Exergen

Videos

Loading the player ...

- Offer Profile

- Exergen designs and produces the world’s only self powered non-contact infrared temperature sensors with a high level of accuracy and repeatability to regulate and control various industrial OEM machine applications. We will provide solutions for temperature related problems you face.

Product Portfolio

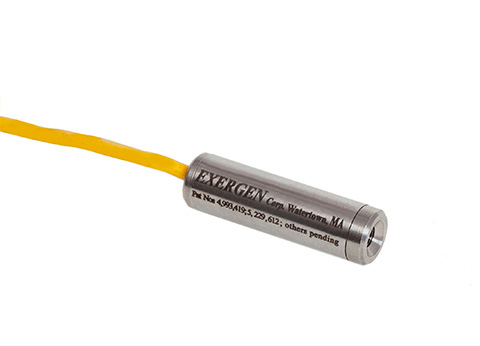

Non-Contact Infrared Sensors

- Our sensors vary in size and optics. Small or even

smaller, they are an essential component of your product and/or complex

machine.

The commonality is the focus to ameliorate your next generation machines beyond belief (The contradiction lays in the fact that it has to do a lot more and cost less). More speed, higher output and better quality but...all at less cost. Combine that with hardly to no maintenance costs (as our sensors do not drift) you provide your customer with the most unique buying reasons. We all realize that this “more for less” maximizes the tension between the engineer who wants the best sensor and the purchaser who wants the best price. Well we have good news for the engineering - and the purchasing side.

Our sensors will help to achieve your intensified specification fulfillment and pricing. Maintenance of our sensors are hardly to non existent. SmartIRt/c

-

Plug and play, linearized, precise accuracy, with integral design which

eliminates thermal drift. No leakage current, impedance, or cold junction

compensation to worry about.

Powered SmartIRt/c’s are microprocessor based with full scale linearization. Plug and play, analog or RS232 output. –30 to 1000 °C temperature ranges available. Optics to 40:1, and designed to measure non-metal or coated metal surfaces.

NOTE: Micro IRt/c’s have higher impedance than typical IRt/c’s. Smart transmitters are available to linearize and deal with impedance issues or see our Schematics section for tips how to design the read-out electronics

Smart IRt/c.01

Smart IRt/c.03

Smart IRt/c.07

Smart IRt/c

Smart IRt/c.SV

Smart IRt/c.1X

Smart IRt/c.3X

Smart IRt/c.3SV

Smart Micro IRt/c.SV

Smart Micro IRt/c.4SV

Smart Micro IRt/c

Smart Micro IRt/c.4

Smart IRt/c.5

Smart IRt/c.10

Pre-calibrated IRt/c

Pre-calibrated IRt/c

-

These IRt/c’s are pre-calibrated at the factory for typical target material emissive properties to match thermocouple signals over selected temperature ranges. This means they can be connected directly to “thermocouple input” controllers, PLCs, transmitters, and recorders available worldwide

The most reliable non contact temperature sensors on earth. No active electronics, so these passive devices can not fail. MTBF (Mean Time Between Failure) reports have been documented with a rate of > 1,000 years between failures and all sensors are intrisically safe. The patented technology separates the IRt/c from all other non contact temperature products. If you are building reliable equipment, reliable sensors that will minimize downtime and increase your production should be on there.

Precalibrated Micro IRt/c

Precalibrated Micro IRt/c

-

The world’s smallest IRt/c’s are self powered, with K t/c output.

For those special applications where mounting is impossible with standard sized sensors, the micro IRt/c can go places no other IR sensors have gone before, with the same high performance as all of the IRt/c products. Optics available are 1:2 (all temperature ranges available) and 4:1

NOTE: Micro IRt/c’s have higher impedance than typical IRt/c’s. Smart transmitters are available to linearize and deal with impedance issues or see our Schematics section for tips how to design the read-out electronics

Adjustable IRt/c sensor

Adjustable IRt/c sensor

-

These models allow for the user to calibrate the IRt/c’s to match a thermocouple in whatever temperature range they desire. As opposed to our Pre-calibrated IRt/c's, these Adjustable IRt/c's are not yet calibrated in the factory. The range adjustment screw is adjusted to calibrate for temperature range of interest and material properties (emissivity). Models for non-metals (HiE) and metals (LoE) are available.

Ordering information : (Model)-(Thermocouple Type) - (HE or LoE) Select the model for temperature range , sport size , thermocouple type desired (J.K.R or S) and target Example IRt/c 10A-K-HiE

Attention OEMs: - All of the adjustable model available precalibrated from Exergen with NIST traceability for quick multiple same sensor installations. Also the millivolt output curves, mv table, and Eurothern downloadable files are available for all sensor models for special calibration

Customized sensors

Customized sensors

-

Exergen Global is widely recognized for its Sensoranics MethodologyTM, a unique, proprietary, and fully integrated approach to developing customized best-in-class infrared temperature sensor solutions. Sensoranics combines Exergen’s unmatched thermal management expertise, its innovative sensor technology and its mechanical engineering knowledge allows the company to provide award-winning solutions for even the toughest thermal challenges.

For OEM applications Exergen offers customized solutions. This can be:- Custom specific calibrations

- Custom specific sensor housings

- Custom specific optics

- Custom specific assemblies: every desired cable length, labels, heatshrinks, connectors

- Specilized multi-channel solutions for more accurate readings

- Wireless solutions

Handheld IR Scanner

Handheld IR Scanner

-

The D- and DX-Series handheld IR scanners are entirely different types of instruments than conventional temperature measuring devices. Designed specifically for the highest possible accuracy, they are the only infrared instruments which are certified with NIST-traceable accuracy on real surfaces of unknown emmissivity, while remaining completely free of the contact errors and heat sinking errors of contact devices.

They are the preferred choice of reference thermometer for OEM customers. They come in 4 different configurations for measuring temperatures between -45°C (-50°F) and 871°C (1600°F)

Market Solutions

Graphics

-

We’re willing to bet that production quality, speed and reliability are a top priority for all of your printing and graphics customers. Would they like a cost-effective means to: improve ink drying efficiency, identify dry out points in webs and scan them for thermal profiling, measure roller temperatures, or measure webs and ink rollers to increase speed and reduce scraps? Our IR temperature sensor technology can be used for those processes and more. Look at Exergen’s IR sensors to enhance operations for web and sheet fed presses, ink rollers, platens, conventional offset and waterless printing presses, and laminating machines. Medical/Aestethical

- As medical professionals introduce new techniques and devices into their practices, they need foolproof, reliable thermal measurement solutions to ensure patient safety and device sterility. Our non-contact infrared temperature sensors can provide fast and contamination-free temperature measurement for a range of applications to monitor and control fluid temperatures in which fluid much reach a certain temperature, including: transfusion systems, IV warming systems, dialysis systems, cardio-pulmonary bypass systems, ECMO systems, and IVF workstations. Diagnostic applications include point-of-are blood analyzers, plate readers, (immuno)heamatology analyzers and immunohistochemsitry equipment. We employ our patented Heat Balance method to measure fluid temperature internally but yet noninvasively using disposable tubing. Our knowledge and background in medical devices is enhanced through collaboration with our Medical Division, a group that is recognized world-wide for its award-winning Temporal Scanner product line.

Packaging

- Your customers can reduce scrap and gain greater control in their packaging production by using our non-contact infrared sensors. IRt/c infrared thermocouples help accurately control the temperature of rotating and moving stainless steel heaters commonly used in the packaging industry, without ever touching the heaters. Exergen’s SnakeEye Thermal Switch detects the presence of hot objects (such as hot melt adhesive, labels, laser engravings, seals, and pressed fit parts), and with photocell-like simplicity -- and extraordinary thermal sensitivity -- allows your customers to “see” production in real-time, increasing speed and reducing errors.

Textile

- Textile manufacturers can speed production and avoid wasting materials using IRt/c sensors. Exergen Global’s non-contact sensors let manufacturers accurately monitor and measure textile temperatures throughout the drying process after textile printing production, allowing them to remove garments at precisely the right moment, accuratly measuring the dry-out improves throughput and prevents detoriation of the printed image duo to over-exposure to heat. Our sensors will help your customers gain better control over heat-intensive processes such as curing.

Plastic

- Exergen’s IRt/c sensors provide highly accurate monitoring and measurement, allowing plastics manufacturers to quickly adjust process parameters to enhance productivity, ensure quality and reduce repairs. Your customers can use our non-contact IR sensors to be certain that parts have cleared in high volume plastic injection molding. When forming plastics, they’ll find that our IRt/c sensors with radiant heat can provide an excellent combination of heating method and control. Exergen’s thermal sensors are also well-suited for monitoring plastic extrusions -- either at the point of extrusion, to monitor correct extrusion temperature -- or, after air cooling, to monitor and control the cooling process prior to cutting to length.

Others

-

Save Water, Enhance Crop Yields using IRt/c Sensors

Exergen IRt/c sensors play a major role in helping the agricultural industry grow crops at the lowest cost, with speed and accuracy. In high drought areas, our IRt/c can help your customers detect plant stress by monitoring temperatures and ensuring the crop is watered where absolutely necessary.

Exergen’s IRt/c Sensors Help Ensure Food Production Quality & Safety

Exergen’s IRt/c sensors can help your customers ensure quality and safety in processes such as bread and pastry dough mixing, microwave heating, frozen food production, and baking. Our non-contact sensors can continuously measure the temperature of any food product -- whether extremely hot, cold or in between -- without ever touching the product. Our sensors help customers comply with HACCP regulations by providing the highly accurate temperature readings needed to anticipate and prevent health hazards, such as contamination, before they occur. Your customers will also want to try Exergen’s portable DX501 sensor for spot inspections to help prevent microorganism contamination by bacteria, viruses and parasites.

Our Sensors Deliver Performance, Speed and Quality for a full range of Automotive Needs

Whether your automotive market customer is concerned with achieving the perfect paint job, the winning racing speed or the best tire production, our IRt/c sensors can help enhance product quality, performance and production speed. Our sensors can help reduce a car or trucks friction with the road by optimizing tire performance, tune a race car’s suspension by profiling its tires’ temperatures, can monitor the temperature of a torque converter or of brake pads, and monitor mechanical drives for bearing failure. Your automotive manufacturing customers can use our special heat balanced IRt/c to measure the internal temperature of tires’ treads, and body shops will love our portable IRt/c sensors to measure spot repair temperatures. Exergen’s portable NIST traceable DX501is the only IR thermometer that provides truly accurate temperature measurement for tuning R/C race car engines.