IRCON

- Offer Profile

- If you are looking for

solutions to difficult temperature measurement and monitoring challenges,

IRCON is the company to call. IRCON offers a product range and experience

that are unmatched in the industry.

In business since 1962, IRCON products perform with accuracy and repeatability in the harshest and most volatile conditions requiring precise temperature measurement and control.

Product Portfolio

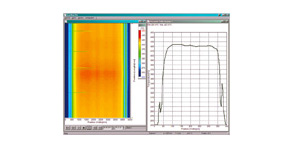

Linescanning Systems

- ScanIR®3 infrared linescanner bridges the gap between spot thermometer and thermal imager. Well-suited for temperature measurement from continuous sheet and web-based processes to discrete manufacturing, it offers one of the fastest scan speeds available.

SCANIR3 SERIES

-

The ScanIR®3 linescanner and thermal imaging system is

designed for a wide varierty of noncontact temperature measurement

applications, including those in harsh industrial environments. Its robust

housing incorporates standard water-cooling and air purge, and also features

built-in laser sighting. A rugged processor box provides universal input and

output (I/O) capabilities in the field without the need for an external

computer.

The ScanIR3 linescanner has one of the fastest scan speeds in the industry and offers complete data about even the highest-speed manufacturing processes. Unlike point sensors that measure a single point, the linescanner measures multiple temperature points across a scan line. Its motorized mirror scans at rates up to 150 lines per second, allowing rapid detection of temperature non-uniformities and hot spots. Rotating optics collect infrared radiation at 1024 points within a 90-degree field of view, and industry-leading optical resolution (up to 200:1) enables detection of smaller temperature anomalies.

The ScanIR3 system is exceptionally easy to deploy and manage: a single bundled sensing head cable with a one-click connector to the scanner allows for fast and trouble-free installation. The unit’s processor box supports various industry interfaces, including Ethernet, fiber optics (optional), and analog/digital I/O.

Designed for reliability and continuous operation, this advanced infrared linescanner provides accurate, real-time thermal imaging and additional features, including:- Reliable brushless scanning motor

- Field-replaceable window

- Temperature range: 20 to 1200°C (68 to 2192°F)

- Fast scan speed up to 150 lines per second

- Up to 1024 measurement points per line

- High optical resolution up to 200:1

- PC independent input/output capabilities

- Reliable Ethernet Communication

- Rugged, waterproof housing with built-in laser

- Built-in air purge and water cooling as standard

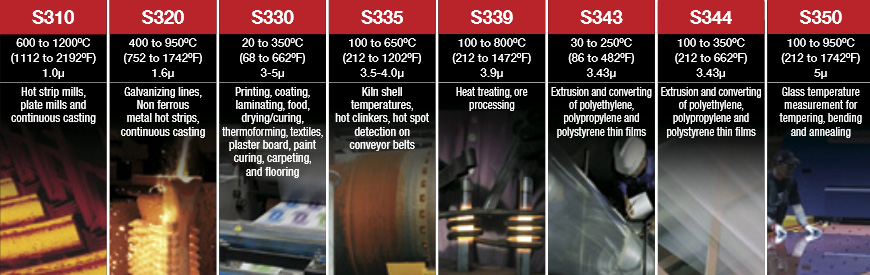

System Thermometers

- Need noncontact temperature measurement with a display? What about relay alarms? System thermometers let you create your own temperature control loop.

MODLINE 7 SERIES

- The Modline®7 infrared thermometers are designed for

continuous temperature monitoring in nearly any application in industrial

temperature process control. Offering 8 different series to choose from (7V,

72, 7G, 76, 75, 77, 78 & 74), these rugged pyrometers feature an IP65 (NEMA

4) enclosure, standard motorized focus control, as well as through-the-lens

and laser sighting.

With extended temperature ranges, high resolution optics and fast response times, the Modline 7 provides the versatility to solve your most demanding applications. An intuitive sensor design, with integral water cooling in a stainless steel enclosure or high temperature waterjacket, reduces installation and setup time. Standardized installation accessories and common ModView™ Pro software platform minimize multiple product configurations at your factory.

The new PROC-7 processor box (option) is a self-contained control unit designed to operate all Modline 7 sensors independent of Modview Pro software. Remote setup and operation can be done through the digital panel when the sensor is located in hard-to-reach or hazardous locations.- Temperature range: -40 to 3000°C (-40 to 5430*F)

- Standard through-the-lens and laser sighting on all models

- Integral stainless steel cooling enclosure

- Remote motorized focus

- High resolution optics

- Simultaneous analog and digital outputs

- 5 year warranty included

MIRAGE SERIES

- The Mirage® temperature monitoring and control systems

are compact, economical and designed to set a higher standard for

performance, reliability, versatility and value in industrial applications

from 250 to 3500°C (500 to 6500°F).

The Mirage infrared thermometer consists of a signal processing unit with a large and highly visible 4-digit LCD display. The Mirage system offers a wide range of sensors to meet your process needs with solutions for your temperature measurement application.

No matter which type of sensing head you choose with your Mirage system, you will get a sensor with sophisticated single lens reflex (SLR) focusing with adjustable response times from as fast as 10 milliseconds to 30 seconds. In addition, the close focus, high resolution option can measure targets as small as 0.6 mm (0.025 inches).- Temperature range: 250 to 3500°C (500 to 6500°F)

- Thru-the-lens sighting

- Single Lens Reflex (SLR) Focus

- High resolution optics with optional close focus lens

- Large LCD display with with two point on/off control

- Single color & two-color ratio thermometers

INFRARAIL SERIES

- The InfraRail® series successfully combines a signal

conditioner and two-wire transmitter in one modular DIN-rail infrared

thermometer. Now, you can integrate temperature measurement with other

relays and signal conditioners already on your process line. The InfraRail

infrared thermometer can be wired directly into any existing 24 Vdc power

supply or connected to a power supply ranging from 16 to 40 volts, making it

the ideal option for OEMs and users in furnaces and induction heating

systems, as well as steel and glass applications.

The basic InfraRail system consists of a temperature sensor, electronic module, 4 meters (12 feet) of interconnecting cable and connectors, as well as an operator's manual.- Temperature range: 375 to 3000°C (700 to 5000°F)

- Standard sensor with thru-the-lens focusable optics

- Economical miniature sensing head

- Convenient, standard DIN-rail mounting

- 4-20 mA two-wire signal conditioner/transmitter

Standalone Thermometers

- When all you need is the temperature signal, the Ircon® family of standalone spot pyrometers can solve your application with accurate and repeatable noncontact temperature measurement.

MODLINE 6 SERIES

-

The rugged Modline® 6 line of infrared thermometers delivers the

best value in terms of price, performance, features and ease-of-use.

These high performance IR sensors permit measurement of targets in

harsh industrial environments that are otherwise inaccessible with

non-fiber optic thermometers.

The Modline 6 pyrometers feature advanced signal processing and background-reflected energy compensation capabilities on 62 and 6G Series. In addition, Modline 6 includes the 6R that operates in a two-color mode designed for intermittent targets and severe environments.

The Modline 6 fiber optic infrared thermometers consist of a rugged fiber optic cable and re-imaging lens. The assembly is connected to an electronics housing containing the detector, processing electronics, brightly lit LED user-interface/display and termination connections for field wiring.

The fixed focus re-imaging lens consists of a small stainless steel cylindrical housing and lens assembly. The re-imaging lens accommodates an air-purge accessory to prevent lens contamination and the fiber-optic cable is protected by metal armor to allow for higher ambient temperatures up to 315°C (600ºF).- Temperature range: 250 to 3000ºC (482 to 5432ºF)

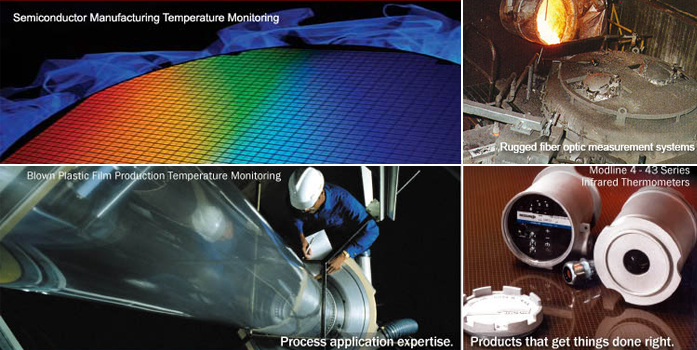

- Rugged fiber optic measurement systems

- Designed for harsh industrial environments

- Simultaneous analog and digital outputs

- Background compensation capabilities on 62 and 6G series

- Fiber cable rated to 315ºC (600ºF) ambient on selected models

MODLINE 5 SERIES

-

The Modline® 5 is a durable, standalone infrared sensor built to

serve a wide range of industrial temperature measurement

applications. This line features System Health Check – a diagnostics

tool that confirms that the Modline 5 spot pyrometer, including

temperature detector, internal circuitry, and even the output signal

is working within factory specifications. The System Health Check

runs continuously in the background and notifies the operator of

failures with a relay or analog output.

The Modline 5 Dirty Window Detector (DWD) automatically senses for dust, condensation, or other contaminants that build up on the lens. It sends an alarm or analog output to notify the user of any obstructions. Programmable coarse and fine settings within the Modline 5 setup menus let you tune the DWD, depending on how severe your process application is.

Unique Emissivity or E Slope Match Function helps you to easily determine the emissivity or E Slope to achieve correct temperature measurements. Simply aim the sensor at the target and adjust settings to the known temperature—Emissivity or E Slope settings will be automatically adjusted, taking the guesswork out.

Designed to withstand long durations in harsh environments, all components of the Modline 5 sensor are contained within a sealed, stainless steel NEMA 4 (IP65) enclosure. With a diameter less than 5.7cm (2.25 inches), it is one of the most capable small infrared thermometers on the market.- Temperature range: 50 to 3000ºC (122 to 5432ºF)

- Self-contained, standalone IR sensor

- Internal self-calibration

- Heated detectors for drift free stability

- Thru-the-lens sighting and optional laser aiming

- Optional active Dirty Window Detector (DWD) for checking build-up on the lens

- Unique emissivity or E Slope Match Function

- Field selectable ºC or ºF

MODLINE 4 SERIES

-

The Ircon Modline® 4 Series is an economical infrared sensor for OEM

applications. This pyrometer requires two wires, a power supply

(range of 16 to 40 Vdc) and an installed compatible output

(recording or control instrument) to complete the instrument system

loop. A number of instruments can be placed within the series

current loop—provided that the total voltage drop for each

instrument does not exceed the total loop voltage.

The Modline 4 DC operation has no moving parts, which guarantees stable performance. The solid state electronics incorporates a chopper-stabilized amplifier, which assures long term, accurate, drift-free, stable operation. The instrument is available with 3 optical resolutions, allowing it to measure spots as small as 7.6 mm (0.3“). It can be calibrated in the field using a certified black body.

The digital emissivity control allows adjustments in 0.01 increments and a response time adjustment pot (potentiometer) lets you select values from 0.15 to 10 seconds to match almost any process requirements.

An optional Peak Picker Filter is available to provide smooth temperature indications and outputs when measuring intermittent targets.- Temperature range: -50°C to 1300°C (-50°F to 2500°F)

- Self-contained, standalone IR sensor

- Versatile, easy-to-install, two-wire transmitter

- Stable drift-free operation

- Provides 4-20 mAdc linear temperature output

- Emissivity & response time adjustment build-in

- Optional Peak Picker Filter

JAVELIN SERIES

-

The Ircon® Javelin™ noncontact infrared thermometer is a compact,

highly versatile temperature sensor. With a NEMA 4 (IP65) stainless

steel body, plastic lens option, and temperature sensing

capabilities from -20°C to 1300°C (0°F to 2400°F) the Javelin series

is the perfect spot pyrometer for OEM, food, paper, packaging,

converting and plastics applications.

With proven Ircon optics, this sensor has standard and close focus resolution, as well as unique Ircon micro-processor digital circuitry for accurate ambient sensor compensation and digital linearization.

The Javelin sensor has additional optical resolutions with standard focal distances – and its shatter-proof plastic lens provides solutions for many food and pharmaceutical applications. This series, incorporating a stainless steel housing, rugged, unbreakable plastic lens and temperature ranges from -20 to 200°C (0 to 400°F) is ideal for measuring food molds, pill coating, plastic films and thermoforming of food containers.

Javelin comes packed with features that are easily adjusted using two push buttons. You can quickly select the peak picker, emissivity, response time, and either one of two outputs that best fits your process application. Selection is verified on the digital display located inside the housing. Utilize the peak picker for consistent temperature measurement of targets that are intermittent, or that have intermittent interferences, such as smoke, steam or dust. Emissivity can be selected from 0.10 to 1.00 in 0.01 increments, and users can choose among five response times: 165 ms, 400 ms, 1 second, 3 seconds and 10 seconds to 95% of scale.- Temperature range: -20 to 1300°C (0 to 2400°F)

- Standard Focus – 200mm (8 in.) to infinity and Close Focus – 100mm (4 in.) to infinity options

- Economical IR pyrometer

- Peak Picker, emissivity and response time adjustment

- Optional plastic lens for sanitary processes – food & pharmaceutical applications

SR SERIES

-

The SR Series infrared thermometer is a two-color infrared

thermometer protected from dust and spray by a NEMA 4 (IP66) rated

casting. This pyrometer is ideally suitable for high temperature

measurements and a good choice for molten metal, wire and rod

forming, vacuum furnaces, induction heating and kiln applications.

The SR Series provides a 4-20 mA or 0-10 Vdc temperature output signal directly to the user's own analog or digital display, controller, recorder or computer, and eliminates the need for a separate indicator/processor unit. This unique, self-contained sensor saves valuable panel space, reduces installation costs and eliminates costly duplication of control instrumentation.

The advantage of a two-color, or ratio thermometer, allows reliable temperature measurements for difficult high temperature applications where target emissivity changes; where the target is too small and/or moving and cannot be completely resolved; or for applications where the object is partly obliterated by dust, smoke, or dirty viewing windows. The SR series will tolerate approximately a 95% reduction in radiation intensity due to low emissivity and non-resolved or obliterated targets.- Temperature range: 700 to 3500°C (1300 to 6500°F)

- Self-contained, two-color IR pyrometer

- Focusable, thru-the-lens viewing

- No moving parts or filter wheels

- Choice of optical resolution, response time and output signal

- Rugged industrial housing for hostile environments

Handheld Thermometers

- Handheld thermometers provide the high-end functionality of Ircon pyrometers in a portable unit with measurement capabilities from -50 to 3000°C (-50 to 5430°F).

ULTIMAX SERIES

- The Ultimax® series are handheld, portable infrared

thermometers designed for maintenance applications and verification of

process temperatures. For users that need temperature reporting

capabilities, the Ultimax infrared thermometer can be used in datalogging

mode to store up to 1000 temperature measurements. Ultimax data analysis

software can then be used to graph, display, or export this temperature

information.

Sophisticated microprocessor-based electronics allow simple push-button selection of emissivity, response time and measuring mode. Single lens reflex (SLR) optics and a reticle that precisely defines the measured area deliver ultimate accuracy. Both analog and digital outputs are standard features and the temperature values are displayed both in the viewfinder and on the external LCD. Reliability is enhanced by surface mount technology, DC operation and an optical system that does not require optical modulation techniques, such as mechanical choppers.- Temperature range: -50 to 3000°C (-50 to 5430°F)

- Through-the-lens viewing

- Focusable optics

- Microprocessor-based electronics

- Single color & two-color ratio thermometer

- Analog & digital outputs

Industry Applications

Metal Processing

- Accurate and reliable temperature measurement is a part

of efficient metal processing and steel manufacturing. Incorrect temperature

during the metallurgical process results in poor quality steel products,

waste, extra energy consumption, increased refractory wear, surface defects,

and time lost due to inaccurate temperature monitoring and control.

Ircon rugged and dependable noncontact infrared pyrometers, including two-color or single wavelength thermometers, allow accurate temperature measurement of metal processing even in the rough environmental conditions present during primary and secondary metal production, such as smoke, steam, dust or intermittent interferences, including scale or water. Factory operators can selectively control the temperature measurement of heat treated parts, resulting in significant energy and time savings, as well as increased safety, productivity and product quality.

Glass Processing

- During the production of glass products, temperature monitoring and controlling are essential for high productivity and quality of the end product. Due to the hot hostile environments and high product temperatures, temperature measurement utilizing thermocouples is often expensive and difficult to install and maintain. Infrared thermometers are the ideal instrument to measure molten glass, furnace refractory, and the final processing of the glass product because they are easy to install and maintain, and they have long term life and stability.

Plastic Processing

- Plastic parts and films are becoming increasingly

expensive due to the high cost of raw materials. In addition, due to the

high volume of parts produced, the customer cannot afford to generate scrap

and waste excess energy. The temperature of the product during the

production cycle is very critical and a noncontact infrared thermometer can

remove the guesswork out of the production process.

The advantages of an infrared thermometer are:- Noncontact, so it does not interfere with the process

- Fast response for fast temperature control

- Ability to measure individual targets or the complete width of the target

- Availability of alarms, recording and control outputs

Packaging, Paper & Converting

- Noncontact infrared thermometers are used in many applications for paper production and processing paper into finished products. From processing the pulp to converting the paper into labels, lottery tickets and coated papers, the temperature of the product is critical to improve the quality, insure proper drying and reduce production costs.

Semiconductor & Solar

- Temperature measurement during many semiconductor

processes is very difficult. Often the process will not allow the use of

temperature sensors like thermocouples because the product cannot be touched

or is inside of a vacuum chamber. The processes require fast response times

and very accurate repeatable readings from room to high temperatures. The

instruments must maintain accurate temperatures for a process that may take

days to complete.

Ircon® rugged and dependable noncontact infrared thermometers allow temperature measurement that has small optical resolutions, fast response times and drift free operation for long periods of time. Listed below are examples of how Ircon infrared products are used in semiconductor processes and how they can improve quality, insure accurate and long term temperature control.

Other Applications

- There are many industries that require heating or cooling of their products and controlling temperature is critical to achieving quality products at the lowest cost and fastest production time. There are many ways to measure temperature, but noncontact infrared thermometers have several advantages. Noncontact thermometers measure actual product temperature and not the temperature of the environment surrounding the product. With noncontact measurement, there is no contamination of the product and the process is not interrupted. The response time of these sensors can be very fast - 10 ms is very common.