BD|SENSORS

- Offer Profile

- BD|SENSORS is a mid-sized,

owner-managed company, which attaches great importance to independence and

sustainability.

With our unremitting product and quality strategy we have been successful in becoming a major player on the world market for electronic pressure measurement devices within a few years. Our consistent product and quality strategy has enabled us to set new benchmarks on the global market with the development of a portfolio of pressure measurement devices that range from 0.1 mbar up to 6,000 bar.

Product Portfolio

PRESSURE

PRESSURE TRANSMITTERS

- For vacuum,

overpressure and absolute pressure measurement

Pressure ranges: 0 ... 10 mbar to 0 ... 6000 bar

Based on different sensor technologies, combined with housing materials of stainless steel and various plastics, the industrial transmitters are suitable for almost all industrial gases and fluids.

Our industrial pressure transmitter may be adapted to almost any application due to a variety of electrical and mechanical connections.

DIFFERENTIAL PRESSURE TRANSMITTERS

- For differential

pressure measurement

Pressure ranges: 0 ... 1 mbar to 0 ... 70 bar

Thanks to different sensor technologies combined with compact aluminium die-cast cases or plastic housings, our differential pressure transmitters may be used for numerous fluids and gases, e. g. for monitoring ventilation ducts, filters and fans in HVAC areas as well as for level measurement in closed pressurized tanks.

DIGITAL PRESSURE GAUGES

- With a great variety of

mechanical and electrical connections, BD|SENSORS offers a new generation of

digital pressure gauges for different applications.

Due to the two sensor technologies in use (stainless steel sensor or ceramic sensor), our digital pressure gauges are suitable for nearly all fluids, pasty media and gases.

The display module is continuously rotatable, so that a clear readability is guaranteed even in unsual installation positions.

SPECIAL VERSIONS OF PRESSURE MEASURING DEVICES

LEVEL

SUBMERSIBLE TRANSMITTERS

- The hydrostatic level

probes made by BD|SENSORS are suitable for measuring the level of liquid and

pasty media of all kind.

The separable submersible probes LMP 308 / LMP 808 / LMK 358 / LMK 858 are a speciality, the cable part can be separated from the sensor head effortlessly and without tools. This is an enormous advantage for many of our customers during assembly as well as when performing service and maintenance.

SCREW-IN TRANSMITTERS

- Level monitoring and

process industry

with flush stainless steel and ceramic diaphragm

Due to the ability to combine stainless steel and ceramic diaphragm with housing materials of stainless steel or plastic and different sealing materials, our screw-in-transmitters are suitable for almost all liquids occurring in industrial level and process measurement.

SPECIAL VERSION OF LEVEL MEASUREMENT

SWITCH

PRESSURE SWITCHES WITH DISPLAY

- Depending on the

requirements, the universal pressure measuring devices with display and

switching contacts can be used as pressure transmitter, electronic pressure

switch or digital pressure gauge.

Due to the simple handling as well as the variety of software features (switching points and hysteresis freely configurable, delay function, Min/Max-value data storage, display and analogue output signal scalable, etc.) the DS 200 / DS 400 series is especially suitable as an intelligent pressure switch for general plant and machine construction and the processing industry.

PRESSURE SWITCHES WITHOUT DISPLAY

- The pressure switches

DS 4 and DS 6 were designed also for OEMs (original equipment

manufacturers).

These electronic pressure switches are used in hydraulic and pneumatic applications for monitoring and controlling the pressure via switching outputs.

EVALUATION

EVALUATION DEVICES AND DISPLAYS

- In order to correctly

interpret analogue signals, display and evaluation devices are

indispensable.

Besides the classic version with display and analogue outputs (PA430, ASM430), BD|SENSORS offers with the process display of CIT-series an evaluation device that can be combined with our pressure measuring devices and hydrostatic submersible probes and is futhermore also suitable for acquiring for example temperature and potentiometer signals.

DATA LOGGER

- The data logger can record up to 2 million

measurement values with a maximum measuring rate of 1 Hz in internal memory

(8 MB).

By connecting a USB stick, the capacity can be enlarged to several GB. The LoogySoft software (CIT 600 / CIT 650 ) or DAQ-Manager (CIT 700 / CIT 750) helps the

INDUSTRIES

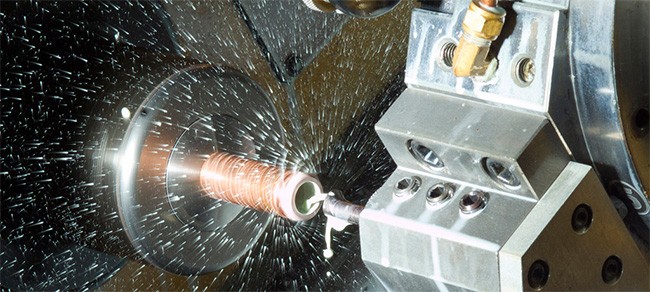

- The number of different applications across the various

sectors is virtually limitless. However, a special solution that meets

customer requirements must be found in each specific case.

This is exactly what BD|SENSORS does best. We are able to cater for most of our customers' needs through our extensive range of standard products that can be modified as necessary in order to create the optimum solution. However, we can quickly come up with special designs too thanks to our highly qualified team of expert developers.

plant and machine engineering

- Plant and mechanical engineering is a global industry involving complex applications. This demands flexibility, quality, reliability and customer focus. Given the wide range of possible applications, there is a need for various pressure ranges, appropriate accuracies, suitable electrical and mechanical connections and output signals agreed in consultation with the customer.

energy industry / renewable energy

- In this era of economic crises, oil crises and

discussions regarding nuclear power stations, there is an increasing focus

on "renewable energy sources" and the "energy industry".

Not only high efficiency but also precision, durability and stability are essential factors here. Pressure transmitters and level transmitters from BD|SENSORS guarantee exactly that. Whether you are involved in conventional energy production or in the field of renewable energy sources, with BD|SENSORS you have a reliable partner to help you solve any specific problems.

shipping / offshore

- The systems and equipment used in shipping and on board

offshore facilities are exposed to severe climatic conditions, harsh

environments and extremely high mechanical loads. Even when faced with these

demanding conditions, the electronic pressure and level transmitters from

BD|SENSORS must remain stable and continue functioning reliably.

Thanks to optimised quality management, products such as the DMK 456, DMP 457 and LMK 458 have been perfected and thoroughly tested to ensure that they meet all these requirements.

food and beverage

- The hygiene requirements in the food and beverage

industry are governed by international guidelines and directives. Naturally,

the preparation and processing of food must take place under hygienic

conditions. Impeccable hygiene is essential not only on company premises but

also in machinery and other systems.

Given that our pressure measuring devices form part of these machines and systems, they are developed in accordance with the guidelines issued by the EHEDG (European Hygienic Engineering & Design Group) and 3-A (3-A Sanitary Standards Inc.), a North American organisation that promotes hygienic equipment design for food, beverage, and pharmaceutical industries.

environmental engineering / water and sewage

- Products from BD|SENSORS are becoming increasingly

popular in the environmental engineering sector, too. In the industrial and

municipal water industry, electronic pressure sensors are used for a variety

of purposes, for example measuring filling heights. In this case, the

materials must meet very specific requirements. They must be able to

withstand aggressive media and mechanical loads.

Pressure and level transmitter from BD|SENSORS meet these requirements thanks to the use of specially selected sensors, robust housing materials (PP, PVC, PVDF, stainless steel etc.), seal materials and cable materials.

With our wealth of experience in the field of environmental engineering and our highly qualified workforce, we are able to provide exactly the right solutions for our customers. The service team in our Technical Sales department can offer you comprehensive advice and assistance when selecting a suitable device for your particular measuring needs.

chemical industry / petrochemistry

- The chemical industry develops and manufactures many

substances and products which are designed to make life easier for us. The

requirements that apply to systems and equipment in this area are as varied

and individual as the products themselves.

While accurate measurements must be taken in order to monitor processes and measure materials precisely, considerable demands are placed on the materials and surfaces as well. BD|SENSORS' pressure sensors for use in the chemical / petrochemical sector offer remarkable precision, reliability and resistance when exposed to an extremely wide range of temperatures and aggressive media. Given the large number of possible coatings available, optimum resistance to media such as sea water, fluorhydric acid and hydrogen can be achieved.

To ensure that the pressure sensors can deliver exact measurements for many years to come, the surfaces that come into contact with the media have anti-adhesive, anti-frictional properties. A highly qualified team is available to assist customers requiring individual solutions.

oil and gas industry

- As a result of global industrialisation and increasing

mobility, the demand for crude oil and natural gas continues to grow. As the

amount of oil and gas produced increases, so too does the need for

transportation and further processing facilities.

In order to meet global demand for crude oil, special processes are now being used in order to extract additional crude oil from reservoirs that have already been exploited. These processes go beyond primary and secondary production where 30 - 40 % of the oil in place is extracted. Given the extreme conditions encountered in the oil and gas industry, high-quality, reliable equipment is essential.

In order to monitor and increase the efficiency of this equipment, BD|SENSORS has developed pressure measuring devices specially for use in these demanding environments.