- Offer Profile

- We offer our customers a

complete range of cranes, drives and handling technology for every

application – optimised by comprehensive sales and service support. These

solutions provide our customers with valuable quality and efficiency

benefits. In small workshops as well as in major industrial enterprises.

Our extensive product range includes a wide range of solutions for specific industries for travel applications, load handling at the workplace and material flow in production and storage. The Demag crane experts always focus on the benefits for our customers – the greatest possible efficiency and reliability, optimum availability and maximum performance.

KBK light crane system

KBK Aluline

-

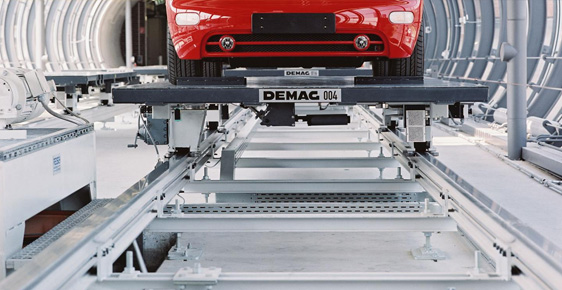

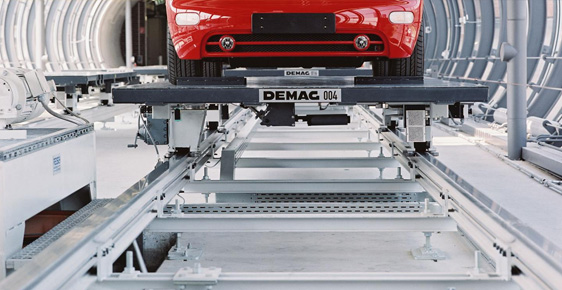

Demag KBK Aluline light crane system

International studies prove that ergonomic workplace design has an immediate impact on productivity. Benefit from the productivity opportunities that KBK Aluline has to offer. We have redefined smooth running characteristics for our KBK Aluline light crane system. The result: one of the smoothest-running systems on the market. For operating sequences that are more ergonomic and convenient than ever before. And now for loads weighing up to 2,000 kg.- Extremely smooth travel

- Fast and simple installation and conversion

- Load capacity up to 2,000 kg

- Ergonomic load handling for even heavy loads

- Low noise levels

- Virtually maintenance-free system

- Six different aluminium profile sections in four sizes

- Integrated conductor line for two profile sizes

- Maximum freedom of planning thanks to modular system design

- Unique combinations with steel profile sections for maximum distances between suspensions

KBK single-girder suspension cranes

-

Safe and reliable transport at high level

Single-girder suspension cranes from our KBK light crane system enable you to achieve fast and reliable area-serving overhead handling and exact positioning of a wide variety of goods. What other qualities do our KBK single-girder suspension cranes offer?- Modular system design

- Smooth and reliable handling

- Smooth manual travel

- Cost-effective implementation

- Customer-specific configuration to meet individual requirements

KBK double-girder suspension cranes

-

Reliable transport also for large spans and high load capacities

Double-girder suspension cranes from our KBK light crane system enable goods of all kinds to be transported with ease. They provide area-serving, overhead handling – and guarantee fast, reliable and precise positioning even for heavy loads and large span dimensions. What other successful characteristics do they offer?- Cost-effective implementation

- Modular system design

- Smooth and reliable handling

- Favourable installation dimensions

- Rated for loads weighing up to 3,200 kg

KBK overhung and extending cranes

-

Large overhang – constant or variable

Loads can also be moved beyond the crane runway using overhung and extending cranes from our KBK light crane system. These solutions offer greater room to manoeuvre – and facilitate optimum utilisation of the available space. Our solutions to meet specific requirements include:- Overhung cranes which are fitted with crane girders that extend beyond the width of the crane runway

- Extending cranes that consist of a fixed section and a crane section that can extend in both directions

- Crane girders that extend up to 2,500 mm beyond the runway span

KBK cranes for manipulators

-

Ergonomic and efficient

Our KBK cranes for manipulators are an oustanding example for the versatility of our KBK light crane system. They can be designed to meet the exact needs of a wide variety of loads, processes and production conditions. They reliably accommodate kick-up forces with great positioning accuracy – and at high operating speeds. Further strengths include:- optimum positioning of workpieces and sub-assemblies into the most favourable positions for the relevant process

- workplaces, machinery and installations can be served from alsmost any direction

- installations can be built with steel or aluminium profile sections.

KBK suspension monorails

-

Perfect for linear overhead material handling

KBK suspension monorails from our KBK light crane system give you the certainty of solutions tailored to meet your specific requirements for linear, overhead handling. Their special strengths are to be found in their many options:- simple, manually operated straight sections – also possible with aluminium profile sections

- complex installations

- load capacities up to 3,200 kg

- flexible routing by means of straight and curved sections, track switches and turntables

- direct link between pick-up and deposit points in reversing operation or a closed circuit

- besides manual operation, semi- or fully automated designs also possible.

Pillar and wall-mounted slewing jibs

-

Switch to improved productivity and ergonomics

Demag slewing jib cranes ensure that all types of workpieces can be lifted and transported quickly and easily and deposited gently and precisely. They provide handling performance at machine tools and assembly stations, as well as in outdoor storage yards and on loading ramps. They are installed direct at the workplace and can be equipped with a wide selection of hoist units.

Manual handling and combining or moving relatively light loads is often not only time-consuming, but also an ergonomic burden for employees. Demag pillar and wall-mounted slewing jib cranes help to improve workplace ergonomics. We provide you with solutions to meet your specific requirements. For high efficiency and improved operating safety for workers, equipment and loads.- Further strengths of our pillar and wall-mounted slewing jib cranes:

- light and fast load handling

- ease of operation and high operating safety and reliability

- load capacities up to 10,000 kg

- simple installation using fittings included in the system

KBK stacker cranes

-

Flexible handling equipment for stores and factories

Our KBK stacker cranes make it possible to complete all storage and handling tasks in one operating cycle without the need for ladders, order-picking trolleys or similar equipment. Unit loads, containers or pallets weighing up to 500 kg can be safely and reliably transported, sorted and stored.- Combination of KBK double-girder suspension crane and special stacker trolley

- Load handling attachments to match the load – forks, prongs, grippers and other attachments can be supplied

KBK portal cranes

-

Mobile workplace units – load-bearing flexibility

Our KBK portal cranes are the ideal solution wherever a permanent crane would be too complicated or cannot be installed. They run on solid, even floors and can be easily manoeuvred in any direction. This makes them ideal for a wide variety of loading and unloading operations in your factory as well as for maintenance and repair work. What other benefits do they offer?- Load capacity up to 3,200 kg

- Crane girder span can be adjusted over a wide range

- Optimally suited for repair and assembly work

- Ideal for help in loading and unloading operations

KBK pillar and wall-mounted slewing jibs

-

Manually handling and combining or moving relatively light loads is often not only time-consuming, but also an ergonomic burden for employees. Together with a wide selection of hoist units, our slewing jibs and cranes installed direct at the workplace enable all types of workpieces to be lifted and transported quickly and easily and deposited gently and precisely. In this way, setting up and idle times can be significantly reduced and periods of waiting for workshop cranes to become available can be completely eliminated. Further strengths of our pillar and wall-mounted slewing jibs include:

Further strengths of our pillar and wall-mounted slewing jib cranes:

- light and fast load handling

- ease of operation and high operating safety and reliability

- load capacities up to 10,000 kg

- simple installation using fittings included in the system

Crane sets for universal cranes

-

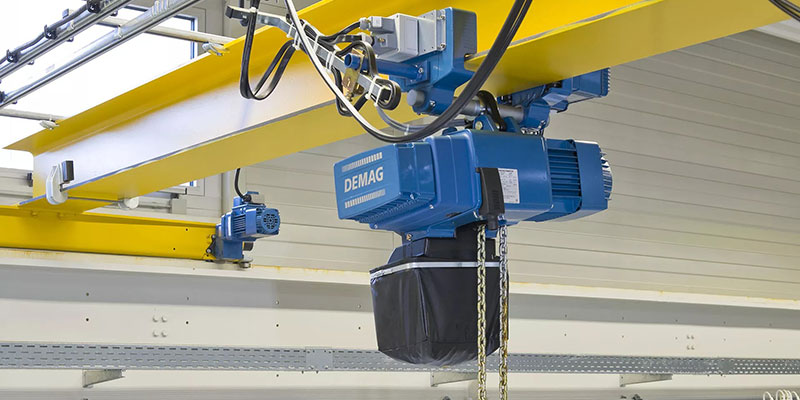

Hall cranes and overhead cranes

Universal cranes – hall cranes or overhead cranes – handle a wide range of lifting and transport tasks in production and warehouses. With Demag crane components, our partners build crane systems that offer you the highest level of quality, economy and reliability. Every crane component reflects our holistic expertise and reliability as an industry partner, which has grown over decades.

The Demag product portfolio includes crane sets and components for overhead cranes and overhead travelling cranes in single and double-girder designs as well as wall-mounted travelling cranes and gantry cranes. The Demag partner network specialises in the planning, production and assembly of cranes and also ensures their ongoing operation through a comprehensive range of services. With our assistance and comfort features, the cranes provide safety and support during operation.

See all the performance details and advantages for yourself on the product pages!

Crane sets for overhead travelling cranes

-

Single-girder and double-girder overhead travelling cranes offer maximum stability with optimised dead weight. This minimises the load on the crane runway – and enables a hall to be set up in a cost-effective design. With Demag crane components and pre-configured crane sets, our crane construction partners manufacture cranes that are tailored precisely to your requirements. There is also a wide range of hoists, from chain hoists to 80t hoists, from the basic variant to the smart high-end solution with intelligent assistance functions. In addition, overhead travelling cranes have an excellent crane geometry that not only ensures excellent travel characteristics, but also enables precise adaptation to the contours of the hall. For all-round greater efficiency and ease of use.

What else distinguishes overhead travelling cranes?

- Crane girder made of torsionally rigid box-type girder section or

- sturdy profile-section girder according to DIN standard for optimal load distribution

- Crane gantries in torsionally stiff design for top or side connection

- Hoists with a wide range of configuration options:

- DVR rope hoist up to 80 t

- DC chain hoist with up to 5 t

- Low-sway load movement thanks to stepless cross-travel

Crane sets for overhead cranes

-

With overhead cranes, the entire hall area is available for production: The hall cranes are simply attached to existing ceiling structures – this removes the need for crane runway supports. A larger usable area is therefore available. Alternative: Steel construction islands also enable the solution to be adapted to changes in production structures.

Demag offers fully configured crane sets for overhead cranes.Other impressive strengths of the overhead cranes include:

- Sturdy profile-section girders or box-section girders as crane bridges for optimal load distribution

- Operation of sub-areas of the hall possible

- Handling the load directly on the hall wall via individual adjustment of the overhangs

- Lateral overhangs for extending the cross-travel beyond the span

- Optionally with DVR rope hoist or DC chain hoist (up to 5 t)

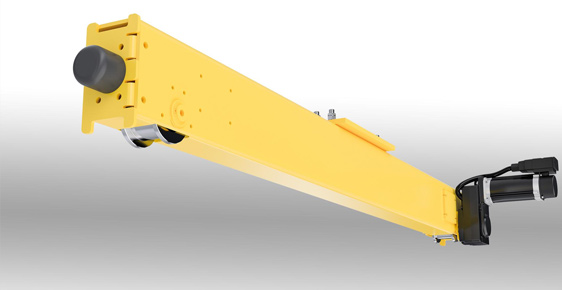

Crane sets for wall-mounted travelling cranes

-

As hall cranes, wall-mounted travelling cranes are the ideal workstation cranes for stations behind one another. They transport material to the individual workstations and simultaneously perform positioning tasks at the assembly stations. They travel below the level of overhead cranes on overlapping crane runway rails along the building wall. Demag offers fully configured crane sets for wall-mounted travelling cranes.

Other features of Demag crane sets:

- Jib lengths up to 12 m

- Load capacities up to 6.3 t

- Can be operated either via a wired control switch or wirelessly

- Trolleys made of Demag drive components

- Travelling hoist optionally with DVR rope hoist or with DC chain hoist on cantilever bracket

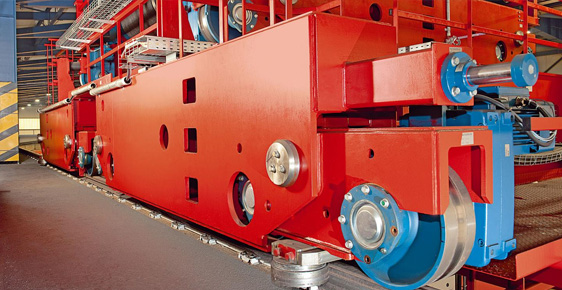

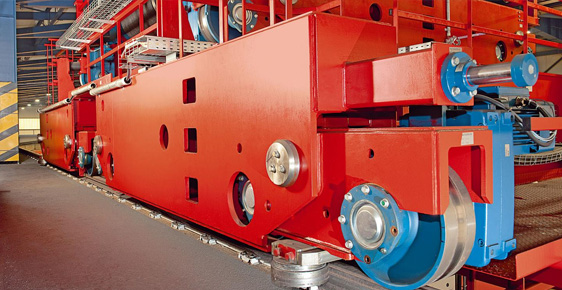

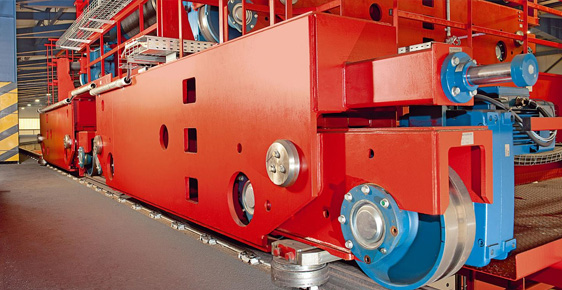

Components for process cranes

-

Components for process cranes

Demag components for process cranes turn a crane into a fully fledged process crane, without the need for any additional design or development work. They're fast, safe and reliable, making these components extremely worthwhile elements of the Demag process crane engineering product line.

The individual components – MPW open winch units, MPW open winch crabs and corner-bearing end carriages – are proven components that have been tried and tested for many years. They are individually configured to meet the specific requirements of your process crane. The variety of possible applications is virtually unlimited. See all the performance details and benefits on the product pages.

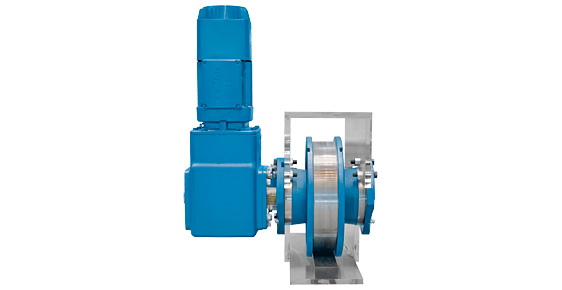

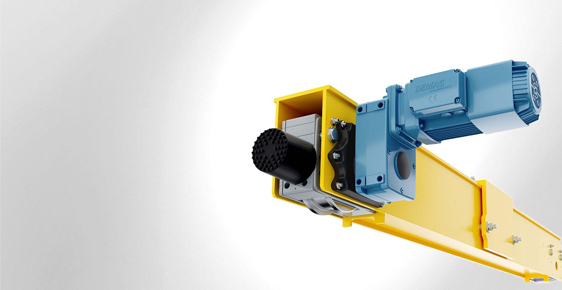

MPW open winch units

-

Compact, robust, high performance

Our MPW (Multi Purpose Winch) open winch crabs are as variable as the needs that they have to meet. Individually configured from reliable system components, they also satisfy the most demanding quality requirements. Their variable configuration makes it possible to implement the most efficient technical solution for your application. Further benefits of MPW open winch units:

- matching modular components

- compact arrangement of drive, brake and gearbox

- high level of safety thanks to a second hoist brake

- clear interfaces for ease of assembly and maintenance

- minimum maintenance requirement and easy to service.

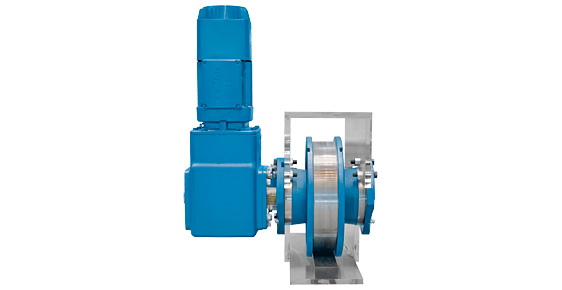

MPW open winch crabs

-

Compact, universal, ready to install

Fully equipped, assembled and supplied just-in-time. You can eliminate any delivery time and interface problems with our MPW (Multi Purpose Winch) open winch crabs, which are ready to be installed. Precisely designed to meet the customer's specific requirements, MPW open winch crabs feature outstanding benefits.

- Modular design

- Few connection interfaces (drum, gearbox, motor and brake form a unit)

- Proven travel unit design used in our crane end carriages

- Jig-built crab frame

- Bolted crossbeam connection

- Minimum assembly requirement

Demag HCW High Capacity Winch Crabs

-

Lifting on a higher level

Demag HCW open winch units feature an extremely compact design. Thanks to their outstanding combination of size and lifting capacity, they can be used to create a full range of solutions for power stations, shipyards and heavy mechanical engineering applications. The load on the crane superstructure can be significantly reduced due to the low hoist unit deadweight.

HCW hoist units are equipped with wear-resistant components and offer good accessibility for service and maintenance. They can also be used to modernize existing crane installations where little space is available. HCW open winch units can be configured to meet individual needs thanks to their modular system design. Fast, safe and reliable – thanks to clearly defined interfaces. And without the need for any additional design or development work.

Process Cranes

-

Process cranes are tailored production equipment for your processes. Individually planned and built based on our crane components. With our components, we ensure the highest level of performance and efficiency for the availability and safety of your equipment.

Selected Demag partners manufacture high-performance special cranes for various processes based on our crane components for process cranes.

The Konecranes Group also designs and manufactures process cranes as industry-specific solutions with automated equipment and warehouse management systems for the steel industry, aircraft industry, paper industry, automotive industry, and other applications.

Demag HCW High Capacity Winch Crabs

-

Demag HCW open winch units feature an extremely compact design. Thanks to their outstanding combination of size and lifting capacity, they can be used to create a full range of solutions for power stations, shipyards and heavy mechanical engineering applications. The load on the crane superstructure can be significantly reduced due to the low hoist unit deadweight.

HCW hoist units are equipped with wear-resistant components and offer good accessibility for service and maintenance. They can also be used to modernize existing crane installations where little space is available. HCW open winch units can be configured to meet individual needs thanks to their modular system design. Fast, safe and reliable – thanks to clearly defined interfaces. And without the need for any additional design or development work.

MPW open winch units

-

Our MPW (Multi Purpose Winch) open winch crabs are as variable as the needs that they have to meet. Individually configured from reliable system components, they also satisfy the most demanding quality requirements. Their variable configuration makes it possible to implement the most efficient technical solution for your application. Further benefits of MPW open winch units:

- matching modular components

- compact arrangement of drive, brake and gearbox

- high level of safety thanks to a second hoist brake

- clear interfaces for ease of assembly and maintenance

- minimum maintenance requirement and easy to service.

MPW open winch crabs

-

Fully equipped, assembled and supplied just-in-time. You can eliminate any delivery time and interface problems with our MPW (Multi Purpose Winch) open winch crabs, which are ready to be installed. Precisely designed to meet the customer's specific requirements, MPW open winch crabs feature outstanding benefits.

- Modular design

- Few connection interfaces (drum, gearbox, motor and brake form a unit)

- Proven travel unit design used in our crane end carriages

- Jig-built crab frame

- Bolted crossbeam connection

- Minimum assembly requirement

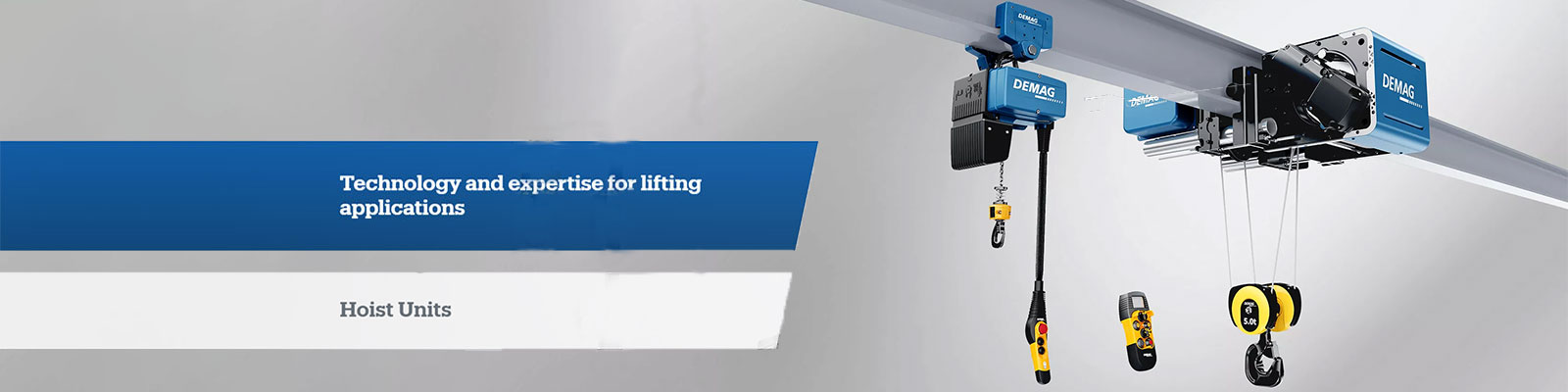

Technology and expertise for lifting applications

-

Our hoist units have served as reliable components in cranes and materials handling systems for many decades. All over the world. Customers in many industries and in more than 100 countries rely on our technology and expertise in lifting applications. For good reason: we offer a unique range of lifting appliances – from chain hoists to open winch units with load capacities of more than 230 tonnes.

Rope Hoists

-

Hoists to meet individual needs

Demag rope hoists feature high handling rates, cost-effective operation and maximum safety. As basic hoist units for integration into plant and machinery or as lifting solutions with electronic controls that are optimized for crane applications, with our wide range of rope hoists we offer the optimum solution to meet our customers' specific requirements for efficiently lifting loads weighing up to 100 tonnes.

DVR rope hoist

-

It offers high levels of efficiency and productivity. You benefit from its flexibility in all areas of application. Thanks to its extensive product portfolio, the DVR offers customisable solutions for the various requirements of crane and lifting technology. From the standard version to the smart high-end solution with intelligent safety functions, the DVR rope hoist meets the demands for economical and ergonomic lifting solutions.

The choice is yours:- Five sizes with load capacities of up to 80 tonnes

- Different application types: Foot-mounted hoist, low-headroom monorail hoist, double-rail crab and standard-headroom monorail hoist (with/without articulated trolley)

- Control system: conventional contactor control or provided by the customer

- Variable-speed or two-stage drive solutions

- Control concept exactly as required: cable-connected or radio control

- Wide range of options available

- Additional smart features can be integrated for safe and convenient load handling

DH hoist units

-

Demag DH hoist units can be used in a wide variety of applications, both as travelling hoists on cranes or monorails and as stationary solutions. These powerful hoist units offer a number of special technical features that enable loads to be handled reliably even under demanding requirements. More than lifting: Installed as stationary or travelling units, they are more than just hoists – thanks to gentle handling with high load capacities up to 100 tons and flexible integration into almost any design.

- Rugged design – proven worldwide

- Easy integration into any design

- High switching frequencies and high duty cycles

- Precise positioning with mechanical microspeed or frequency-controlled lifting

- Load capacity up to 100 t

- Hook path up to 104 m

DHR rope hoist

-

Innovative lifting solutions for safe and forward-looking operation: The new DHR rope hoist offers a high level of versatility and productivity. The DHR combines the powerful features of its two predecessor generations: Reliability, productivity and – thanks to numerous options – tailored implementation to meet the requirements of many industries. From simple lifting applications to high-performance rope hoists with smart assistance and convenience features, the DHR meets all demands for highly efficient load handling.

DHR rope hoists fulfil almost any requirement:

- EK-DHR: monorail hoist, optimised for use on single-girder cranes or monorails

- G-DHR: basic hoist for plant engineering

With the DHR rope hoist, you have the choice for the first time: Proven lifting technology with steel ropes or with innovative synthetic ropes.

Demag DS10-Wind rope winch

-

When maintenance work needs to be carried out on wind turbines, the spare parts and tools have to be lifted on the outside up to the nacelle to heights of 100 meters or more. For onshore and offshore installations we offer cranes, rope and chain hoists that are specially designed to meet the needs of the wind power industry.

Demag hoists ensure fast, convenient and reliable service procedures and minimize the time required to transport material. They help to ensure that facility downtimes are cut to a minimum and to boost the efficiency of these installations. Many companies in the wind power industry also employ our technologies to manufacture their wind turbines.

Convenient operation

- Fast main lifting and precise creep lifting motions

- Ergonomic and fatigue-free handling

- Compact dimensions due to low-headroom trolley design

- Unrestricted view of the working area thanks to large chain collector bag

- No damage to the inner or outer surface of the tower caused by lifting motions thanks to a protective sleeve on the hook assembly (optional)

- Simple movement on I-beam girders or in the KBK system for horizontal transport of loads within the nacelle

- Even more convenient movement thanks to optional handles

- Cyclic duration factor up to 100% enables efficient operation even at large lifting heights

- Slipping clutch for overload protection

Chain Hoists

- Demag chain hoists meet all the requirements of state-of-the-art hoist units, such as high productivity, efficiency, safety and reliability, and give you the certainty of a secure long-term investment. We develop and produce materials handling solutions for all industries and companies of all sizes, from small workshops to major industrial corporations.

DC chain hoists

DC-Pro chain hoist

-

With our DC-Pro chain hoist, we meet our own high standards in terms of quality and innovation.The DC-Pro chain hoist is a fully featured, highly versatile chain hoist, which can be installed and put into service in minimum time. Many features that have to be ordered and bought as extras elsewhere are already integrated as standard. The result:

- "all inclusive" features at no extra cost

- two lifting speeds as standard

- improved safety thanks to 24 V contactor control, operating limit switches and elapsed operating time counter as standard

- slipping clutch with automatic cut-out by means of speed monitoring

- optimum ergonomics and ease of service

- main components are maintenance-free for up to 10 years.

DCS-Pro chain hoist

-

Our DCS-Pro chain hoist offers high efficiency and reliability to ensure maximum precision in assembly operations – for gently and safely lifting, lowering and positioning valuable and sensitive parts. Thanks to almost double rated speed in the partial load range, lifting motions can be performed very quickly. What other benefits does it offer?

- Variable speed over the entire load spectrum

- Exceptionally fine control at slow speed

- Up to 90% higher speeds for reduced loads thanks to its Pro-Hub function

- Load capacities up to 3,200 kg

DCM-Pro Manulift

-

The DCM-Pro Manulift was developed for handling loads quickly and safely with only one hand. The DCM-Pro is based on the lifting unit of the DC-Pro chain hoist and the DSM-C control unit. Thanks to the control unit which is rigidly connected to the load handling attachment, the operator only needs one hand to operate the hoist and guide the load. Further strengths:

- convenient operation and load guidance with one hand

- for all Manulift load handling attachments or specially developed load handling attachments

- simple replacement thanks to quick-change coupling

- suitable for right-hand and left-hand operation

DC-Com chain hoist

-

Our DC-Com chain hoist is the right choice for everyday needs: designed for applications with normal requirements – simplicity and reliability in proven Demag quality. DC-Com units can be integrated into the rails of our KBK light crane system or installed on I-beam girders – where our U 11–U 22 generation of trolleys provides smooth transport of your loads. And what else do they offer?

- Simple commissioning

- Ergonomic handling

- Service-friendly

- FEM classification from 2m

- 24 V contactor control

- Two hoist speeds as standard

DCMS-Pro Manulift

-

Our DCMS-Pro Manulift combines fast and reliable load handling with variable speed control and operation with only one hand. It is based on the lifting unit of our DCS-Pro chain hoist and our DSM-CS control unit. The wide range of performance offered by the DCMS-Pro:

- chain hoist operation and load handling with one hand

- safe, reliable and precise positioning of sensitive goods and valuable products thanks to variable speed control

- fast lifting motions at almost double the rated speed in the partial load range

- quick-change coupling for a reliable hold

- simple replacement of the load handling attachment

- suitable for right-hand and left-hand operation.

DCBS chain hoist

-

Intuitive load handling has never been so easy and, at the same time, efficient: Based on our DC range, DCBS chain hoists include a balancer function that allows loads be guided and precisely positioned with ease. DCBS units are available in two sizes with load capacities up to 250 kg. They are compatible with our comprehensive Demag KBK light crane system.

DCBS units can easily travel on KBK profile section rails: on single-girder suspension cranes, suspension monorail systems or on slewing jib cranes. If you want to implement an application with lifting masts, manipulators or your own load-handling attachments, the controller sensors can be installed in the load-bearing arrangement.

DCBS core functions- Lifting and lowering by manual force on the control handle

- Manipulating loads

- Protection against slack chain

- Protection against snatching loads

- Movements can be stopped if loads fluctuate widely

- Monitoring/reducing load capacity

Demag DC-II chain hoist

-

The Demag DC-II chain hoist meets high standards of quality and innovation. With its second generation, Demag is consistently following the DC path and once again defining the industry benchmark. Naturally made in Wetter.

Like its predecessor, the DC-II offers the most comprehensive standard equipment and also a wide-ranging option package, which underscores the flexible application possibilities of the hoist and its modular design.

Demag sets the industry benchmark:- Demag sets the industry benchmark

- Standard version is already fully equipped

- Two lifting speeds as standard

- Proven 24 V contactor control

- Operating limit switch (top/bottom)

- Elapsed operating time counter and status display

- Powder-coated aluminium housing parts

- Height-adjustable control cable for ergonomic operation

- Duty cycle: 60% (40/20), 360 s/h at 45°C, can be used up to 60°C

- Signal design for three-axis applications

- Suspension bracket for improved C-dimension and simple installation

DBC chain hoist

Demag DBC chain hoist

-

The electric DBC chain hoist offers a further addition to the existing product portfolio. Thanks to its reliable series components and pre-configured selection, the DBC is the ideal entry-level solution for many industries and meets the wide range of requirements for modern lifting equipment. With three sizes and in finely graduated load capacity ranges, the DBC can lift loads of 63 to 2,500 kg.

- Hook path up to 6 m

- 48 V control voltage

- Low noise level: 68 dB

- Protection class IP55

- Pendant controller for 1-axis and multi-axis operation

- Mechanical limit switches for upper and lower hook position

- Lifting speeds:

- Two-stage pole-changing up to 8 m/min

- Single-stage version up to 6 m/min

- Travel speeds: 20/5 m/min

- Trolley limit switch (option)

- Built-in operating hours counter (optional)

- Application range: -20°C – +40°C

The DBC is available directly from stock within a short space of time in four defined versions.

DC chain hoists - special solutions

DC-Wind chain hoist

-

Our DC-Wind Demag chain hoists are used for the maintenance and service of wind turbines all over the world. Both in onshore and offshore applications, DC-Wind units can overcome adverse conditions. They can safely and reliably transport loads and tools weighing up to 1,500 kg to heights of up to 180 metres.

Safe. By Demag.

Its high lifting speeds enable it to cut maintenance and downtimes to a minimum – making a valuable contribution towards its high availability and efficient operation. The DC-Wind chain hoist can be conveniently controlled and offers all the benefits of our DC chain hoist range as standard. Its high safety standard with a brake/coupling system and corrosion-protected brake with IP55 enclosure are just two of the benefits to improve workplace safety.

LDC-D & KLDC-D Double chain hoists

-

Double chain hoists are particularly suitable for handling long material or for operation with load bars. Demag offers solutions with two mechanically synchronised chain lead-offs that can lift and lower bulky loads in perfect balance. The load can also be asymmetrically distributed to meet special application needs.

The right double chain hoist for your application

LDC-D double chain hoists are suitable for higher speeds. The chain hoist can transport loads weighing up to 5,000 kg at 24 m/min. You can choose between a 2-stage or variable-speed control system and can use the chain hoist as a stationary, push or electric-travel unit, for example on our modular Demag KBK light crane system.

Chain hoist with KDC low-headroom travelling hoist

-

The particularly compact KDC monorail travelling hoist offers extremely low headroom for optimum utilisation of the hook path. KDC hoists can be used with all trolley variants, for example in combination with KBK suspension cranes or KBK monorails. Therefore, you can easily move loads weighing up to 2,000 kg over any area or from point to point. You have the choice between 2-stage or variable lifting and cross-travel speeds.

KDC monorail travelling hoists offer the same benefits as our entire range of DC chain hoists.

Safe. By Demag.

All KDC units are equipped with operating limit switches for the highest and lowest hook position as standard, ensuring convenient lifting and lowering with the chain hoist at all times. Smooth cross-travel starting and braking motions of the trolley provide for low-sway load handling. The safety-related functions satisfy Performance Level c and Category 2 to EN ISO 13849-1 as a minimum requirement.

KLDC travelling hoist for big bags

-

The combination of long load bars and a low lifting height can cause problems in some applications. KLDC travelling hoists for big bags combine the maximum lifting height of a Demag KDC low-headroom travelling hoist with an extended hook lead-off, which enables the load to be lifted to the highest hook position. This results in maximum utilisation of the C dimension for handling loads weighing up to 2,000 kg.

Convenient load handling of bulky goods

Together with the modular Demag KBK light crane system, this creates a winning combination for the convenient handling also of bulky loads. KLDC travelling hoists for big bags are equipped with operating limit switches for the highest and lowest hook position and can be operated with 2-stage as well as variable lifting and travel speeds.

Durable components for uncompromising cost-efficiency

The components installed in the DC chain hoist range feature reliability and a long service life. The generously specified gearbox allows for FEM classification up to 4m and, therefore, 6,300 hours of operation for demanding applications.

LDC-Q quadro chain hoist

-

Four attachment points are a good solution for transporting customised load handling attachments or loads weighing up to 3,200 kg that have a large surface area. With its LDC-Q quadro chain hoist, Demag can supply a chain hoist with four mechanically synchronised chain lead-offs that can lift and lower loads evenly and with high precision. Its special feature is a chain hoist that drives all four chain lead-offs. With high safety and reliability. LDC-Q units allow work to be performed under suspended loads according to accident prevention regulation BGV D8+.

Precision engineering by Demag

Smooth cross-travel starting and braking motions for low-sway load handling. A choice between 2-stage or variable lifting speeds rounds off a convenient and precise lifting solution with the Demag LDC-Q.

Durable components for uncompromising cost-efficiency

The components installed in the DC chain hoist range are selected for their longevity. The generously specified gearbox allows for FEM classification up to 4m and, therefore, 6,300 hours of operation for demanding applications.

DC chain hoists - trolleys

Trolleys for DC chain hoists

-

Demag trolleys for chain hoists are a perfect match for DC chain hoists and ideal for installation on I-beam girders or on the modular KBK light crane system. For push travel or with electric positioning – these trolleys provide horizontal travel solutions tailored to meet specific requirements for our compact hoist units.

All trolleys feature a low rolling resistance and smooth travel characteristics over their entire service life. The robust components are perfectly matched and can provide convenient transport solutions for your application needs.

Demag trolleys – the choice is yours:

- U type trolleys for manual travel

- E type trolleys for low-sway electric travel

- Click-fit trolleys that can be clicked into position

- Smooth-running KBK trolleys as system components

- Low-headroom travelling hoists for optimum utilisation of the available height

- Double chain hoist for mechanically synchronised lifting, e.g. for long material or large-volume components

DDC articulated trolley

-

R/EUDDC (standard-headroom) and R/EKDDC (low-headroom) monorail travelling hoists with articulated trolleys are ideally suited for travel on curved tracks made of I-beam girders. DDC units are the solution for normal or low-headroom applications for a minimum curve radius of 800 mm. Their lateral guide rollers provide for quiet travel characteristics that are kind to the track.

Adapted to meet your needs

Demag geared motorscan be installed as an option, making the trolley suitable for electric travel with even more convenient control via a radio or pendant controller. The installation of an angular gearbox also allows the unit to travel through narrow openings.

Demag Drives

-

As a leading supplier of industrial drives, we offer the entire range of products – from sub-assemblies to complete systems. These include motors, gearboxes, geared motors and wheel systems. These components can be combined to create complete travel units. Frequency inverters and power supply lines round off our portfolio. All components are designed to match precisely for perfect drive element combinations and sophisticated controls for efficient integrated systems.

We use our modular drive system to provide cost-effective solutions to meet specific requirements on the basis of standardized sub-assemblies. This saves you valuable project engineering time and gives you the certainty of reliable product specification. Benefit from our comprehensive plant and engineering expertise.

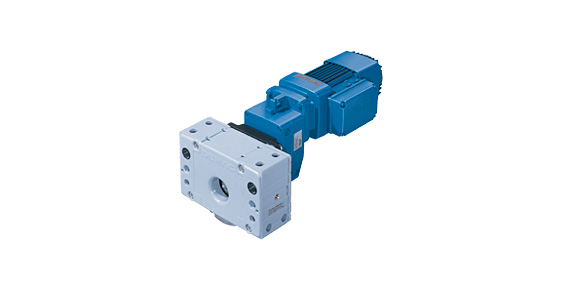

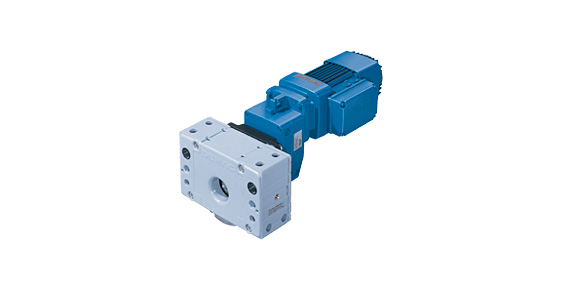

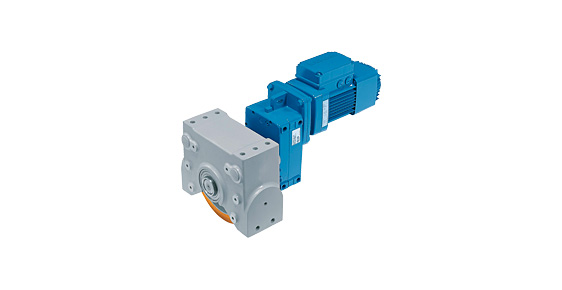

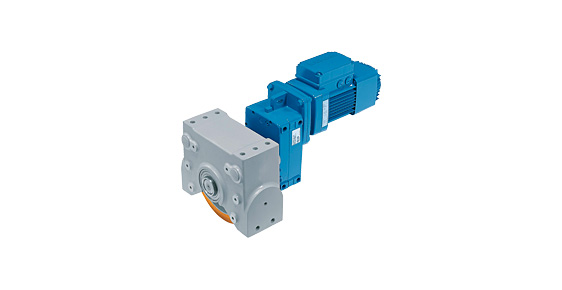

Geared motors

-

Our geared motors are configured from a modular range of motors and gearboxes that are designed for a perfect match. Our modular system enables us to implement solutions tailored to meet your needs quickly and cost-effectively using standardised sub-assemblies to create offset geared motors, angular geared motors and helical geared motors.

This saves you valuable project engineering time – and gives you the certainty of reliable specification. At the same time, you benefit from our extensive design and application expertise in every module.

See all the performance details and benefits on our product pages and specify your own drive solution using our online configuration tool at www.drives.demag-designer.com.

Offset geared motors

-

Full drive performance, also in a small space

Our offset geared motors are specially designed for space-saving drive solutions. The housing design offers good ground clearance for travel applications at ground level. The large centre distance between the parallel gearbox shafts enable these units to be used in a central drive arrangement, e.g. when fitted with shaft ends on both sides. What else do they offer?- Wide range of transmission ratios

- Cost-effective solutions with high efficiency

- Practical designs for a variety of travel applications

- 9 gearbox sizes

Angular geared motors

-

A compact solution tailored to meet your needs for every drive application

Our angular geared motors feature an extremely compact design – which makes them suitable for a wide variety of applications. They enable efficient travel drive solutions to be implemented with ease, even with narrow track gauge dimensions. The basis is provided by outstanding parameters:- large torque range from 120 to 12,000 Nm

- wide range of transmission ratios

- particularly smooth operation

- bevel-wheel gearbox with high efficiency

- 10 gearbox sizes.

Helical geared motors

-

Rugged drive solutions to meet your needs

Above all, our helical geared motors offer one outstanding benefit: their rugged design. They enable high radial forces to be accomodated on the output shaft in a wide torque range. Other features:- torque range from 90 to 1,800 Nm

- excellent efficiency

- coaxial design

- 7 gearbox sizes

- 3 housing designs.

FG microspeed units

-

Gearing up for wide speed ratios

Our FG microspeed units can handle tough applications. They are extremely resilient to vibrations and increased ambient temperatures. Microspeed drives consist of main and microspeed motors that are connected by means of microspeed gearboxes, which enables them to be used for wide speed ratios in rugged, simple and cost-effective solutions. They provide for:- maximum positioning accuracy

- high switching frequency

- movement of large masses in short cycles

- implementation of extremely high speed ratios of up to 500:1.

Motors

- Our motors perform a wide variety of industrial drive tasks. Reliably and effectively. For example, our type Z cylindrical-rotor brake motors – also as brake motors – offer high drive efficiency – also in continuous duty. They are specially designed to match our gearbox range and provide for simple project engineering. Our conical-rotor brake motors with outputs of up to 55 kW are used for stopping-and-starting drives or for direct line-fed travel applications. Thanks to their unique brake principle, they are the first choice wherever demanding requirements have to be met by the brake.

Cylindrical-rotor motors

-

Cylindrical-rotor motors

Our Z cylindrical-rotor motors perform a wide variety of industrial drive tasks – reliably and effectively. They are suitable for a broad range of applications, offering outstanding performance:- motor output up to 45 kW

- inverter-fed drives for travel applications, line-fed travel and continuous operation

- specially designed to match our range of gearboxes

- simple project engineering

- high drive efficiency

- software tools to calculate drive requirements according to specified physical characteristics at www.drives.demagcranes.com.

Conical-rotor brake motors

-

Starting and stopping with maximum performance

Simple, robust and reliable – these are the key characteristics of our KB conical-rotor brake motors. Their unique brake operating principle eliminates the need for separate control or additional switching elements. This is due to the mechanical connection between the brake and rotor. The result:- particularly high braking performance

- approval for operation with extremely high switching frequencies

- two-speed pole-changing motors

- drives for starting-and-stopping applications and for direct line-fed travel motions

- resistance to temporary overload

- KB motors can be connected to gearboxes via a coupling.

Wheel range

-

Our wheels and wheel block systems are designed and manufactured as modular solutions for a wide variety of applications.

They are used in countless mobile devices and systems – as single components or as complete travel units. They demonstrate their high reliability and long service life in operation every day – with only a minimum maintenance requirement. Simple installation and alignment, favourable dimensions and a wide variety of versatile connection options make our wheel systems particularly cost-effective. The broad range covers wheel loads up to 60 tonnes. See all the performance details and benefits on the product pages.

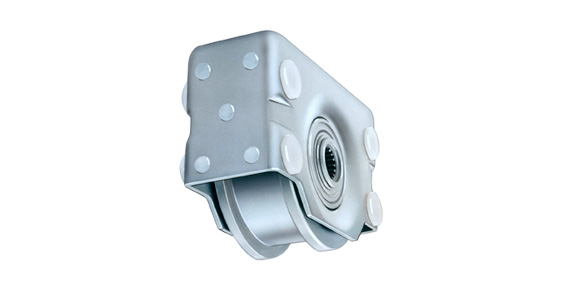

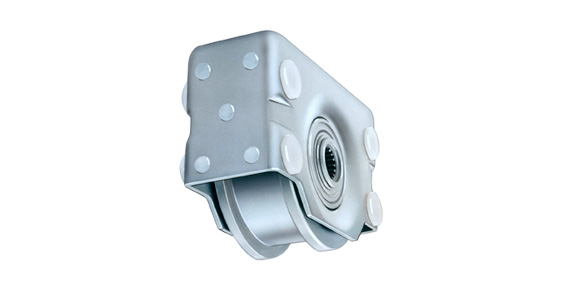

DRS wheel block system

-

Modular system for tailor-made solutions

Our DRS wheel block system is a versatile travel wheel system and is perfectly integrated into our modular drive system. Eight finely graded sizes with load capacities of up to 40 tonnes per wheel provide the right wheel block for every application. And the large selection of travel wheels and special wheel designs enable them to be adapted to almost any travel rails and operating conditions. Cost-effective and ready to install. Further strengths:- high performance range and maximum load capacity

- many travel wheel shapes as standard as well as customer-specific designs

- 4 variants for connection to the customer's superstructure

- high-quality housing with optimum protection of the travel wheels and bearings

- high rigidity

- direct connection of optional accessories

- laser alignment system for wheel blocks on multiple travel units.

LRS travel wheel system

-

The system that is ready to install for a perfect fit

Using our LRS travel wheel system, you can meet your drive requirements quickly and reliably for transport, feed, transfer, distribution or merge applications. We can supply you with the travel wheels and drive units to suit every application. Ready to install, tried-and-tested designs at extremely attractive prices. What other benefits does the LRS travel wheel system offer?- Suitable for wheel loads up to 6.5 tonnes and travel speeds up to 240 m/min

- High-quality sheroidal-graphite cast-iron housing

- 5 connection surfaces provide for a multitude of connection variants

- Versatile thanks to the modular design

- Also ideal for OEMs

- Maintenance free

RS wheel block system

-

Performance and versatility – also under extreme conditions

Our RS wheel block system is suitable for applications in which a housing made of sheet steel is required, such as for impact loads. The RS system is also employed in high-temperature applications up to 250 °C or wherever a stainless steel housing is needed. Various travel wheel designs and possible connections to superstructures make the system suitable for universal applications.

Further strengths include:- 5 sizes with load capacities from 3.5 tonnes to 18 tonnes

- housing made of steel or stainless steel

- many travel wheel contours as standard

- 4 variants for connection to the customer's superstructure

- driven by Demag offset geared motors

- integrated connections, e.g. for torque brackets, guide roller arrangements and buffers.

DWS wheel sets

-

DWS wheel sets

Our DWS wheel set performs transport duties on rails, including for heavier loads. We use it to build complete travel units of driven and non-driven design. These are equipped with our offset and angular geared motors from our modular range of industrial drives.

The use of these proven DWS series-manufactured components offers a high level of functional reliability and guarantees ease of installation when the wheel is replaced. Thanks to its versatility, the DWS wheel set is not only used in the crane and materials handling sector, but also for related mechanical engineering solutions.- DWS wheel sets can be installed in hollow profile sections, box-section girders and used as corner-bearing travel units

- The entire wheel set can be installed without the need for complicated alignment in corner bearing arrangements

- Complete configuration with torque bracket

- CAD drawings are available in various formats at www.drives.demag-designer.com to support your design process.

Frequency inverters

- Demag frequency inverters ensure that your motors deliver the performance that you expect. We offer solutions for virtually all drive applications with our Dedrive Pro and Dedrive Compact STO ranges. To meet even the most demanding requirements.

Dedrive Pro and Dedrive Compact STO provide optimum utilisation of motor output for variable speed control. The starting current is limited and, at the same time, the motor and gearbox loads are reduced – any mechanical elements (including the crane girders and crane runway) are protected and loads are transported smoothly and gently.

Dedrive Compact STO

-

Outstanding drive performance combined with maximum functionality

Our Dedrive Compact STO frequency inverters offer outstanding performance and satisfy even the most demanding drive requirements with ease. They feature not only tried-and-tested reliability and functionality, but also:- high overload capability

- simple operation

- control characteristics for travel and lifting applications independent of the load

- can already be used for 0.75 kW recommended motor shaft output

- highly cost-effective thanks to low wear on the drive system

- application modules are also available with Dedrive Compact STO

Dedrive Pro 880 frequency inverters

-

Safe. Efficient. Controlled.

Our new generation of Dedrive Pro 880 frequency inverters offers high-performance components ranging from 0.55 to 560 kW for 380 to 690 V systems. This new range of frequency inverters is the right solution for many crane control requirements.

Developed by a crane manufacturer for crane manufacturers: Dedrive Pro 880 offers completely configured software solutions and minimises engineering and design costs with its Demag CraneControl system.

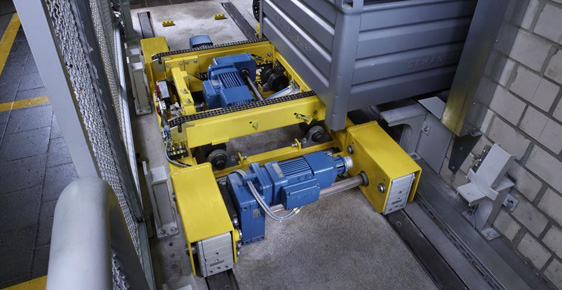

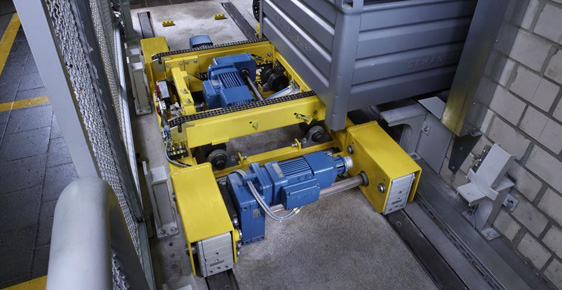

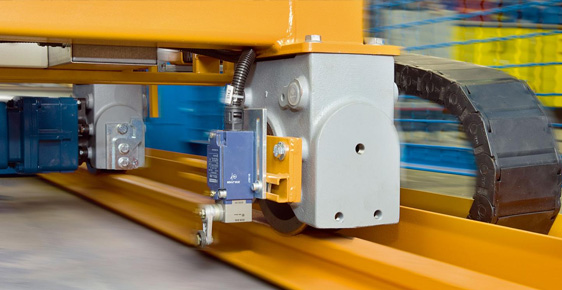

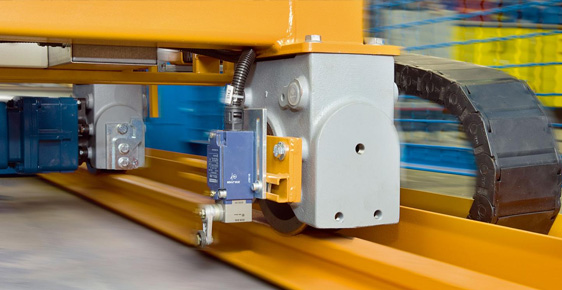

Crane end carriages

-

Solutions ready for installation to meet individual requirements

Our crane end carriages, which we have developed in various designs, offer flexibility and high operating reliability. These compact, modular rail-mounted travel units can be connected direct to crane girders and load-bearing structures. Our end carriages consist of a torsionally rigid box section and complete travel units with geared motors and wheels from the Demag modular system, which can be configured for all load capacity ranges. These combinations result in solutions to meet specific application requirements for safe crane and machinery travel motions that are kind to the rails.

KTL corner-bearing end carriages

-

KTL corner-bearing end carriages

Convenient long and cross-travel motions

Our corner-bearing end carriages are versatile, modular rail-mounted travel units of torsionally rigid box-section design. They can be connected direct to load-bearing superstructures – for cranes or crabs. Further benefits:- precise single or double-girder design with up to four travel wheels

- can be configured for all load capacity ranges

- optimised design of the entire crane system

- convenient adjustment and maintenance

- save time for handling during assembly.

DFO | DFM end carriages

-

Solutions ready for connection to cranes and superstructures

Our end carriages are compact, rail-mounted travel units for direct connection to crane girders and other load-bearing structures. The end carriages consist of a torsionally rigid box section, our wheel blocks and one of our geared motors. They offer excellent travel characteristics – also for high loads

Minimum force transmitted

to the crane runway and building structure by travel units that are specially designed for crane applications:

- Travel units with precisely manufactured wheels made of wear-resistant material provide for smooth running characteristics

- Variable-speed inverter-fed drives for precise positioning and gentle loads on the entire design

- Low maintenance costs: the travel units are rated for the entire crane service life

DFW II end carriages

-

Solutions ready for connection with proven Demag quality for cranes and other load-bearing structures

Demag DFW II end carriages are compact rail-mounted travel units with variable options for connection to crane girders and other load-bearing structures. The end carriages consist of a torsionally rigid box-section profile, Demag DRS wheel blocks, and Demag geared motors. DFW II end carriages can be used for all single-girder and double-girder overhead travelling cranes. To meet your specific needs, our two-wheel and four-wheel end carriages can be combined with Demag drives to offer the performance you need to achieve travel speeds up to 40 m/min (380–400 V) or 48 m/min (480 V). New connection possibilities can increase the wheel base and offer more solutions for your needs.

Transfer carriage with battery drive

Transfer carriage with battery drive

-

Transfer carriage with battery drive: flexible and autonomous

Demag drives make the right moves – with perfectly matching components for an efficient overall system

With our components for battery-powered transfer carriages, we can offer you a self-sufficient solution in which the charging and power unit is already integrated on board. All Demag drive components can be used with their full performance features for battery-powered systems.

Extend the range of your travel applications, e.g.

- Rail-bound transfer carriages with the ability to overcome gaps at crossings

- Indoor and outdoor applications where the power supply cannot be laid due to obstacles

- In painting booths and other areas that are not suitable for an electric power supply

- As a cost-effective solution for long travel paths – without the need for additional cabling & wiring for the power supply

- For emergency power supply to vertical applications

Components for cranes and machinery

-

Using our components, we have developed a unique range of products for cranes and machinery – always tailored to meet the specific needs of our customers. Every single component reflects our many years of experience: as a proven module for crane installations, machinery and equipment and as a single component.

We also offer the optimum solution for your most demanding applications. Regardless of whether you need radio controls or control units that always ensure excellent performance, or power supply lines that guarantee a high level of safety and reliability. And our wide range of load handling attachments provides the right solutions for your load handling needs.

See all the performance details and benefits on the product pages. Control pendants and wireless control systems

-

Thanks to our many years of experience in the controls sector, you can benefit from a comprehensive range of products that also includes the right solution for even the most demanding requirements.

Control your cranes, machinery and installations with our wire-connected control pendants – and utilise the wide choice of configuration options. Or profit from the maximum flexibility, safety and reliability offered by our radio and infrared controls.

All of our controls give you ergonomic design, convenient operation and many opportunities to tailor the solution to meet the needs of your application.

DSC-3, DSC-5 and DSC-7 control pendants

-

Compact and ergonomic: DSC-3, DSC-5 and DSC-7 control pendants for operation of chain hoists

With the DSC-3, DSC-5 or DSC-7 control pendants, users literally have hands-on control of Demag DC chain hoists. DSC-5 is much more compact than previous control pendants designed for controlling two motion axes (lifting and cross travel). DSC5 and DSC7 control pendants fit well in the user’s hand and allows both left and right-handed operators to control the hoist safely, reliably and intuitively, both with and without gloves. Single-handed control also makes it possible for the operator to manipulate the load with a free hand at the same time.

DRC MJ mini joystick

-

Ergonomics @ Intuition

You can control your cranes safely and precisely with the Demag DRC MJ hand-held transmitter, while concentrating fully on the handling task. By controlling your crane with two joysticks, you can intuitively and easily move it on three levels – and always keep the load safely in sight at the same time.

This transmitter is ideally suited for intuitive control with just one hand, since you can precisely control combined crane and crab motions with one thumb.

The compact transmitter design ensures fatigue-free control, even after several hours of operation.

Demag D3 radio control

-

Demag D3 radio control: our goal – the best of its class

The safety and efficiency of a manually controlled crane is largely influenced by control equipment.

Radio controls offer freedom of movement and improved safety. As the control system for Demag V-type cranes, the latest generation of the DRC range of equipment, the DRC D3 radio control system, provides important features. The hand-held transmitters as well as the receivers meet the requirements of the future EN 300 328 V 1.8.1 radio standard.

DRC-DC radio control system

-

Fast installation. Ergonomic control.

The DRC-DC radio control system is the ideal solution for optimum ergonomic operation of high-performance DC chain hoists. It offers much greater flexibility than cable-connected control systems and ensures that the operator can maintain a safe distance from the load at all times.- Two sizes to control up to two (DRC-DC 6) or three axes (DRC-DC 10), respectively

- Strong, tough hand-held transmitter

- Reliable radio transmission thanks to frequency hopping

- Ergonomic design

- Fast installation and simple operation

DRC-MP radio control system

-

Convenient, safe and reliable control

The versatile alternative to wire-connected controls. DRC-MP radio controls are used for reliably controlling cranes, hoists, industrial doors, machinery and installations. You can choose between the DRC-10 key-actuated transmitter and the DRC-J joystick transmitter. Further benefits?- High level of safety thanks to greater distance to the load

- Highly reliable data transmission thanks to frequency hopping

- Rugged housing

- Ergonomic design

- Fast and simple commissioning

DSE control pendants

-

Safely control simply everything

DSE-10 control pendant for ergonomically controlling hoists and machinery. These wire-connected units are used for controlling DC chain hoists and DR rope hoists in applications with up to three motion achses. To serve these needs, we supply DSE-10 control pendants for two different control technologies:

DSE-10C/CS: control pendants to control DC chain hoists, travelling hoists and cranes with an innovative 'triState' interface

available with 2-stage pushbuttons (C) or with variable pushbuttons (type CS)

DSE-10R: control pendants with a CAN bus interface prepared for the safe control of DR rope hoists, travelling hoists and especially DR cranes that are fitted with CAN bus-based safety control.

Both types offer outstanding features, such as:- particularly ergonomic control pendant design for safe and fatigue-free operation

- housing that is highly resistant to impacts

- comprehensive accessories for operation in harsh environments and for protection against fluids and aggressive media.

DSK control pendants

-

Convenient control

Regardless of whether you need to control hoists from ground level or want to control machinery, wire-connected DSK control pendants are the ideal solution.

Why?- High level of safety

- For direct or contactor control

- Ergonomic design and operation

- Can be configured to meet a wide range of specific needs

DST control pendants

-

Safely control simply everything

DST control pendants are real universal solutions – for universal operation of cranes, hoists and machinery. Their benefits are evident:- three sizes with multiple combinations of operating and switching elements

- ergonomic design and operation

- switching elements for direct and contactor control

- high switching capacity

- high operating reliability.

DRC-J and DRC-JT(S) radio control systems

- With the DRC-J and DRC-JT(S) radio control systems, crane control is safe and convenient. The basic structure of the two control systems is almost identical: A bright and high-contrast two-colour display provides information on the crane’s current operating statuses using easy-to-understand symbols. Cranes and hoists can be intuitively controlled by means of two joysticks. These allow the operator to control the crane without taking their eyes off the crane and the load. Additional pushbuttons can be used for optional programmable special functions.

DRC-J is the basic control system. The ‘T’ extension is a model specifically designed for tandem crane operation. The DRC-JTS variant also offers the possibility to incorporate a key-operated safety switch (‘S’) between the two joysticks for switching on and off.

Power supply lines

-

Conductors and power supply lines

Our power supply lines and conductors are extremely rugged systems for supplying power and control signals to mobile equipment. They feature high transmission reliability and ease of installation and maintenance. And they are equally suitable for applications on cranes and other rail-mounted equipment. In harsh outdoor operating conditions and in dusty working environments.

Depending on requirements, our power supply lines and conductors can be supplied in various designs with different numbers of poles. DCL-Pro compact conductor line

-

Safe and reliable power supply

Our DCL-Pro compact conductor line sets new standards for power supply arrangements for mobile equipment. It features innovative technology all along the line. The highly rugged enclosure profile has a low deadweight and its flexible configuration provides for a wide performance range.

The current collector system has been developed with absolute reliability in mind to ensure safe and reliable operation over a long service life. The patented connection arrangement with prepared modules makes installation much easier – and cuts the time required for assembly.- High profile section rigidity with a low deadweight

- Long service life thanks to optimised current collector trolley design

- Up to 200 A in continuous operation

- Fast installation thanks to pre-assembled connection system

- Compatible with DCL predecessor model

Compact magnets

-

In our comprehensive range of compact magnets, you can always find the right solution for handling and transporting sheet and plate metal and metal parts. Choose from our permanent and battery magnets, which operate independently of a power supply.

Whatever solution you choose, our compact magnets guarantee safe, convenient and reliable handling of all magnetisable loads at all times. See all the performance details and benefits on the product pages.

DPM permanent magnets

-

Our permanent magnets are universal load handling attachments for all magnetisable loads. They can be used at various workplaces – in production and assembly areas or outdoors. They provide safe and reliable operation in all applications. And the following features:

- operation independent of the mains

- five sizes with load capacities from 125 kg to 2,000 kg

- suitable for round and flat material

- no residual magnetism

- single -handed-operation with lever control with integrated safety feature

Demag DBM battery magnets

- Demag DBM battery magnets are the ideal solution wherever you need to transport magnetisable loads safely and efficiently. They can be used independently of a power supply and are therefore highly versatile. Whether used as stationary units with wall or slewing jib cranes or as mobile equipment with cranes or forklift trucks, Demag DBM battery magnets allow you to transport loads weighing up to 4 tons easily and safely from A to B.

Demag Apps

-

The crane and hoist can do more, especially thanks to electronic monitoring units. Assistance and convenience systems make material handling easier for the operator and collected data provides information for even more efficient and safe utilisation of cranes and hoists.

The information flow of condition and operating data helps with preventive measures and makes critical conditions visible. Demag digital tools categorise and sort the collected data, and help you to keep an eye on crane and hoist data at all times.

Demag StatusControl 2.0 visualises the current operating data of cranes or hoists, enabling a view of detailed information and facilitating the planning of preventive measures.

The Demag Equipment App (DEA) further increases safety when using Demag hoist units. The continuous monitoring of safety-relevant hoist components and the monitoring of usage provide information before a standstill or fault becomes imminent. Preventive measures and plannable repairs secure the operating process and increase the availability of the systems. The hoist can be conveniently parameterised via the app on a smart device.

Demag Equipment App (DEA)

-

Do you only find out the usage and wear data for your hoist units once a year during inspection and maintenance? This is a thing of the past with the Demag Equipment App. Within the radio range of the hoist, you receive current data in real time on your end device with an iOS or Android operating system.

This hoist data is retrieved and displayed:

- Usage and operating data:

- Current load capacity

- Hoist remaining service life (SWP)

- Remaining service life of the hoist brake

- Maximum value of the calculated duty cycle (ED)

- Total hoist power-on time

- Total number of lifts

- Number of lift cycles

- Average load capacity

- Supply voltage

- Usage and operating data:

Demag StatusControl 2.0

-

Demag StatusControl 2.0 enables the monitoring of cranes and hoists by accessing up-to-date operating data. At a glance, your system data is visually classified using signal colours and provides clear information on condition, usage, utilisation, failure risks and service life. This means that you can always rely on safe, smooth operation and optimise the productivity of your systems in a targeted manner.

The information about your systems can be accessed with any Internet browser via statuscontrol.demagranes.com. Thanks to mobile communications and VPN encryption to the AWS cloud service, this is possible with maximum security. Users can access it flexibly via PC, laptop, tablet or mobile phone. Developed for crane users and service managers, StatusControl 2.0 offers the highest possible transparency in ongoing operation and for predictive maintenance measures. This means that safety and efficiency come first.

Services

- Demag is known worldwide for the reliability of its crane components. One reason for this is our global network of partners, who offer high-quality service in close proximity to our customers. Our partners are committed to keeping your equipment in safe and reliable condition with our original parts, expert training and sound technical support.

Training

-

Expertise is a key factor for the success of your company in today’s marketplace. Only with well qualified staff can you be certain of success.

Individual contact for training

Direct contact for Demag partners

Commissioning

-

Extensive experience for your safety. Our competent and experienced Demag partners have trained service teams with expertise for the professional and timely commissioning of crane systems and components.

Successful approval

Before crane installations can be put into service for the first time and following any significant changes, legislation requires them to be approved by a qualified crane inspector. The approval test is carried out using an appropriately rated load. To ensure safe and reliable operation and to keep your employees safe, your crane installation must be inspected before it enters service – regardless of the brand.

Repair Center

-

Repairs carried out quickly, reliably and efficiently. The Demag Repair Center at our factory in Wetter, Germany, can provide you with a perfect range of technically efficient services for repairs, overhauls and preventive maintenance measures. The services offered by the Demag Repair Center encompass all Demag product generations and products made by other manufacturers.

The repairs are carried out by highly qualified personnel. The use of genuine spare parts ensures maximum operational reliability. Processing takes place via our partner network.

Spare parts

- Our genuine spare parts reduce maintenance requirements and ensure the functional reliability, long service life and continuous availability of our products. They are perfectly matched to fit our products and to meet your needs as a customer – and thanks to excellent and reliable logistics, they can be rapidly supplied all over the world. All genuine spare parts meet the highest quality requirements and are always state-of-the-art.

General overhaul

-

Demag general overhauls ensure that your plant components and equipment operate safely and reliably. Even after the end of their theoretical service life.

Cost-effective alternative to new equipment

After a general overhaul, your equipment is comparable with new technology in terms of operation, performance values and its expected service life. This is an attractive alternative to new equipment. A Demag general overhaul is carried out by specially trained partners and includes all genuine parts specified by the manufacturer.