- Offer Profile

-

Since our beginnings we have been driven by our customers’ needs and our passion for new technologies.

With 70 successful years in the Japanese market and 30 years in the European market, we have become a global company.The word Accrete is hidden in ACCRETECH, which means: Using synergies, combining power, finding solutions together, offering the best support for the best products, growing closer and growing together. The name is our driving force for new pioneering technologies – in both the nanometre precision sector of industrial measuring technology and also in the fascinating area of semiconductor equipment technology.

SEMICONDUCTOR

-

High-tech semiconductor equipment for efficient microchips.

Manufacturing microchips is very complex and costly. Hundreds of automated process steps are required to produce a modern microprocessor from the raw material, quartz sand. The most common base for chips are discs of silicon crystals, called wafers. The requirements made of these discs are increasing every year. This is because ultra-thin, extremely durable and perfectly smooth wafers with unevenness of only a few nanometres are necessary for ever smaller and even more powerful microchips – and thereby for

smartphones, laptops, electronically controlled machines or intelligent cars of the future. ACCRETECH offers you ultra-modern machines and systems which you can use to manufacture precisely the types of wafers required in the semiconductor industry. We see ourselves not only as a developer and manufacturer, but also as a service provider and partner. Our global and European presence with a full sales and service network, as well as an application and demo centre in Munich, guarantees optimal support to our clients.

Successful for more than 70 years

From the very beginning, our customers’ needs and our passion for new technologies have determined our actions. Intrinsically driven by achieving perfection and reliability, we develop high technology systems and machines for the semiconductor manufacturing industry, supporting our customers in fierce international competition. For over 70 years in Japan and since 1989 in the European market.

Wafer Prober

- Wafer Probers are machines which are required for electrically testing the wafers of individual chips. The Prober therefore undertakes the fully automatic loading and handling of the wafer while ensuring the best positioning accuracy. A full test cell consists of a wafer prober, a test unit and a probe card. Our flagship wafer probers for wafers up to 200 mm or 300 mm diameter not only work with the highest precision thanks to the latest technology, but also ensure maximum capacity and productivity with their above average and high throughput.

UF190R

-

Fully automatic Wafer Prober for 100 or 120 to 200 mm wafers

- Now with the latest SW and Electronics generation

- Also available for numerous special applications, such as MEMS wafer handling

- Highest speed 300 mm/s in the XY-axis, 30 mm/s in the Z-axis, rotation angle +-5 deg

- With second card feeder as an option

- Wafer Handling with robot arm and backside holding

UF200R

- Fully automatic Wafer Prober for 120 to 200 mm wafers

- Now with the latest SW and Electronics generation

- Also available for numerous special applications, such as MEMS wafer handling

- Highest speed 300 mm/s in the XY-axis, 30 mm/s in the Z-axis, spindle rotation angle +-5 deg

- With second card feeder as an option

- Wafer Handling with robot arm and backside holding

UF2000

-

Fully automatic Wafer Prober for a high throughput – for 120 to 200 mm wafers

- Precision +-1.5 µm, with the newest optics to determine the positioning precision

- Ultra-stable Z/θ platform for Multi-Pin Probing Contact

- Precise control of the surrounding temperature – optionally with Low Temperature Chuck or Hot Chuck

- High flexibility – numerous options such as the double loader

- Simple operation – multifunctional display and touch screen operation

- Each drive axis can be separately controlled – for optimum control of each individual component

AP3000/AP3000e

-

Next-generation ultra-high-performance probing machine

- Needle cleaning (cleaning wafer, or cleaning unit)

- Fan filter unit (mini-environment)

- HF jig/manipulator, Tester interface

- Loader : 2 Loader / Automation with AMHS

- Head stage tilt (Probe card tilt)

- Chuck: Ambient / Hot temp. / Low temp. /Low noise

- APC : Auto probe card exchange

- Cassette ID reading

- Wafer ID reading (Top surface / Back surface)

- GB-IB Interface

- Prober Network (Veganet, Light-Veganet, Vega-Planet, GEM)

- PCAS (Probe card auto setup)

FP2000

-

Fully automatic 200 mm Frame Handling Prober with Frame Gripper Function

- For testing all wafers as well as wafers on Dicing Frames

- For wafers on Dicing Frames 2-8- 1, 2-6- 1

- For normal 5, 6 and 8 inch wafers

- Newly developed software to correct the chip position

- Automatic alignment of the wafer

- Automatic probe needle for contact point adjustment

- Optionally with Multiple Die Probing, spindle cleaning, GP-IB Interface, Probe-mark Inspection, Printer, Barcode Reader, Wafer ID Reader, Colour Camera and Flat Loader

FP3000

- Tried-and-tested 300 mm Frame Handling Prober with Frame Gripper Function

- For Wafers up to 300 mm on Dicing Frames

- Optionally with wafer handling – for maximum versatility in production

- Software to correct the chip position

- Automatic wafer alignment

- Automatic sample needle for contact point alignment

- Optional with multiple probing, needle cleaning, GP-IB interface, sample inspection, printer, barcode reader, wafer ID reader, color camera and flat loader

Wafer Dicing Machines – Blade Dicer

- The task of the Wafer Dicing Machines is to separate the whole wafers into chips. Blade Dicers cut the wafers using fine saw blades. Our semi and fully automatic ACCRETECH Blade Dicers are available for wafers up to 150 mm, 200 mm and 300 mm diameter. In addition to user-friendliness, their excellent properties include high processing speed and the very compact construction. The AD2000T and AD3000T, with two opposite-facing spindles, are the smallest fully automatic Blade Dicers in the world, setting new standards with their small footprint and high-efficiency.

SS10

-

Semi-automatic Dicer Machine from the new Small Footprint Generation.

- Smallest and quickest 6 inch Dicing Machine in the world

- Suitable for various types of wafers

- Image preparation processor automatically adapts to the different wafers

- High Performance Spindle with 60,000 rpm

- 14-Inch Touch Panel and new Graphical User Interface

- Microscope with High Resolution

- Easy & simple kerf check function

- Simple operation with 17-Inch Touch Panel and new Graphical User Interface

SS20

-

Semi-automatic Dicer Machine from the new Small Footprint Generation.

- Also suitable for quadratic wafers up to 250 mm

- Microscope with High Resolution

- Easy & simple Kerf Check Function

- Simple operation with 17-Inch Touch Panel and new Graphical User Interface

- Standard spindle up to 60,000 rpm, optional High Speed Spindle with 80,000 rpm

AD20T

-

Semi-automatic Dicing Machines

- High throughput thanks to the double spindle

- High Cutting Precision

- High Stability, Low Vibration

- 17-Inch Touch Panel Screen

- Graphical User Interface

AD2000T/S

-

Very compact, fully automatic Wafer Dicing machine for 200 mm

- High Processing Speed

- X-axis up to 1,000 mm/ Y-axis up to 300 mm/s

- The smallest blade-to-blade distance worldwide

- Graphical User Interface with Help Function

- Easy & Simple Kerf Check Function

- Standard Spindle up to 60,000 rpm, optional High Speed Spindle up to 80,000 rpm

- Simple Maintenance – Easy to Access

SS30

-

Semi-automatic Wafer Dicing machine for 300 mm

- Suitable for different types of workpieces: 12-inch Frame, rectangular workpieces with max. 350 x 250 mm

- Higher X-axis throughput 800 mm/sec, Y-axis 300 mm/sec and Z-axis 80mm/sec

- Standard Spindle up to 60,000 rpm, optional High Speed Spindle up to 80,000 rpm, High Power Spindle with 30,000 rpm

- Microscope with High Resolution

- Easy & Simple Kerf Check Function

- Simple operation with 17-Inch Touch Panel and new Graphical User Interface

- USB Port as a standard option

- Simple maintenance – easy to access

AD3000T Plus

-

Twin Dicing Concept with two spindles located opposite each other

- Smallest 12 Inch Dicing Machine in the World

- High processing speed: X-axis up to 1,000 mm/ Y-axis up to 300 mm/s

- The smallest blade-to-blade distance worldwide

- Graphical User Interface with Help Function

- Easy & Simple Kerf Check Function

- Standard Spindle up to 60,000 rpm, optional High Speed Spindle with 80,000 rpm,

- Simple routine maintenance – easy to access

Laser Dicing

- With the new generation of wafers, wafer dicing machines with laser technology have a clear advantage. The ML lasers developed by ACCRETECH do not cut with blades, but contactlessly from the inside out with a laser beam. The laser is focused below the wafer surface and breaks up the crystalline structure. Afterwards, the wafer can be separated completely dry and dust-free with an expander. With 85% less power consumption and 100% less water consumption.

ML301 EXWH

-

Laser Dicing Machine for Wafer until 300 mm

- Visible light microscope

- High dicing-speed

- Maximum yield – no cutting loss, no chipping

- Does not require water, needs 85% less power

Wafer Dicing – Blades

- Dicing blades are saw blades which are used in fully and semi-automated blade dicing machines. The selection of the right kind of dicing blade is a prerequisite for good sawing quality, with high-precision cut edges. ACCRETECH precision dicing blades are available for a vast range of applications and wafer materials. Unique electroplating technology ensures even granulation distribution, and high stability. We also offer our customers dressing plates, in order to avoid clogging

Hub Type Blades

-

- Cuts quickly and with high precision, and reduces splitting on the edges

- Galvanising technology for even granulation distribution and high stability during the cutting process

- Modular system for many different cut variations

Blades with Nickel Bonds

-

- DS type – trusted for over 20 years, precise, robust and durable

- LY type – cost-effective sawing with stable quality, for mass production

- MN type – ultra-thin premium blades with high stability and precise cutting

Ultra-hard Metal Blades

-

- Prevents burr formation on the edges

- Enables sharp cuts

- Also suitable for synthetic resins

Blades with Synthetic Resin Bonds

-

- High speed

- Long lifespan

Blades with Metal Bonds

-

- HM design for quartz glass; also suitable for QFN package cutting

- YM series especially for ceramics; no splitting – even in thicker materials – and no hairline cracking on the reverse

- GM series with high stability, specialising in glass, different connections available for a number of applications

Conditioning Plates

Conditioning Plates

-

- Conditions the hub blade in a short time

- Significant production cost reduction by replacing the silicon pre-cutting

The RGC series conditioning plate significantly reduces the startup time of the fine-grained blade.

By using it before wafer dicing of the silicon or the compound semiconductor, etc., an excellent unclogged state of the blade tip is achieved, so improving the processing product rank.

This achieves a significant reduction in the required time compared to the conventional process.

Grinding Machines – High Rigid Grinders

- The High Rigid Grinder is particularly suitable for companies who use very hard materials such as SiC, Sapphire, Si, ALN or GaN for wafer production. With the HRG300/HRG300A, individual wafers with a larger diameter (300 mm or 450 mm) can be ground as well as whole wafer stacks with a smaller diameter. The high stability and lower vibrations significantly reduce the grinding time and increase the service life of the grinding stone. The system is complemented by an optional In-Process Dressing function and a device which automatically measures the thickness of the wafer during the grinding process.

HRG200 X

-

Fully automatic High Rigid Grinder for wafers up to 200 mm

- Double axis

- Less grinding damage, shorter processing times

- Low Costs

- High Precision

- Surface Grinding with Mirror Finish

- Integrated cleaning unit that prevents silicon dust drying on the wafer surface

HRG300

-

Semi-automatic High Rigid Grinder for wafers up to 300 mm

- Ideal for processing individual 300 mm wafers and batch grinding for wafers with a small diameter

- Also available for numerous special applications, such as MEMS wafer handling

- High stability – for shorter preparation times, less grinding damage and individual, separate Self Sharpening Function

- It extends the lifespan of the grinding stone

- With the In-Process measuring instrument, which is also suitable for wafer processing in piles and which measures the wafer thickness during the procedure

- Inspects the clogging of the grindstone and performs dressing if required

HRG300A

-

Fully automatic High Rigid Grinder for wafers up to 300 mm

- Ideal for processing individual 300 mm wafers and batch grinding for wafers with a smaller diameter

- High precision for extremely hard materials such as SiC, Sapphire, LiNb, Lithium Tantalate (TTV smaller than 0.5 µm/WTW thinner than +-1 µm)

- High stability – for shorter preparation times, less grinding damage and individual, separate Self Sharpening Function

- It extends the lifespan of the grinding stone

- With an In-Process measuring instrument which is batch compatible and measures the wafer thickness during processing in piles

- Inspects the clogging of the grindstone and performs dressing if required

Polish Grinder

PG3000RMII

-

Polish Grinder for simultaneous thinning and defect removal of wafers up to 300 mm

- Grinder + CMP Stress Release

- Higher throughput – for 15 µm wafer thinning in high volume production

- The RM200/300 module (Wafer Mounter/Remounter) offers complementary PG200/300 Processing in one unit – it removes the protective tape from thinner wafers and applies the wafers to the dicing frames

- Performs pre-grinding, fine grinding, polishing and cleaning of both sides of the wafer in the machine

- All processes are carried out on the same chuck – the wafer does not need to be moved

Wafer Edge Grinder

W-GM-4200

-

Edge grinding machine for wafer manufacturing up to 200 mm

- Suitable for various wafer materials, for example GaAs, SiC, GaN etc.

- Newly developed Grinding Unit for better rotational precision of the spindle and the profile sharpness

- non-contact measurement technology ensures stable alignment

- Performs a non-contact measurement of the wafer thickness at numerous different locations before grinding

- Performs a non-contact measurement of the diameter and the indent depth

- Mirror Finish Technology to reduce grinding damage

W-GM-5200

- Edge grinding machine for wafer manufacturing up to 300 mm

- Suitable for various wafer materials and connections for example GaAs, SiC, GaN etc.

- Newly developed Grinding Unit for better rotational precision of the spindle and the profile sharpness

- non-contact measurement technology ensures stable alignment

- Performs a non-contact measurement of the wafer thickness at numerous different locations before grinding

- Performs a non-contact measurement of the diameter and the indent depth

- Mirror Finish Technology to reduce grinding damage

W-GM-6200

-

Edge grinding machine for the new generation of 450 mm wafers

- Improved use of space due to the compact design

- High grinding precision thanks to synchronised X, Y, θ Support Control

- Simple operation with the Touch Panel

- Automatic Feedback from the preparation results

- Optimum preparation of the subsequent process steps

CMP

ChaMP 211/232

-

High Performance CMP Technology for wafers up to 200mm

- Modular, flexible and compact design

- Dry in Dry Out with cleaning option

- Polishing head with Air Float Technology

- Easy Maintenance

- End Point Detection (EPD) for high precision and even polishing

- Processed Cu / STI/ ILD / SOI etc.

- For ChaMP 232, also with 3 polishing tables and 2 polishing heads – ideal for mass production

ChaMP 332

-

High Performance CMP Technology for wafers up to 300mm

- Modular and compact design

- Dry in Dry Cut with cleaning option

- Polishing head with Air Float Technology

- Easy Maintenance

- End Point Detection (EPD) for high precision and even polishing

- Processed Cu / STI/ ILD / SOI etc.

- For ChaMP 332 also with 3 polishing tables and 2 polishing heads – ideal for mass production

Product for machine tools - Grinding

- Process control solutions for grinding machines

ACCRETECH are able to provide a comprehensive process control solution package for your grinding machine. Our SBS brand includes automatic and manual balancing systems for grinders, as well as acoustic emission (AE) monitoring for gap elimination and crash prevention. The Pulcom product line of In-Process gauging systems can also be integrated for work-piece sizing and positional control, and the TL-02 touch probe can be used for work setup. The industry trend towards grinding machines utilizing automatic tool changing using HSK type tooling means that ACCRETECH’s ATC Run-Out Detection system can be installed on new or retrofit to existing grinding machines.

Balancing (SBS)

-

Industrial production also places high demands on grinding machines. Unwanted vibrations of the grinding wheel relative to the workpiece surface lead to surface defects, so-called chatter marks. Shape and dimensional accuracy also suffer when the rotating tool exceeds important tolerance values. Imbalances not only have negative effects on product quality. They can also affect the bearing life of the machine. The loss of mechanical energy also leads to increased power consumption.

In addition, customers are demanding higher accuracy from the workpieces they produce, while at the same time cycle times are shortening. Therefore, it is important to keep the vibrations of the grinding wheel low. In operation, sensors must be able to quickly detect rotational deviations and pass this information on to the operator or automated to other machine components in production.

Process Control (SBS)

-

ACCRETECH’s SBS product line includes some of the most advanced and comprehensive machine tool process control currently available on the market.

Process monitoring involves the detection and analysis of high frequency noise (acoustic emission or AE) generated by the machining or grinding process. The AE-1000 and the AEMS add-in card for the SB-5500 help reduce air grind time and provide automatic crash protection by using proprietary acoustic detection technology.

In Process Gauging

-

The demands on CNC grinding processes in automated and industrial applications are challenging. Perfect surfaces should be achieved in short cycle times and the grinding tools used for this purpose should be subject to only minimal abrasion. Therefore, diameter, size and position must be precisely and permanently measurable during the grinding cycle. Only if measurement data are within specified tolerances, an economical and high quality CNC grinding process is ensured.

The ACCRETECH Pulcom gauges fulfill exactly this purpose. Its solutions are used worldwide and have long been synonymous with reliable and highly accurate in-process measurements for grinding machines. And ACCRETECH offers the right sensor solution for every type of machine tool. Starting with the V2 platform and the easy-to-use, self-intuitive control in analog and digital format, up to the multifunctional Pulcom V10.

Touch Probes

-

Contemporary machine tools must be able to position and index themselves with high precision. This is crucial for the precise, wear-free and ultimately economical machining process. Especially in a challenging and harsh manufacturing environment, these features are extremely important.

ACCRETECH’s touch probes TL02 and Pulcom measuring heads fulfill exactly these measuring tasks. They enable optimal machine tool positioning even under difficult conditions.

Milling Machines

-

Wear is a serious factor in milling. In the machining process, the tool is exposed to thermal and mechanical stresses. Wear of the cutting edge increases the contact area between the workpiece and the tool. As a result, friction increases and the temperature consequently rises. Furthermore, the cutting force may increase. This can lead to cutting force fluctuations and consequently to scoring on the workpiece surface.

The consequences are:- The precision of the milling process suffers and consequently the component quality

- The tool used threatens to wear out more quickly

Conventional ATC Runout Detection System

-

- Measurement time of 0.3 seconds at 600rpm with an edy current sensor

- Detection of less than 5µm run-out

- Up to 32 tools can be reigstered

- Operating ambient temperature is 0-40°C

ATC run-out detection system - ATC System RD10

-

- Measurement time of 0.15 seconds at 2400 rpm

- Detection of less than 3µm run-out

- Up to 100 tools can be registered

- Operating ambient temperature is 0-50°C

- Remote monitoring of status information and measurement data available thanks to Ethernet connection

- Larger display for improved operator experience

TL02

-

- Measurement direction is available for XY surface plane as well as Z axis direction

- Improvement of setup time, machine operating time processing precision of works

- Suitable for detection tools such as NC lathes

E-DT-175A

-

General purpose measuring head for Pulcom Gamma

- Bidirectional workpiece detector

- Three-direction cutting edge detector (X, -X and Z direction)

SB-5500 Automatic and Manual Balancing System

- Automatic and Manual Balancing System

SBS solidifies its reputation as the world leader in automatic dynamic balancing and process monitoring systems for the grinding industry with the SB-5500 control unit. Featuring fully digitized electronics, a compact design and a large, high-resolution, removable display, the SB-5500 is unsurpassed in accuracy (up to 0.02 microns), speed (300-30,000 rpm) and flexibility (four-channel operation).

Advantages:

- Increases productivity through shorter setup times

- Increases work-piece quality with automatic balancing down to 0.02 microns

- Fully digitized electronic design provides longer life and higher reliability

- Easy installation and operation

- Longer life of grinding wheels, dressing wheels and spindle bearings

- Works with existing SBS equipment

- Compatible with Profibus, Ethernet and USB 2.0 communications

- Designed for international use: Voltage, frequency, communication and display language

- Four-channel capability reduces costs by allowing multiple machines to be balanced

- Supported by world-class SBS customer service

AE-1000 Monitoring System

- Acoustic Emission Monitoring System

The SBS AE -1000 reduces air grinding time and alerts the operator of crash conditions by using proprietary acoustic detection technology to monitor and analyze the high frequency signals generated by the grinding process.

The AE-1000 reports initial contact between the wheel and a new part to the machine control system so it can stop wheel in-feed without operator intervention, which can save up to 20% of the typical cycle time. It can also detect and report abnormal contact from an incorrectly loaded part or fixture within milliseconds, allowing the in-feed to be stopped, avoiding a crash, damage or injury.Advantages:

- The functionality of two products in one

- Increases throughput by saving setup time

- Improves part quality by automatically balancing to as low as 0.02 microns

- Change balance mode with the push of a button

- All-digital design increases operating life and reliability

- Compact and easy to install and operate

- Economical price

- Longer life for grinding wheels, dressing wheels and spindle bearings

- Works with all SBS installations and accessories

- Easy CNC/PLC interface; USB 2.0 communication capability for firmware upgrades

- Backed by world-class and worldwide customer service

AEMS Card Monitoring System

- Acoustic Emission Monitoring System

The AEMS Card eliminates air grinding gap time and alerts the operator of crash conditions by using proprietary acoustic detection technology to monitor and analyze the high frequency signals generated by the grinding process.

Advantages:

- Cut cycle time and increase productivity by 20% or more

- Increases throughput with less setup

- Eliminate gap time with automatic grind in-feed

- Improve part quality with precise grind/dress monitoring

- Prevent crashes, damage, and injury

- Automate shut-down on detection of extreme contact

- Extend life of grinders, dressers, and spindle bearings

- Four-channel capability permits balancing and monitoring of multiple machines

- Control a wide range of grinding machine types/brands

- Easy to install and operate

- Sensor options accommodate diverse environments

- Communications versatility: Profibus, Ethernet and USB

- Enables CNC machines to re-position wheel at zero

- International adaptability: voltage, frequency, communication, and display language

- Backed by world-class, worldwide SBS customer service

ExactControl Card

- Process monitoring for grinding and dressing processes

The SBS ExactControl Card has been developed to meet today’s requirements for comprehensive process monitoring.

Advantages:

- Acoustic emission, power, spindle current, vibration, temperature, torque and speed, as well as information from the controller, e.g. alarms and positions can be used individually or in parallel for process monitoring

- Six acoustic emission sensors can be connected

- Two acoustic emission sensors be operated simultaneously

- The ExactControl Card is multi-channel capable and has Profibus and Ethernet interfaces, and analogue and digital inputs /outputs

- A micro SD card is integrated for data storage and records all grinding cycles in a continuous loop to its memory for process analysis

External AE sensor

- Bolt-on and Stud Mount Acoustic Emission (AE) Sensors

ACCRETECH’s standard external acoustic sensor is easily bolted onto the grinding machine using an M6 cap-screw. It is ideal for situations when it can be bolted near to the grinding process such as onto shoe-plates on bearing grinding machines for race grinding or onto a point dresser block for dresser monitoring. The ease of retrofitting with the AE sensor makes it a popular choice for many grinding applications.

Advantages:

- Easy to retrofit

- Broad frequency response

- IP rated for harsh environment/ coolant zone

Fluid AE sensors

- Fluid Hydrophone Acoustic Emission (AE) Sensor for difficult machinery applications

The Fluid AE sensor is ideal for situations where a direct AE contact is required in the grinding process. This can be situations where machine design or high frequency bearing, mechanical or electromagnetic noise prevent the use of other types of AE sensor. The Fluid AE sensor uses the existing grinding machine coolant which can be water or oil based.

Advantages:

- Useful when there is restricted AE signal path through machine structure

- Direct AE contact with the work-zone

- Avoids disturbances

- Easy to retrofit

In-Spindle AE Sensors

- Rotary Non-Contact Acoustic Emission (AE) Sensors for dresser spindles

The in-spindle AE sensors are non-contact and come in two formats. These include a telescopic type and spiral-cable type. The telescopic type has a slide tube to facilitate installation and it sits inside a 4mm bore within a grinding machine spindle or rotary diamond dresser unit. This configuration allows the acoustic sensor to spin with the spindle and to be in close proximity to the grinding event, giving a clear uninterrupted signal.

Advantages:

- For OEM mounting in rotary dresser spindles on grinding machines

- Excellent sensitivity due to proximity to dress-zone

- Avoids spindle bearing noise and other disturbances

- Non-Contact configuration

- High rotational speeds

Mini AE Sensors

- Miniature Rotary Non-Contact Acoustic Emission (AE) Sensors for grinding applications

The Mini AE sensor is useful where space is at a premium, or direct contact with the rotating part of a grinding or dressing spindle is necessary but a spindle bore is not available. It is a non-contact sensor and can be bolted on either end of a spindle using an M6 LH or RH thread. The AE signal is passed from the rotating sensor across an air gap to a non-contact receiver unit. The direct mounting nature of this sensor gives strong uninterrupted signals.

Advantages:

- Mounted onto rotating dresser or grinding spindle shaft

- Non-contact configuration

- Small dimensions

- High rotational speeds

Ring AE Sensors

- Rotary Acoustic Emission (AE) sensors for optimal signal path

The ring AE sensors can be mounted on the chuck, grinding wheel and dressing wheel. These customized solutions grant normally the best AE signal detection. Ring AE sensors are the ultimate solution for difficult condition.

Advantages:

- Rotor and stator pair in a ring configuration

- Direct mounting to work-holding or machine spindle

- Avoid spindle bearing noise and other disturbances

- Close Proximity to work-zone – short AE path – excellent sensitivity

- Customisable designs for OEM applications

Power Sensors

- Process Control using Spindle Power

With the drive towards Big-Data and multiple sensor inputs from machining processes, the SBS ExactControlTM Card SB-5560 is capable of not only accepting up to 6 acoustic emission (AE sensors) using expansion slots, but also up two 2 analogue inputs from many third party sensors.

Power sensors, for example, are useful for machine tool applications where acoustic emission monitoring is not possible.Advantages

- 2 analogue inputs are simultaneously sampled at a 250Hz rate

- 16-bit conversion resolution applies to a -10 VDC to + 10 VDC – many sensors can be connectes

- Useful when acoustic emission sensors cannot be used due to poor acoustic path

- Mechanically tidy installation: Power sensor is mounted in the electrical cabinet, not in the work-zone

- No sensors exposed to machine coolant

- Less susceptible to electrical interference than acoustic emission sensors

- 7 x ExactControlTM Strategies can be used to monitor the power signalt

- Easy retrofitting

- Useful when disturbances or poor signal path make Acoustic Emission (AE) monitoring impossible

Surface measuring systems

-

Surface measuring systems for roughness and contour

Surfaces characteristics have a crucial impact on performance, lifespan, visual appearance and ultimately the quality of technical products. That’s why the measurement of surface roughness and quantification in the form of profile, roughness and waviness parameters is of vital importance to many components. In many industries, tolerances regarding surface parameters are narrowing – be it in the automotive industry, Aerospace or general mechanical sectors.

Other developments:- A surface measuring system is no longer found only in the measuring room, but increasingly needed in manufacturing as well in order to take measurements right on the production line.

- That’s why in addition to traditional, physical instruments, optical measuring instruments that can be operated much more quickly and without touching are seeing more frequent use.

- Surface testing instruments are also mobile and therefore suitable for flexible use in manufacturing.

- Today, 2D profile sections represent the state of the art when it comes to characterising surface roughness. More frequently, machines that can define the surface in 3D are used to get a more detailed surface characterisation.

- Multi-sensor technology enables roughness and contour to be measured on one measuring instrument, even in a single pass.

Roughness measuring systems

-

Measuring systems for quality room and manufacturing

Surface roughness is a measurement for the structure of the surface. It is calculated as a vertical deviation of the actual surface from its ideal shape, caused by machining or by chemical or physical processing in production. If these deviations are high, the surface is rough. If the value is low, the surface is smooth.

HANDYSURF+ 35/40/45

- Portable, versatile surface texture measuring instrument

- 2,4″ Full colour LCD

- High resolution 0.0007 µm

- 16 mm Stroke length

- Measuring speed up to 1mm/s

- Measurement height range -210 to +160 µm

- Very simple operation and user-friendly software

- USB connector

- Extension cable for remote use

- 20 languages available

- Immediate data analysis and display

- Internal data storage/battery operation

- Direct data output on the Laptop/ PC

- Analysis of the roughness values in Excel, or Supportware II

- Connectable to a thermal printer

- Meets all common surface standards

Area of application

With the HANDYSURF+ devices, the surface measuring instrument comes to the workpiece and still delivers very precise measurement results. The standard HANDYSURF+ 35 product can be used anywhere – vertically, horizontally and overhead. As a result, the devices can be used by a number of industries, from mechanical engineering to automotive as well as from aerospace to the plastics processing industry.

The operation of HANDYSURF+ is kept extremely simple so that any employee in production can check standard surface parameters, even if they don’t have knowledge of measurement technology, which is another advantage for operators and production managers.

SURFCOM TOUCH 35 | 40 | 45

- Portable surface measuring devices with bottom runner attachment

- Entry-level model of surface measurements for various production applications, especially suitable for small and medium-sized companies.

- Excellent price-performance ratio

- Simple and self-explanatory user interface with 7-inch touch display

- Depending on the application, up to three different measurement units can be combined with the evaluation unit

- Automatic detection of the feed unit

- User-friendly, multilingual user software

- USB/Micro USB interface for extended data storage and transfer to the analytical software (supportware II)

- Analysis unit with integrated printer

- High-performance battery for mobile use

Area of application

The surface measuring instruments for the SURFCOM TOUCH 35 I 40 I 45 are particularly suitable for the measurement of medium and large workpieces during production due to their small, lightweight design and bottom runner system. All models feature simple and self-explanatory navigation menus to ensure easy and trouble-free operation. The measuring conditions and parameters for the respective workpiece can be saved and retrieved at any time.

SURFCOM TOUCH 50

- Portable surface measuring device with free probe system

Compact model for surface measurements in the production hall and measuring room — with high straightness precision and a wide measuring range.- Excellent price-performance ratio

- Simple and self-explanatory user interface with 7-inch touch display

- Resolution of up to 0.0001 μm and a maximum Z measuring range of 1000 μm (2000 μm/double probe arm length)

- X axis guide accuracy of 0.3 μm with a measuring length of up to 50 mm

- Different probe arms can be easily changed and calibrated

- User-friendly, multilingual user software

- USB/Micro USB interface for extended data storage and transfer to the analytical software (supportware II)

- Analytical unit with integrated printer

- High-performance battery for mobile use

- High-precision and compact tracing driver

- The tracing driver is characterised by a high guide accuracy of 0.3 μm / 50 mm.

Area of application

The large Z measuring range of the probe system enables flat as well as oblique and round surfaces to be measured and saves considerable time and effort to alignment of the workpieces. Deep measuring positions can be easily reached and even the smallest holes measured thanks to a wide range of compatible probe arms. These can be changed quickly and easily with a probe-arm spring clamp, without the need for tools.

An additional measuring stand can be used for tall workpieces

SURFCOM TOUCH 550

- Semi-automatic surface measuring device with intuitive user interface

High-precision surface measuring system for the measuring room, with automatically controlled Z and X travel axis.- Modular design with different sizes available for the Z pillar, granite and feed unit

- Probe with maximum resolution of 0.0001 μm and maximum Z measuring range of 1000 μm

- X axis guide accuracy of 0.2 μm with a measuring length of up to 100 mm (optionally 200mm)

- Evaluation performance complies with all current international calculation standards as well as P + R + W parameters

- Simple and self-explanatory user interface with 7-inch touch display

- User-friendly, multilingual user software USB/Micro

- USB interface for extended data storage and transfer to the analytical software (supportware II) Analytical unit with integrated printer

Area of application

The SURFCOM TOUCH 550 is ideal for high-precision and semi-automatic surface measurements. The system meets all the requirements of the measuring room and is easy to operate thanks to its intuitive user interface. Semi-automatic operation during measurement, evaluation, data storage and logging simplifies the measurement process. The large Z measuring range of the probe system allows flat, oblique and round surfaces to be tested. In addition, it eliminates time and effort aligning the workpieces. Deep measuring positions can be easily reached and even the smallest holes measured using a wide variety of compatible probe arms. This is facilitated by a simple changing system with a probe-arm spring clamp.

SURFCOM NEX 001

- SURFCOM NEX 001 offers the possibility of taking higher precision roughness measurements at higher measurement speeds, due to its patented linear system

Fully CNC controlled with Teach-in programming- Linear motor drive ensures high accuracy and high speed movement (patented)

- Low vibration ensures stable measurement at high resolutions (patented)

- High resolution of the measurement probe up to 0.0001 µm

- Straightness precision: (0.05 µm +1L/1000) Z measurement range of 1000 µm

- Sensor with a compact design (Ø14 mm) for high accuracy and comprehensive measurements max. 500,000x increase in the measurement

- Measurement is possible in the X and Y direction

- Can be extended with 2D and 3D surface measurement

Area of application

The SURFCOM NEX Series can be used to equip or modify future-proof modular systems on-site. Thanks to various modular parts such as a Y table, horizontal rotating table, vertical rotating table, hybrid sensor, white light sensor, surface sensor and contour sensor, you can design the measuring station exactly to your requirements. Due to the removal of the drive spindle and the gears in the feed unit, the system is low maintenance, robust and extremely resistant to wear.

SURFCOM C5

- Fully automated CNC surface measurements for series production.

- Measurement in both the X and Y directions

- Faster, reliable and cost-effectiv with 5 CNC axes

- Measurement in all directions by rotatable probe head

- Non-contact linear technology in the X-axis

- Fast, low maintenance and low vibration

- Positioning speed of 100 mm/s for high measuring efficiency, even for large work pieces

- Extensive safety concept for maximum protection of operator and device

- Optional: CNC stylus change

- Optional: additional rotation axis and tailstock for fully automatic measurement of crankshafts and camshafts

Area of application

The SURFCOM C5 has been developed for fully automatic surface measurement and quality assurance in production. It is ideal for crankshafts and engine components in series production. The SURFCOM C5 features a massive granite construction and a specially developed active vibration table to minimize the environmental impact. The feed in the X direction is equipped with a vibration-free, low-maintenance and high-precision linear drive and provides additional stability.

Contour measuring systems

-

Flexible contour measuring systems for various applications

Angles, radii, distances and coordinates of workpieces can be determined with the highly precise ACCRETECH contour measuring systems.

Due to the elimination of the ball screw and the nut, the inspection instruments work at a low vibration with a resolution of up to 0.31 nm. Another major advantage of the linear technology, is it requires little maintenance and will maintain the measurement accuracy over the life of the system much better than tradition ball screw approach due to the reduction in mechanical wear. This gives our customers enormous cost savings over the life of the system.

The SURFCOM NEX 030 and the SURFCOM NEX 040 contour measuring systems are available for two-dimensional, physical contour measurement. These are both flexible CNC measuring stations. SURFCOM NEX 030 with a measuring accuracy of ±(1.5+|2H|/100) µm, standard version is suitable for measuring all contour geometry and standard workpieces. SURFCOM NEX 040 with a high measuring accuracy of ±(0.8+|2H|/100) µm, suitable for measuring highly precise contour geometry such as ball screws or ball bearings.

ACCRETECH keeps a wide range of probes for contour measuring systems on hand so that even positions that are hard to reach can be measured. Probes can be swapped out quickly thanks to kinematic magnetic holders and high positioning accuracy.

The software for operating the contour measuring systems is deliberately kept simple and self-explanatory. Measurements are fully automated. Even calibration and adjustment are easy for the user to do, which saves times.

SURFCOM NEX 030

- The SURFCOM NEX 030 is suitable for measuring all contour geometries and standard workpieces in manual or CNC controlled measurement procedures.

- Linear motor drive ensures high accuracy and high speed movement (patented) Low vibration ensures stable measurement at high resolutions (patented) Z

- measurement

- range for 60 mm contour Contour probe head with a glass

- scale, with 0.04 µm resolution using the full measurement range

- Standard measurement precision ±(1.5+|2H|/100)µm Manual

- probing force setting

- Quicker change of probe with a positioning magnetic holder (patented)

- Innovative safety system prevents collisions with the workpiece

- Self-correcting temperature function which identifies and compensates for temperature fluctuations

- Maintenance-free, due to the non-contact drive

- CNC tables for automatic positioning of the workpieces

- Probe head geometries are compensated from the software side

- Surveys and measurements for determination of the diameter are possible with a T stylus

Area of application

The SURFCOM NEX Series can be used to equip or modify future-proof modular systems on-site. Thanks to various modular parts such as a Y table, horizontal rotating table, vertical rotating table, hybrid sensor, white light sensor, surface sensor and contour sensor, you can design the measuring station exactly to your requirements.

SURFCOM NEX 040

- SURFCOM NEX 040 is suitable for measuring high precision contour geometries such as ball spindles or large bearings in manual or CNC controlled measurement procedures.

- Linear motor drive for high precision and high speed movement (patented)

- Low vibration for stable measurement at high resolutions (patented)

- Z measurement range for 60 mm contour

- Contour probe head with a glass scale, with 0.02 µm resolution over the full measurement range

- High measurement precision ±(0.8+|2H|/100) µm

- Automatic setting of the probing force, software-controlled in 2mN steps

- Quicker change of probe with a positioning magnetic holder (patented)

- Innovative safety system prevents collisions with the workpiece

- Self-correcting temperature function which identifies and compensates for temperature fluctuations

- Maintenance-free, due to the non-contact drive CNC tables for automatic positioning of the workpieces

- Probe head geometries are compensated from the software side

- Surveys and measurements for recording of the diameter are possible with a T stylus

Area of application

The SURFCOM NEX Series can be used to equip or modify future-proof modular systems on-site. Thanks to various modular parts such as a Y table, horizontal rotating table, vertical rotating table, hybrid sensor, white light sensor, surface sensor and contour sensor, you can design the measuring station exactly to your requirements.

Combined contour/roughness measuring systems

-

Higher productivity from measuring both parameters in one work step

The requirements for manufacturing metrology are growing: there are always more workpieces to measure in ever shorter timespans in order to reduce the volume of scap and keep production processes under control.

Companies save time on inspecting workpieces for surface parameters by measuring contours and roughness of workpieces with combined contour and roughness measuring systems. In these cases, the workpiece is only clamped once for both measurements.

The question here is whether a hybrid system with a dual sensor or a system with quick-changing sensors is preferable. ACCRETECH offers measuring systems for both options:

The SURFCOM CREST and the SURFCOM NEX 100 make roughness and contour analysis possible at the same time with only one measurement and only one sensor.

SURFCOM NEX 200

-

The SURFCOM NEX 200 makes contour and surface measurements possible in a single system with a hybrid sensor.

- Hybrid sensor with high resolution and high measuring range at the same time

- Combined roughness and contour sensor with Z measuring range up to 26 mm

- Deflection with contour probe arm up to max. 52 mm

- No need to change the scanning system

- Straightness precision (0.05+L/1000) µm

- Z accuracy +/- (1.0+2H/100) µm (standard probe arm)

- Roughness resolution over the entire measuring range of 0.0009 μm (standard probe arm)

- Fully CNC controlled with teach-in programming

- High traversing speed: X-axis (horizontal) 100 mm/s, C-axis (vertical) 50 mm/s

- Modular structure with sensors for different applications

- Low vibration ensures more stable measurements at high resolution

- Low maintenance thanks to contactless linear drive

- Safety system prevents collisions with the workpiece

- Comprehensive and user-friendly evaluation software

- All instruments available with anti-vibration table (DX version)

- Automated measurement procedures thanks to CNC positioning tables (optional)

SURFCOM CREST

- Z measurement range up to 26 mm

- 0.00031 µm with 50 mm arm

- Precision ±(0.2+|H|/1000) µm with 50 mm arm

- Linear motor drive ensures high accuracy and high speed movement (patented)

- Low vibration ensures stable measurement at high resolutions (patented)

- Roughness and contour can be analysed in a single measurement

- Large measurement range from 200 mm (horizontal direction) and 13 mm (vertical direction)

- Can be extended with 2D and 3D surface measurement

Area of application

SURFCOM CREST can be used in all sectors where high precision and resolution are indispensable.SURFCOM CREST can be used in both the contour and surface sector due to the special hybrid system, and achieves high end results.

Mobile surface measuring systems

- Production and workshop managers know the dilemma: The surface parameters of a workpiece need to be measured soon and quickly – and the space to perform the measurement is too far away or is occupied. Metrology is then the bottleneck in production.

With mobile surface measuring systems for process-related measurements, this bottleneck can be dissolved. This allows companies to measure quickly and efficiently outside the precision measurement room; for example in manufacturing, at the incoming goods or final inspection – all based on the principle that the measuring system comes to the workpiece.

ACCRETECH offers two different series of mobile surface measuring systems: HANDYSURF+ and SURFCOM TOUCH.

ACCRETECH emphasised easy operation in both series so that even employees without skills in metrology can inspect common surface parameters in production or in incoming goods. This is made possible in particular by menu navigation that is as self-explanatory as possible.

SURFCOM TOUCH 35 | 40 | 45

- Portable surface measuring devices with bottom runner attachment

Entry-level model of surface measurements for various production applications, especially suitable for small and medium-sized companies.- Excellent price-performance ratio

- Simple and self-explanatory user interface with 7-inch touch display

- Depending on the application, up to three different measurement units can be combined with the evaluation unit

- Automatic detection of the feed unit

- User-friendly, multilingual user software USB/Micro

- USB interface for extended data storage and transfer to the analytical software (supportware II)

- Analysis unit with integrated printer

- High-performance battery for mobile use

- Analytical unit 35 (standard)

Standard tracing driver for surface measurement in the longitudinal direction. - Tracing driver 40 (retraction type)

Tracing driver for surface measurement in the longitudinal direction, with retract function to minimise wear on the probe tip. - Tracing driver 45 (horizontal type)

Tracing driver for surface measurement in the transverse direction, ideal for hard-to-reach measuring positions such as crankshaft journals.

Area of application

The surface measuring instruments for the SURFCOM TOUCH 35 I 40 I 45 are particularly suitable for the measurement of medium and large workpieces during production due to their small, lightweight design and bottom runner system. All models feature simple and self-explanatory navigation menus to ensure easy and trouble-free operation. The measuring conditions and parameters for the respective workpiece can be saved and retrieved at any time.

SURFCOM TOUCH 50

- Portable surface measuring device with free probe system

Compact model for surface measurements in the production hall and measuring room — with high straightness precision and a wide measuring range.- Excellent price-performance ratio

- Simple and self-explanatory user interface with 7-inch touch display

- Resolution of up to 0.0001 μm and a maximum Z measuring range of 1000 μm (2000 μm/double probe arm length)

- X axis guide accuracy of 0.3 μm with a measuring length of up to 50 mm

- Different probe arms can be easily changed and calibrated

- User-friendly, multilingual user software

- USB/Micro USB interface for extended data storage and transfer to the analytical software (supportware II)

- Analytical unit with integrated printer

- High-performance battery for mobile use

- High-precision and compact tracing driver The tracing driver is characterised by a high guide accuracy of 0.3 μm / 50 mm.

Area of application

The large Z measuring range of the probe system enables flat as well as oblique and round surfaces to be measured and saves considerable time and effort to alignment of the workpieces. Deep measuring positions can be easily reached and even the smallest holes measured thanks to a wide range of compatible probe arms. These can be changed quickly and easily with a probe-arm spring clamp, without the need for tools.

An additional measuring stand can be used for tall workpieces

Optical surface measuring systems

-

Fast contour and roughness measurements

It’s no longer enough for many workpieces these days to collect dimensional measurements. More and more, it’s necessary to collect the entire two- or three-dimensional topography of a surface. With the services of optical measuring technology, point clouds are created with extremely high point density. The resolution that this enables is suitable for being able to evaluate even the smallest geometries.

For larger and flat measuring ranges in particular, optical measuring technology is an advantage because it allows measuring to proceed much more quickly.

By doing so, measurements can even be made directly against a CAD model – and a two-dimensional display of the deviations can be rendered in close to real time. These results allow for fast conclusions on the production process and enable short reaction times up to closed control loops.

Another advantage of optical measuring technology is that workpieces and their surfaces can be measured without contact so as to avoid damaging them with the measuring probe. This is relevant to sensitive plastic and mirror surfaces, for example Opt-Scope

- Non-contact and quick measurements for 3D surface structures of processed components and contour profiles with white light interferometer in the nano. measurement range.

- Vertical Scanning

- Range 20 mm

- Resolution 0.01 Nm Precision ±(0,1+|H/1000|) μm

- Surface measuring instrument for optical/three dimensional surface roughness (ISO25178-2)

- Save lots of time, up to 100 times quicker in comparison to tactile measurement with a stylus

- Patented DEAP analysis includes a specially developed algorithm for improved data structure

- The revolver exchange system makes it possible to select the appropriate lens for the respective measurement task

- A CNC controlled X Y table is available to extend the measurement range (stitching – data overlapping)

- The system is integrated into an active damping system to guarantee the highest precision

Area of application

The Opt Scope makes the measurement of surface topographies possible in a measurement time of a few seconds. It is perfect for sensitive surfaces which could be damaged by tactile measurements, as well as very small and difficult to access measurement positions. High precision and highly polished surfaces can also be measured too, such as for example from mirrors, to extremely rough surfaces such as for example grinding stones.

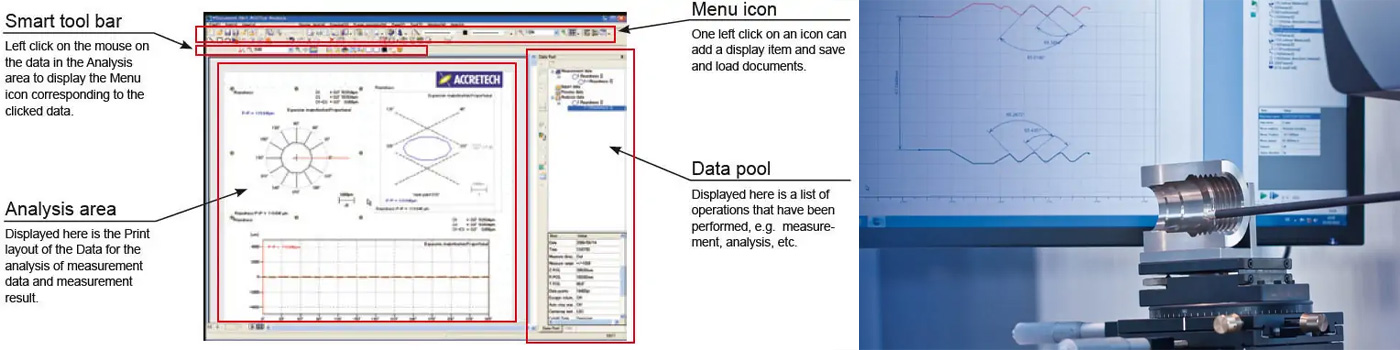

Evaluation software

-

ACCTee – Integrated analysis software for surface measuring instruments

New measurement style with new measurement concept. All measurements and analyses available in one document

- Leading-edge operability in the document screen

- Self-diagnosis function

- Efficiency improvement of re-analysis and re-measurement with easy operation

- CNC function

- Comprehensive evaluation display document

- Favorite

- Multi language support

- Help system

ACCTee roughness measurement and analysis system

- Roughness measurement and analysis system

- Preview function when changing analysis settings

- Al measurement wizard

- Pickup calibration wizard

- Calibration reminder alarm

- Parameter figure and symbol input wizard

- Stylus tip check wizard

ACCTee contour profile measurement and analysis system

- Contour profile measurement and analysis system

- Calculation result preview function

- Al function (automatic element evaluation)

- Elements calculation with icon guidance

- Work trace function

- Masterball calibration function (patented)

- Stylus calibration wizard

- Profile synthesis function

- Edge detection measurement

- Importing external data

ACCTee integrated analysis software

The Next-generation ACCTee measurement system has been developed to incorporate the new concept of TiMS integrated software. By enabling the measurement and analysis all on one document, the software provides leading-edge operability and an intuitive work environment for measurement and analysis tasks. With the document-based new measurement style, all of the operations are available on one document (measurement result sheet), and all of the data and information can also be saved with the related data. This is the ACCTee “all in one document” Next-generation integrated software.

Form measuring instruments

-

High precision form testers for all occasions

Depending on the function, many mechanical precision components are requiring fewer and fewer deviations from the ideal shape. Tolerances for dimension and form in the sub-micrometre range to the nanometre range are now required in some parts of industrial production. This is particularly important against the background that components sometimes have to be produced in the millions without any alterations over the years. Only the smallest of differences in fitting dimension and spacing are permitted, so that there are no problems in assembly or spare part changes. This is why production metrology is an essential component of the production process.

ACCRETECH has developed a series of profile measuring instruments specifically for these tasks in production metrology. The special feature of this profile measuring instrument is that the measurements are based on turning movements – resulting in high measurement precision. This means that the system is extremely flexible in probe angle variation: the automatic workpiece alignment ensures high accuracy in measurement and repeatability. The measuring devices scans rotationally symmetrical geometric elements such as planes, cylinders or cones, recording sub-micrometer results and maps the complex measuring sequences. The profile measuring technology is also used to measure micro geometry elements.

ACCRETECH offers its RONDCOM profile measuring instruments in different versions for different levels of automation. CNC-controlled profile measuring instruments

-

Fully automatic profile measuring instruments with automatic workpiece alignment

Experts from manufacturing and quality assurance are familiar with this dilemma: They have several dimensions to measure in a series of parts with a high throughput – and little time. The solution for this challenge is a fully automated, CNC-controlled profile measuring instrument with automatic workpiece alignment.

To ensure correct measuring results, the workpiece being measured must be carefully positioned under the measuring instrument. But even with multiple measurements, high parts throughput and time constraints, manually aligning the workpiece can be a source of problems. The advantages of automatic workpiece alignment are obvious: it saves time and reduces machine downtimes. Furthermore, it renders alignment devices unnecessary.

This is why ACCRETECH has developed a series of CNC-controlled profile measuring instruments that automatically perform workpiece alignment with the use of software. With the intuitive ACCTee PRO software, measurements can be programmed and the results evaluated and logged in graph form. Its unique feature is re-measuring at the press of a button.

RONDCOM 60

- Highest precision, reference class roundness measuring instrument

- Measurement range up to 420 mm diameter

- Rotation precision: (0.02+6H/10,000) µm

- Z-axis precision: 0.05 µm/100 mm

- Highest rotation precision worldwide

- Measurement range and probing force can be adjusted

- Higher throughput due to quick, automatic alignment in less than a minute

- Air bearing equipped high precision table-rotating instrument for wear-free run-out.

- Precision of 20 nanometres with 60 to 100 kg load carrying capacitym

Area of application

RONDCOM 60 is perfectly suitable for cylindrical profile measurements of high precision automotive parts.

RONDCOM 65

- Highest precision, top class roundness measuring instrument

- Measurement range up to 420 mm diameter

- Rotation precision: (0.01 +6H/10,000) µm

- Z-axis precision: 0.05 µm/100 mm

- Highest rotation precision worldwide

- Measurement range and probing force can be adjusted

- Higher throughput due to quick, automatic alignment in less than a minute

- Air bearing equipped high precision table-rotating instrument for wear-free run-out

- Precision of 10 nanometres with 60 to 100 kg load carrying capacity

- Thermally insulated, active anti-vibration table

Area of application

Optimal for cylindrical profile measurements of high precision automotive parts. Also suitable for high precision workpieces and meets calibration standards.

RONDCOM NEX RS 200/300

- High precision CNC roundness and roughness measuring instrument with fully automatic workpiece alignment

- Measurement range up to 360 mm diameter

- High precision roughness measurement (ISO)

- Rotation precision: (0.02+3.2H/10,000) µm

- Z-axis precision: 0.10 µm/100 mm

- Fully automatic alignment of the workpiece and CNC programming of the measurement procedure

- Roughness measurements in the R and Z axis as well as the gyration rotation axis

- Offset probe sensor holder (patented) makes measurement below the R-axis possible

- Simple upgrade to a fully CNC capable profile measuring station (RONDCOM Nex 200/300)

- Ceramic R-axis – reduced weight and thermally stable

- Additional linear scale in the R-axis and Z-axis and rotation axis

- New design protects the base unit and Z column from negative environmental influences

Area of application

The RONDCOM NEX RS offer the possibility of taking high precision measurements of the profile and surface parameters at the same time, in accordance with ISO standards.The RONDCOM NEX RS is able to not only measure the position, profile and roughness in the R and Z direction, but also in the rotary axis. The instrument is particularly suitable for quality measurements for complex workpieces such as large bearings.

RONDCOM NEX 200/300

- High precision CNC roundness instrument with fully automatic workpiece alignment

- Measurement range up to 360 mm diameter

- Rotation precision: (0.02+3.2H/10,000) µm

- Z-axis precision: 0.10 µm/ 100 mm

- Fully automatic alignment of the workpiece and CNC programming of the measurement procedure

- Offset probe sensor holder (patented) makes measurement below the R-axis possible

- CNC rotation and swing head (optional = Rondcom nex 300)

- Simple upgrade to a fully CNC capable profile measuring station (RONDCOM Nex 200/300)

- Air bearing equipped high precision table-rotating instrument for wear-free run-out

- Ceramic R-axis – reduced weight and thermally stable

- Additional linear scale in the R-axis and Z-axis

- New design protects the base unit and Z column from negative environmental influences

- Different variants with the manual probe system, X = 300 mm or 500 mm

- Workpieces up to 30 kg (optionally 60 kg)

- DX version with active anti-vibration table and system enclosure (optional)

Area of application

The full automation of the RONDCOM NEX 200/300 makes use in the measurement room and user-independent operation in production and mass production possible. This minimises the influence of the operator, increases the measurement precision and is more time and cost effective in comparison with manual systems. The instrument is suitable for quality measurements for complex workpieces such as large bearings.

RONDCOM CREST

- Table-Rotating Type CNC Measuring Instrument

- Radial direction rotation accuracy (0.01+3H/10000) μm

- Axis direction rotation accuracy (0.02+3R/10000) μm

- Stylus setting controlled by software within a range of ±1mm

- Surpassing the previous generation with a repeatability of 0.3 μm

- Linear motor drives, contactless guides supported by air bearings and unique positioning ensure ultra-low vibration levels

- Contactless guides/air bearings equals low wear rates resulting in longer accuracy over the life of the system

- High precision diameter measurement

Automatic crowning function

Opposed diameter measurement – patented - Straightness/taper angle measurement by R-axis tracking

- Spiral Cylindricity measurement

- Z/R/T-axis roughness measurement (optional)

- Automatic force adjustment detector allows

form measurement

roughness measurement Lead twist measurement (optional)

Area of Innovation

RONDCOM CREST has a significantly improved rotation accuracy as well as the positioning accuracy and straightness of each axis, realizing an ultra-high accuracy at the world’s highest level, which makes RONDCOM CREST worthy to be a reference machine in the Metrology world.

This accuracy has been achieved via newly developed mechanisms mounted on the Z axis of the column and the R axis of the drive unit. For the drive system, a new system combining the non-contact and low-vibration linear motor drive technology, which has an established reputation on our roughness and contour measuring machines, and a newly developed original positioning mechanism is adopted.

Automatic profile measuring instruments with manual workpiece alignment

-

Compact form tester for large number of workpieces

If a manageable number of workpieces from a series needs to be measured in the measuring room for profile parameters, CNC-controlled devices with manual workpiece alignment lend themselves to this task.

ACCRETECH’s product range has a variety of profile measuring instruments here – for different applications and different precision requirements. The RONDCOM 31 and RONDCOM 41 form testers are suitable for assessing roundness, flatness, coaxiality, concentricity and radial runout. The measuring systems in the RONDCOM NEX series also measure roughness, cylindrical profile, perpendicularity, parallelism, straightness and differences in thickness.

RONDCOM NEX 100

- High precision CNC roundness measuring instrument with fully automatic workpiece alignment

- Measurement range up to 360 mm diameter

- Rotation precision: (0.02+3.2H/10,000) µm

- Z-axis precision: 0.10 µm/100 mm

- Save time during manual alignment thanks to the supporting correction software and the large alignment range of the rotating table

- Offset probe sensor holder (patented) makes measurement below the R-axis possible

- Simple upgrade to a fully CNC capable profile measuring station (=RONDCOM Nex 200/300)

- Air bearing equipped high precision table-rotating instrument for wear-free run-out

- Ceramic R-axis – reduced weight and thermally stable

- Different variants with the manual probe system, X = 300 mm or 500 mm

- Workpieces up to 30 kg (optionally 60 kg)

Area of application

With easy and software supported workpiece alignment, RONDCOM NEX 100 is ideal for high precision individual measurements and a wide spectrum of parts in the measuring room.

RONDCOM 41

- Manual profile measuring station with high precision Z-axis

- Software-supported alignment of the workpiece

- Measurement range up to 250 mm outer diameter

- Rotation precision: (0.04+6H/10,000) µm

- Z-axis precision: 0.5 µm/100 mm

- High quality axes with air bearing equipped table-rotating instrument, optional 500 mm Z columns

- Measurement range and probing force can be adjusted

- Semi-automatic procedures

- CNC analysis with printout

- ACCTee measurement software with help functions for centralising and levelling

- Workpieces up to max. 25 kg

Area of application

RONDCOM 41 is designed for the quick, simple and precise execution of profile measurement tasks such as measurement of polar and linear parameters, for example cylinder profiles, straightness, concentricity, etc.

RONDCOM 31

- High precision polar profile measurement with a large measurement area

- Software-supported alignment of the workpiece

- Measurement range up to 250 mm outer diameter

- Rotation precision: (0.04+6H/10,000) µm

- High quality axes with air bearing equipped table-rotating instrument, optional 500 mm Z columns

- Measurement range and probing force can be adjusted

- CNC analysis with printout ACCTee measurement software with help functions for centralising and levelling

- Workpieces up to max. 25 kg

Area of application

RONDCOM 31 is designed for the quick, simple and precise execution of profile measurement tasks such as measurement of polar parameters, roundness, evenness, coaxiality, concentricity, etc.

Form measuring devices with manual columns

-

Compact form tester for production

Anyone in production or workshops is familiar with the challenge: The profile parameters of a workpiece need to be measured soon and quickly – and the measuring room is too far away or is occupied. Metrology is then the bottleneck in production.

With form testers for process-related measurements, this bottleneck can be dissolved. So that companies can carry out precise, fast, uncomplicated and efficient measurements outside the fine measuring room; for example in production, at incoming goods or the final inspection.

ACCRETECH offers the RONDCOM TOUCH for workers to do their own measurements directly in production. There is space on every workbench for it, due to its compact form: It is a mere 32 x 41 x 55 cm in size. With a weight of 26 kg, the RONDCOM TOUCH is one of the lightest devices in its category. RONDCOM TOUCH

- High precision polar profile measurement in the workshop

- Software-supported alignment of the workpiece

- Measurement range up to 150 mm outer diameter

- Rotation precision: (0.04+6H/10,000) µm

- Simple – Touch operation

- Precise – air bearing equipped precision table-rotation instrument

- Effective – final measurement at the push of a button

- Modern and practical – bluetooth and wireless: operate and print wirelessly

- Compact – patented design for your workbench

- ACCTee measurement software with help functions for centralising and levelling

- Workpieces up to max. 15 kg

Area of application

RONDCOM TOUCH is ideal for self examination by the worker, directly when manufacturing. There is space on every workbench for this, due to the compact form. Operation is simple and intuitive using the Touch Screen interface.

Systems for large and heavy workpieces

-

Measure profiles on big and heavy workpieces

Whether engine blocks, crankshafts, cylinder heads or large ball bearings – many profile measuring instruments are stretched to their limits when the workpieces to be measured are too big and/or heavy. Three special profile measuring instruments from ACCRETECH see their chance here: The two spindle form testers RONDCOM 73 and RONDCOM 76, as well as the RONDCOM GRANDE, are ideal for measuring big and heavy components.

The ACCTee PRO software included allows for intuitive operation and guides you through the entire measuring process. With the ACCTee PRO software, users can program measurements and the evaluate and log the results in graph form. Using the playback function, re-measurements can be started at the press of a button. Changes in evaluations such as filters, centring procedures or notch saving functions can be performed without re-measuring. The changes in the measuring result will be displayed immediately.

RONDCOM 73

- Compact design and larger Measurement range

- Highest precision in its class

- Rotation precision 0.06 µm

- Z axis straightness 0.9 µm/200 mm

- Max. load 200 kg

- Measurement range up to 450 mm diameter

- ACCTee Software for fully automatic CNC procedures

- CNC workpiece alignment using the Tx/Ty/Cx/Cy axes

- Probe head protection and automatic balance mechanism of the R axis

Area of application

RONDCOM 73 was specially developed for ever smaller, lighter but high precision engine blocks, cylinder heads or crankshafts. The machine dimensions and weight were reduced and the precision has been increased. The new ACCTee software makes very simple operation and programming of the measurement procedure possible in Teach-In mode.

RONDCOM 76

- The high precision spindle profile tester for oversize workpieces in the automotive industry

- RONDCOM 76 with granite construction and air bearings, fully CNC controlled

- Max. load 200 kg to 1000 kg

- Rotation precision of (0.04+3H/10,000) µm

- The first high precision air bearing for X-, Y- and Z-axes

- Measurement range up to 500 mm diameter

- 7 fully automatic, controlled axes

- CNC workpiece alignment using the Tx/Ty/Cx/Cy axes

- Diameter measurement

- Parallelism measurement of the cylinder

- Multi-evenness through a high precision R axis

- Integrated vibration minimising table

- Teach-in programming

Area of application

RONDCOM 76 is particularly suited to high precision measurements of heavy or cubic automotive parts such as cylinder heads, motor blocks or crankshafts, for example.

Evaluation software

-

ACCTee – Integrated analysis software for form measuring instruments

New measurement style with new measurement concept. All measurements and analyses available in one document

- Excellent operability in the document screen

- Easy mode

- Expert mode

- Detector calibration wizard

- Effective utilization as offline analysis software

- Change of analysis condition with preview function

- Help system

- Edge detecting function

- Gear tip analysis (Patented)

- Self-diagnosis function

- Available in multiple languages (Standard function)

ACCTee Integrated analysis software

The ACCTee measurement system is the next evolution of TiMS software and has been developed to replace the TiMS integrated software with the all in one document solution.

By being able to perform the measurement and analysis on a document basis, the software provides excellent operability and a comfortable work environment for measurement and analysis tasks. With the document-based new measurement style, all of the operations are available on the document (measurement result sheet), and all of the data and information can also be saved with the related data.