- Offer Profile

-

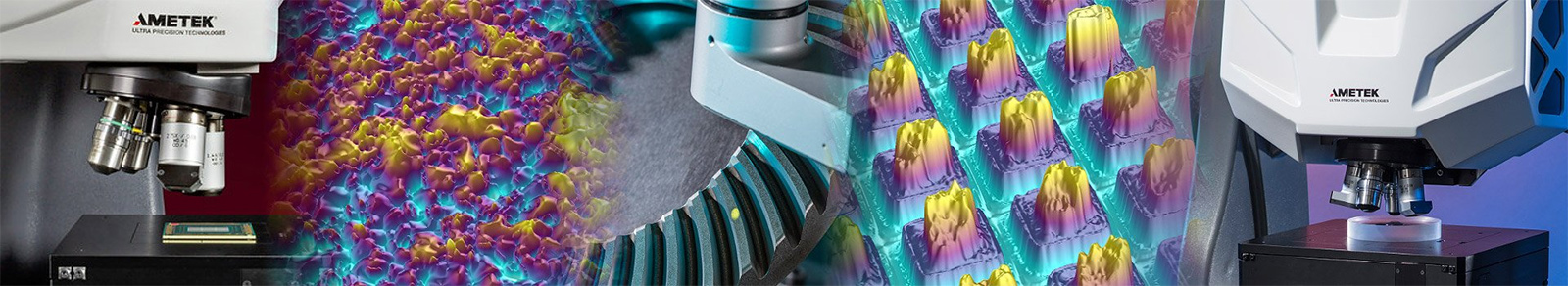

Zygo Corporation is a global leader in the design and manufacture of advanced optical metrology systems and ultra-precise optical components and assemblies.

Our mission is to enable customer success by delivering innovative precision optical and metrology solutions that exceed expectations.ZYGO is comprised of these groups:

- 3D Optical Profilers

- Laser Interferometers

- Nano Position Sensors

- Precision Optical Components & Systems

Metrology Systems

- ZYGO has elevated the status of metrology to a disruptive, enabling technology. ZYGO's metrology solutions measure using light, and it offers two key product types, 3D optical profilers, and laser interferometers.

Optical metrology is an extremely versatile laboratory inspection tool, and has an important role to play in the verification of quality and design intent. Today, it has become the "go to" metrology solution, benefitting from that fact that it is non-contact, non-destructive, fast, highly sensitive, and has exceptional resolution and accuracy.

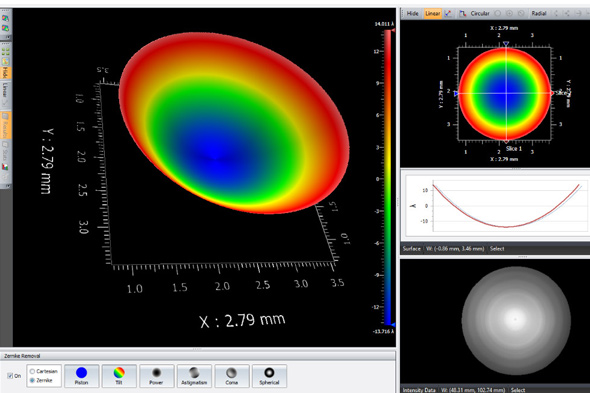

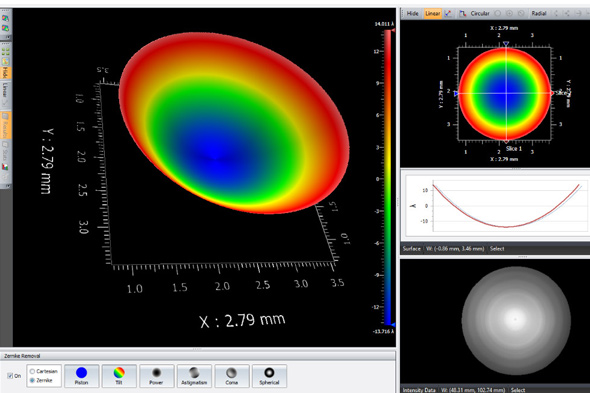

3D Optical Profilers

-

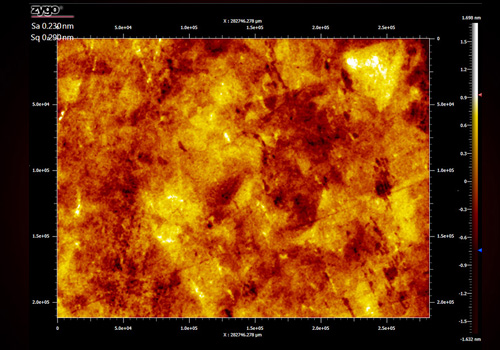

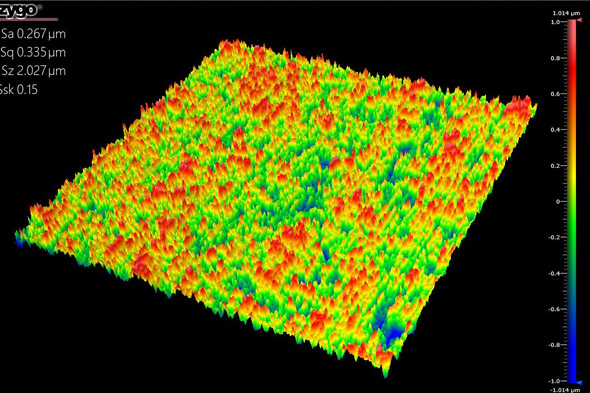

ZYGO's 3D Optical Profiler instruments enable precise, quantitative, ISO-compliant, non-contact surface measurement and characterization of micro- and nano-scale surface features, capturing up to two million data points in just seconds. Applications range from topography and waviness to roughness and microstructure characterization on samples as that vary from ultra-smooth sub-angstrom optical surfaces, to extremely rough and diffuse 3D printed surfaces.

Choosing the right optical profiler system depends on your application's requirements, including speed, precision, vertical range, automation, and flexibility.

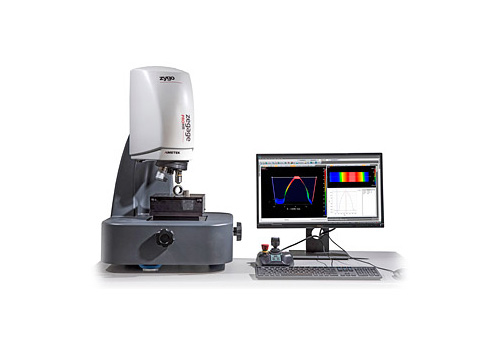

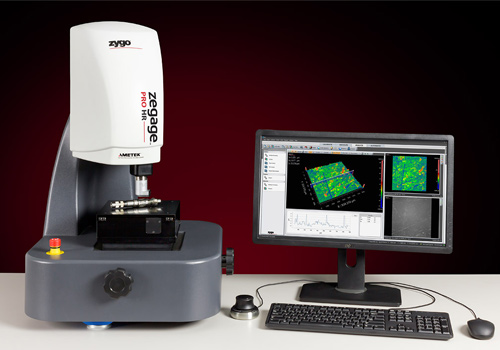

ZeGage™ Pro 3D Optical Profiler

-

Standard performance bench-top optical profiler. Compact design. Simple to use. Measure parts right on the shop floor!

The ZeGage™ Pro and ZeGage™ Pro HR 3D optical profilers provide non-contact measurement and characterization of micro- and nano-scale features of many types of surfaces, ensuring quality control and process monitoring in your manufacturing environment.

Our industry-leading ZeGage Pro-series sets the standard for performance, ease of use, flexibility, and precision of benchtop-class industrial non-contact surface profilers. Built on ZYGO’s proprietary CSI technology, the ZeGage Pro delivers innovative technologies to enable precise, reliable, simple, and confident surface metrology.

Exclusive capabilities include SureScan™ technology for vibration robust metrology, Part Finder, and Smart Setup for simplified part setup and optimized measurements. It’s never been simpler to measure a wide variety of surfaces and parts, quickly and easily.

Key Features:

- Vibration-resistant, for metrology and process control on the production floor.

- ISO 25178-compliant results ensure confidence in your metrology.

- Non-contact, area-based metrology technique prevents part damage and is insensitive to part lay.

- Measurements require no consumables.

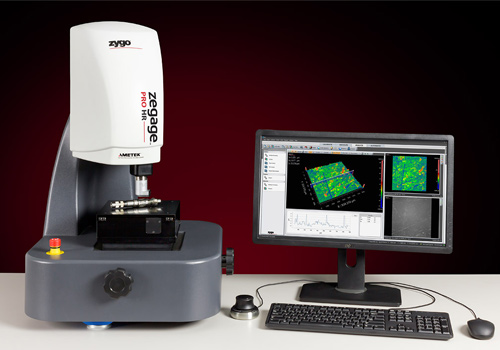

NewView™ 9000 3D Optical Profiler

-

High performance optical profiler. Well suited for a wide range of applications, and highly configurable to meet your needs!

The NewView™ 9000 3D optical surface profiler provides powerful versatility in non-contact optical surface profiling. With the system, it is easy and fast to measure a wide range of surface types, including smooth, rough, flat, sloped, and stepped. All measurements are nondestructive, fast, and require no sample preparation.

At the core of the system is ZYGO's Coherence Scanning Interferometry (CSI) technology which delivers sub-nanometer precision at all magnifications, and measures a wider range of surfaces faster and more precisely than other commercially-available technologies, thus optimizing your return on investment.

Key Features:

- High-sensitivity 1.9 MP sensor

- Fast non-contact measurements

- Superior 3D surface visualization

- Sub-angstrom precision

- Ultra precision & gage capability

- Enhanced optical imaging

- Automated part setup

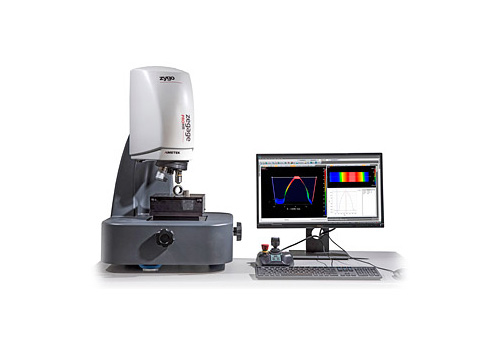

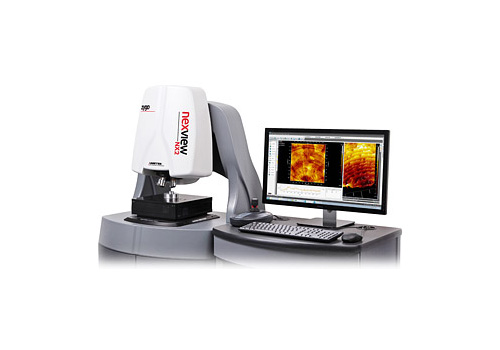

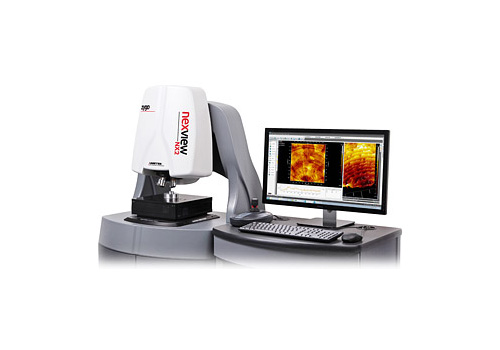

Nexview™ NX2 3D Optical Profiler

-

For ultra performance and industry-leading speed, precision, and automation. Designed for the most demanding applications. Measure virtually any surface!

Designed for the most demanding applications, the Nexview™ NX2 3D optical profiler combines exceptional precision, advanced algorithms, application flexibility, and automation into a single package that represents ZYGO's most advanced Coherence Scanning Interferometric (CSI) profiler.

The completely non-contact technology optimizes the return on investment by delivering sub-nanometer precision at all magnifications and measuring a wider range of surfaces faster and more precisely than other comparable technologies commercially available. With applications as varied as flatness, roughness and waviness, thin films, step heights and more on virtually any surface and material, Nexview NX2 truly is the no-compromise profiler.

As the latest generation flagship, Nexview NX2 provides a wide range of differentiated features targeted at making users' metrology better, faster, and more reliable:

- Large-area 1.9 MP sensor with high sensitivity lets you see more in a single measurement

- High-speed measurements take only seconds for improved productivity and process control

- Automated part focus and setup minimizes operator variability and training while reducing the time to data

- Gage capable performance through exceptional precision and repeatability for the most demanding production applications.

- Vibration robust metrology with SureScan technology and built in isolation enables high quality metrology even in vibration-prone environments

- SmartPSI™ technology for ultra-fast profiling of ultra-smooth surfaces

- 2D and 3D correlation provides confidence in your measurements with results that comply to ISO 25178 and ISO 4287 standards.

- Mx™ software for instrument control, analysis, and measurement automation

- True Color imaging for enhanced visualization

- Variable image zoom with three included zoom lenses lets users optimize the field of view and maximize instrument flexibility

3D Optical Profilers: special configurations

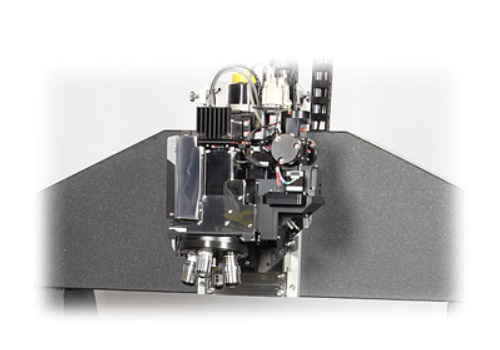

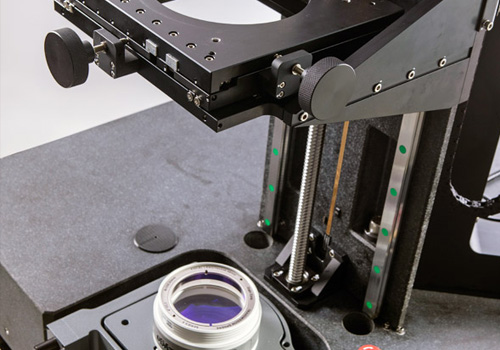

OEM 3D Optical Profiler

-

Leverage and integrate our industry-leading technology

Do you have a need for precise, high-speed, non-contact surface metrology and inspection? Are you an OEM manufacturer or system integrator looking to partner with a leading company with the experience to ensure your success? ZYGO's 3D Optical profilers are now available as a fully integrable solution with a long history of successful production integrations.

Why partner with ZYGO?

We bring decades of experience working with OEM manufacturers serving critical in-line metrology, inspection and process control for advanced manufacturing applications. Key industries served include:

- Consumer Electronics

- Automotive & Precision Machining

- Semiconductor

- Optics & Photonics

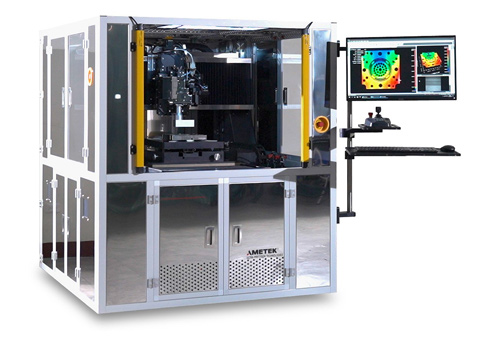

Guardian™ Industrial Enclosure

-

Optimize efficiency by using your ZYGO optical profiler right on the shop floor.

Now you can meet the most rigorous standards for precision metrology under challenging environmental conditions. Our Guardian™ enclosures isolate the metrology core from the surrounding environment, so you get optimal performance when and where you need it. Designed and built by ZYGO exclusively for our optical profilers, Guardian™ enclosures are built to perform and last.

Ergonomic Design

The system is designed to be a self-contained unit, which can be operated from standing or seated positions. All user interface peripherals can be positioned and adjusted. A large front-side opening makes the task of loading and unloading test parts and fixtures simple and efficient. The unit's interior lighting conveniently illuminates the work area as well. For serviceability, access panels are also provided around the unit.

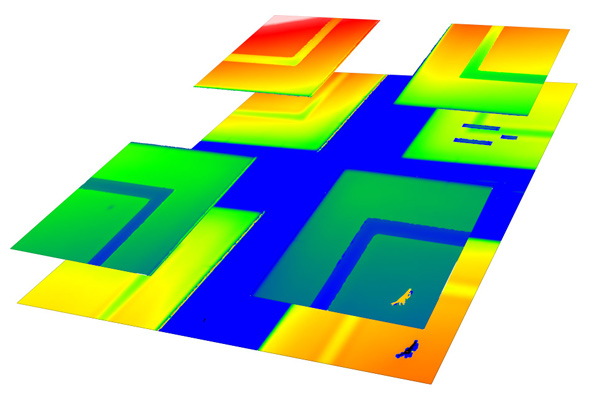

Large Format Inspection & Metrology

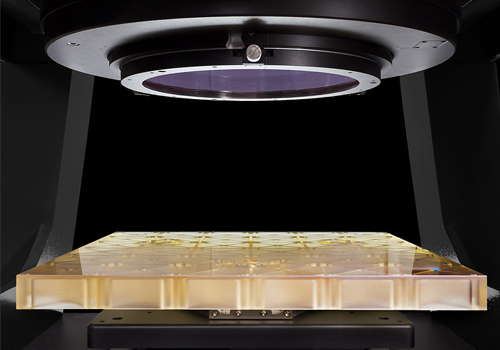

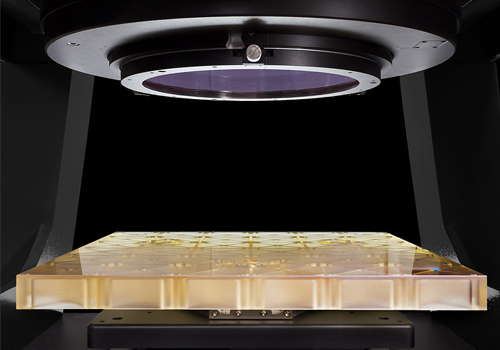

-

The Nexview™ 650 metrology system is an inspection tool for automated measurement of injection molding tooling, PCBs, glass panels and other samples requiring an extended work volume up to 650 x 650 mm. It provides 2D & 3D measurements of a variety of surface features with sub-nanometer vertical precision and sub-micron lateral precision.

Powerful Performance

Coherence Scanning Interferometry (CSI) is the measurement technology at the core of the Nexview™ 650 system.This non-contact technique provides high-precision, and high-value surface metrology benefits including:

- Measures virtually all types of surfaces, from rough to super smooth, including thin films, steep slopes, and large steps.

- Sub-nanometer measurement precision is independent of field magnification

- Gage capable performance - exceptional precision and repeatability for the most demanding production applications.

- SureScan™ vibration tolerance technology - robust operation in virtually any environment.

- Mx™ software enables seamless data exchange with other ZYGO Profilers including ZeGage™ Pro, NewView™ 9000, and Nexview™ NX2.

Micro Lens Process Metrology Systems

-

ZYGO's Compass™ metrology systems set the benchmark for automated, non-contact 3D surface metrology and process control for discrete micro lenses and molds critical to compact imaging systems such as automotive vision systems and cameras for smart phones and tablets.

There are two models of Compass™ systems available, depending on your metrology needs.. .

- Compass – ZYGO's advanced solution for precision metrology of micro lens surface form and deviation, topography, and relational/dimensional parameters. This is the ideal choice for applications that require complete characterization of spherical or aspherical micro lenses and their alignment features.

- Compass RT – A fast and flexible system for precision metrology of micro lens relational/dimensional parameters, plus general profilometry applications. This is the ideal choice when form deviation metrology is not required.

Laser Interferometers

-

ZYGO laser interferometers support and enable the most demanding metrology applications in industries from semiconductor and lithography to space-borne imaging systems, cutting-edge consumer electronics, defense-related IR and thermal imaging systems and ophthalmics.

There are a number of factors to consider when selecting an interferometer – primarily what it will be used to measure and the environment in which it will operate. ZYGO offers a range interferometers, from cost-effective production level to instruments optimized for difficult environments, and the highest resolution commercial interferometer purpose built for mid-spatial frequency characterization. See the latest instruments, technology, and capabilities below, as well as the applications and industries we serve.

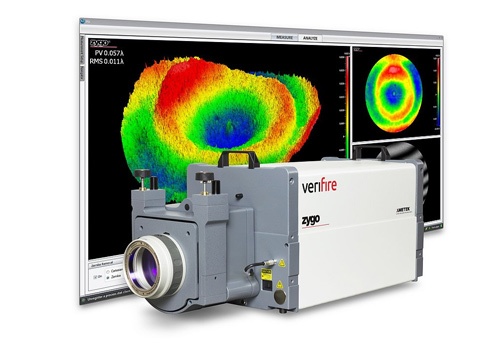

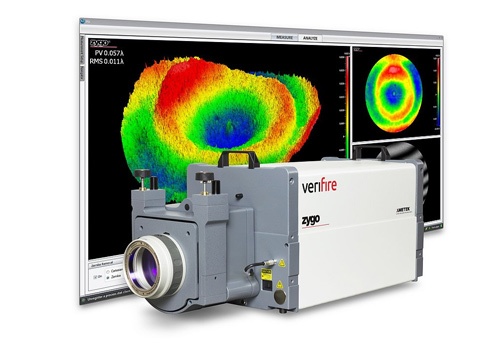

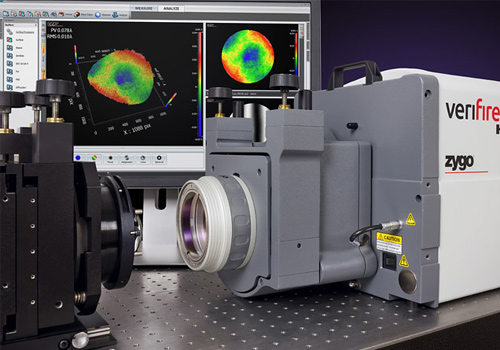

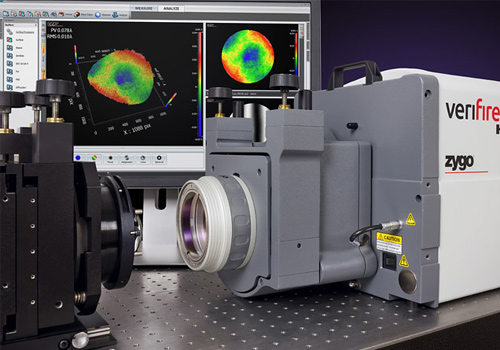

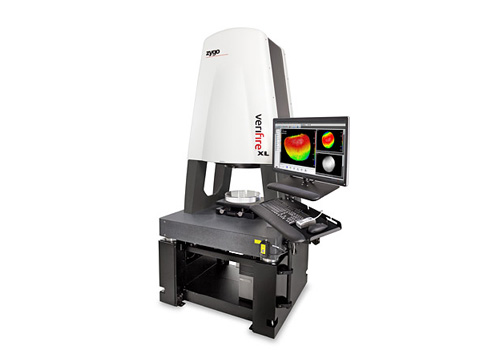

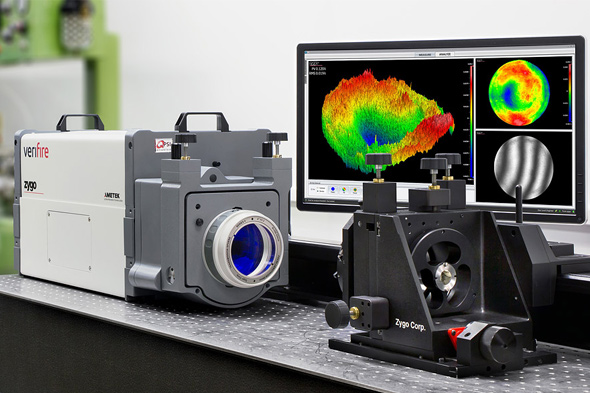

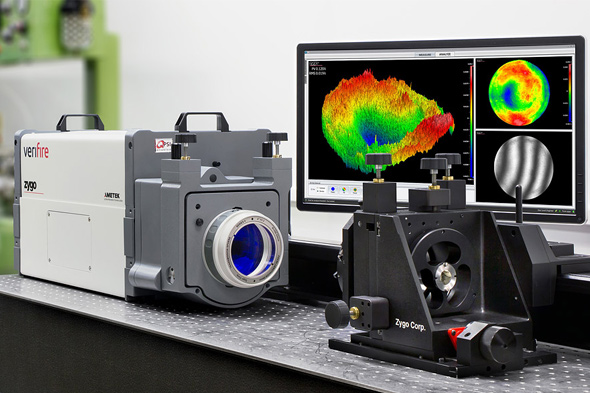

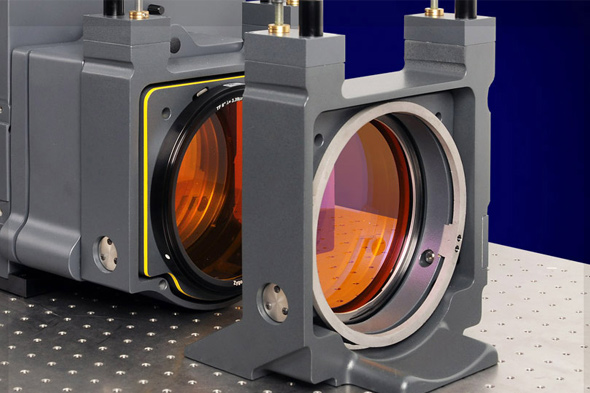

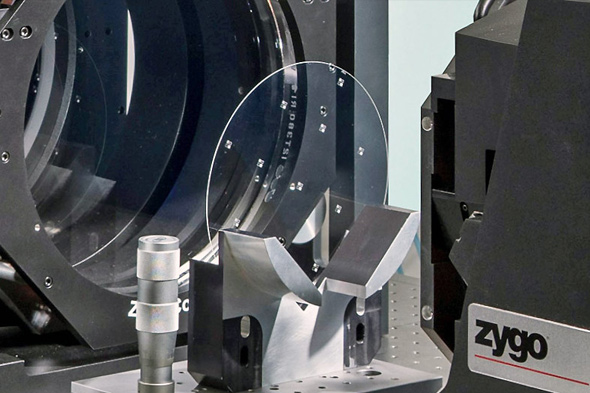

Verifire™ Laser Interferometer

-

The workhorse that the optics industry has relied upon for decades – cost effective optics shop-floor interferometer packed with technology and features, including an unmatched 3-year laser warranty.

Metrology workhorse of the optics shop

The Verifire™ interferometer system provides fast and reliable measurements of surface form error, and transmitted wavefront of optical components, systems and assemblies.

A true laser Fizeau design, the Verifire™ system expands upon ZYGO's unmatched experience in surface form metrology. The ZYGO-manufactured HeNe laser source combined with ZYGO's patented acquisition algorithms and full-featured Mx™ metrology software, enables high-precision metrology with easy to use analysis capabilities

Confident Metrology on the Shop Floor

Technology for optical metrology has advanced significantly in recent years. In the past, environmental effects needed to be carefully controlled to achieve reliable measurements. Today, ZYGO offers technologies that enable reliable measurements in harsh environments where vibration and air turbulence can make traditional optical metrology difficult or impossible.

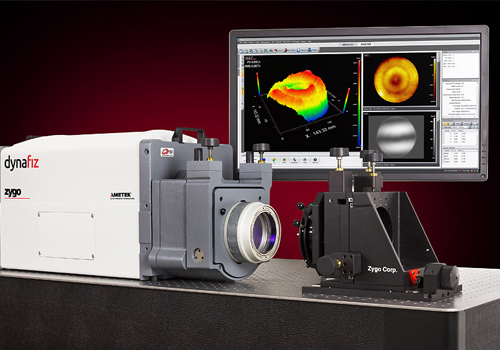

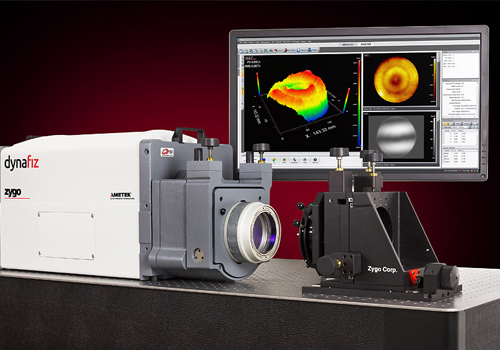

Dynafiz® Laser Interferometer

-

Measure in the most extreme environments, the Dynafiz is the most capable dynamic interferometer in the industry, purpose built and backed by patented technology.

Dynamic metrology... with confidence: Highest level of performance. Reliable metrology even in extreme vibration and air turbulence.

The new ZYGO DynaFiz® dynamic laser interferometer is a highly optimized optical instrument designed specifically for performing accurate metrology of optics in the presence of air turbulence and extreme vibrations.

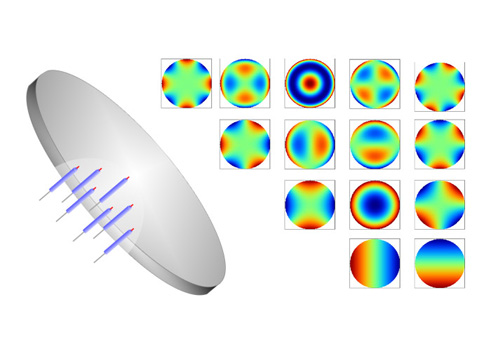

The high light efficiency of the DynaFiz® interferometer's optical system, combined with its long life, high power, HeNe laser source, enables operation at high camera shutter speeds that "freeze" vibration. This dynamic capability provides reliable metrology in environments that are too violent for traditional temporal phase shifting techniques.The low-noise, high resolution camera and optical magnification in the DynaFiz® dynamic interferometer enables clear visualization of the mid-spatial frequency characteristics in the surface of a test artifact.

Optical system testing can also benefit from the unique capabilities of the DynaFiz® interferometer and its ability to capture live data. LivePhase™ acquisition provides real-time Zernike feedback for active monitoring of the alignment of an optical system. This capability is the basis for movie mode which combines numerous dynamic images into a movie clip that provides a history of how an optic or system changes over time.

NEW! QPSI™ vibration-tolerant acquisition is now available standard on the DynaFiz interferometer. Take control of your metrology with any level of vibration. QPSI allows a faster vibration-robust measurement than dynamic acquisition, without the need for calibration or cavity changes.

Get the most from your metrology investment with the unique capabilities and unmatched versatility of the DynaFiz® interferometer. Reliability you can trust, only from ZYGO.

Key Features:

- Dynamic acquisition in turbulent air and extreme vibrations

- NEW! QPSI™ vibration-tolerant acquisition

- Optimized optical system provides clear visualization of mid-spatial frequency characteristics

- LivePhase™ enables real-time Zernike analysis [watch video]

- Movie mode captures wavefront changes over time

- High-power, long-life, frequency-stabilized HeNe laser

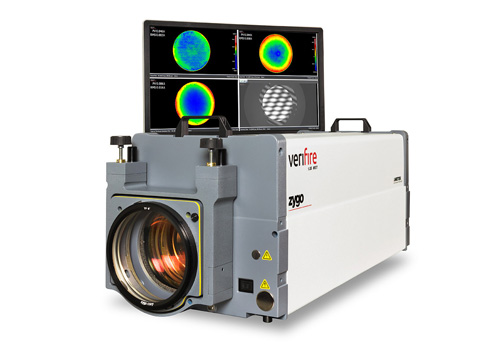

Verifire™ HD Laser Interferometer

-

High Definition Interferometer System with QPSI™ Vibration Tolerant Technology

ZYGO's Verifire™ HD interferometer system provides fast high-resolution measurements of flat or spherical surfaces, and transmitted wavefront measurement of optical components and assemblies. The interferometric cavity length is precisely modulated while a high-speed camera captures several fringe images, which are analyzed by the software to create a highly detailed measurement of the part being tested.

Exposes Mid-Spatial Frequency Surface Features

Mid-spatial frequency features can't hide any longer. The Verifire HD system boasts a hi-res camera and optimized optical design to reliably measure surface features that have been difficult to discern in the past. Plus, the Mx™ software package provides the facility to quantify mid-spatial frequency content with powerful Power Spectral Density (PSD) and diffraction simulation tool.

QPSI™ Vibration Tolerant Interferometry

QPSI technology eliminates ripple and phase noise caused by common sources of vibration such as grinding and polishing equipment, motors, pumps, blowers, and personnel, which means you can use the Verifire HD system right on the production floor, without the hassle and expense of vibration isolation tables.

QPSI is enabled by a powerful new proprietary laser and a high frame rate camera. No calibration or special setup is required. A simple change of a menu option enables/disables QPSI technology.

Verifire™ MST

-

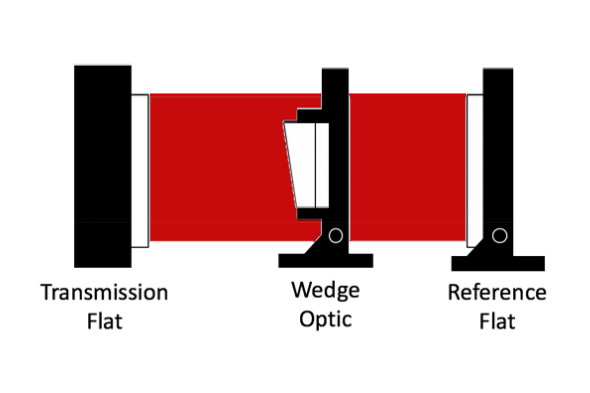

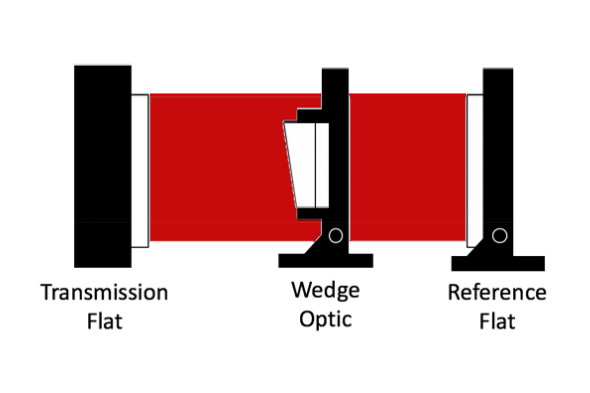

Laser Interferometer System for Multiple Surface Testing

The Verifire™ MST utilizes a wavelength shifting laser and patented data acquisition methods to enable simultaneous measurement of the front and back surface of transparent optics, thickness variation (including wedge) and simple 2-step homogeneity metrology without difficult part preparation or messy coatings.

The Verifire™ MST Multiple Surface Test laser interferometer system provides high precision measurements of surface form and transmitted wavefront of optical components and lens systems. It is the only commercial interferometer system that can measure multiple surfaces – with a single measurement.

Other important capabilities include measurement of optical material homogeneity and total thickness variation (TTV), and measurement of plano glass thinner than 1 mm. The system is available in 1.064 µm, 1.053 µm and 1.55 µm wavelengths, in addition to the standard 633 nm wavelength, for qualification of near-IR and short-wave-IR materials and systems.Differentiating Technology

The Verifire™ MST interferometer employs innovative and differentiating technology, including ZYGO's patented Fourier Transform Phase Shifting Interferometry (FTPSI) and wavelength-shifting technology. These technologies set it apart from all others, making it well-suited for the most challenging applications, such as the measurement of plane-parallel optical components where multiple reflections often confuse traditional phase-shifting interferometers.

Measure Multiple Surfaces with a Single Measurement

The Verifire MST system's differentiating technology enables you to confidently measure the front and back surfaces of an optic, the internal cavity, and thickness variation – all in a single measurement. No special calibration, part set-up, or surface preparation is needed. All data is automatically collected and analyzed by ZYGO's user-friendly Mx™ software, which provides detailed analysis of any or all of the surfaces measured.

Infrared Interferometers

-

At-wavelength metrology for demanding IR testing applications.

Testing at a system's design wavelength is critical for final alignment and qualification. ZYGO offers a range of Interferometers for testing optical systems and materials at their operating wavelength, from NIR to SWIR, MWIR and LWIR – including optical references and accessories.

Optical imaging applications are broad and varied. Testing at a system's design wavelength is critical for final alignment and qualification, Night vision, IR and thermal imaging systems for aerospace and defense, lithography subsystems, remote sensing telescopes, and exotic material qualification represent broadly-varying wavelength requirements, and all benefit from testing at design wavelength with an infrared interferometer system.

ZYGO, long recognized as the world leader in interferometric testing instruments, has designed and built many specially-equipped interferometer systems, including NIR, SWIR, MWIR and LWIR wavelengths. ZYGO also designs and manufactures an array of reference optics (transmission spheres and transmission flats) for these wavelengths.

Confident Metrology for a Dynamic World

In addition to specific wavelength requirements, many optical testing applications must be conducted in difficult environments where vibration and air turbulence are extreme. These environmental effects can make precision metrology difficult or impossible. ZYGO has developed unique acquisition technologies that enable confident metrology in these demanding environments, and are available on all NIR, SWIR and MWIR interferometers.

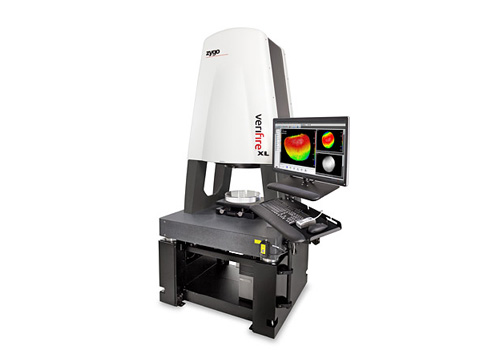

Verifire™ XL

-

Large-Aperture Downward-Looking Interferometer Workstation

The Verifire™ XL interferometer is a stand-alone workstation designed for simplistic and reliable metrology of large flat surfaces up to twelve inches (300 mm) in diameter. Examples include front-surface reflectors, windows, and semiconductor wafers or wafer chucks.

This fully integrated system is easy to use, with a heavy duty tip/tilt stage that provides repeatable part placement without the need for custom fixturing. The compact footprint, with built-in vibration isolation, requires minimal production floor space.Vibration Robust

The Verifire XL system includes ZYGO's patented QPSI™ acquisition technology which enables reliable high-precision measurements in the presence of vibration. QPSI enables true on-axis surface form metrology, without degradation from typical production vibrations.

Accurate Metrology

The high-performance transmission flat in the Verifire XL system is designed for minimal sensitivity to gravitational sag, and includes a full-area calibration file to enable optimum system accuracy.

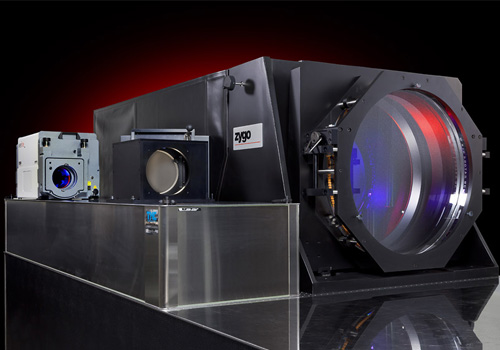

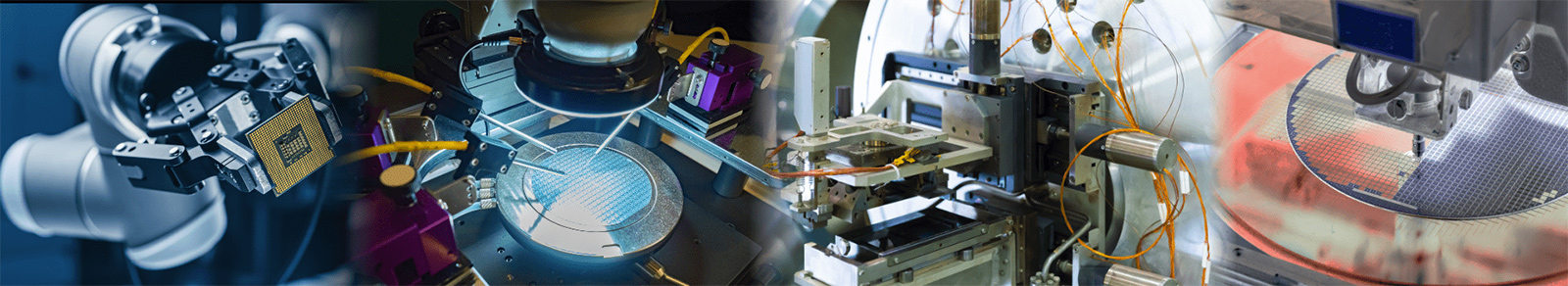

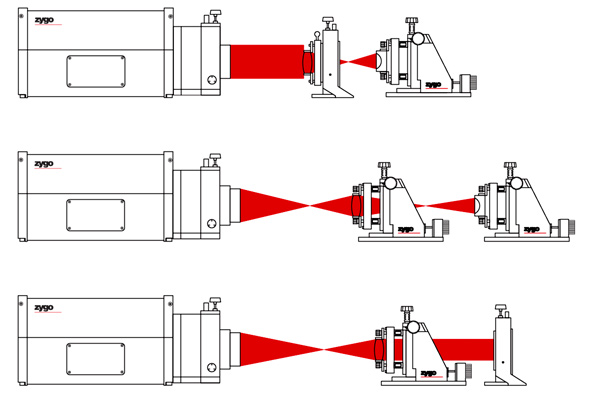

Large Aperture Interferomter System

-

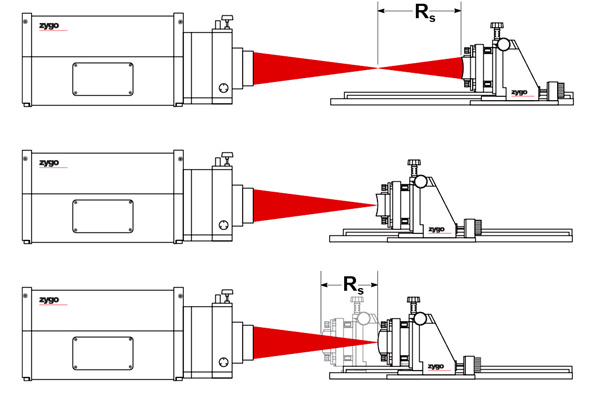

Expanded apertures for large format optics metrology

ZYGO's horizontal-axis Large Aperture Systems offer the unique capability to maintain two independent metrology cavities; one of the nominal interferometer aperture (4") and the other a choice of one of four beam expander diameters (12", 18" 24" and 32"). When configured with the proper accessories the Large Aperture Systems can be used to measure both surface form and transmitted wavefront quality.

Large Aperture Systems consist of...- The interferometer mainframe (Verifire™ or Dynafiz®)

- MUX cube (switchable mirror assembly)

- Beam Expander (available as 12", 18", 24" or 32" diameter)

- Phase measuring receptacle (for 12" and 18" systems; 24" and 32" utilize wavelength shifting mainframes and do not require a PMR)

- Reference optics - transmission and reference flats as required depending on the optical configuration

- Mounts - Mounts for the reference optics and test optics are available

The Large Aperture System components can be purchased separately from the interferometer mainframe. Contact your local ZYGO representative for assistance in configuring the system to meet your metrology needs.

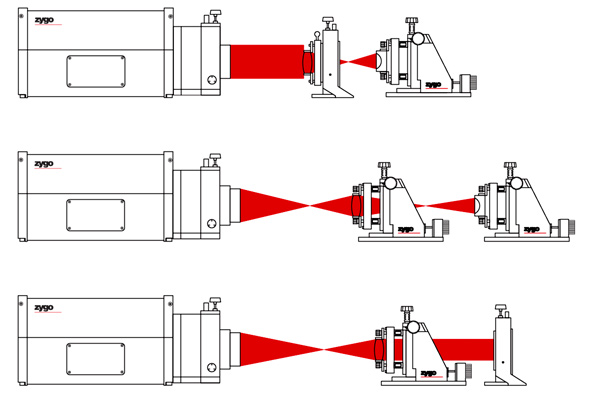

Workstations Verifire™ VTS

-

Interferometer workstations for efficient production optics manufacturing

ZYGO’s Verifire VTS is a purpose-built spherical optics interferometer workstation. The vertical upward-looking workstation enables fast pick-and-place measurements by working with gravity to hold test parts in place. The integrated passive vibration isolation system and granite base ensure a rock-solid metrology platform designed for peak performance even in production environments. A motorized Z-stage with 1 m of travel enables quick automated placement of the test part, as well as point-to-point radius of curvature.

The VTS is compatible with a range of interferometer mainframes, select the performance level that suits your production or development needs. The compact footprint is available with or without a safety enclosure with light-curtain motion interlock that meets CE machine safety requirements.

Vertical workstation kits enable the flexibility of a vertically oriented interferometer in a no-frills cost-effective package. Check out the Laser Interferometer Accessory Guide for more information on the configurations and options available.

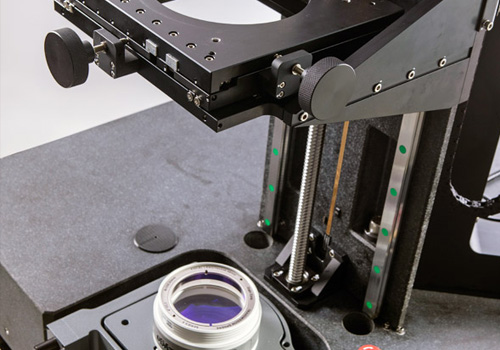

Nano-Position Sensors

- ZYGO nano-position sensors are widely used in closed-loop motion control systems, mainly for lithography and inspection tool staging, as well as for deformable optical systems. We have pioneered innovations in the displacement and position sensors for over 30 years, and we work closely with applications requiring the highest precision and reliability. Our team of applications experts is ready and able to help you tackle your position metrology needs.

Displacement Measuring Interferometer Systems

-

ZYGO position sensors are widely used in closed-loop motion control systems, mainly for lithography and inspection tool staging systems. We have pioneered innovations in the displacement position sensors for over 30 years, and we work closely with applications requiring the highest precision and reliability. Our team of applications experts is ready and able to help you tackle your position metrology needs.

Lasers

ZMI™ lasers provide highly stabilized, two-frequency output which provides a firm foundation for high-precision position metrology. These lasers are based on robust Helium Neon technology that has high reliability and is used as a standard definition of the meter.Interferometers

ZYGO’s standard interferometer configurations support many types of measurement scenarios. Most interferometers can support a straight-through or right-angle measurement orientation and can be manufactured for operation in vacuum.Measurement Electronics

Measurement electronics calculate displacement using optical signals from the interferometers driven by the laser source. Our patented Cyclic Error Correction option automatically and seamlessly eliminates common non-linear errors intrinsic in DMI systems.

Absolute Position Sensors

-

High-precision non-contact absolute position measurement on up to 64 synchronized channels

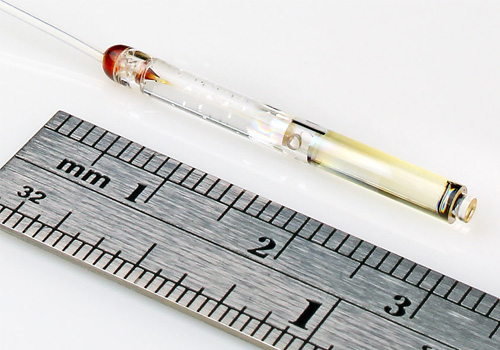

ZYGO's new ZPS™ system measures absolute position using ultra-compact optical sensors that are easily integrated into high-precision applications such as deformable mirrors and lens positioning.

The optical sensor system provides up to 64 synchronized channels of high-precision, non-contact, absolute position measurement over a range of 1.2 mm. Measurement resolution is 0.01 nm with ≤ 1 nm/day measurement stability.

The optical sensors do not generate heat and are insensitive to electromagnetic interference, making the ZPS system ideal for high-precision applications that may be affected by these factors. The ultra-compact sensors connect to the compact centralized enclosure via fiber optic cables. ZYGO's complimentary ZPS™ software provides a plug-and-play connection between the ZPS system and your computer, allowing you to get up and running with your system quickly and easily.

Applications

The ZPS system is typically used in closed-loop feedback systems that require a continuous stream of high-precision position data from multiple sensors to compensate for drift and maintain precise positioning and alignment. The system can also be used as a tool in RD&E and manufacturing environments for alignment in test fixtures or to quantify dynamic mechanical performance.

Click on each of the thumbnail images below to see illustrations of sample applications.

Application: Stage Servo Control

-

With over 30 years of experience, ZYGO's nano-position sensing products have become one of the most trusted, delivering continuous operation with exceptional performance. ZYGO is a market leader in displacement sensors providing feedback for closed loop servo control on an OEM basis. Semiconductor and flat panel manufacturing and process control tools in production today rely on ZYGO sensors to provide the precision and reliability needed for high volume manufacturing environments.

Our ZMI™ displacement measuring interferometer sensors are used to measure relative motion of reticle/mask and wafer stages in these systems to the nanometer level. Our modularized components can be configured to provide all degrees of freedom necessary for your specific application to enable successful nanometer-level motion control. A single ZMI laser head is capable of measuring between 2 and 22 axis of measurement, allowing for a fully synchronous measurement across all axes.Application Examples

- 2-Axis Vacuum DMI System

- Flat Panel DMI System

As your partner in motion control, you can expect ZYGO to be there to support your continuous system improvements and provide a path forward towards your next generation requirements.

Application: Adaptive Optics Control

-

Gain finer control of your adaptive optics by knowing how they are actually deforming!

ZPS™ offers a massively parallel arrangement of up to 64 small-footprint sensors to directly measure the front or rear surface of a mirror or other optic, allowing you to reconstruct the surface deformation for best aberration correction. This enables real-time in situ monitoring of the optic which together with closed loop control can maintain the shape or deform it deterministically.

Mirror shape can be changed unintentionally with thermal loads, actuator drift, or mechanical creep. Certain adaptive optics applications cannot monitor the performance of the optic without interrupting operation or impacting optic system performance. Other possible solutions are either not practical or do not measure fast enough to be effective. Enter ZPS™.ZPS' high repeatable absolute position means that you are able to store known good deformation states and dynamically drive to these states, enabling rapid adjustment of the optical configuration and avoiding the slow iterative processes typically involved.

Application Examples

- Synchrotron Deformable Mirror

Applications

- ZYGO metrology products are highly versatile, and can be used for a wide variety of measurement applications. There are too many applications to list individually, but the list below represents several of the types of measurements that are possible.

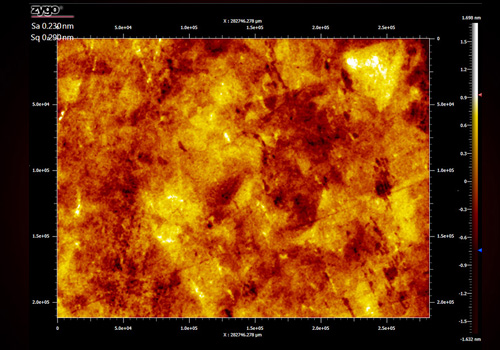

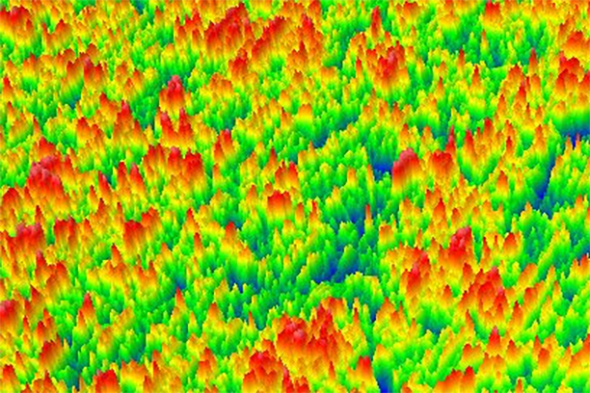

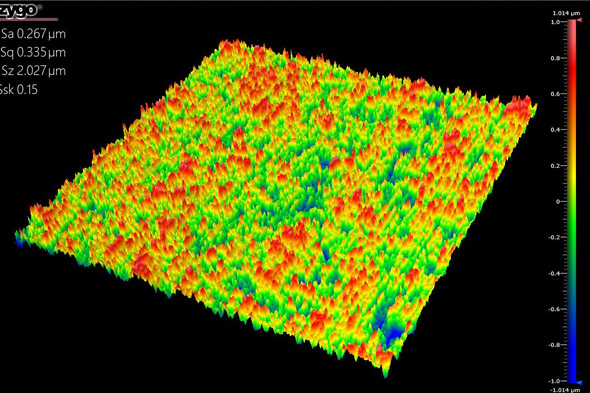

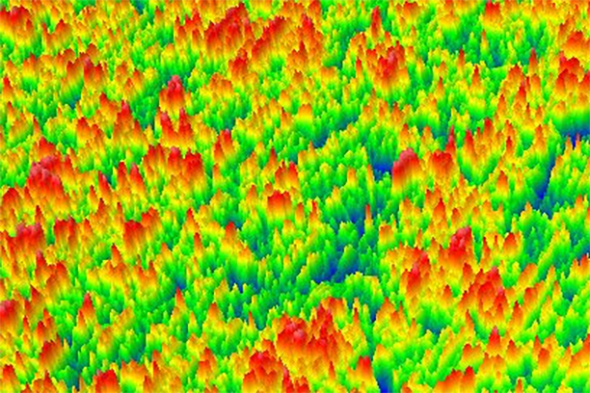

Topography & Texture

-

As technology pushes forward, surfaces are being manufactured with exacting control and the need to measure surface texture with high precision and accuracy has become even more critical. When it comes to roughness measurements, there are 3 important factors: measuring the surface, processing the data, and reporting the results.

Measuring the Surface

Measuring the surface with sufficient precision is critical to making sure your roughness values are accurate. ZYGO's 3D optical profiler systems make collecting precise data quick & simple with ease of use features like SmartSetup™ Technology which will find focus, adjust the measurement parameters, and take a measurement all in a single button click.Analyzing the Data

With any roughness measurement, the raw data needs to be processed or filtered to separate the roughness from the waviness & shape of the surface. The ZYGO’s Mx™ software makes it easy filter your surface with ISO-compliant filtering.

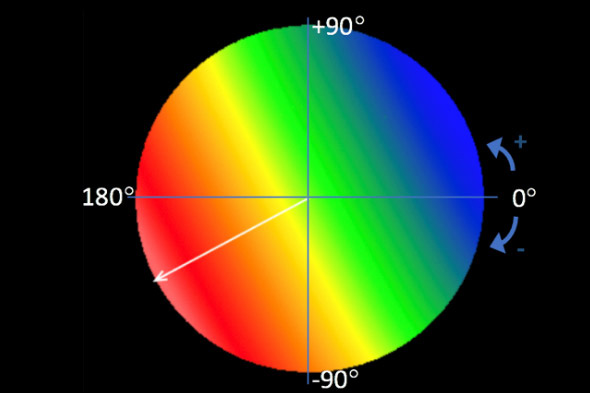

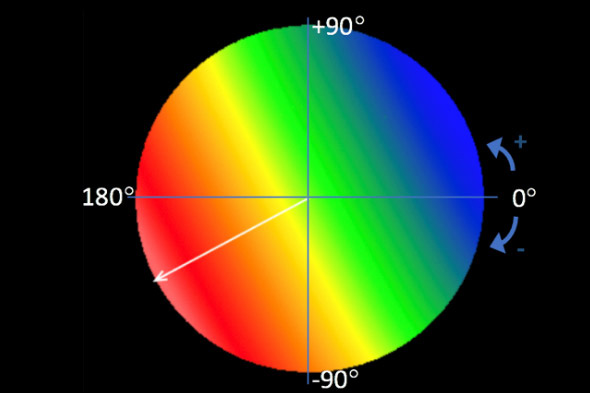

Wedge & Prism Angle

-

The performance of optical systems such as telescopes, camera lenses, and laser systems rely on the quality of the optical components within the systems. Many plano optical components appear completely parallel from a side view, however there is typically some wedge between the sides. In extremely precise systems, knowing the degree of a window’s wedge is crucial.

Non-Contact Methods

There are multiple non-contact methods to measure wedge or parallelism. Autocollimators are a common device used in the optics industry to do this. When light passes through an optical wedge, the beam is deflected by some angle, δ, which is defined by the refractive index of the glass, n, and the glass’s mechanical wedge angle, α. The calculation for this is given by the formula: δ = 2(n-1) · α.

While this method is useful, the accuracy and reproducibility of the results are dependent on having a skilled operator. It is also necessary to have a target mirror that is flat to λ/4 or better to ensure that the return image is sufficiently well focused. In addition to all of the measurement capabilities that an interferometer has, it is also useful in measuring the wedge of a window under certain conditions.

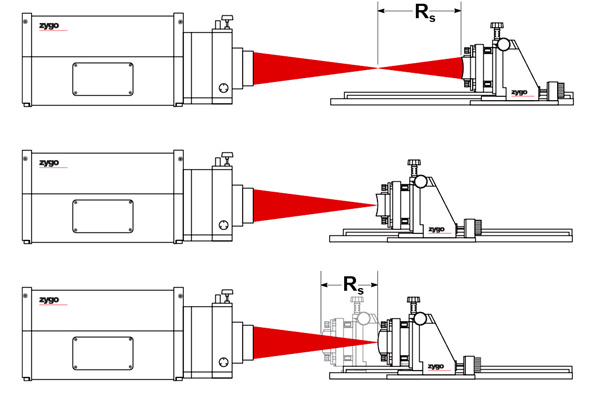

Radius of Curvature

-

ZYGO laser interferometers are powerful and precise instruments for measurement and characterization of optical components and systems. One of the most common applications include the measurement of the radius of curvature. The radius of curvature is a fundamental and functional parameter of spherical optical surfaces, which requires quality control during manufacturing.

Interferometers are often the preferred solution for optical manufacturers as they possess key attributes and advantages, including:

- Non-contact, 3D measurements

- Precise, high quality data

- Rapid part setup and measurement

- Compatible with short- and long-radii surfaces

The radius of curvature of spherical surfaces is commonly determined using a phase measuring interferometer to identify the null positions at the best fit spherical surface (confocal) and center of curvature (cat’s eye) of the test optic. A linear guide provides motion between these positions and one or more displacement sensors are used to record the distance between the cat's eye and confocal positions and, hence, the radius of curvature.

Transmitted Wavefront

-

Transmitted wavefront error (TWE) is used to qualify the performance of optical elements as light passes through.

Unlike surface form measurements, transmitted wavefront measurements include errors from the front and back surface, wedge, and homogeneity of the material. This metric of overall performance offers a better understanding an optic’s real-world performance.

While many optical components are tested individually for surface form or TWE specifications, these components are inevitably built into more complex optical assemblies with performance requirements of their own. In some applications it is acceptable to rely on component measurements and tolerancing to predict final performance, but for more demanding applications it is important to measure the assembly as-built.

TWE measurements are used to confirm an optical system is built to specification and will function as expected. Additionally, TWE measurements can be used to actively align systems, decreasing assembly time, while ensuring the expected performance is achieved.

Optical Measurement of Films & Coatings

-

Precise characterization of thick and thin film topography and thickness, and substrate topography

There are many applications in which the deposition and control of films and coatings is critical to enabling functionality or efficiency of devices, including consumer electronics, semiconductors, optics and many more. Such advanced devices often demand accurate characterization of film topography and layer thicknesses to ensure high quality and performance.

Based on non-destructive, non-contact areal-based optical technologies (CSI - Coherence Scanning Interferometry), our versatile and precise 3D metrology instruments and sensors can measure a diverse range of transparent surfaces with varying topography and layer thicknesses, from 50 nanometers to 150 microns, over an area of microns to millimeters.

Form & Flatness

-

Manufactured surfaces can take on many shapes and sizes. For surfaces where the characterization of shape is function critical, ZYGO laser interferometers and 3D optical profilers stand out with sub-nanometer repeatability of non-contact surface data. Incorporating industry standards for form and flatness into Mx™ analysis software creates a single stop measurement tool for surface inspection. Explore the solutions for your application in surface form and flatness metrology below.

Form

Form metrology can be summarized as the absolute or relative measurement of a surface compared to a base shape. ZYGO products cover general applications like spheres and cylinders for ready measurements using standard products along with specialized application and tools for more complicated forms such as aspheres or thin glass.

The ZYGO application space on form metrology is as wide and our tools are flexible. Radii on bevels, angles of prisms or between surfaces, or surface curvature are just a few examples. Cartesian and rotationally symmetric fitting functions accompany millions of data points across a given surface to ensure confidence in our form metrology.

Flatness

Flatness measurements are performed in various ways across the ZYGO product line. High quality transmission flats (up to λ/50) allow ZYGO laser interferometers to measure flats for space telescopes down to ground steel surfaces. Mx™ software extends the flatness metrology application space for oversized (greater than 4 to 6”) rectangular surfaces by way of the grazing incidence measurement.

Optical profilers with motorized staging overcome small field of view measurements with stitching and patterned moves to explore and render flatness results of your surface. Similarly, the range of working distances for our microscope objectives allow for measure of flat seats and seals in recessed cavities.

With a number of solutions and a robust application space, ZYGO prides itself on being a leader in surface form and flatness metrology. Learn how ZYGO can meet surface specifications while exceeding your expectations.

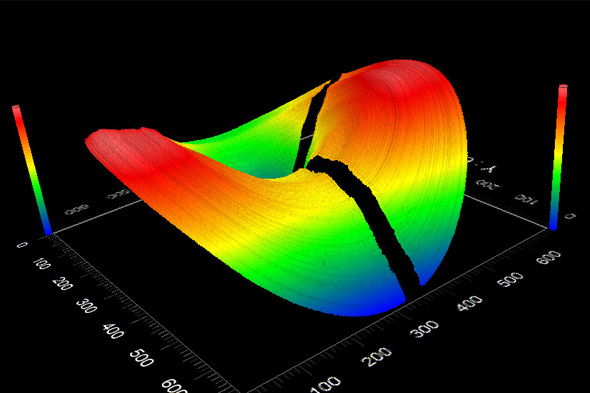

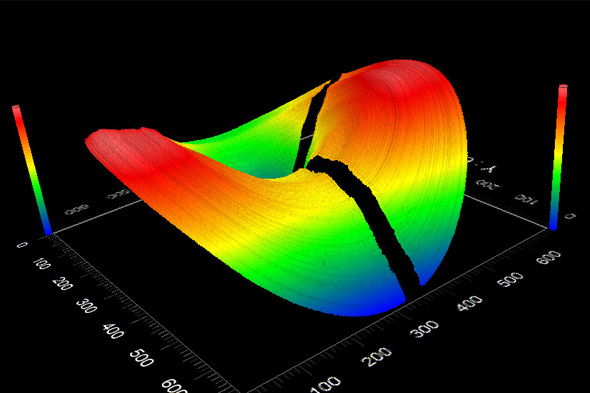

Asphere & Freeform Metrology

-

Applications for aspheric and freeform optics are growing and are commonly used where improved imaging performance and fewer optical elements are desirable. Design of these complex optics and their precision manufacturing methods have become enablers in the commercialization of advanced optical systems used in diverse applications, such as LED illumination, laser beam shaping, consumer electronic devices, imaging sensors, telescopes, head-mounted displays, cameras, and lithography stepper lenses.

Unlike traditional curved optics where the surface shape is nominally spherical, aspherical and freeform surfaces exhibit an asymmetrical optical surface with typically complex, high-aspect ratio, sloped surfaces. A freeform optic designed to include spherical, aspherical and toroidal surfaces into a single part, thus making them challenging to design, measure and manufacture.

For these types of complex surfaces, precise metrology plays a key role in providing essential quality control and feedback during the fabrication process. ZYGO laser interferometers and 3D optical profilers ensure quality and process monitoring during manufacturing by characterizing and quantifying critical surface parameters such as form errors, waviness, defects, and surface roughness.Compared to tactile methods for measurement of optical surfaces, ZYGO interferometers offer several key advantages for more efficient quality control and yield optimization:

- Non-contact methodology – prevents possible damage to the finished, high-quality surfaces

- Full-area, 3D measurement – provides better process insight and characterization of the surfaces compared to individual (2D) profiles.

Optical Material Homogeneity

-

An important property of an optical component is the variation of the refractive index of the material from which it is made, broadly referred to as homogeneity. Material inhomogeneity causes variation of the refractive index in a glass, which can be in the form of sharp, cord-like regions called striae or it can occur as a gradient of the refractive index through a larger region of the sample. Material index variations must be qualified to ensure their impact is within tolerance for a particular optical design where the material is used.

ZYGO laser interferometer products offer a range of capabilities for qualifying optical material homogeneity as well as built-in analyses in our comprehensive Mx data acquisition and analysis software.

Verifire MST – Multiple Surface Test interferometer is well suited to qualify material homogeneity of plane parallel windows by simultaneously measuring the transmitted wavefront of the window and removing the effects of surface deformation (required to achieve precise material measurements). The simultaneous nature of measurement using the MST reduces measurement uncertainty for the most precise results, and maintains the important linear component of homogeneity, information lost with other metrology methods.

Verifire and Dynafiz interferometers enable similar measurement capabilities of wedged optics with an acquisition and analysis software package designed specifically for material homogeneity measurements.

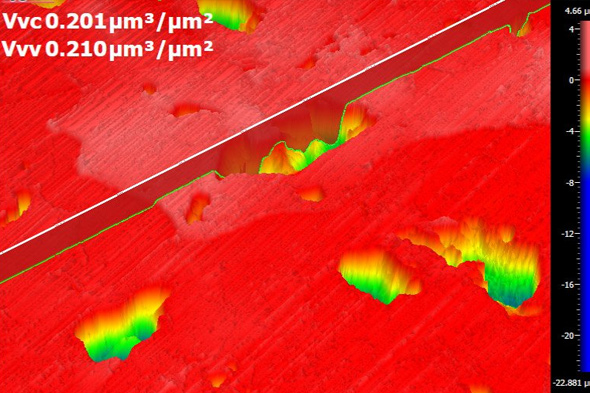

Wear & Volume Analysis

-

Measuring volumetric properties of a surface is most often used in wear analysis of lubricated surface but has uses in many other applications such as adhesion, porosity, and particle distribution.

Material Wear Analysis

When it comes to tribological studies, understanding and quantifying wear scars is critical to understanding the complete picture. ZYGO’s 3D optical profiler systems make quick work of segmenting the wear scar from the unworn area to provide quantitative metrics. Some of the metrics that are commonly looked at include:

Void

- Volume

- Max & Avg. Depth

- Area

Material Push-Up

- Volume

- Max & Avg. Height

- Area

What We Measure

-

ZYGO's high-precision, versatile, non-contact 3D metrology systems are applied across a wide range of industries. We offer standard and customized solutions for many metrology applications, including measurement and characterization of surface shape and roughness, part geometries and dimensions, transmitted wavefront and optical performance, transparent films and coatings, wear and volume analysis, defects and image analysis, to name just a few.

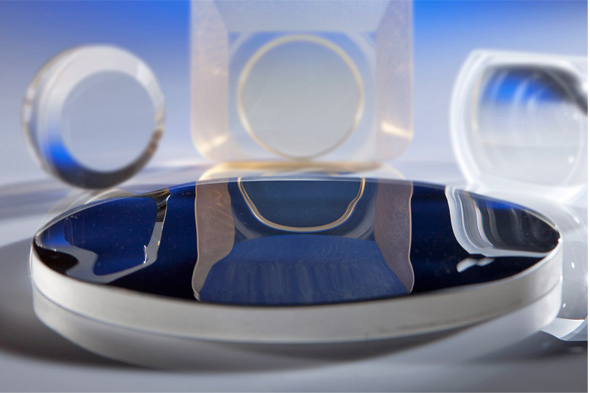

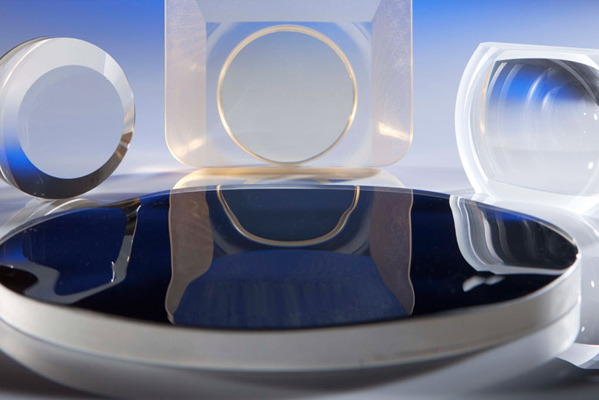

Precision Optical Components & Systems

- ZYGO's Optics business segment specializes in producing complex electro-optical systems and high-precision optical components for the Medical/Life Sciences, Defense & Aerospace, Semiconductor, and Industrial OEM markets.

Precision Optical Components

- ZYGO is a premier fabricator of high precision optical components. Our reputation has been earned by consistently exceeding customer expectations, even when the project has a high degree of difficulty. We have a vertically-integrated approach, with precision verified by ZYGO's interferometric metrology products. Watch the video below to learn more about our processes. Use the links at left to learn more about the types of components we fabricate.

Windows

-

ZYGO is trusted worldwide to provide optical windows for the most high-precision, advanced applications. For over 45 years, we specialize in bringing the most challenging optical designs to life. ZYGO works as your design partner, ensuring you receive windows meeting your most stringent specifications.

An optical window is a polished piece of material that is transparent at some portion of the electromagnetic spectrum, which allows the desired portion of the spectrum to pass into an optical instrument unaltered.

Mirrors

-

ZYGO creates precision optical mirrors using stringently-controlled fabrication processes, enabling them to function reliably in a variety of extreme environments. Our mirrors are found underwater, in deserts, at high altitudes and orbiting the earth. We customize every mirror to meet or exceed your requirements.

Mirrors can also be light-weighted for applications where weight is critical, as is common in aerospace applications. Light-weighting is a process in which material is removed from an optical component by machining, or other methods, while still preserving the mirror's optical performance.

Spherical Elements

-

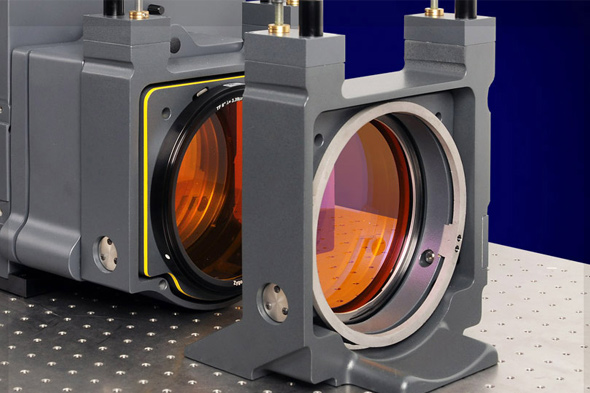

ZYGO's Optics business segment manufactures precision spheres and lenses ranging in diameter from 50 mm to 700 mm with radii from 12.7 mm to 8 meters.

Our standard product line of transmission spheres is available in 100 and 150 mm clear apertures ranging in f-numbers from f/.65 to f/11 with wavefront errors of λ/10 or λ/20. Our new line of Ultrasphere™ transmission spheres is available at λ/40. Various convergers and divergers are also part of our standard product line. We are a qualified vendor for high laser fluence lenses.

Aspheres & Freeforms

- ZYGO manufactures the world’s most accurate aspherical, spherical and freeform optics. These can be manufactured in sizes up to 600 mm, with surface figure tolerances better than 100 picometers. To put this into perspective, imagine an optic the size of the Unites States with a surface accuracy of less than a millimeter!

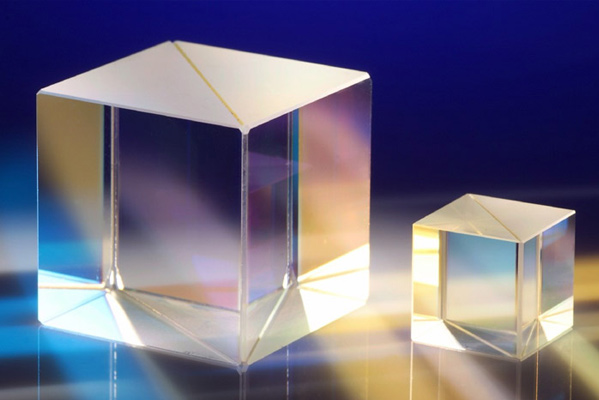

Custom Beamsplitters

- ZYGO specializes in providing large format, complex beamsplitters for use in aerospace, defense, and research applications. All beamsplitters are custom made per your design. Our interdisciplinary optics team will work closely with you to ensure manufacturability while still meeting stringent specifications.

Straight Edges

- Straight edges are precision machined and polished structures used as a physical or optical reference surface. ZYGO manufactures extreme precision straight edges from low CTE (coefficient of thermal expansion) materials, achieving tolerances up to 1,000 times better than a machinist’s straight edge. Fabrication, coating, and metrology are all performed by ZYGO. Ask us about high volume / OEM pricing options.

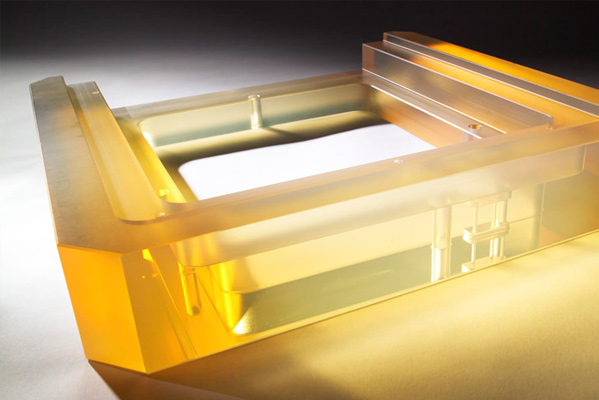

Light-Weighted Optics

-

Modern Defense, Aerospace and NewSpace customers require high performance optical systems which minimize Size, Weight and Power (SWaP) while maximizing optical performance. One proven technique for achieving demanding SWaP requirements is to require light-weighted optics.

Light-weighting is a process by which material is removed from the optical component by machining or other methods while preserving the optical performance. This is often performed with low-expansion ceramics and glasses, and careful attention must be paid to the light-weighting structure to ensure optical performance and rigidity. ZYGO experts are available to assist in our partners design of these components for manufacturability.

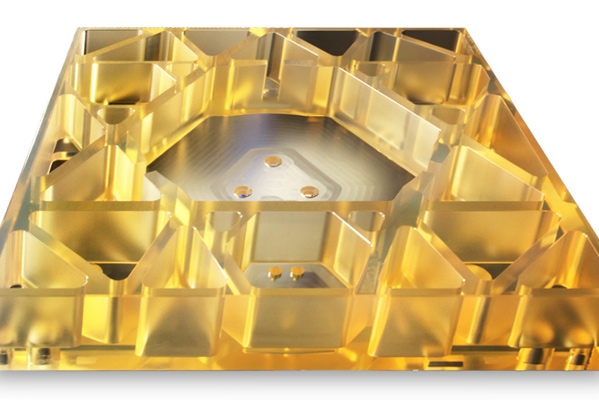

Machined Structures

-

ZYGO serves our Semiconductor, Industrial, and Research customers by providing non-traditional glass and low-expansion components and systems which fall outside of the traditional definition of “optics”. Examples include light-weighted wafer stages for semiconductor lithography, zero-expansion metrology reference frames for precision positioning control, and traditional straight-edge mirrors and references. We routinely manufacture these items in sizes up to 1.25 m with nanometer precision (when required!).

Optical Coatings

- ZYGO’s world class coating design engineers and technicians work closely with our metrology and optical manufacturing teams, creating a “one stop shopping” advantage for our customers. This simplifies your supply chain, reduces program risks and overall timeline. Select a single, vertically integrated manufacturer when it is critical your substrate will meet all requirements after a coating is applied.

Services

-

In the field of precision optics, ZYGO fabricates world-class plano, aspheric and spherical surfaces, and precision machined structures.

Our precision optics team has over 20 engineers with a distinguished heritage. Their project experiences range from aspherical optics used to repair the Hubble Space Telescope, to the development of sub-nanometer precision EUV optics used in today's most demanding lithographic systems. Whether you need us to develop a Scope of Work, build a prototype system, or redesign for improved performance, ZYGO is ready to take on your most demanding optical challenges.