- Offer Profile

-

Kadant PAAL is a leading manufacturer of baling presses, specializing in the design and manufacture of high-performance balers and ancillary equipment.

Kadant PAAL concentrates on developing and manufacturing high-performance baling presses presses and compaction equipment of the highest quality. The focus on quality and reliability within Kadant PAAL takes high priority at every stage of the production process from development to assembly. The high performance and long service lives of our products, as well as their high levels of availability at low running costs, help our customers to be extremely competitive in their markets.

Balers and conveyors for every application

- Established designs tried and tested in thousands of installations. Robust construction combined with the latest cutting-edge technology Kadant PAAL: where tradition meets technology.

Balers

- For more than 150 years, our robust and advanced designs have delivered unrivalled performance and reliability at the lowest possible cost of ownership.

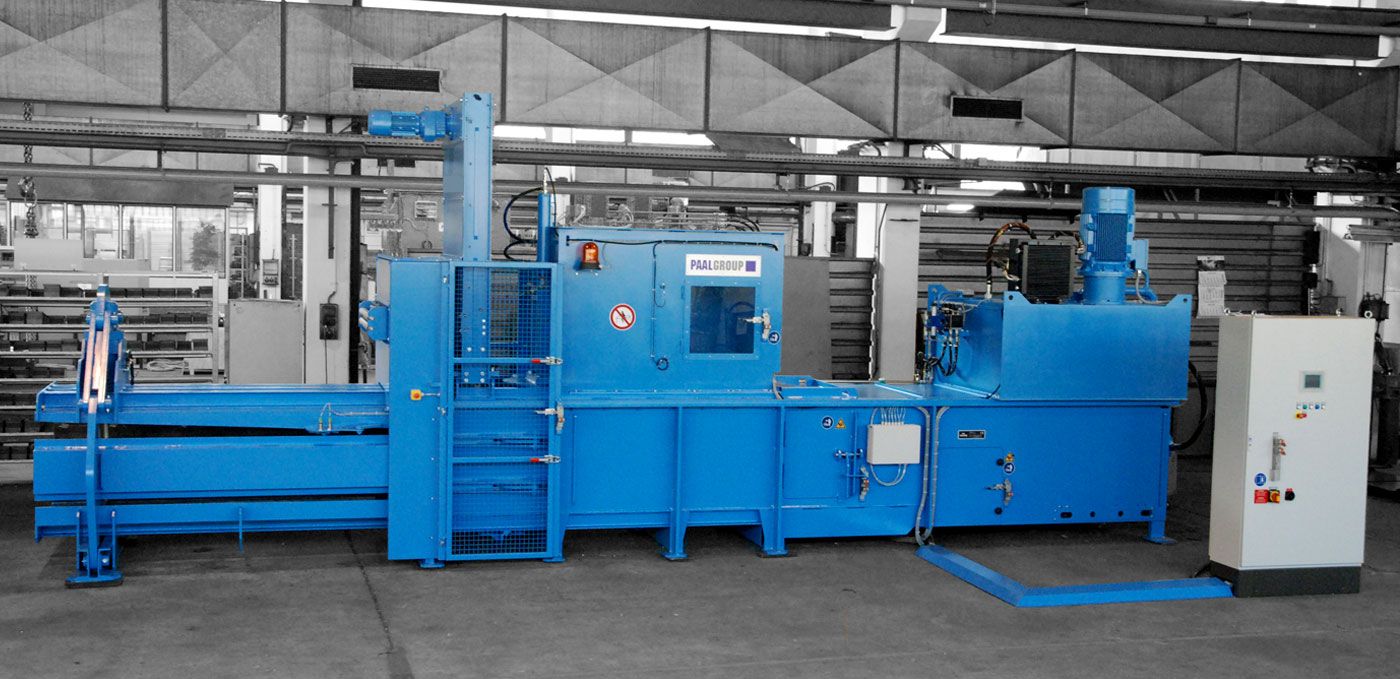

KONTI SERIES

-

Kadant PAAL’s KONTI automatic channel baler delivers high throughput and bale weights with low energy consumption.

The PAAL KONTI range is offered with either a vertical tie, horizontal tie, or with a cross tie option for more difficult material. The PAAL KONTI balers can be supplied with pre-baling options such as a ruffler or perforator to maximize performance with particular material types.

The robust construction of the KONTI balers delivers optimum performance and reliability, even under the most demanding operating conditions.

Features

- Optimized knife, stamper, and channel design

- Modern axial piston pumps with low drive power

- Advanced positional ram measurement system

- Large doors on both sides of the press chamber and at the rear section of the baler

- PLC offering remote access and service as well as high resolution operator panel

Benefits

- High throughput and bale weights

- Low energy consumption

- Easy access to tying unit via optional ladder to three-sided platform

- Simple operation and maintenance

- Low total cost of ownership

S1W SERIES

-

Kadant PAAL’s S1W fully automatic baler is designed to press tin and aluminium cans into highly compressed packages.

These highly efficient balers are renowned for their robust construction, high performance, and long service lives.

Features

- Compact design

- High specific pressing force

- Bolted, high-resistant wear steel plates

- Automatic, hydraulically operated tunnel door is self-cleaning via an “intelligent” control

Benefits

- Small footprint

- High bale density

- Quick and easy replacement of wear plates

- Long service life, reduced maintenance

PACOMAT SERIES

-

Kadant PAAL’s range of PACOMAT channel baling presses, which is offered with either vertical or horizontal wire tying, is the ideal baler for most grades of paper, cardboard, cartons, foils, and many other materials.

The PACOMAT range of balers is robust and fully automatic yet the PACOMAT is also an affordable and cost-effective baler option.

Features

- Optimized knife, stamper, and channel design

- Modern axial piston pumps with low drive power

- Densitronic control system for tunnel adjustment

- Modular feeding concept

Benefits

- High throughput and bale weights

- Low energy consumption

- Quick response to various material grades

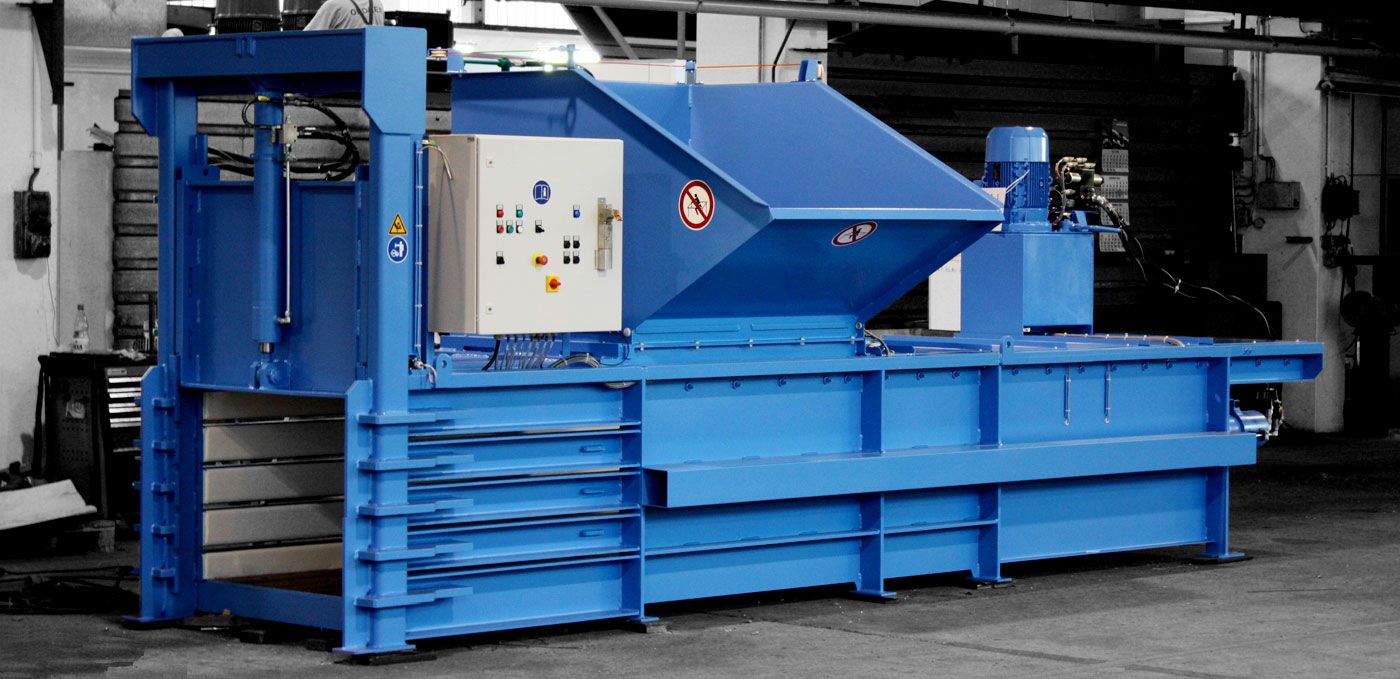

PAC SERIES

-

Kadant PAAL’s PAC baler is a semi-automatic, closed end baler with manual horizontal tying.

The PAAL PAC series of balers is designed to process a wide range of materials such as paper, cardboard, PET bottles, foam, aluminium cans, and much more. The PAC series includes a vertical sliding door that is designed for manual strapping of the bales with wire in a horizontal direction.

The PAC has a small footprint due to the vertical, hydraulically operated door, but still incorporates full bale ejection (very long ram stroke). The ejection of the finished bales is made easy with full bale ejection rather than machines with only partial ejection. With the choice of hopper designs and motor sizes and with a wide range of other options, the PAC series machines represent great value for the money but with the capacity to process sufficient volumes/tonnages.

Features

- Low space requirement due to compact construction and portcullis ejection door

- High bale weights by compaction against the closed ejection door

- Easy operation and simplified maintenance thanks to Siemens S7 controls

- Hydraulically operated tunnel door for easy bale ejection

Benefits

- Small footprint

- Easy ejection of finished bales

DOKON SERIES

-

Kadant PAAL’s DOKON, with polypropylene twine tie, is the only high performance, fully automatic channel baler in the market to offer consistent and reliable operation with a horizontal twine tying system.

The PAAL DOKON range of balers provides pressing forces of between 80 and 200 tonne with bale formats of either 800 x 1100, or 1100 x 1100 mm. Unlike steel-tied bales, a DOKON bale is ideal for wrapping (no sharp edges) and for incineration as the twine burns.

Features

- Optimized knife, stamper, and channel design

- Modern axial piston pumps with low drive power

- Advanced positional ram measurement system

- Twine tying

Benefits

- High throughput and bale weights

- Low energy consumption

- Low operating costs

- Easy transport, storage, and handling

- Safer operating and handling conditions

HTR SERIES

-

Kadant PAAL’s HTR baler is a fully automatic, high-compaction two-ram baler offered with a plastic strap tying system and a patented telescopic tunnel for maximum throughputs.

The multipurpose baler is capable of baling municipal solid waste (MSW), refuse derived fuel (RDF), and agriculture material (including alfalfa, grass, and straw) as well as the full range of recyclable materials.

Features

- Polyester straps

- Patented telescopic tunnel design

- High bale density

- Range of machines with high specific pressing force developed for the agricultural market

Benefits

- Increased throughput – the strapping process can be carried out at the same time as the next bale is being compacted

- Reduced operating cost

Conveyors

- Kadant PAAL’s chain conveyor is characterized by its stable construction and is well suited for transporting all types of press material.

CHAIN CONVEYOR

-

Kadant PAAL’s chain conveyor is characterized by its robust and stable construction which delivers reliable performance to maximize the baler’s output and efficiency.

Kadant PAAL’s KEF series of conveyors are solid, high-performance chain conveyors optimized for feeding balers with recyclable and non-recyclable material. The conveyor consists of a durable frame with lateral side walls, rubber belt, drive, and stretching device station. Widths range from 1000 to 1900mm, with drives from 1.5 to 15kW.

Features

- Modular frame

- High vertical side pieces

- Extra-large chain wheels

- Robust chains with belt support profiles

- Rubber conveyor belt

- Changeable, bolted chain guides

- Access doors

Benefits

- Smooth, efficient running

- Ease of maintenance