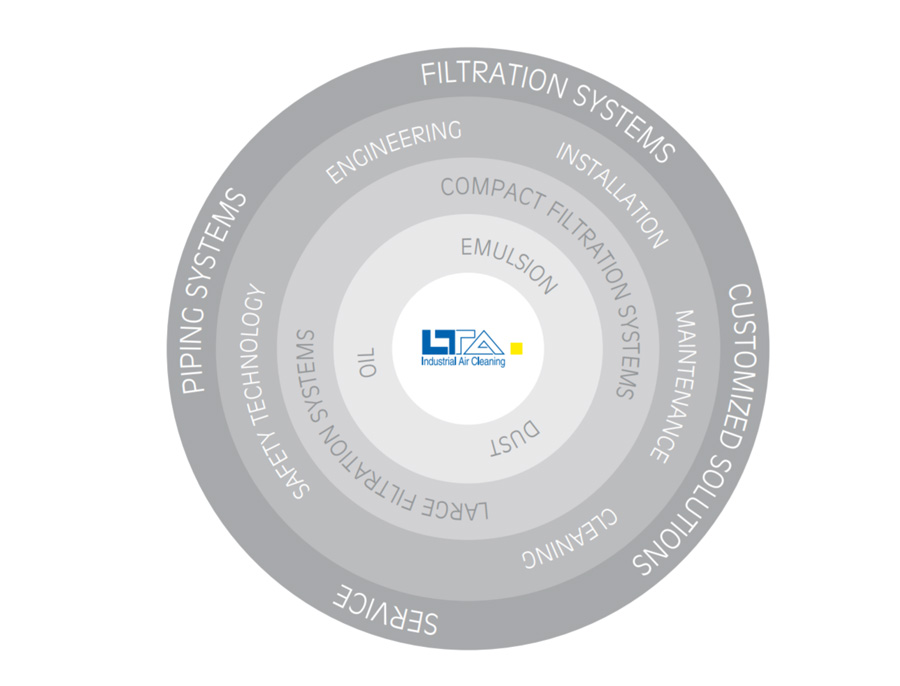

- Offer Profile

- LTA filtration solutions provide the right filter for every type of particle. Our solutions are highly efficient and economically attractive, both at initial purchase and in use; you can lower your operating and energy costs, protect the environment, as well as resources and ensure air quality in your place of business. LTA solutions are a long-term answer to provide you with a healthy and productive working environment – an atmosphere, in which your employees can work, unhindered and with higher morale, assuring your company‘s continued success.

Air Filters

-

Developing the future of filtration

With LTA Lufttechnik at your side, you can solve practically any filtration task. Our trained experts carry out research, development and production – with over 35 years of experience and in-depth understanding of customer requirements.

Why not turn our advanced knowledge into a lasting benefit for yourself? We will support you throughout the entire product life cycle, from advice and planning to installation and commissioning, through to professional services.

Breathe easy with LTA Lufttechnik.

LTA Air Filters

-

LTA Lufttechnik has the ideal concept for all environmental conditions. Whether a large company or a small business – LTA filtration systems adapt flexibly for a wide range of applications.

Electrostatic oil and emulsion mist filters are the preferred solution for precipitation of aerosols in industry. Not only are these highly efficient (far in excess of 99% as new), they also work with fully washable filter elements that are almost free from pressure loss. This means that the power for the conveying fans can be reduced to a minimum while the disposal costs are limited to the wastewater when cleaning the filter elements. Electrostatic precipitation only loses a minimal amount of cooling lubricant during the transition to the gas phase.

Applications which allow limited use of electrostatic filtration systems (for example the flash point of the oil is less than 120°C) require mechanical solid matter filters. These applications need optimized flow conditions in order to achieve ideal extraction with high separation efficiency and low volume flows. Such optimization enables aerosol capture with minimal energy and also maximizes the service life of the filter elements.

HIGHLIGHTS

- Increased occupational safety

- Less wear

- More efficient workforce

- Long-term availability

Electrostatic filtration systems for cooling lubricant mist

-

Electrostatic filtration systems for oil and emulsion mist are the ideal solution for sustainable production in industry and skilled trades. The pre and post-filters are fully washable so they can be reused. As highly flow-optimized solutions, the electrostatic cooling lubricant mist filters have a long service life and offer sustained, constant performance.

In electrostatic filtration systems for cleaning and extracting oil and emulsion mist, the first step involves extracting the polluted air via a pre-filter. This separates coarse particles larger than 3 µm and the pre-filter also protects the downstream filter elements from foreign bodies. Next, an electric field gives the incoming neutral aerosols a positive charge in the ionizer. These positively charged particles are deflected by collector plates (negative charge) and separated out in the downstream collector. The neutralization filter neutralizes any remaining positively charged dust particles in the penultimate step. Optional post-filters, such as those for smoke or odors, can also be fitted. The fan sucks the air flow through the air filter via the connection opening and coveys the purified air out of the housing.

HIGHLIGHTS:

- Constant high separation ratio

- Sustainable

CIP - AUTOMATIC CLEANING SYSTEM

- Automatic cleaning system with consistently high filtration efficiency and operational reliability over the long-term. This LTA automatic system cleans using the cooling lubricant in the machine (e.g. lathe or grinding machine) without chemical additives or diluted solution. The CIP automatic cleaning system for machine tools permanently reduces material, personnel, energy and disposal costs.

BSC - INEXPENSIVE ENTRY-LEVEL AIR FILTERS

- TInexpensive entry-level air filters which do not have an interface to the machine but still offer all the advantages of electrostatic filtration systems.

CMP - COMPACT FILTRATION SYSTEMS

- Compact filtration systems for use in situations with limited space.

MG - FOR MACHINING MAGNESIUM

- Electrostatic filtration systems, especially for machining magnesium.

Mechanical filtration systems for cooling lubricant mist

-

The mechanical cooling lubricant filters for emulsion and oil mist are low maintenance, budget-optimized air filters for industry and skilled trades. In mechanical filtration systems for cleaning and extraction of emulsion and oil mist, the polluted air is cleaned using various different mechanical filter elements.

Coarse particles are separated in the first stage of the air filter via a pre-filter. The pre-filter is based on the principle of inertial separation and protects against foreign bodies. The pre-cleaned air flows through the main filter where cooling lubricant particles are removed from the air. Depending on the density and design of the main filter elements, ever smaller particles are separated. The process of particle separation can take place in four different ways: through the sieve effect, inertia effect, interception effect and diffusion effect. An optional post-filter, e.g. for smoke or an active charcoal version for odors, can be fitted. The purified air leaves the air filter’s fan via the post-filter.

HIGHLIGHTS:

- Modular design

- A wide range of filter elements can be used for a variety of applications

CMP - COMPACT FILTRATION SYSTEMS

- Compact filtration systems for use in situations with limited space.

Mechanical filtration systems for dust

-

The mechanical solid matter filters for dust from LTA Lufttechnik are used to capture and separate all kinds of dust and fumes. They are used for simple industrial applications as well as complex industrial requirements and filtration according to special customer specifications. They can also be used for mobile systems or systems without a compressed air supply. Cartridge and pocket filters are available for removing harmful particles.

The polluted air is brought in via a suction line or with the aid of an extraction arm. It then flows through the container area where the decline in air speed results in separation of the heavier particles. Afterwards, the air mass flows through the filtration chamber with pocket filters or cartridge filters where fine pollutants smaller than 1 μm and aerosols are separated. The air exits via the ventilator chamber. Housing with another filtration stage and filter inserts adapted accordingly for the task at hand can be lined up before or after the ventilator chamber to filter out very fine dust or to separate various different gaseous pollutants and vapor. The filtered air can then be fed to the room from which it was extracted through a grid in the outlet or guided outside via a pipe fitted to the connection on the outlet cover.

HIGHLIGHTS:

- Sturdy construction

- A wide range of filter media can be used for a variety of applications

CIP - AUTOMATIC CLEANING SYSTEM

- Automatic cleaning system with consistently high filtration efficiency and operational reliability over the long-term. This LTA automatic system cleans using the cooling lubricant in the machine (e.g. lathe or grinding machine) without chemical additives or diluted solution. The CIP automatic cleaning system for machine tools permanently reduces material, personnel, energy and disposal costs.

MPCIP - CLEANING FUNCTION WITH MECHANICAL-PNEUMATIC ACTUATION

- Mechanical dust filter including built-in cleaning function with mechanical-pneumatic actuation.

CIPX - CLEANING SYSTEM WITH ADDITIONAL EXPLOSION PROTECTION

-

Automatic cleaning system with consistently high filtration efficiency, operational reliability over the long-term and additional explosion protection. Filter elements are cleaned by means of compressed air pulses.

Fields of application

-

LATHES

Lathes are machine tools for producing rotationally symmetric workpieces. Continuous developments in this field and faster cutting and feed speeds present ever new challenges for occupational safety and cleaning of machinery exhaust air. LTA filtration systems are ideal for extracting and removing cooling lubricants and dust.

MILLING MACHINES

Milling machines are machine tools for producing three dimensional bodies that range from simple to complex. At least three feed directions are available on milling machines. Material is removed by means of rotating cutting tools. LTA air filters are used to remove cooling lubricant from the machine’s exhaust air.

GRINDING MACHINES

Grinding machines are machine tools for smoothing surfaces and for fine machining of shapes and geometries. Because of the fast tool speeds, the finest particles of cooling lubricant form in high-speed grinding machines due to atomization. These cooling lubricants are collected by LTA oil and emulsion mist filters.

Individual, group or central extraction

-

INDIVIDUAL SUCTION

Extraction and purification of air at the source. A filtration system is either positioned on or next to each machine. In this case, this air filter is only designed for one individual machine.

GROUP OR CENTRAL EXTRACTION

Exhaust air collection via a central pipeline system which guides the exhaust air to be purified to the central system. There it is purified in filtration systems and discharged. Extraction and purification can take place for groups of machines or entire production lines with a central extraction system.

Practical example

-

WELDING FUMES AND DRY DUSTS

Welding fumes and dry dust cause air pollution in metalworking shops. Space-saving mechanical group and central extraction systems purify the air and improve occupational safety and employee satisfaction through adjustable air inlets and high, effective extraction volumes.

CENTRAL EXTRACTION FOR CRANKSHAFT PLANT

Flexible filtration systems for oil, emulsion and dust particles can be customized to suit every requirement. Central filtration systems designed for central extraction can be used to remove pollutants in a space-saving and maintenance-optimized way, even from complex systems made up of a wide range of machine tools (such as lathes and grinding machines) with oil and emulsion lubricants. Custom solutions result in optimized production when carrying out complete machining at large plants.

AEROSOLS AND FUMES IN MACHINING CENTERS

Turning or milling large workpieces can result in a large amount of emulsion mist as well as fumes which can escape if the machine hood is not completely closed. LTA’s task was to prevent this. Here an electrostatic filtration system is used to remove pollutants while the purified exhaust air from the air filter is used to create an air curtain over the machine openings to prevent emulsion mist or fumes that were not collected from escaping.

EXTRUDER VAPOR WITH PLASTICIZERS

The plastic vapors that arise in the plastics processing industry often contain plasticizers which must not be mixed with water. These substances crystallize at a defined temperature which is why the temperature must be monitored to ensure it does not fall below this during the process. The solution is to keep the vapors above the crystallization temperature while the process is underway. The plastics processing industry benefits from LTA air filters in a stainless steel design.

Practical example

-

OIL SMOKE AND AQUATENSID IN HARDENING MACHINES

During steel processing on a hardening machine, vapors, gases, smoke and other combustion particles form on the induction coils and must be captured and removed as efficiently as possible. If oil is used for quenching, then the resulting oil smoke is captured by nozzle plates, for example, and can be extracted and removed using electrostatic filtration systems. The material is then often tempered once again and cooled with the aid of an Aquatensid, for example. Mechanical filtration systems have proven themselves in this regard.

AIR POLLUTION IN PAINT DRYING OVENS

Products wetted with water-soluble paint, for example, are dried in induction paint drying ovens. Electrostatic filtration systems extract and remove the resulting air pollution. The high filtration efficiency and re-usable filter elements enable sustainable and environmentally-friendly production.

COMBINATION MACHINING – CHIP AND AEROSOL EXTRACTION

An extremely wide range of materials are often machined on lathes and milling machines. LTA filtration systems extract and remove the resulting mix of air pollution. For example, glass-fiber reinforced plastic (GFRP) is machined dry (chips) and aluminum with is machined with minimal quantity lubrication (MQL) (sticky dusts). A special chip capturing channel, the combination of various filter elements incl. a pre-coating unit and other clever solutions mean that just one air filter can be used instead of two different ones.

HEAT RECOVERY ON ANNEALING FURNACES

When silicone undergoes vulcanization processes in annealing furnaces, silicone vapors arise which require extracted. An electrostatic filtration system removes the pollutants while also recovering the heat contained in the air flow. A powerful fan negates the pressure drop of a heat exchanger. This system leaves the air pollutant-free while reducing the energy consumption of the annealing furnace.

Cooling lubricant mist

-

Cooling lubricants are used in machine tools for machining or forming. Atomization on rotating tools or vaporization on hot surfaces results in vapors and mist. Cooling lubricants such as oil or emulsion are used to cool and lubricate as well as to transport away the chips during milling, turning, drilling and grinding. The use of cooling lubricants is highly advantageous but there is one key drawback: High tool speeds and temperatures disperse the cooling lubricant into fine particles in the air. According to DGUV 109-003, these particles must not exceed specific occupational limit values as they can lead to dangerous lung exposure levels. Cooling lubricant mist may also be easily flammable, so further safety measures come into effect.

NON-WATER-MISCIBLE COOLING LUBRICANTS: OILS

Non-water-miscible cooling lubricant usually consist of mineral oils, however poly-alpha-olefins or other oils are also used. Depending on the application, additives are added to the cooling lubricants. Non-water-miscible cooling lubricants offer several advantages compared to water-miscible cooling lubricants:

- Better lubrication

- Greater anticorrosion properties

- Higher pressure capacity

- Longer service life

- Outstanding resistance to microorganisms

WATER-MISCIBLE COOLING LUBRICANTS: EMULSIONS AND SOLUTIONS

Water-miscible cooling lubricants are divided into two types of emulsions and solutions and used where the priority is cooling. They consist of over 90% water and therefore largely share its physical properties.

Emulsions consist of oil, water, emulsifiers and additional additives. They are characterized by the following advantages:

- Low price

- Outstanding cooling

In contrast to emulsions, solutions are free from mineral oils and normally consist of polymers or salts mixed with water:

- Good cooling properties

- Fewer foaming problems

- Good resistance to microorganisms