LumaSense

Videos

Loading the player ...

- Offer Profile

- LumaSense Technologies, Inc.® is one of the world's most trusted providers of innovative temperature and gas sensing devices. By applying LumaSense's proven systems and software, customers in Global Energy, Industrial Materials, Advanced Technologies, and Other Markets are able to reduce waste and inefficiency in their processes.

Product Portfolio

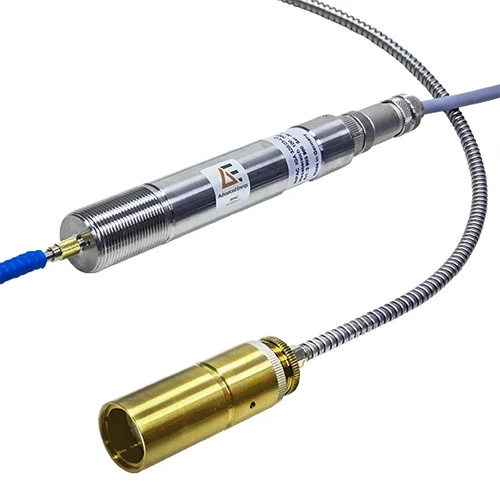

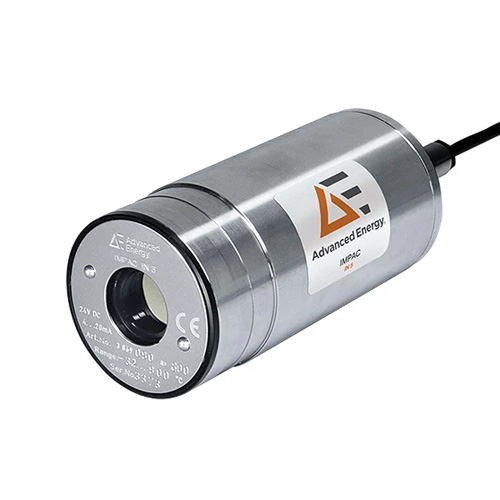

Infrared Thermometers (Pyrometers)

- Highly Accurate Infrared Thermometers for

Non-contact Temperature Measurements

Pyrometers are temperature measurement instruments that operate on the principle of infrared radiation, i.e. they detect infrared radiation of objects to determine the temperature.

In many industry sectors, the use of non-contact temperature measurement instruments is an important technology. For example, it is used for controlling complete factory processes or measuring even the smallest components to ensure a consistent quality level.

With a huge pyrometer product portfolio developed from years of research and customer contact, LumaSense Technologies provides solutions for nearly every application request. This overview gives an impression of the possibilities that pyrometry provides. Special solutions that are not listed below can also be quickly adapted to customer or application specific specifications. IMPAC Pyrometers

- On Feb 9, 2007, LumaSense acquired industry proven

IMPAC. IMPAC was founded in 1958 and an industry leader in temperature

measurement using Infrared technology.

The key benefit to using an infrared thermometer, or pyrometer, to measure temperature is that you do not have to make contact with the process or surface being measured. This is especially useful when traditional contact measurement is impractical or may introduce contamination. Measuring molten steel, which would normally melt traditional thermocouples, is a good example. Glass, semiconductor, and research are other industries that commonly make use of pyrometers, but the possibilities are limitless.

IMPAC pyrometers are well known for their accuracy and dependability in the harshest environments. The IMPAC Series 8 celebrated its 30th year in production! The IGA 140-TV was launched into space on a JAXA (Japan Aerospace) mission to help scientists gather temperature data in zero-gravity. Last year, we introduced the ISR 6-TI Advanced, the world’s first industrial grade infrared pyrometer with thermal imaging capabilities.

We invite you to learn more about LumaSense’s IMPAC pyrometers and applications.

Portable Pyrometers

- Quick diagnostics at different applications

Series 5

- Compact pyrometer-series in 50 mm-tube housing

Series 6

- Stationary, digital pyrometers for general and special applications

Series 12

- Very precise pyrometers in robust alu die cast housing

Series 50

- Modern pyrometer series with fiber optics

Series 140

- Modern, robust pyrometer series, with extensive equipment

Series 210

- Small pyrometer series with service interface

Series 300 & 310

- Very small, good value pyrometers

Series 320

- Small, short wavelength digital pyrometers

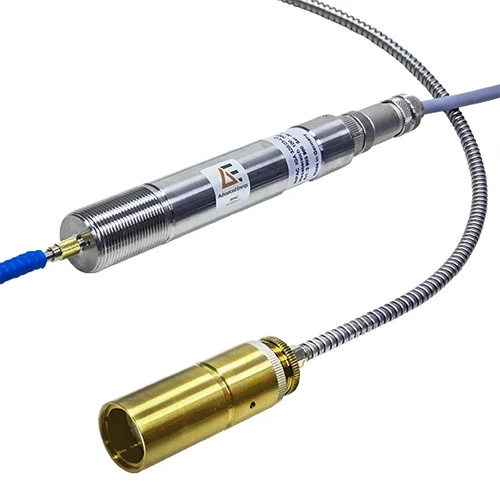

Series 510 & 520

- Digital pyrometers with miniature sensor head

Series 2000 & 3000

- Small, simple sensors with different measuring outputs

IMPAC Highspeed Pyrometers

- Extremly fast analog pyrometers

UV Series 400

- True Wafer Surface Temperature for GaN-based Epitaxy

Temperature Switches

- Switches for recognizing without contact a hot object

MIKRON Pyrometers

M67S

- Robust pyrometers with many options for optics and wavelength

TRR200

- Thin Film Deposition Monitor

PhotriX Series

- Precision near infrared optical radiation thermometers

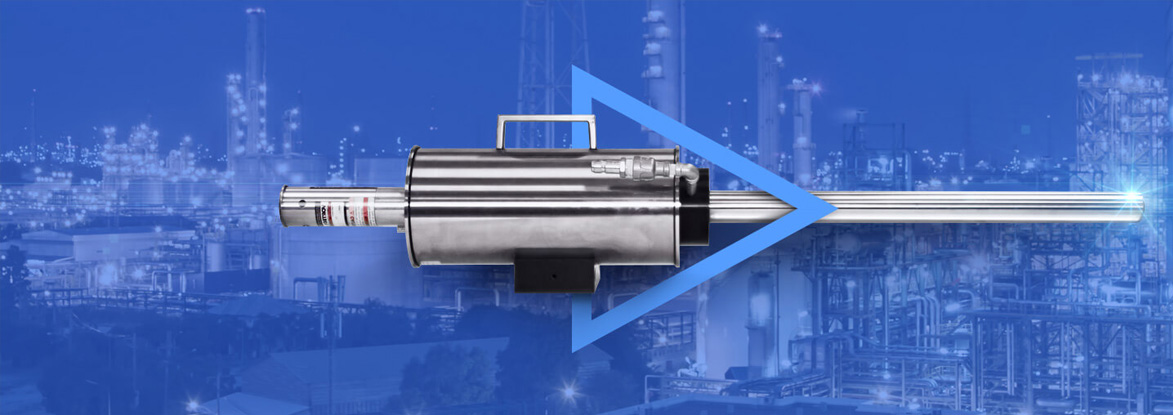

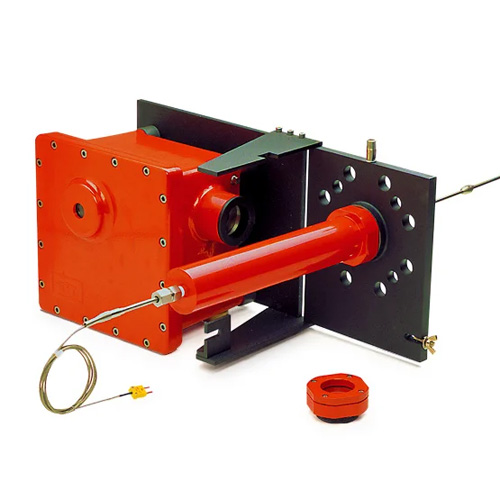

E²T - Petrochemical Sensors

- Infrared Detection Systems for Sulfur Reactors and

Other High Temperature Furnaces

In-plant tests show infrared pyrometers are the most precise way to measure temperatures. Over 550 refineries, gas plants and petrochemical companies with over 1,700 installations worldwide have looked to LumaSense's E²T product line for accurate infrared temperature data.

When you install our lnfrared Detection Systems, you are investing in proven experience, superior performance, and cost savings. Eliminate the need for turn around with our on-site service package tailored for E²T products. LumaSense Field Service Engineers are dedicated to providing expert, on-site support every step of the way. Our comprehensive Service Program ensures peace-of-mind and the highest level of customer satisfaction.

E2T Pulsar

- Continuous monitoring of Refractory Temperature

E2T QUASAR

- Continuous flare stacks monitoring

Accessories

Software

- Evaluation and Analyzing Software for portable and fixed Pyrometers

Electrical Hardware

- Displays, Power Supplies, Converters, etc.

Mechanical Hardware

- Mounting supports, Adapters, Cooling Jackets, etc.

Thermal Imagers & Systems

- Thermal Imaging Cameras and Systems designed for

temperature measurement of dedicated industrial applications

LumaSense thermal imaging cameras and systems accurately measure temperature and operate by using reliable infrared technology. These high-tech Instruments can precisely determine the object temperature and the temperature distribution even on small and fast moving objects.

Thermal imaging cameras perform an essential control function in major manufacturing industries. By monitoring the temperature, users can control entire factory production processes as well as ensure highest quality standards.

These LumaSpection™ systems are fully turn-key so you get the most out of your investment.

By delivering high-quality, reliable products combined with consistent service and support, our goal is to ensure peace of mind and the highest level of customer satisfaction. MIKRON Process Cameras

- LumaSense specializes in turn key solutions consisting

of complete engineering, design, and installation services to meet the most

severe and challenging thermal imaging system requirements.

The MIKRON MC320 and MCS640 Series represent another milestone in innovative infrared thermometry. Designed with advanced maintenance-free electronics and Industrial Protective Packaging, these thermal imagers offer unparalleled accuracy for demanding industrial and manufacturing applications.

LONG WAVELENGTH (LW) THERMAL IMAGERS

For measurement on non-metal surfaces at temperatures between -40...1600°C. As an option, there are several protective housings available. Alternatively, the cameras can be built into individually designed housings or machines by system integrators. For specific applications, additional lenses are available.

MID WAVELENGTH (MW) THERMAL IMAGERS

For measurement on metal and ceramics starting at 150°C, on glass and through flames at temperatures between 150...1600°C. As an option, there are several protective housings available. Alternatively, the cameras can be built into individually designed housings or machines by system integrators. For specific applications, additional lenses are available.

SHORT WAVELENGTH (SW) THERMAL IMAGERS

For measurement on metal surfaces, graphite and ceramics, etc. at temperatures between 600...3000°C. As an option, there are several protective housings available. Alternatively, the cameras can be built into individually designed housings or machines by system integrators. For specific applications, additional lenses are available.

MC320 Series

- Long and Mid Wavelength Thermal Imagers for temperature measurement

between -40...1600 °C

MCS640 Series

- Short Wavelength Thermal Imagers for temperature measurement between 600...3000 °C

Avio Portable Cameras

- Avio imagers come in a variety of sizes with varying degrees of resolution and temperature range to meet your specific needs.

InfReC R500 Series

- Maximum Storage 1.2 Megapixel High Resolution

InfReC R300SR Series

- Versatile and Superior Image Quality

InfReC R300BP-TF

- Infrared Thermal Imaging Camera for Passing Through Flame

Thermo GEAR G120EX

- Panoramic Thermal Image Shooting Function / Vibration Alarm Function Installed!

LumaSpection Systems

- Innovative and Customizable Systems for

Difficult-to-Measure Processes

LumaSense thermal imaging cameras and LumaSpection™ systems accurately measure temperature and operate by using reliable infrared technology. These high-tech Instruments can precisely determine the object temperature and the temperature distribution even on small and fast moving objects.

These LumaSpection™ systems are fully turn-key so you get the most out of your investment. By delivering high-quality, reliable products combined with consistent service and support, our goal is to ensure peace of mind and the highest level of customer satisfaction.

BoilerSpection™ SD

- Thermal imaging camera for continuous infrared imaging inside boilers.

BoilerSpection™ MB

- Built for mobile use, BoilerSpection-MB utilizes special mid-wave infrared detectors to see through flames.

FurnaceSpection™

- Designed and developed for continuous temperature measurement inside high temperature furnaces in refining, metals and glass production

ThermalSpection™ CVM system

- Solution for monitoring critical vessels, such as gasifier skin temperature.

ThermalSpection™ 724 system

- Automated, continuous thermal imaging for remote and automated early fault detection in substations and industrial sites

Furnace Exit-Gas Temperature (FEGT) Measurement System

- Continuously measure Furnace Exit-Gas Temperature (FEGT) using Non-Contact Infrared Sensors

Accessories Thermal Imagers

Software

- Windows-Based Thermal Imaging Software

Electrical Hardware

- Power Supplys, I/O Modules, Cables, etc.

Mechanical Hardware

- Enclosures, Mounting Supports, etc.

LUXTRON Fiber Optic Temperature Sensors

- Products based on Fluoroptic and Gallium Arsenide

material technologies

Our Fiber Optical Temperature product lines have set the standard in the energy, research and medical industries. Based on Fluoroptic and Gallium Arsenide material technologies, each individual product can be configured for a specific application starting from basic electronic instruments or OEM modules to complete turn-key systems.

LumaSense’s Fluoroptic Thermometry (FOT) product line best fits large power transformers, as well as transformers that are UHV, EHV, HVDC and all reactors. LumaSense pioneered the FOT technology and was first to introduce transformer hot spot fiber optic temperature sensors to the market. With decades of accumulated experience, LumaSense continues to innovate and maintain high quality and service standards to hold its position as industry leader with its Luxtron brand of products.

LumaSense’s Gallium Arsenide (GaAs)-based product line is best fit for utility companies that want to measure hot spot winding for small power transformers and distribution transformers that have a smaller asset management budget. LumaSense’s GaAs-based product line uses the same basic technology as the competition, however it offers a simplified installation technique and value-added product features.

LumaSHIELD

- LumaSHIELD measures

hot spot winding for small power transformers and distribution transformers.

LumaSMART

- LumaSMART is designed for large power transformers, UHV, EHV, HVDC transformers and all reactors

ThermAsset2

- Effective Fiber Optic Hot Spot Monitor and Controller for Power Transformers

OEM Modules

- High quality fiber optic temperature measurement solutions for the OEM market.

FOT and GaAs Probes

- Probes for a variety of applications and custom probes for OEM applications.

Tank Wall Plate

- LumaSense Transformer Tank Wall Plate is designed to be easily bolted or welded to any transformer tank wall.

Instruments and Packages

- Instruments for general purposes as well as setup tools for transformer probe testing during installation.

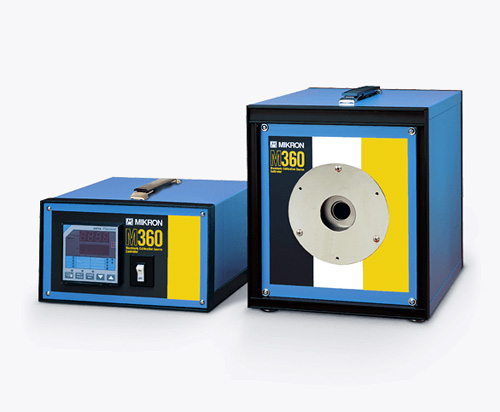

MIKRON Calibration Sources

- Highly accurate calibration equipment for

pyrometers, thermal imaging cameras, radiometers, heatflux and

spectrographic measurement sytems.

Calibration sources are infrared radiators with fixed or adjustable temperatures between -40 and 3000 °C, used for the calibration or verification of the correct temperature-indication of pyrometers, thermal imaging systems, heatflux measurement systems or spectrographic analysis systems. Depending on the model of the calibration source single temperature points or temperature curves of an infrared measurement device can be monitored and recorded.

LumaSense Technologies supplies a unique selection of very precise blackbody and calibration sources. These are defined by cutting edge emissivity values, very homogenous emission areas, a wide range of different sized apertures to adapt to the desired target area. Fast heat up times and high temperature stability are guaranteed.

The internal feedback control loop of the calibration sources are driven by integrated or external digital PID-controllers. Temperature control of low to mid temperature radiation sources is by integrated thermocouples. High temperature radiators are controlled by integrated pyrometers. Portable Calibration Sources

M310

- Compact calibration source with very large surface area.

Ambient +5 up to 450 °C

M315 Series

- Large area sources for calibrating thermal imaging

systems

(Ambient +5) ... 400 °C

M316 (US)

- Ultra-Portable Calibration Sources Operates to 300 °C.

Available for sale in the US only.

M340

- Compact, portable, for low temperatures. Very high

temperature stability.

-20 ... 150 °C

M360

- Very wide temperature range. 2 separate, portable

modules.

50 ... 1100 °C

LUXTRON Fiber Optic Temperature Sensors

- Products based on Fluoroptic and Gallium Arsenide

material technologies

Our Fiber Optical Temperature product lines have set the standard in the energy, research and medical industries. Based on Fluoroptic and Gallium Arsenide material technologies, each individual product can be configured for a specific application starting from basic electronic instruments or OEM modules to complete turn-key systems.

LumaSense’s Fluoroptic Thermometry (FOT) product line best fits large power transformers, as well as transformers that are UHV, EHV, HVDC and all reactors. LumaSense pioneered the FOT technology and was first to introduce transformer hot spot fiber optic temperature sensors to the market. With decades of accumulated experience, LumaSense continues to innovate and maintain high quality and service standards to hold its position as industry leader with its Luxtron brand of products.

LumaSense’s Gallium Arsenide (GaAs)-based product line is best fit for utility companies that want to measure hot spot winding for small power transformers and distribution transformers that have a smaller asset management budget. LumaSense’s GaAs-based product line uses the same basic technology as the competition, however it offers a simplified installation technique and value-added product features.

IRC 45...IRC 150

- Small, easy to use. Large surface area. Ideal for benches and multiple, calibration fix temperature setpoints.

M300

- Large calibration source with high emissivity for

calibration indipendent of the wavelength.

200 ... 1150 °C

M305

- General purpose calibration source for medium

temperatures.

100 ... 1100 °C

M330-US / M330-EU

- Calibration source with specially manufactured heating

elements which provide excellent uniformity.

300 ... 1700 °C

M335

- High temperature, very quick heat-up time. With

independent over temperature alarm and control system.

300 ... 1500 °C

M390 Series

- for extremely high temperatures at very quick heat-up time.

M345 X Series

- Large area sources for low temperatures.

Accessories for CalibrationSources

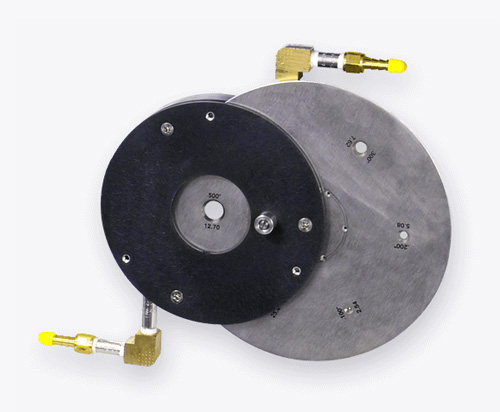

Water-cooled wheel

- 2 models each with 6 different diameters

Gas Sensing

- LumaSense Technologies, Inc. was founded in 2005 as the

world’s first company to focus exclusively on reducing preventable waste and

inefficiency across our planet’s most resource-intensive global industries.

LumaSense delivers advanced sensing solutions to detect, reduce and prevent

waste and inefficiency in resource-intensive industries including Global

Energy, Industrial Materials and Advanced Technologies.

Microphone technology, for example, is an important tool in measuring gases through the use of Photoacoustic Spectroscopy – also known as PAS. This is a unique technique offering the customer an outstanding degree of measurement stability with exceptional sensitivity. The LumaSense engineering department continually works to improve the PAS technique and to test its applications in new areas. This is how the knowledge accumulated at LumaSense is used to meet the needs of our customers.

Product development is always based on customer needs for specific solutions. Consequently, customers are an integral part of the development process. Not until we deliver user-friendly solutions that meet the customers’ requirements for quick, efficient and reliable solutions to problems, do we at LumaSense consider the job done! LumaSense’s past, thus, bears witness to our never ending efforts at meeting the application demands of our customers. We feel confident that you, too, will benefit from the expertise we have built in this field.

Our gas portfolio not only helps our customers achieve process efficiency and waste reduction, but is also capable of monitoring the world’s most harmful and dangerous gases. Because our gas sensing solutions offer superior sensitivity over other gas detection techniques, our gas modules and instruments are particularly beneficial when the environment and human safety are involved. SmartDGA for Transformers

- The industry’s most cost-effective Dissolved Gas

Analysis (DGA) solution, designed to provide the best user experience and

maximum flexibility.

SmartDGA® is the industry’s most cost-effective Dissolved Gas Analysis (DGA) solution, designed to provide the best user experience and maximum flexibility.

LumaSense Technologies is a world leader in sensing solutions, with over 50 years of temperature and gas sensing expertise in various industries. We’ve brought together our experience with over 5,000 transformer temperature sensing installations and over 400,000 NDIR instruments.

The LumaSense Solution

LumaSense has developed a cost-effective online monitoring solution based on proven, state-of-the-art non-dispersive infrared (NDIR) technology.

This new suite of products is designed to allow customers to continuously monitor, record, and diagnose the condition of LTCs and transformers.

SmartDGA Gauge™

- Online Load Tap Changer DGA monitor – 3 gas + moisture

SmartDGA Guard™

- Online 4 gas + moisture DGA monitor

SmartDGA Guide™

- Online 9 gas + moisture DGA monitor

SmartDGA® Accessories

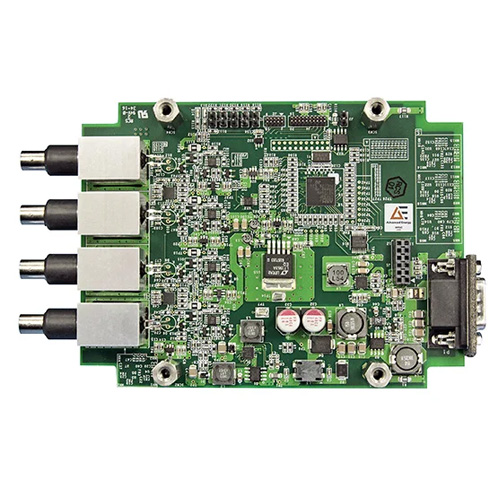

SmartDGA EZHub™

- Power and Communication Hub for SmartDGA® monitors

LumaSMART iCore™

- Local display along with

enhanced memory storage and communications

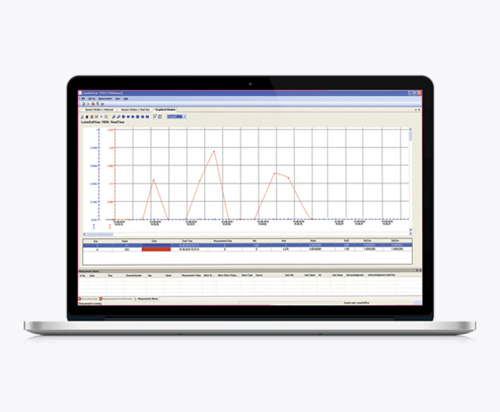

SmartDGA® Software

- Software enables easy setup and interpretation of online DGA results

ANDROS OEM Gas Modules

- Non-Dispersive Infrared (NDIR) quantifies known gases. While the technology has long existed, ANDROS pioneered NDIR gas analysis for automotive emissions and patient monitoring. In addition, we developed a unique single path approach. With ANDROS NDIR modules , the cost of gas measurement is greatly reduced because our modules can measure multiple gases and field calibration is not needed.

OEM Gas Analyzer ANDROS 6500 and 6520

- High performance OEM Gas Analyzer for Vehicle Diagnostics and Inspection and Maintenance Programs.

OEM Gas Analyzer ANDROS 6511

- Continuous, real-time measurement of multiple gases, including methane and carbon dioxide

OEM Gas Analyzer ANDROS 6552

- OEM gas sensor detects Freon refrigerants and Carbon Dioxide

INNOVA Gas Monitoring

- A wide range of gas solutions based on infrared

spectroscopy for all kinds of environments and applications.

Our gas portfolio not only helps our customers achieve process efficiency and waste reduction, but monitors the world’s most harmful and dangerous gases. Because our gas sensing solutions offer superior sensitivity over other gas detection techniques, our gas modules and instruments are particularly beneficial when the environment and human safety are involved.

While there are numerous ways to detect and analyze gases, at LumaSense we utilize two different types of infrared (IR) technologies to deliver cost-effect solutions with high sensitivity, accuracy, and reliability. These are Photoacoustic (PAS) and Non-dispersive IR (NDIR) spectroscopy.

As a leader in trace and multi-gas monitoring, LumaSense delivers a complete range of NDIR and PAS gas solutions for all kinds of environments and applications in the Global Energy, Industrial Materials, Advanced Technologies, as well as in many other markets and R&D applications. Photoacoustic Spectroscopy (PAS)

Field Monitor - INNOVA 1412i

- Highly Accurate, Reliable, and Robust Multi-Gas Monitor for Quantitative Measurement in Field Conditions

Fixed Monitor - INNOVA 1314i

- Highly Accurate, Reliable, Stable, Quantitative and Remote Controllable Gas Monitoring System

Multipoint Sampler - INNOVA 1409

- Reliable, fully remote-controlled for gas sampling of up to 24 different locations

SF6 Leak Detector - 3434i

- Market-leading Photoacoustic SF6 leak detector for Accurate, Reliable and Fast Integral Leak Testing

Specific Measurement Solutions

Automotive Emissions Monitor - 3433

- Highly Accurate and Reliable Multi Gas Monitor (PAS) with Specific Configuration for Exhaust Gas or SHED Evaporative Testing

SF6 Leak Detection System - 3731

- Highly Reliable systems for high sensitivity SF6 area monitoring and early leak detection

Non-Dispersive Infrared (NDIR) Spectroscopy

Multi-Gas Monitor - INNOVA 1316

- Cost-effective, customizable multi-gas monitoring system for a wide variety applications

Application Software

LumaSoft 7810 Software

- User-friendly and graphical interface for the setup and online monitoring of one multi-gas PAS analyzer

LumaSoft 7870 Software

- User-friendly application software and graphical interface for a PAS monitoring system with multi-channel sampling

LumaSoft 7950 Software

- User-friendly application software and graphical interface for the remote control and supervision of up to 24 multi-gas monitors (NDIR)