders are available in screw diameters from 18 to 150 mm.

Mounting Configurations and Custom Designs

-

EXTRUDEX extruders offer design possibilities with virtually no limits.

EXTRUDEX knows plastics extrusion inside and out, offering solutions which are far superior to conventional technologies.

Mounting Configurations- On scissors-type elevating platform, 360° rotatable

- On universal mounting stand for horizontal operation

- On universal mounting stand for vertical operation

- On universal mounting stand for operation at any angle from vertical to horizontal

- Tandem coextruders mounted on gantry frame

Custom Solutions

EXTRUDEX develops and fabricates extruders and coextruders as custom solutions for specific applications. These solutions permit optimum attainment of technical, process and economic requirements.

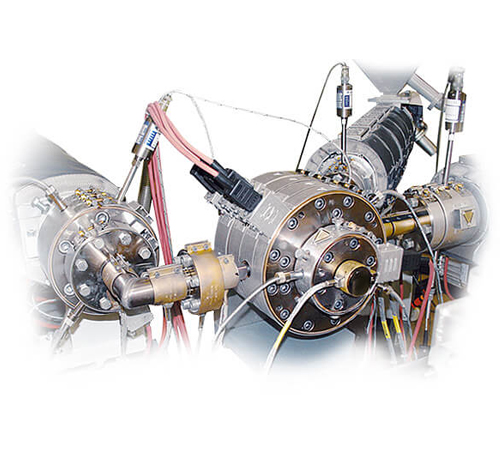

For example: shown at right are two single-screw extruders in tandem in a "jockey" design configuration.

This special configuration allows realization of a high-performance production unit with minimum floor space requirements.

EXTRUDEX Process Equipment

-

For retrofit systems and modernization

Retrofitting with EXTRUDEX-HELIBAR® process equipment upgrades throughput performance and energy efficiency of existing extruders with outstanding cost effectiveness.- All EXTRUDEX extruders carry CE marking certifying full compliance with corresponding EU standards.

- APPLICATION SECTORS

Multilayer and co-extrusion lines for sheet manufacturing, Extrusion blow moulding machiery, Hot melt application

- APPLICATION SECTORS

Modernization of existing extruders and, Replacement of defective or worn process units in blow moulding and other process machinery

- DESIGN CONFIGURATIONS

Different design configurations ("U" or "Z" design, direct or belt drive) can be supplied in accordance with specific requirements.

- All EXTRUDEX extruders carry CE marking certifying full compliance with corresponding EU standards.

EXTRUSION TOOLING

-

Extrusion Tooling to Highest Standards

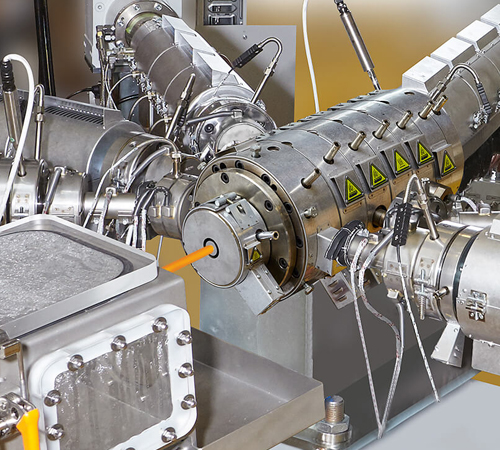

In the year 2000, EXTRUDEX changed course from previous practice and began in-house design and development of pipe and tube extrusion tooling. The decision was driven by shortcomings of existing technologies in meeting EXTRUDEX’s requirements for quality, versatility and performance.

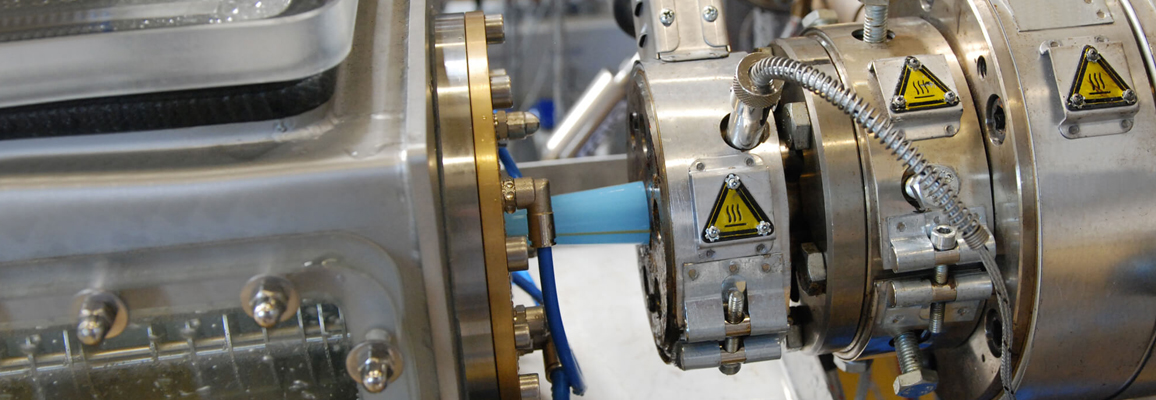

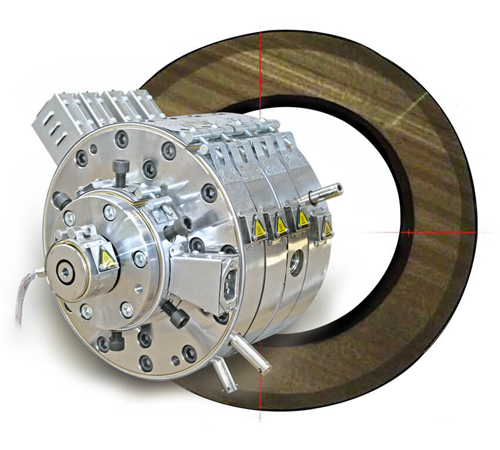

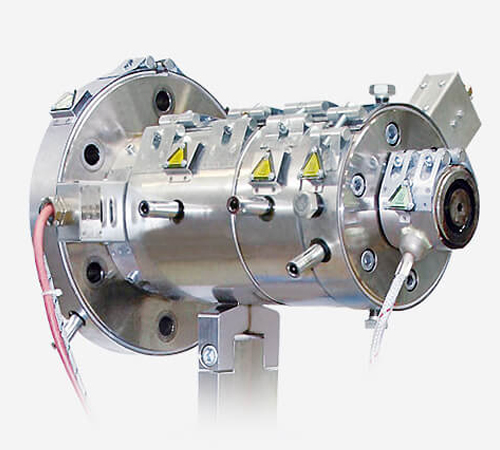

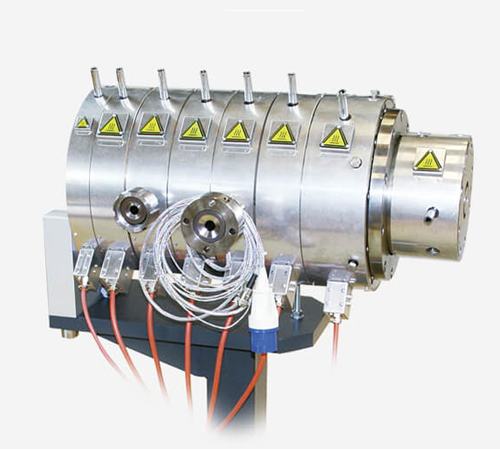

EXTRUDEX VARIOSYSTEM

-

Multilayer die heads with interchangeable rotary distributor for maximum process flexibility

- Exchangeable rotary distributor permits realization of almost all common layer structures with only one extrusion head

- Expandable plate-module design permits simple upgrading of extrusion head from 2 to up to 6 layers

- Suitable for tube outer diameters in range 4 - 20 mm (larger diameters available on request)

Advantages:- Excellent melt homogenization

- Maximum concentricity of layers relative to one other

- Accurate layer distribution even with different melt viscosities

- Quick colour changes

- Outstanding process flexibility

- High throughput rates

- Excellent self-cleaning effect

- Very compact design

- Available in fluorine-resistant materials of construction

MONOLAYER Pipe Die Heads

-

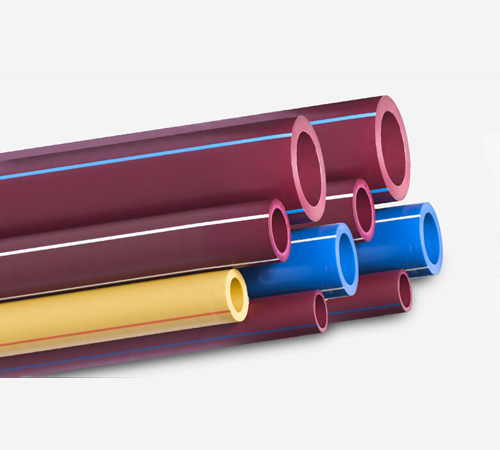

for extrusion of monolayer pipes and tubing e.g. in PP, PE, PA, PPS or WPVC

- With spiral mandrel or spider distributor

- Outer diameters in range 4 -110 mm

- Wall thicknesses in range 0.5-20 mm

- Personalized colour stripes as required

MONOLAYER Crossheads and Sheathing Heads

-

for coating / sheathing of pipes, tubes, wires and cables

- With rotary distributor

- Outer diameters in range 4-100 mm

- Wall thicknesses in range 0.1-3 mm

MULTILAYER Pipe Die Heads

-

for extrusion of multilayer pipes and tubing, suitable for nearly all thermoplastic resins

With rotary distributor

Simple plate-module design

Outer diameter range 3-110 mm

Wall thicknesses in range 0.3-20 mm

Up to 6 individual layers

Flexible layer configurations with VARIOSYSTEM

Up to 6 individual layers

MULTILAYER Crossheads and Sheathing Heads

-

for multilayer coating / jacketing of pipes, tubes, wires and cables

With rotary distributor

For O.D.'s in range 4-100 mm

Up to 6 individual layers

Flexible layer configurations with VARIOSYSTEM

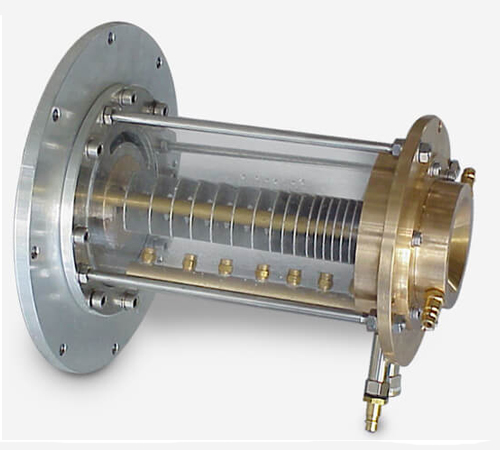

EXTRUDEX Calibration Stations & Distributors

-

EXTRUDEX designs and manufactures disc and sleeve calibrators as well as PlexiglasTM pre-chambers for calibration before spray cooling.

- All EXTRUDEX calibrators carry CE marking certifying full compliance with corresponding EU standards.

- BRASS AND STAINLESS STEEL CALIBRATORS

for pipes in O.D. range 16 - 160 mm

- DISC CALIBRATORS

for pipes in O.D. range 6 - 25 mm

- BRASS SLEEVE CALIBRATORS

with intensive inlet cooling

- 2-PART BLOCK CALIBRATORS

for tubing with O.D. < 5 mm

- IRIS-DIAPHRAGM CALIBRATORS

for medical micro-tubing

- PLEXIGLASTM PRE-CHAMBER

immersion bath for calibration before spray cooling in vacuum tank

- EXTRUDEX Distributors for Optimum Melt Flow Control

Our portfolio includes:

- Double distributors with melt flow control valves regulating infeed of two pipe layers from one extruder

- Spider (torpedo) distributors for flexible PVC, PUR and polyamides

- Spiral mandrel distributors for polyolefins and fluoropolymers

- Heated tubes for flexible infeed connections between tooling and extruder for hot melts, colour stripe application on pipes, etc.

- All EXTRUDEX calibrators carry CE marking certifying full compliance with corresponding EU standards.

EXTRUSION LINES

-

High-Speed Extrusion Lines and Turn-Key Systems

EXTRUDEX offers a wide range of complete single-source solutions:

Turn-key lines with single-source supply responsibility (turn-key solutions) for- Manufacturing of smooth and multilayer composite pipes

- Manufacturing of automotive parts

- Manufacturing of medical technology components

- And a wide variety of special application sectors

- Many well known manufacturers in the automotive, medical and laboratory equipment sectors as well as the tube, pipe and cable industries rely on quality solutions supplied by EXTRUDEX.

All EXTRUDEX extrusion lines carry CE marking certifying full compliance with corresponding EU standards.

Monolayer Pipe

-

Our extrusion lines for smooth and composite pipe (e.g. PPR, PE and PP pipe) offer highest efficiency with absolutely consistent product quality and stable process parameters.

Every EXTRUDEX extrusion line supplied is configured in exact accordance with customers' specifications and requirements.

Medical Tubing

-

EXTRUDEX offers a broad spectrum of complete single-source solutions (turn-key solutions) for:

- manufacturing of multi-lumen medical tubing

- manufacturing PP and PE medical tubing in O.D. range 2 – 4 mm

- manufacturing of flexible PVC medical tubing in O.D. range 2 – 12 mm

- manufacturing of 3 to 6-layer medical tubing

- Well-known manufacturers in the medical and laboratory equipment sectors worldwide rely on quality solutions from EXTRUDEX.

All EXTRUDEX extrusion lines carry CE marking certifying full compliance with corresponding EU standards.

Multilayer Extrusion Lines

-

EXTRUDEX offers a wide range of custom-configurated turnkey extrusion lines for manufacturing of:

- 5-layer pipe: layers configuration PP-R – PP-R+GF – PP-R – PP-R+GF – PP-R

- 2-layer corrugated PA pipe

- 3-layer composite pipe: PE-RT inner pipe – bonding agent – EVOH

- 5-layer underfloor heating pipe: PE-RT inner pipe – bonding agent – EVOH – bonding agent – PE-RT or PE outer skin

- 5-layer composite pipe: PE – bonding agent – aluminium foil – bonding agent – PE

- Well-known manufacturers worldwide rely on quality solutions supplied by EXTRUDEX.

All EXTRUDEX extrusion lines carry CE marking certifying full compliance with corresponding EU standards.

Automotive

-

EXTRUDEX lines manufacture automotive products with consistently high quality, providing outstanding operating efficiency and rock-solid process control.

- Reduced energy consumption due to quick ramp-up from start-up to production mode.

- Product-specific process parameters and ramp are stored in process recipes which can be recalled and implemented at the push of a button. When the production line speed is attained, in-line O.D. and wall thickness monitoring begins and any out-of-spec products are separated off. The result: start-up scrap and resultant costs are held to a minimum.

- Process and product data are gathered, externally stored (optional feature) and displayed in process control charts.

- All EXTRUDEX extrusion lines carry CE marking certifying full compliance with corresponding EU standards.

Cable Jacketing

- EXTRUDEX offers a wide range of expertly engineered components for cable jacketing lines. Each system supplied is configured in exact accordance with customer specifications and product requirements. Well-known cable manufacturers worldwide rely on quality solutions supplied by EXTRUDEX.

Sheathing Lines

-

EXTRUDEX offers a wide variety of customer-personalized turnkey sheathing lines, for instance:

For sheathing of PEX-a pipe:- Applied layers: bonding agent – EVOH – bonding agent – PE outer skin

- For foamed PE hose production with outer LDPE film jacketing

- Sheathing unit for PP pipe sheathing (O.D. range: 16–110 mm) by application of a 150–200 µm outer aluminium foil layer to form flex-stabilized pipe

- Sheathing of prefabricated pipe by application of a bonding agent and an EVOH outer skin

- Well-known manufacturers worldwide rely on quality solutions supplied by EXTRUDEX.

All EXTRUDEX extrusion lines carry CE marking certifying full compliance with corresponding EU standards.

Specialty Lines

-

We can provide custom-engineered systems tailored to specific customer, product and quality requirements.

You tell us your specifications and we will provide the extruders and equipment required to meet them.

We see our role as that of a partner with our customers. By constantly setting new benchmarks and providing advanced solutions, we keep you a step ahead of your competition.

The premium materials of construction and products we use,

the dedication and expertise of our staff as well as our

cutting-edge innovation in processes, products and service

ensure highest quality and performance of the systems we provide.

Well-known manufacturers worldwide rely on quality solutions supplied by EXTRUDEX.

All EXTRUDEX machines and equipment carry CE marking certifying full compliance with corresponding EU

DOWNSTREAM EQUIPMENT

-

EXTRUDEX develops and manufactures downstream equipment satisfying customers' needs for optimum extrusion lines.

Offering custom-designed systems to satisfy customer, product and quality requirements, EXTRUDEX supplies personalized solutions which provide convincing advantages in even the toughest applications. Customers benefit from our ongoing development and continuous upgrading of existing technologies.

All EXTRUDEX downstream equipment carries CE marking certifying full compliance with corresponding EU standards. EXTRUDEX Belt and Caterpillar Haul-Offs

-

EXTRUDEX offers a broad range of in-house developed belt and caterpillar haul-off units. Their user-friendly operation, constant-speed synchonized drive and long service life make them the optimum solution for continuous take-off of pipes and profiled parts.

All EXTRUDEX haul-offs carry CE marking certifying full compliance with corresponding EU standards.

BA030 / BA050 / BA100 Belt Haul-Off

-

for continuous take-off of pipes and tubing, suitable for nearly all thermoplastic resins

- For constant-speed removal of thin-wall extruded pipe

- All units mounted on base frame

- Vertically guided belt carriers

- Mechanical or pneumatic contact pressure control for haul-off

- Manual adjustment capability for stroke, height and guide elements

- AC servomotor drive with planetary gearing

- Safety doors with transparent panes and safety shutdown function, Performance Level d

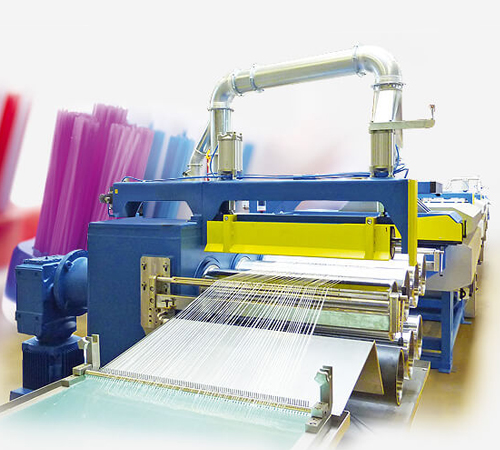

BA030/4, BA030/8 4-Lane/8-Lane Belt Haul-Off

-

for simultaneous take-off of 4 or 8 welding rod strands

4 or 8-lane belt haul-offs- For take-off of multistrand output, e.g. PP or PE welding rods

- Manual adjustment of belt clearance

- Locked covering hood with transparent panes and safeguard enclosure

- Swivel-mounted operator control console

RA160/2 EP Caterpillar Haul-Off

- for continuous take-off of large pipes and profiled parts

EXTRUDEX Vacuum Calibration Baths and Calibration Tables

-

EXTRUDEX develops and manufactures product-specific vacuum calibration baths and calibration tables for superb dimensional control and cooling of thermoplastic tubing and pipes.

All EXTRUDEX vacuum calibration baths and calibration tables carry CE marking certifying full compliance with corresponding EU standards.- Vacuum Calibration Baths and Calibration Tables with high cooling efficiency for dimensional control and cooling of plastic pipes and tubes

- Disc or collar-type calibrator maintains cross-sectional shape while cooling.

- Front-to-back, side-to-side and height adjustment (standard equipment) ensures optimum positioning of calibration unit and problem-free product passage.

- Our fully automated EVS vacuum control system (available as an option) permits optimum process configuration for consistently high product quality and outstanding energy savings.

Vakuum-Kalibrierbad Typ VB150

VB300 / VB600

-

vacuum calibration bath

for cooling and calibration of pipes

ED-KT300/400/600 calibration table

- for calibration of profiled parts, with 12 / 24 flow meters, with top-mounted cooling bath

EXTRUDEX Cooling Stations

-

EXTRUDEX designs and manufactures product-specific immersion and spray cooling baths used to cool thermoplastic tubes, pipes and profiled parts.

All EXTRUDEX cooling stations carry CE marking certifying full compliance with corresponding EU standards.

Our product spectrum includes:-

COOLING BATHS

Spray and Immersion Designss

Cooling uniformity, cooling water temperature and length of the entire cooling path significantly influence the dimensional trueness and quality of the pipe produced.

-

COOLING BATHS

WB300 / WB600 cooling bath

- simple immersion bath

SB200 / SB300 / SB600 spray cooling bath

- for high cooling efficiency

Segmenting Stations & Haul-Off / Segmenting Stations

-

For precise cutting of extruded products

EXTRUDEX offers a broad selection of cutting and segmenting systems to choose from to get the right solution to your specific manufacturing needs.

All EXTRUDEX segmenting stations carry CE marking certifying full compliance with EU regulations.-

GUILLOTINES

for virtually debris and burr-free cutting of tough and semi-rigid strands, pipes, tubes and profiled parts extruded from various resins.

- ROTOCUT

with rotary cutting blades for virtually debris and burr-free cutting, particularly well suited for tough and semi-rigid strands, pipes and profiled parts extruded from various resins..

- SAWS

various models available with compatible debris exhaustors.

- PELLETIZERS

for cylindrical pellet production of thermoplastics with wide-ranging materials properties.

-

GUILLOTINES

PG100 guillotine

-

in standard design for debris and burr-free cutting of tough and semi-rigid material

- Motor-powered precision guillotine.

- Heavy-duty cutting force allows cutting of parts with high cross-sectional area, parts made from semirigid or tough materials and parts incorporating metal lining or reinforcement.

- by means of rodless pneumatic cylinder

- motor-driven linear thrust unit with high-dynamic, high-precision AC servo motor ensuring lowest cut tolerances and cycle times.

DRC010 double rotary cutter

-

for segmenting of small tubes with

- tolerance of +/– 0.2 mm

PS300 / PS400 precision saw

- with debris exhaustor

EXTRU-CUT BC034, BC105

-

for haul-off and segmenting of flexible

and semi-rigid plastic products

Take-Off Stations

-

Custom-designed for your product and process

EXTRUDEX offers in-house developed and fabricated:

TAKE-OFF STATIONS

TRANSPORT AND TAKE-OFF DEVICE

with cross conveyor belt and roller conveyor for sensitive parts

designed to your specifications and adapted to your specific extrusion line and manufacturing requirements for maximum economic efficiency.

All EXTRUDEX take-off stations carry CE marking certifying full compliance with EU regulations.

AT300 / AT600

- tilting table tiltable receiver for segmented pipe sections

Take-off table (custom design)

- Take-off table (custom design) with cross conveyor belt and roller conveyor for sensitive parts

Transport and take-off device

- Transport and take-off device

CONTROL SYSTEMS

EC307 touch-screen control system

-

for extruders and extrusion lines - Based on Sigmatek® Control Panel with integrated PLC

The heart of the control system is the ETV Control Panel (TFT colour touch display) with integrated PLC and real-time capable communication via an Ethernet-based VARAN bus.

The standard version controls up to 7 freely selectable extruders with 15 heating zones each along with a total of 24 heated tooling elements and downstream drives, melt temperatures and melt pressures. The temperatures are shown graphically and in tables and controlled by an integrated 3-point controller with heater current monitoring. All drives can be operated in synchronous operation or by a ramp function.

Additional features:- Storage of process recipes with specified drive, temperature and product parameters

- Self-optimizing temperature controller with weekly timer program and ramp-function integrated pressure-RPM control

- Trend displays with separate scales and simultaneous recording of up to 10 channel inputs (storage capability in CSV files available as option).

- Alarm administration with clear-text displays,alarm journal and additional freely configurable alarms

- Help texts displayed in pdf format; file loading via USB port of control system

- Remote maintenance capability via Ethernet / Internet

- Interfaces to external control units and systems such as Ethernet, PROFIBUS and CAN available if required

- Access authoization to screen pages by different password levels

- Available screen sizes: 8", 12", 15", 19"

SC300 touch-screen control system

-

For extruders and extrusion lines - based on Siemens S7 with Siemens Multi Panel touchscreen

The heart of the control system is the Multi Panel (TFT colour touch display) with integrated soft PLC and real-time capable communication via PROFIBUS. The standard version controls up to 6 freely selectable drive units, 32 heating zones, melt temperatures and melt pressures. The temperatures are shown graphically and in tables and controlled by a remote 3-point controller. All drives can be operated in synchronous operation.

Additional features:- Storage of process recipes with machine and product parameters

- Self-optimizing heater current monitoring with weekly timer program for heater zones

- Integrated pressure - RPM control

- Trend displays with separate scales and simultaneous recording of up to 8 channel inputs

- Alarm administration with clear-text displays, alarm journal and 6 freely configurable alarms

- Remote maintenance capability via Teleservice modem available as option

- Interfaces to external control units and systems such as PROFINET and PROFIBUS available if required

- Access authoization to screen pages by different password levels

- Available screen sizes: 12", 15", 19"

- SIMATIC industrial-grade PC 427D with Industrial Flat Panel can be used as alternative hardware

- Data logging in CSV format is available as an optional feature.

- All EXTRUDEX machines and equipment carry CE marking certifying full compliance with corresponding EU standards.

Screws, Dies, Distributors and Calibration Stations

-

EXTRUDEX designs and manufactures extruder screws and barrels in standard and custom designs which set highest standards in thermoplastics processing. All EXTRUDEX products carry CE marking certifying full compliance with corresponding EU standards.

Screws

-

- The product portfolio offered includes a broad spectrum of screw types and designs

- in diameters from 10 mm to over 150 mm and

- lengths up to 4500 mm.

- Advanced coatings with hardness up to 68–71 HRC (Rockwell "C" hardness) permit processing of even difficult-to-plastify resins.

Calibrators

-

Disc and collar calibrators, block calibrators and specialty products such as iris-aperture calibrators for medical microtubing.

- Brass and stainless steel calibrators for pipes in O.D. range 16 - 160 mm

- Disc calibrators for pipes in O.D. range 6 - 25 mm

- Brass sleeve calibrators with intensive inlet cooling

- 2-part block calibrators for tubing with O.D. < 5 mm

- Iris diaphragm calibrators for medical microtubing

- PlexiglasTM pre-chambers for calibration before vacuum-tank spray cooling.

EXTRUDEX Accessories

-

for optimum performance and cost-efficiency in extrusion.

All EXTRUDEX products carry CE marking certifying full compliance with corresponding EU standards.- Ultrasonic wall thickness gauge

- Gravimetric weighing and metering station on main extruder

- EVS closed-loop vacuum control module

- Laser gauge providing up to 3-dimensional measurement, i.e. X-Y-Z axes

- Blower nozzle for pipe drying

- Conveyor for pellet feed into resin hopper

- Ink jet printer for I.D. printing on pipes and parts

- Pellet dryer with control system and dry tank

- Pre-mixer for infeed of mixed resin stocks

EVS closed-loop vacuum control module

Laser gauge for X-Y-Z dimensions

Ultrasonic wall thickness gauge

Gravimetric weighing and metering station on main extruder

Blower nozzle for pipe drying

Conveyor for pellet feed into resin hopper

Ink jet printer for I.D. printing on pipes and parts

Pellet dryer with control system and dry tank

Pre-mixer for infeed of mixed resin stocks