- Offer Profile

-

DELTARAY offers disruptive 3D X-RAY equipment for 100% inspection of mission critical mechanical parts:AI enabled - 10 to 100 times faster - detection at production speed - CAD file as quality master – form fit inspection at 100 to 50um resolution.Our full system approach, hardware, software & services, is a perfect fit to the industrial needs of product manufacturers.

DELTARAY is a recent tech startup, founded in BE-Flanders on July 4th 2019, with the ambition to become the new class leader in the market of Quality 4.0 inspection. We offer turnkey inspection solutions to zero defect industry leaders as the missing link in their Industry 4.0 approach.

Our technology originating from Imec and the university of Antwerp brings uncompromised detection beyond the human eye.

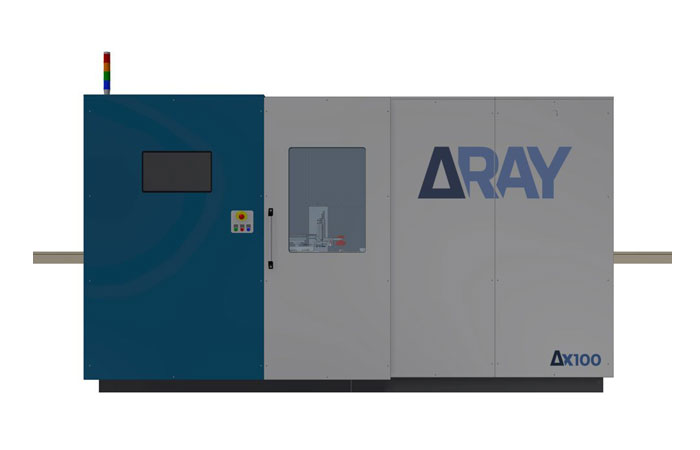

Deltaray in-line quality inspection.

Accelerated 3D XRAY

DELTARAY offers disruptive 3D X-RAY equipment for 100% inspection of mission critical mechanical parts: AI enabled - 10 to 100 times faster - detection at production speed - CAD file as quality master – form fit inspection at 100 to 50um resolution. Our full system approach, hardware, software & services, is a perfect fit to the industrial needs of product manufacturers. Do it right the first time.Why Choose Us

Inspection beyond the human eye. Uncompromised detection precision and speed.- In-line

Designed for integration, in-line or near-line on the production floor. - Speed

Zone of interest inspection with an accuracy from 100 to 50um. The speed can be further increased using multiple scans in parallel. - Automation

Automation through robotised parts handling and fully automated workflows.

- In-line

A quest for perfection

- Deltaray’s accelerated 3D Xray delivers uncompromised capabilities for zero defect manufacturers. Zero defect manufacturers face a daily struggle to assure the quality for their customers. Closing the gap between increasing parts complexity and current inspection capabilities puts pressure on companies profitability. Increasing the sample rate or adding 100% inspection by human eyes is not the right answer to zero defect manufacturing.

Deltaray Solutions

- Accelerated 3D Xray inspection covers a wide range of applications from critical parts to complex assemblies. Our systems are tuned to meet industry specific requirements and come with a fully automated workflow.

Hardware

- ∆X100 Automative

- ∆X200

Medical/Pharma - ∆X300

Additive Manufacturing Complex Assemblies - ∆Xi

3D XRAY kit for system integrators/OEM

Software

- CAD-REF

Using your CAD file as the master for form fitt inspections.

A unique method enabling engineering and quality to go hand in hand. Offering in one step a one on one comparison between the design and the production of a part at the highest precision. - MINING 4.0

Predict and prevent.

Data driven analytics for quality assurance to control and to improve your production processes.

Assisting production teams to predict the next maintenance intervention, prevent potential failures, identify process improvements. - REPORTS

Often quality teams remain occupied with solving yesterday’s quality problems.

Deltaray inspects all parts in real time and automatically generates inspection data per part.

Productivity dashboard for management to monitor performance to achieve company goals and satisfy customers.

Inspection dashboard used by the quality department for compliancy and traceability purposes to achieve their Quality 4.0 objectives. - DISTRIBUTE

Reports made available across departments and for quality reporting to customers. - ARCHIVE

Interface tool, allowing a dynamic interaction with your own digital archive system, to store and query all your inspection data and set up files.

- CAD-REF

Deltaray Services

- Deltaray is committed to help you become successful. Our excellence does not lie solely in the uniqueness of our technology. The quality of our services post installation is just as important. Our experts help ensure maximum uptime and productivity of your system. Deltaray support reflects normal country business hours in your time zone.

- CARE

Deltaray Customer Care Centre, single point of contact for immediate assistance. Registered customers get online support and personal attention from our experts.- Responsibilities of our care centre:

- Call logging

- Severity assignment

- TeamViewer diagnostics sessions

- Remote problem solving

- Application tips and support

- ON-SITE

Get the best care possible and avoid problems before they occur. Become a registered customer and sign up for a Deltaray service agreement.- Comprehensive range of services:

- Scheduled preventive maintenance visits

- Preventive diagnostics

- Spare parts and logistics

- Onsite maintenance

- New software releases

- TRANSFER

Billable services to support your conversion to Quality 4.0 to complement your in-house expertise. Deltaray offers knowledge transfer services.- Our knowledge transfer focus:

- Feasibility of new inspection techniques

- Development of tailored inspection solutions

- Deployment of 100% inspection

- Training for operator and quality staff

- Continuous improvement cycle

- CARE

Industries We Serve

Automative

- Quality Control

Customers in automotive require zero defect products. Meeting the right standards all of the time is mandatory to staying successful and avoiding claims. Delivering consistently high quality in the ever-changing automotive industry is essential. - 100% Inspection

Current 3D inspection methods are only suitable for sample inspections. As a result, there is no full trace on the quality level of delivered parts. Defects detected by your customer can have a huge impact on your profitability and your reputation. -

Predict & Prevent

A system is needed that allows quality engineers to analyse production quality, predicting in real time failure points in preceding process steps. A proactive approach is the way forward for Industry 4.0 leaders. - Profitability

Investing in high quality inspection tools is often perceived as expensive. However, the financial gain will be achieved sooner than expected. Please use our ROI (Return on Inspection) tool to calculate your potential return. - Deltaray

Our Quality 4.0 inspection system is using accelerated 3D XRAY. A disruptive AI inspection solution to introduce 100% inspection where sampling based methods are still used today. Deltaray is offering full 3D inspection at production speed using a digital twin to verify the quality of all parts produced at the precision level desired by your customers.

- Quality Control

Medical - Pharma

- Quality assurance

Assuring full compliance is required in the medical / pharmaceutical industry. Products are not sold nor supplied before the production processes are fully certified so that each production batch is produced and controlled fitting the requirements agreed with the regulatory bodies. - 100% Inspection

Good manufacturing practices enable quality assurance to ensure that all products are consistently produced and controlled to the quality standards appropriate to their intended use. Often producers resort to 100% inspection by the human eye which is error prone. Aiming for 100% automated inspection is the challenge. - Traceability

Internal and external audits are challenging for your organisation. Providing evidence to demonstrate conformity to customers and regulatory bodies are time consuming and stressful activities for the organisation. Ensuring full quality transparency is essential. - Profitability

Prevention of major compliance issues can avoid huge costs. Recalls damage the company’s trustworthiness and has a negative impact on the bottom line. Investing in Deltaray solutions will help you to prevent these dramatic scenarios. - Deltaray

Our Quality 4.0 inspection system is using accelerated 3D XRAY. A disruptive AI inspection solution to introduce 100% inspection beyond the human eye. With our automated solution there is no need to compromise on quality, whilst our ∆Reports will shorten your preparation time for successful audit.

- Quality assurance

Additive Manufacturing

- Inspection methods

Additive manufacturing, also known as 3D printing, is a transformative approach to industrial production enabling the creation of stronger parts at lower weight combining a mix of materials. The available additive manufacturing processes used are each challenging to control and require a new approach to quality inspection. - Product quality assurance

Additive manufacturing excels in producing critical parts for different industries like Aerospace, Automotive, Healthcare and much more. Introducing new CAD tools creating almost unlimited possibilities. At the same time each industry imposes their own safety approval criteria and compliancy processes, requiring specific quality evidence and tailored reporting. - Inspect ability

As the Additive manufacturing technologies continue to advance and mature, the inspection methods for the complex shapes you can print need to follow. To solve this inspection puzzle AI based 3D inspection is the path forward. - Profitability

Using Additive manufacturing to get more functionality for demanding, harsh and complex environments is revolutionary and very promising. At the same time this trend increases the liabilities of Additive manufacturers and urges the usage of advanced inspection methods. Deltaray will help you to manage your risks. Please use our ∆ROI (Return on Inspection) tool to calculate your potential financial returns. - Deltaray

The same way as Additive manufacturing is revolutionising manufacturing, Deltaray is revolutionising inspection by using the same CAD file to inspect your printed objects. Our Quality 4.0 inspection system is using Accelerated 3D XRAY, a fully automated and AI based inspection solution. Our ∆Reports will provide the necessary evidence for successful quality audits.

- Inspection methods

Critical Assemblies

- Assembly process

Assemblies, packaging, and kitting applications exist in virtually every manufacturing industry. Quality inspection of an assembly goes beyond individual parts inspection. The assembly method itself can create its own failures. Challenges during this process, like relative positioning, mounting completeness, mounting damages, contamination, sealing etc, can be the root cause for waste and customer complaints. - Inspection Challenge

The inside matters. To the detriment of overall quality inspection critical assemblies are mainly inspected by vision inspection during the assembly process. 3D XRAY is the path forward. Our ‘zone of interest’ functionality uses a deep learning neural network to detect all defects in complex assemblies. It is the next step for leaders on their Industry 4.0 journey. - 100% inspection

Sample inspections cannot assure that all assemblies fit their purpose and cannot offer full traceability on the quality level delivered to customers. Malfunctioning assemblies detected by your customer can have a huge impact on the company profitability and reputation. - Profitability

Investing in high quality inspection tools is often perceived as expensive. However, the financial gain will be achieved sooner than expected. Please use our ROI (Return on Inspection) tool to calculate your potential return. - Deltaray

Our adaptive methods use 3D XRAY with zone of interests defined by a deep learning neural network to do 100% inspection in real time. Our ∆Reports will provide the necessary evidence for successful quality audits.

- Assembly process

We can help you grow your ROI by growing your Return On Inspection!

- Calculate the negative impact on the company profitability for not doing it right the first time. Quality inspection quantified and translated in financial terms.

Process

Survey & samples

- Validation of our inspection capabilities for your production by scanning a representative sample. You will receive detailed feedback of our inspection results. This part of the process will run under a signed NDA document.

Offer & method

- Based on the results of the survey & sample analyses we can define the correct configuration of our equipment for your inspection applications and make you a price proposal.

Build & calibrate

- We have a build-to-order strategy. Once your down payment is received, your system will be built in our factory. The system will be tested and calibrated prior to shipping.

Installation and validation

- Prior to the installation our specialist will come onsite to kick off the installation project to prepare for a smooth and professional installation. He will collaborate with you to create a plan with defined roles, responsibilities and a clear timeline. Based on the site readiness confirmation from the customer the final installation date will be agreed. A typical installation will take 5 working days including testing.

Knowledge transfer & training

- An important part of the installation completion is the training of the operators. The operator training will be delivered onsite in agreement with the customer. The completion of the training is also the end of the installation project.

Operate & service

- Our Deltaray specialists are available to assist you remotely during working days. They can be contacted via our customer contact centre and will be available online to provide you with advice or to start a remote diagnostics session to solve any issues.