- Offer Profile

-

Kubota Brabender Technologie GmbH is one of the world's leading manufacturers of gravimetric and volumetric feeders for bulk materials such as granulates, powders, liquids, and fibres in all industrial sectors.

The company has over 65 years of expertise in the field of high-precision digital weighing technology and has continuously developed and enhanced its universal and special metering systems, controls, and discharge aids.

Their broad product portfolio consists of Loss-in-weight-feeders, weigh-belt feeders, single and twin-screw feeders, vibratory tray feeders, bulk bag discharge aids for silos and bins, and bulk ingredient mass flow meters.

FLUX Digital

-

Our new online magazine for decision-makers from industry and technology. With FLUX Digital, you can read interesting stories about innovative feeding technologies. We also inform you about all the topics that move us as a company.

Feeders

-

High-tech feeders from Kubota Brabender Technologie

Our broad range of products includes gravimetric and volumetric feeders. We offer various weighing solutions that ensure reliable and accurate feeding of bulk materials. In addition to continuous feeding we offer gain-in-weight batching with our volumetric feeders and loss-in-weight batching with our gravimetric feeders.

Our reliable and accurate gravimetric feeders are ideal for use with a wide range of bulk materials. We manufacture loss-in-weight, weigh belt and volumetric feeders featuring a full range of feed mechanisms and agitation systems including FlexWall technology, hard-sided agitated feeders, single and twin screws, vibratory, fiber feeders, low rate pellet feeders and more. We also offer easy-to-clean solutions allowing for quick product changeovers. All our gravimetric feeders are supplied with state-of-the-art microprocessor-based controls with easy-to-use operator interfaces.

high feed capacity 100 - over 10,000 dm³/h

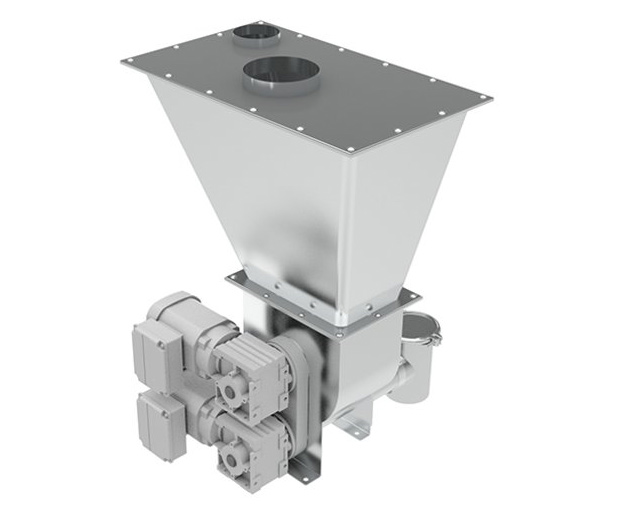

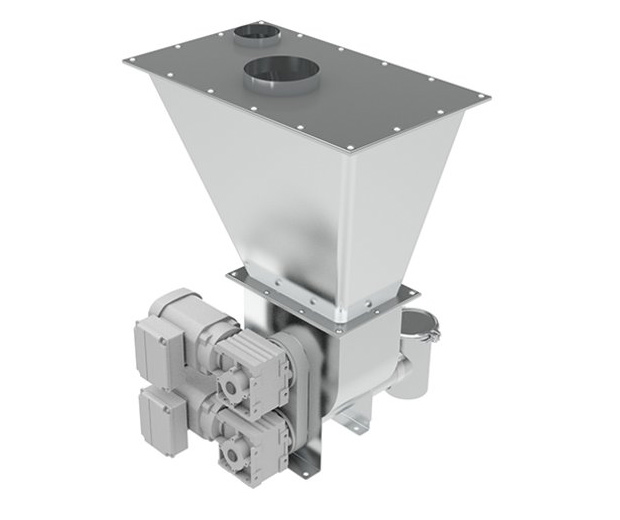

FlexWall®Plus FW80-1

-

FLEXWALL®PLUS LOSS-IN-WEIGHT FEEDER

- Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.)

- Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation

- Compact trapezoidal shape allowing up to 6 feeders to be compactly arranged around a central feed point

- Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

20-7610 dm³/h

FlexWall®Plus FW80-2

-

FLEXWALL®PLUS LOSS-IN-WEIGHT FEEDER

- Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.)

- Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation

- Compact trapezoidal shape allowing up to 6 feeders to be compactly arranged around a central feed point

- Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

20-7610 dm³/h

FlexWall®Plus FW80-6

-

FLEXWALL®PLUS LOSS-IN-WEIGHT FEEDER

- Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.)

- Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation

- Compact trapezoidal shape allowing up to 6 feeders to be compactly arranged around a central feed point

- Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

20-7610 dm³/h

FlexWall®Plus FW80-7

-

FLEXWALL®PLUS LOSS-IN-WEIGHT FEEDER

- Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.)

- Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation

- Compact trapezoidal shape allowing up to 6 feeders to be compactly arranged around a central feed point

- Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

20-7610 dm³/h

FlexWall® FW120-0

-

FLEXWALL®CLASSIC LOSS-IN-WEIGHT FEEDER

- Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.)

- Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation

- Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

- Optional separate paddle motor to allow paddle speed adjustment for difficult flowing ingredients (not available for FW20)

Power range

50-11250 dm³/h

FlexWall® FW120-1

-

FLEXWALL®CLASSIC LOSS-IN-WEIGHT FEEDER

- Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.)

- Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation

- Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

- Optional separate paddle motor to allow paddle speed adjustment for difficult flowing ingredients (not available for FW20)

Power range

50-11250 dm³/h

FlexWall® FW120-2

-

FLEXWALL®CLASSIC LOSS-IN-WEIGHT FEEDER

- Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.)

- Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation

- Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

- Optional separate paddle motor to allow paddle speed adjustment for difficult flowing ingredients (not available for FW20)

Power range

50-11250 dm³/h

FlexWall® FW155-0

-

FLEXWALL®CLASSIC LOSS-IN-WEIGHT FEEDER

- Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.)

- Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation

- Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

- Optional separate paddle motor to allow paddle speed adjustment for difficult flowing ingredients (not available for FW20)

Power range

100-25570 dm³/h

FlexWall® FW155-1

-

FLEXWALL®CLASSIC LOSS-IN-WEIGHT FEEDER

- Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.)

- Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation

- Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

- Optional separate paddle motor to allow paddle speed adjustment for difficult flowing ingredients (not available for FW20)

Power range

100-25570 dm³/h

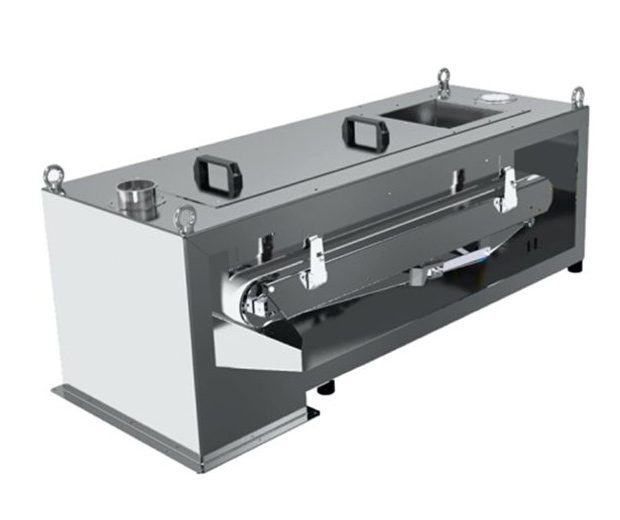

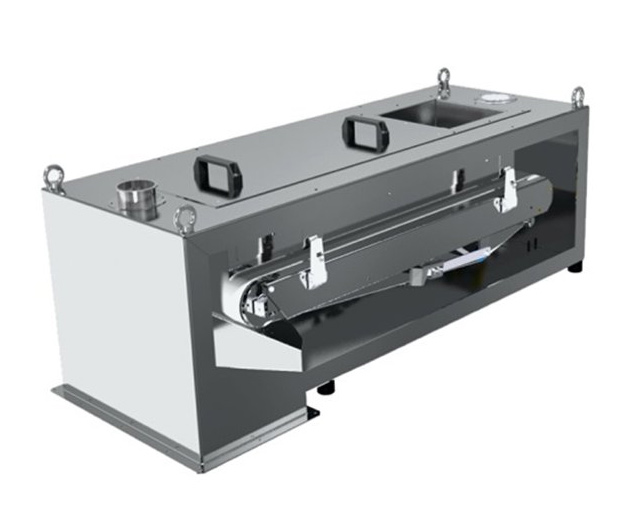

Weight-Belt Feeder DBW800

-

WEIGH-BELT FEEDER

- Weigh-belt feeder for normal to well flowing ingredients

- Stable dust-tight design for harsh industrial conditions

- Removable doors for quick cleaning

- Usable as a continuous or batch-wise metering belt feeder or for throughput metering (operating mode can be changed on the controller)

Power range

500-100000 dm³/h

Coriolis mass flow scale CDW150

-

• dustproof closed compact device

• is suitable for all free-flowing, free-flowing bulk goods

• compact design saves space

More Options:

• explosion-proof designPower range

2000-40000 dm³/h

Liquid Feeder FDDW

-

LOSS-IN-WEIGHT FEEDER FOR LIQUIDS

- Details depend on the characteristics of the medium to be fed (density, viscosity, solids content, temperature, reactivity, toxicological properties, etc.) and the respective process requirements (accuracy, feed rate, turndown ratio, counterpressure, etc.)

- Applicable feed pumps: piston, diaphragm, gear, hose, rotary piston or eccentric screw pumps, etc.

- High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy

- Heated versions available (electrical, hot water, thermal oil, etc.)

Power range

100-10000 dm³/h

FiberXpert FX225

-

LOSS-IN-WEIGHT FIBERXPERT FEEDER

- Loss-in-weight FiberXpert feeder for long and uneven fibers (natural fibers, wood fibers, carbon fibers, etc.)

- Also suitable for film chips and shredded film strips cut off by film edge trimmers

- Technical features: special fiber screw, large steep walled hopper, novel design and special position of the stirring agitator in the hopper

- High-tech weighing system with digital load cell or

high-resolution strain gauge load cell for high weighing accuracy

Power range

200-19900 dm³/h

Vibrating Tray Feeder DVT200

-

VIBRATING TRAY LOSS-IN-WEIGHT FEEDER

- Loss-in-weight feeder for free flowing grained ingredients (pellets, lumpy media, etc.)

- Vibrating tray with electromagnetic vibration drive

- No stirring agitator or other rotating parts for ingredient flow without degradation

- Vibration amplitude feedback ensuring linear conveyance characteristics over the entire feed rate range

Power range

650-6500 dm³/h

Average feed capacity 50 - 5000 dm³/h

FlexWall®Plus FW40-1

-

FLEXWALL®PLUS LOSS-IN-WEIGHT FEEDER

- Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.)

- Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation

- Compact trapezoidal shape allowing up to 6 feeders to be compactly arranged around a central feed point

- Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

4-1075 dm³/h

FlexWall®Plus FW40-2

-

FLEXWALL®PLUS LOSS-IN-WEIGHT FEEDER

- Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.)

- Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation

- Compact trapezoidal shape allowing up to 6 feeders to be compactly arranged around a central feed point

- Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

4-1075 dm³/h

FlexWall®Plus FW40-6

-

FLEXWALL®PLUS LOSS-IN-WEIGHT FEEDER

- Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.)

- Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation

- Compact trapezoidal shape allowing up to 6 feeders to be compactly arranged around a central feed point

- Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

4-1075 dm³/h

FlexWall®Plus FW40-7

-

FLEXWALL®PLUS LOSS-IN-WEIGHT FEEDER

- Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.)

- Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation

- Compact trapezoidal shape allowing up to 6 feeders to be compactly arranged around a central feed point

- Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

4-1075 dm³/h

FlexWall®Plus FW80-5

-

FLEXWALL®PLUS LOSS-IN-WEIGHT FEEDER

- Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.)

- Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation

- Compact trapezoidal shape allowing up to 6 feeders to be compactly arranged around a central feed point

- Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

20-4360 dm³/h

FiberXpert FX120

-

LOSS-IN-WEIGHT FIBERXPERT FEEDER

- Loss-in-weight FiberXpert feeder for long and uneven fibers (natural fibers, wood fibers, carbon fibers, etc.)

- Also suitable for film chips and shredded film strips cut off by film edge trimmers

- Technical features: special fiber screw, large steep walled hopper, novel design and special position of the stirring agitator in the hopper

- High-tech weighing system with digital load cell or

high-resolution strain gauge load cell for high weighing accuracy

Power range

100-3400 dm³/h

Single Screw Feeder DSR67

-

SINGLE SCREW LOSS-IN-WEIGHT FEEDER

- Loss-in-weight feeder for powders and pellets

- Stainless steel hopper with stirring

agitator for consistent screw filling and mass flow of ingredient - Separate screw and agitator motors (3 phase AC gear motors),

except model DSR28 - Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

4-3743 dm³/h

Single Screw Feeder DSR67B

-

SINGLE SCREW LOSS-IN-WEIGHT FEEDER

- Loss-in-weight feeder for powders and pellets

- Stainless steel hopper with stirring

agitator for consistent screw filling and mass flow of ingredient - Separate screw and agitator motors (3 phase AC gear motors),

except model DSR28 - Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

20-3743 dm³/h

Single Screw Feeder DSR103

-

SINGLE SCREW LOSS-IN-WEIGHT FEEDER

- Loss-in-weight feeder for powders and pellets

- Stainless steel hopper with stirring

agitator for consistent screw filling and mass flow of ingredient - Separate screw and agitator motors (3 phase AC gear motors),

except model DSR28 - Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

50-7088 dm³/h

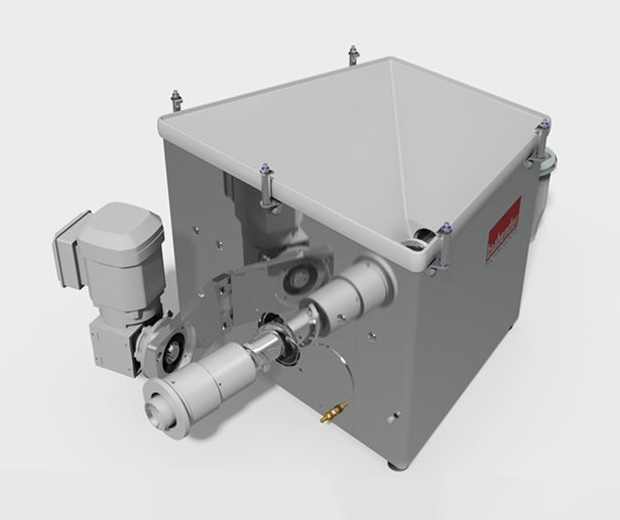

Twin Screw Feeder DDSR40

-

TWIN SCREW LOSS-IN-WEIGHT FEEDER

-

Feeder ideal for difficult flowing, sticky or floodable bulk ingredients at mid feed rates

-

Loss-in-weight feeder for poor flowing or floodable powders

-

Separate screw and agitator motors (3 phase AC gear motors), except models MT and DDSR20

-

Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

4-2693 dm³/h -

Twin Screw Feeder DDSR40B

-

TWIN SCREW LOSS-IN-WEIGHT FEEDER

-

Feeder ideal for difficult flowing, sticky or floodable bulk ingredients that tend to compact or form bridges while at rest in the storage hopper

-

Loss-in-weight feeder for poor flowing or floodable powders

-

Separate screw and agitator motors (3 phase AC gear motors), except models MT and DDSR20

-

Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

20-2693 dm³/h -

Twin Screw Feeder DDSR60

-

TWIN SCREW LOSS-IN-WEIGHT FEEDER

-

Feeder ideal for difficult flowing, sticky or floodable bulk ingredients at mid feed rates

-

Loss-in-weight feeder for poor flowing or floodable powders

-

Separate screw and agitator motors (3 phase AC gear motors), except models MT and DDSR20

-

Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

50-7500 dm³/h -

Vibrating Tray Feeder DVT120

-

VIBRATING TRAY LOSS-IN-WEIGHT FEEDER

- Loss-in-weight feeder for free flowing grained ingredients (pellets, lumpy media, etc.)

- Vibrating tray with electromagnetic vibration drive

- No stirring agitator or other rotating parts for ingredient flow without degradation

- Vibration amplitude feedback ensuring linear conveyance characteristics over the entire feed rate range

Power range

300-3000 dm³/h

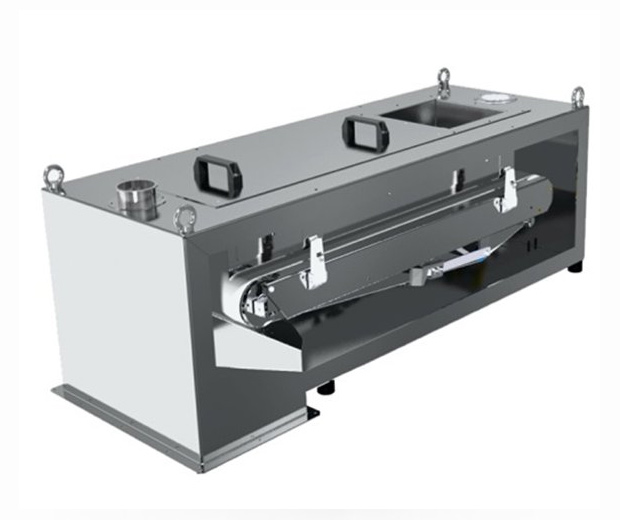

Weight-Belt Feeder DBW600

-

WEIGH-BELT FEEDER

- Weigh-belt feeder for normal to well flowing ingredients

- Stable dust-tight design for harsh industrial conditions

- Removable doors for quick cleaning

- Usable as a continuous or batch-wise metering belt feeder or for throughput metering (operating mode can be changed on the controller)

Power range

200-50000 dm³/h

Liquid Feeder FDDW

-

LOSS-IN-WEIGHT FEEDER FOR LIQUIDS

- Details depend on the characteristics of the medium to be fed (density, viscosity, solids content, temperature, reactivity, toxicological properties, etc.) and the respective process requirements (accuracy, feed rate, turndown ratio, counterpressure, etc.)

- Applicable feed pumps: piston, diaphragm, gear, hose, rotary piston or eccentric screw pumps, etc.

- High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy

- Heated versions available (electrical, hot water, thermal oil, etc.)

Power range

50-5000 dm³/h

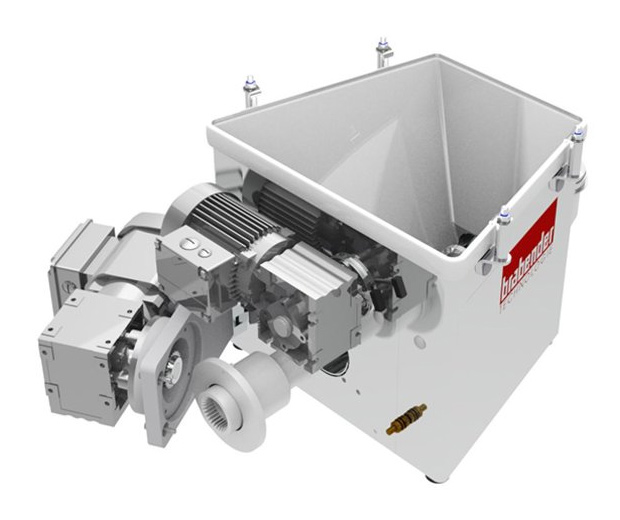

TWIN SCREW FEEDER NXT45M

-

- Handles poor-flowing, sticky powders as well as fibers and pellets

- A special negative angle wall hopper geometry and an diagonal agitator that prevents bridging and ensures optimal bulk material flow into the screw

- Optimized mass flow and a uniform screw fill level

- An add-on hopper for a total bulk storage of 110 dm³ (3.9 cuft)

Power range

10-2000 dm³/h

low feed capacity 1 - 1000 dm³/h

FlexWall® FW20-0

-

FLEXWALL®CLASSIC LOSS-IN-WEIGHT FEEDER

- Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.)

- Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation

- Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

- Easy dismantling for cleaning

Power range

1-75 dm³/h

FlexWall®Plus FW40-5

-

FLEXWALL®PLUS LOSS-IN-WEIGHT FEEDER

- Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.)

- Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation

- Compact trapezoidal shape allowing up to 6 feeders to be compactly arranged around a central feed point

- Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

4-615 dm³/h

FiberXpert FX50

-

LOSS-IN-WEIGHT FIBERXPERT FEEDER

- Loss-in-weight FiberXpert feeder for long and uneven fibers (natural fibers, wood fibers, carbon fibers, etc.)

- Also suitable for film chips and shredded film strips cut off by film edge trimmers

- Technical features: special fiber screw, large steep walled hopper, novel design and special position of the stirring agitator in the hopper

- High-tech weighing system with digital load cell or

high-resolution strain gauge load cell for high weighing accuracy

Power range

5-550 dm³/h

FiberXpert FX80

-

LOSS-IN-WEIGHT FIBERXPERT FEEDER

- Loss-in-weight FiberXpert feeder for long and uneven fibers (natural fibers, wood fibers, carbon fibers, etc.)

- Also suitable for film chips and shredded film strips cut off by film edge trimmers

- Technical features: special fiber screw, large steep walled hopper, novel design and special position of the stirring agitator in the hopper

- High-tech weighing system with digital load cell or

high-resolution strain gauge load cell for high weighing accuracy

Power range

20-1160 dm³/h

Single Screw Feeder DS28

-

SINGLE SCREW LOSS-IN-WEIGHT FEEDER

- Universal gravimetric feeder for granules and free flowing, finegrained ingredients

- Maximum theoretical feed rate approx. 3000 dm³/h

- Easy dismantling for cleaning

- High resolution strain gauge load cell MS6

Power range

5-150 dm³/h

Single Screw Feeder DSR28

-

SINGLE SCREW LOSS-IN-WEIGHT FEEDER

- Loss-in-weight feeder for powders and pellets

- Stainless steel hopper with stirring

agitator for consistent screw filling and mass flow of ingredient - Separate screw and agitator motors (3 phase AC gear motors),

except model DSR28 - Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

1-298 dm³/h

Twin Screw Feeder DDSR20

-

TWIN SCREW LOSS-IN-WEIGHT FEEDER

-

Feeder ideal for difficult flowing, sticky or floodable bulk ingredients at low feed rates

-

Loss-in-weight feeder for poor flowing or floodable powders

-

Separate screw and agitator motors (3 phase AC gear motors), except models MT and DDSR20

-

Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates

Power range

1-489 dm³/h -

Vibrating Tray Feeder DVT45

-

VIBRATING TRAY LOSS-IN-WEIGHT FEEDER

- Loss-in-weight feeder for free flowing grained ingredients (pellets, lumpy media, etc.)

- Vibrating tray with electromagnetic vibration drive

- No stirring agitator or other rotating parts for ingredient flow without degradation

- Vibration amplitude feedback ensuring linear conveyance characteristics over the entire feed rate range

Power range

10-450 dm³/h

Vibrating Tray Feeder DVT60

-

VIBRATING TRAY LOSS-IN-WEIGHT FEEDER

- Loss-in-weight feeder for free flowing grained ingredients (pellets, lumpy media, etc.)

- Vibrating tray with electromagnetic vibration drive

- No stirring agitator or other rotating parts for ingredient flow without degradation

- Vibration amplitude feedback ensuring linear conveyance characteristics over the entire feed rate range

Power range

20-1000 dm³/h

Weight-Belt Feeder DBW350

-

WEIGH-BELT FEEDER

- Weigh-belt feeder for normal to well flowing ingredients

- Stable dust-tight design for harsh industrial conditions

- Removable doors for quick cleaning

- Usable as a continuous or batch-wise metering belt feeder or for throughput metering (operating mode can be changed on the controller)

Power range

100-20000 dm³/h

MiniTwin MT

-

LABORATORY LOSS-IN-WEIGHT FEEDERS

- Small-size twin screw feeder for powders or rotary tube feeder for pellets and fine-grained media

- Feed rates as low as a few grams per hour

- High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy

Power range

1-5 dm³/h

Laboratory Feeder RotoTube

-

LABORATORY LOSS-IN-WEIGHT FEEDERS

- Small-size twin screw feeder for powders or rotary tube feeder for pellets and fine-grained media

- Feed rates as low as a few grams per hour

- High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy

Power range

1-5 dm³/h

Liquid Feeder FDDW

-

LOSS-IN-WEIGHT FEEDER FOR LIQUIDS

- Details depend on the characteristics of the medium to be fed (density, viscosity, solids content, temperature, reactivity, toxicological properties, etc.) and the respective process requirements (accuracy, feed rate, turndown ratio, counterpressure, etc.)

- Applicable feed pumps: piston, diaphragm, gear, hose, rotary piston or eccentric screw pumps, etc.

- High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy

- Heated versions available (electrical, hot water, thermal oil, etc.)

Power range

1-1000 dm³/h

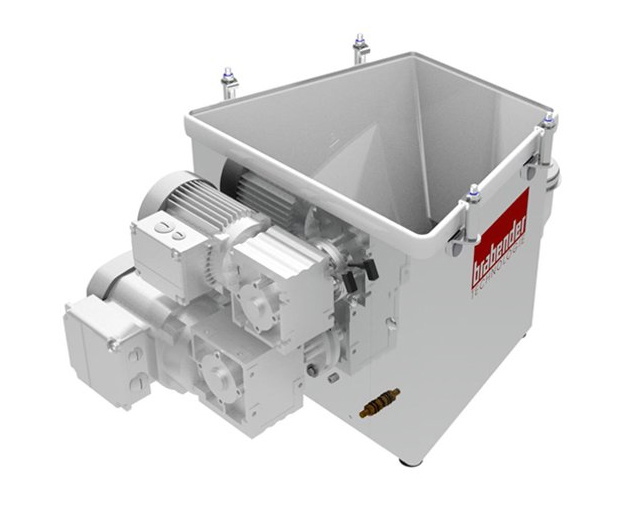

TWIN SCREW FEEDER NXT26

-

TWIN SCREW FEEDER NXT26

- Handles poor-flowing, sticky powders as well as fibers and pellets

- A special negative angle wall hopper geometry and an diagonal agitator that prevents bridging and ensures optimal bulk material flow into the screw

- Optimized mass flow and a uniform screw fill level

- An add-on hopper for a total bulk storage of 50 dm³ (1.8 cuft)

Power range

1-700 dm³/h

Discharging made easy

-

The flow characteristics of bulk materials differ substantially, depending on their composition. This can be observed when bulk materials come into storage and especially when they are discharged. If a bulk material is compacted, for example when being discharged from a silo, this can delay the entire production process. Discharge aids are therefore vital, because they enable bulk materials to flow off continuously and consistently.

Discharging of stored bulk materials is critical and can be challenging as they have many different flow characteristics. It is vital to reliably discharge ingredients from silos or bins to ensure uninterrupted process flow.

Brabender Technologie can provide you with a comprehensive range of discharging solutions specifically developed to discharge a wide range of ingredients. Our discharging equipment is ideal for ensuring reliable and consistent output from sacks, bulk bags, silos and bins even with poor flowing ingredients.

BagDumper

-

AG DUMPING WITH THE BRABENDER BAG DUMP STATION "BAG DUMPER"

- Modular bag dump stationallowing flexible configuration

- Comprehensive variety ofoptions available including:

- integral bin activator "BAV"

for poor flowing ingredients - Integral metering feeder

- glove box design for dusty

or toxic ingredients allowing

dust-free bag emptying inside

the closed bag dumper - others

- integral bin activator "BAV"

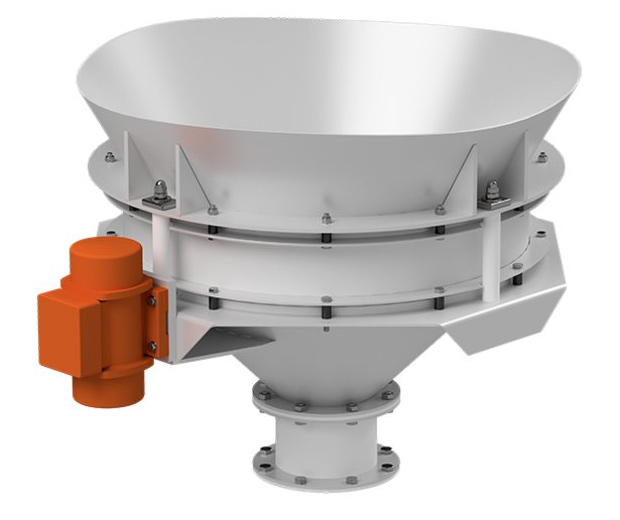

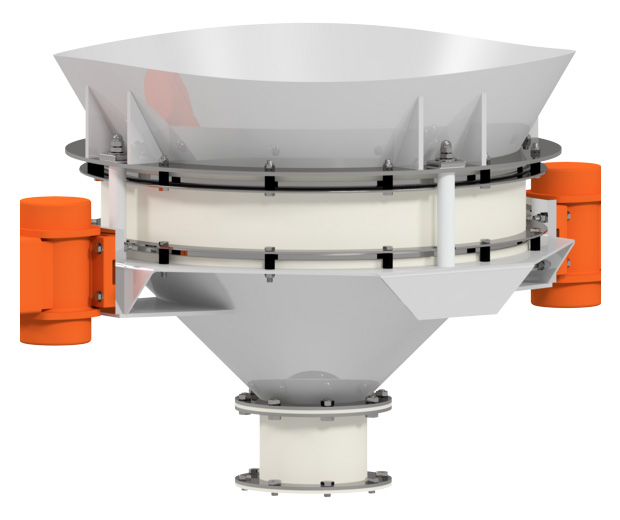

BAV 604

-

DISCHARGE FROM SILOS AND BINS WITH THE BRABENDER BIN ACTIVATOR "BAV"

- Vibratory bin activatorfor silos and bins

- Compaction-free "first in – first out" discharge

- Ideal for consistent refilling of downstream metering or conveying equipment

- Suitable for silos made of mild steel, stainless steel, aluminium or plastic

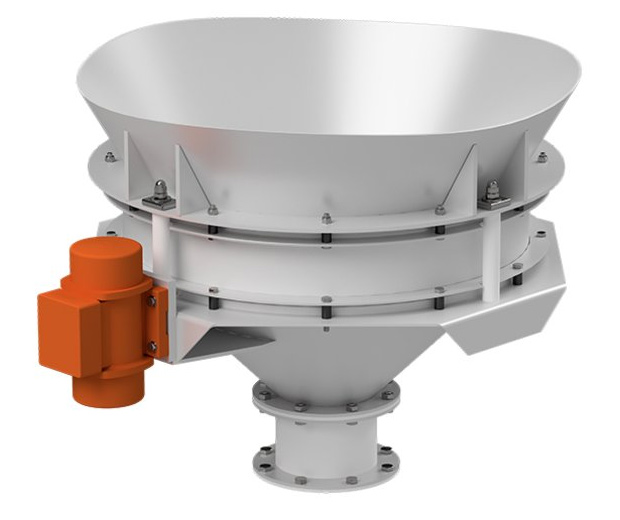

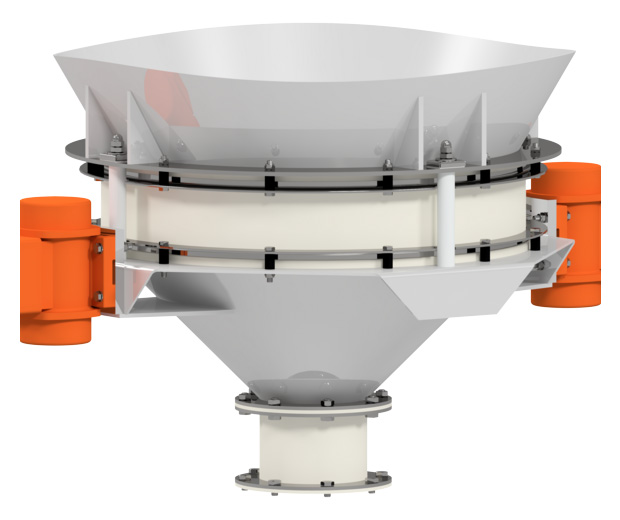

BAV 904

-

DISCHARGE FROM SILOS AND BINS WITH THE BRABENDER BIN ACTIVATOR "BAV"

- Vibratory bin activatorfor silos and bins

- Compaction-free "first in – first out" discharge

- Ideal for consistent refilling of downstream metering or conveying equipment

- Suitable for silos made of mild steel, stainless steel, aluminium or plastic

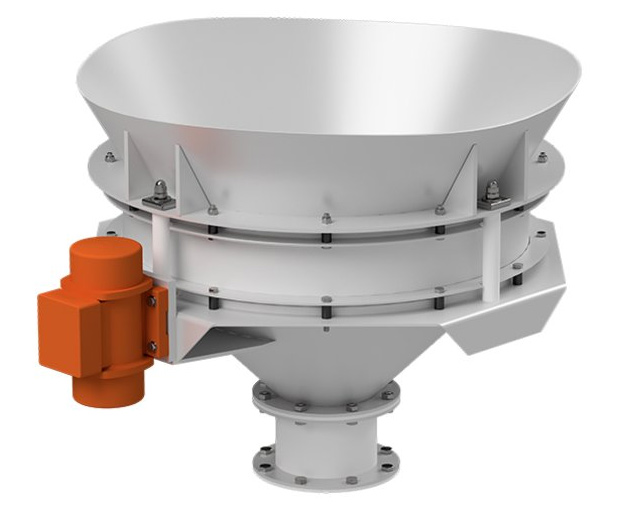

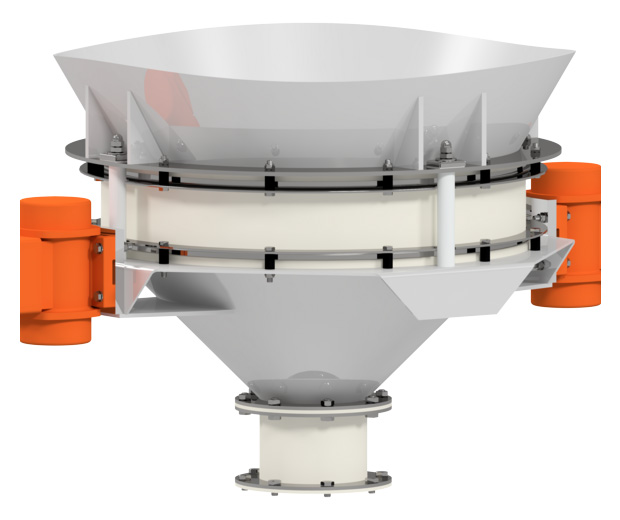

BAV 1204

-

DISCHARGE FROM SILOS AND BINS WITH THE BRABENDER BIN ACTIVATOR "BAV"

- Vibratory bin activatorfor silos and bins

- Compaction-free "first in – first out" discharge

- Ideal for consistent refilling of downstream metering or conveying equipment

- Suitable for silos made of mild steel, stainless steel, aluminium or plastic

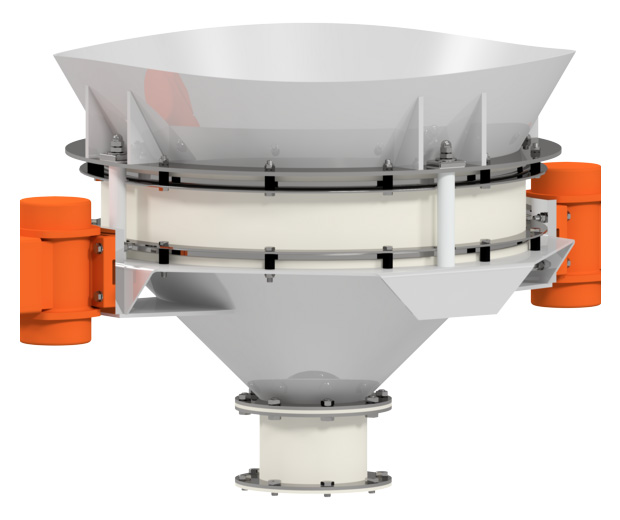

BAV 1504

-

DISCHARGE FROM SILOS AND BINS WITH THE BRABENDER BIN ACTIVATOR "BAV"

- Vibratory bin activatorfor silos and bins

- Compaction-free "first in – first out" discharge

- Ideal for consistent refilling of downstream metering or conveying equipment

- Suitable for silos made of mild steel, stainless steel, aluminium or plastic

BAV 1804

-

DISCHARGE FROM SILOS AND BINS WITH THE BRABENDER BIN ACTIVATOR "BAV"

- Vibratory bin activatorfor silos and bins

- Compaction-free "first in – first out" discharge

- Ideal for consistent refilling of downstream metering or conveying equipment

- Suitable for silos made of mild steel, stainless steel, aluminium or plastic

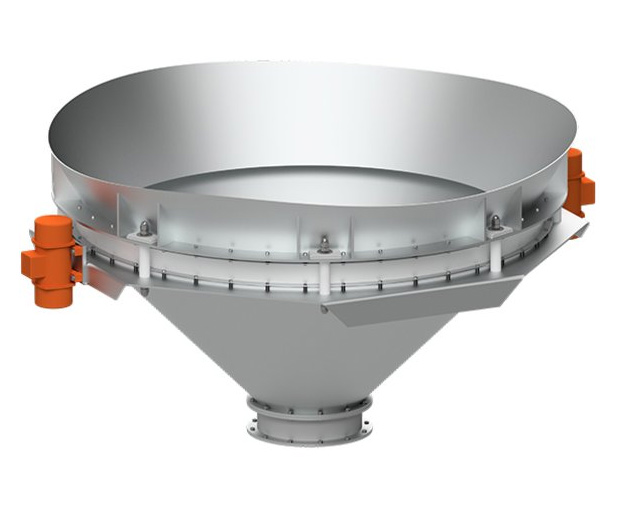

SiloTray 604

-

CONTROLLED DISCHARGE FROM SILOS AND BINS WITH THE BRABENDER METERING BIN ACTIVATOR "SILOTRAY"

- Vibratory metering bin activator for silos and bins with variable speed unbalance motors

- Compaction-free "first in – first out" discharge

- Controlled discharge or volumetric metering

- Ideal for consistent refilling of downstream metering or conveying equipment at a defined rate

SiloTray 1204

-

CONTROLLED DISCHARGE FROM SILOS AND BINS WITH THE BRABENDER METERING BIN ACTIVATOR "SILOTRAY"

- Vibratory metering bin activator for silos and bins with variable speed unbalance motors

- Compaction-free "first in – first out" discharge

- Controlled discharge or volumetric metering

- Ideal for consistent refilling of downstream metering or conveying equipment at a defined rate

SiloTray 1504

-

CONTROLLED DISCHARGE FROM SILOS AND BINS WITH THE BRABENDER METERING BIN ACTIVATOR "SILOTRAY"

- Vibratory metering bin activator for silos and bins with variable speed unbalance motors

- Compaction-free "first in – first out" discharge

- Controlled discharge or volumetric metering

- Ideal for consistent refilling of downstream metering or conveying equipment at a defined rate

BagMaster

-

DISCHARGE FROM FELEXIBLEINTERMEDIATE BULK CONTAINERS WITH THE BRABENDER BULK BAG UNLOADER "BAGMASTER"

- Bulk bag unloader for lined and unlined bulk bags

- Twin paddle massage mechanism promoting reliable complete discharge even of poor flowing ingredients

- Rigging frame for easy bag loading

- Quick docking system for dust-free connection of the bag or liner outlet

SiloTray 904

-

CONTROLLED DISCHARGE FROM SILOS AND BINS WITH THE BRABENDER METERING BIN ACTIVATOR "SILOTRAY"

- Vibratory metering bin activator for silos and bins with variable speed unbalance motors

- Compaction-free "first in – first out" discharge

- Controlled discharge or volumetric metering

- Ideal for consistent refilling of downstream metering or conveying equipment at a defined rate