VEM

- Offer Profile

- The companies of VEM are characterized by an innovative culture, technical competence and great engineering. Extensive experience in the development of drive technology and the constant improvements of our complete system solutions and single components ensures you the value-adding effect of your equipment as well as economic success. Your needs are both our guidance and our challenge. Alongside flexibility, modern technology and quality awareness, our highly qualified employees are the key factors for our success.

Product Portfolio

VEMoDrive

VEMoDrive

- Under the brand name of VEMoDRIVE, VEM supplies controlled drive systems tailor-made to your application and consisting of transformers, frequency converters/ power converters and electrical machines in the performance range of 0.06 kW to 35 MW – from the low-voltage to the medium-voltage range. The VEMoDRIVE system has the components of reputable manufacturers to offer customers and operators all of the options for new planning, modifying, supplementing and expanding automation and drive equipment for each specific user. Beyond this, already existing plants can be easily modernised and expanded upon with VEMoDRIVE. VEMoDRIVE includes both individual controlled drives as a compact variation as well as complex drive solutions including planning:

Compact drives

- The compact unit, consisting of motor and frequency

converter, offers outstanding cost advantages compared to conventional

units:

- no costs for drive configuration

- thanks to the compact setup no separate mounting space for the frequency converter is needed

- high vibration strength and high degree of protection as standard extended lifetime

- generally no output filter necessary

- no motor cables only unshielded power cable needed

- minimum mounting and installation costs

- minimum startup costs immediately operational

Technical details- System: Compact drive system for general applications

- Sizes: 71 – 180 (200 in preparation)

- Output range: 0.55 – 22 kW (30 kW in preparation)

- Voltage: 380-480 V

- Efficiency class: IE2 acc. to IEC 60034-30 in the 0.75 … 375 kW output range

- Degrees of protection: IP 55, IP 54, IP 65 as option, IP 66 acc. to EN 60034-5

- Types of construction: IM B3, IM B5, IM B14 and derived types of construction acc. to EN 60034-7

Single drives

- Drive system for general applications

The VEMoDRIVE single system offers you a drive strategy tailor-made to your application that ranges from analysis to after-sales service depending upon the job and application. With VEMoDRIVE Single, we supply you complete electrical drive units consisting of VEM motors, converters and transformers in the output range of 0.06 kW to 28 MW in low and medium voltage designs. VEMoDRIVE Single provides innovative and intelligent drive strategies for the widest variety of industrial applications such as pumps, ventilators, centrifuges, conveyor belts, mills and compressors.

Technical detailsOutput range 0.05 – 500 kW 500 – 2800 kW 315 kW -28 MW 2 – 28 MW Voltage range 230 - 690 V 380 – 690 V 2.3 – 6.6 kV 2.1 – 10 kV Motor LV LV MV MV Type asynchronous motors in the IE2 and IE3 efficiency classes and special motors for operating on the frequency converter asynchronous motors for operating on the frequency converter asynchronous, synchronous or permanent magnet motors for operating on the frequency converter synchronous motors Cooling medium air-water air-air / air-water air-air / air-water air-air / air-water Converters VSI VSI VSI LCI Mains connection 6/12 pulses 6/12 pulses 12/24/36 pulses 6/12/24 pulses Output frequency to 300 Hz 120 (300) Hz 66/75 Hz 60 Hz Operating mode 2Q-/4Q operation 2Q-/4Q operation 2Q-/4Q operation 4Q operation Transformer 2/3 winder 2/3 winder 2/3/4 winder 2/3/4 winder Design cast resin/oil cast resin/oil cast resin/oil cast resin/oil

Low-voltage

- You can get low-voltage motors from VEM in powers ranging from 0.06 to 500 kW. Our main focus is energy efficiency in the interest of your economic efficiency and our environment. As energy-saving motors, they can already meet future standards in a lot of cases. We supply system solutions and products according to the customer’s needs that are tailor-made for the specific requirements and each particular industry.

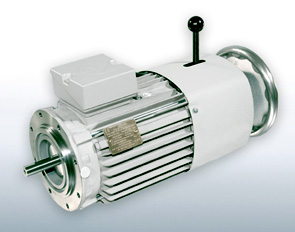

IEC standard motors

- Features:

- Energy-efficient and non-polluting

- these motors are designed for operation on a frequency converter

- designed according to DIN EN 60034 (IEC 60072)

- mounting dimensions and allocation of output according to DIN 42673, 42677, or progressive

- rugged low-vibration gray cast iron design

- type of protection IP 55, higher types of protection up to and including IP 65 available upon request

- thermal class 155 (F) including thermal reserve, 180 (H) available as an option

- terminal box optionally arranged on top, on the right or left

- many modifications available

- can optionally be fitted with a transponder

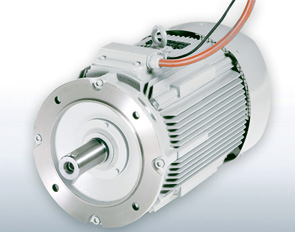

Transnorm motors

- Features:

- Energy-efficient and non-polluting

- these motors are designed for operation on a frequency converter

- designed according to DIN EN 60034 (IEC 60072)

- designs IM B3, IM B35 and IM V1 according to EN 60034-7

- type of protection IP 55, optionally IP 56 or IP 65

- rugged, monobloc pressure die-casting rotor

- winding of thermal class 155 (F), optionally 180 (H)

- impregnated under vacuum

- optimized ventilation system with internal and external cooling as from frame size 355MX

- regreasing device including grease feed regulator

- temperature monitoring with positive temperature coefficient (PTC) resistor (low-voltage design) or PT100 (high-voltage design) respectively

- amply dimensioned terminal boxes

- comes with a standard RFID transponder (Memory Motor)

- non-polluting paint system based on water-based paint

Permanent-magnet synchronous motors

- Driving down CO2 emissions is the greatest challenge of

our time. That makes reducing energy consumption the order of the day.

State-of-the-art speed-controlled electrical drive systems enable us to save

maximum energy. One especially energy-efficient solution is permanent-magnet

synchronous motors (PM motors).

They are exclusively operated with frequency converters and have substantially higher efficiency levels (>IE3) than asynchronous motors as well as improved partial load performance.

PM motors also have higher performance levels than asynchronous motors of the same size. For example, the magnet wheel precisely following the rotary field enables us to use PM motors on conveyor belts with several drives running synchronously. We can provide all sizes and a wide range of modifications to the standard range of motors.

VEM has positioned itself in the technology of permanent-magnet synchronous motors with its two new lines of- permanent-magnet synchronous energy-saving motors

- permanent-magnet synchronous high-power motors

Compact drives

- This compact unit composed of a motor and converter

offers essential benefits as compared to the separate installation of these

units:

- no costs incurred for drive project planning,

- the converter is mounted on the motor ⇒ no mounting surface or floorspace required for the converter,

- high vibration resistance and high level of type of protection come as a standard feature ⇒ long service life,

- no output filter required owing to the design principle,

- no motor cables required ⇒ merely unshielded power cables are required,

- very low assembly or installation input, and

- minimum start-up requirements ⇒ ready for operation in a short time

Explosion-proof motors

- Explosion protection according to EN 60079-0, 60079-1,

60079-7 or according to EN 60079-15/IEC 60079-15 or EN 61241 and according

to ATEX 114 (95, 100a)

Features- energy-efficient and non-polluting

- design according to DIN EN 60034 (IEC 60072)

- mounting dimensions or allocation of output according to DIN 42673, 42677, or progressive

- rugged, low-vibration gray cast iron design

Marine propulsion motors

- VEM motors and drives designed and intended for use in auxiliary power units on board of oceangoing vessels live up to those specific requirements encountered in such environments. These are, among others, high atmospheric humidity and salt content in the air, marine splash water and major temperature fluctuations. These motors conform to the requirements of national and international classification societies. They are designed according to and available with various types of protection and type series and for operation on deck or under deck respectively.

Brake motors

- With many applications, it is imperative that drives stop reliably and fast. Here, VEM brake motors are the right choice when it comes to lifts, hoists, cranes, winches, conveyors, or machine tools. Energy-efficient and non-polluting, designed according to DIN EN 60034 (IEC 60072), mounting dimensions or allocation of output according to DIN 42673, 42677, or progressive, rugged and low-vibration gray cast iron design, thermal class 155 (F) including thermal reserve, 180 (H) available as an option, terminal boxes optionally arranged on top, on the left or on the right, many modifications available.

Fire gas motors

- Based on the proven and tested basic design and

construction of the VEM asynchronous motor series, a type series intended

for use in mechanical smoke or heat venting and extraction systems has been

developed through purposefully modified insulation systems, bearings and

connections.

Under normal conditions, fire gas motors operate as conventional fan motors and are designed such that, in the event of fire, they should operate under strongly increased temperatures for a certain period of time as specified by the customer, and are then allowed to fail. These motors were subjected to severe testing even in the design stage whereby emergencies were largely simulated.

Slip-ring induction motors

- Slip-ring induction motors are used in many industry

sectors, now as before. Owing to their properties, they have a major effect

on the effectiveness of production. VEM three-phase asynchronous motors with

slip-ring rotors combine the benefits of this drive solution with the

extraordinary know-how of VEM in terms of their manufacture.

Due to their large range of modification with regard to customer applications, these motors can be optimally adjusted and tuned; they are especially suited for heavy starting applications such as on instable mains or power supply systems.

Roller table motors

- Motors for power operated roller tables are special drive

elements for the rolling mill industry. Especially during operational or

conveying cycles, these are subjected to especially severe electrical and

mechanical requirements.

This is due to different modes of operation and loading conditions with their variants of continuous operation, intermittent mode or short-time duty as well as starting, braking or reversing cycles.

Motors of the conventional type series ARB 22 – 65 for power operated roller tables made by VEM have proven their functionality and reliability even under extreme ambient conditions for several decades. Based on the experience, VEM has developed several variants of motors for power operated roller tables geared to the conditions of the latest drive technology in frequency converter operation. The windings of these motors are especially adapted to the use with converters.

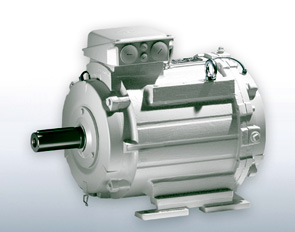

Water-cooled motors

- Features

- Energy-efficient and non-polluting.

- The motors up to and including frame size 280 are gray cast iron with cast integral cooling tubes, and are designed as a double-wall welded steel structures as from frame size 315.

- The terminal boxes, end shields, winding insulation, type of protection and colour scheme conform to those of the standard design configuration.

- The benefit of water cooling is reduced noise emission as compared to surface cooled three-phase asynchronous motors of similar output and frame size.

- The waste heat of these motors is dissipated without any effect on the environment, and their cooling principle facilitates higher output and best vibration damping while the design of these motors remains compact.

Motors for railway drives

- Motors (mainly fan motors) intended for use in railway

vehicles shall be designed and manufactured according to railway

specifications and standards.

For railway specifications or standards, specific conditions to be taken into consideration include shock, vibration, selection or activation via inverter, or high temperatures.

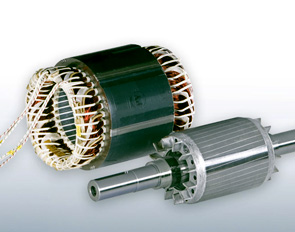

Built-in motors

- From our range of three-phase asynchronous motors with

squirrel-cage rotors, we supply wound stator core packages and rotor bodies.

Winding of thermal class 155 (F), 180 (H) is available as an option. Motors

are also available as energy-saving motors of the IE2 or IE3 design.

The tolerance for the mounting hole of the wound stator core package is as follows:- H7<= frame size 112

- P7 frame size 132

- S7 >= frame size 160

Single-phase motors

- Single-phase motors are double-strand asynchronous motors manufactured with a gray cast iron housing and of the same mechanical design layout as the rugged IEC standardized motor series. These motors are thus available in a wide range of variants, and can be operated on the single-phase alternating voltage network.

Asynchronous generators

- For the use of regenerative energy sources such as wind power or water power, the asynchronous generator is a reliable and cost-efficient alternative to the conventional synchronous generator that is easy to maintain, even in small or medium-sized power generation equipment. Depending on the case of operation, asynchronous generators are operated on an in-house power supply system, or in parallel to an existing power supply system respectively. By now, the previous G21R / G22R type series are supplemented by the GE1R / GE2R type series the design of which is based on the IE-2 type series of asynchronous motors.

Medium and High-voltage

- VEM concentrates on the complex demands of selected market segments of all industries with large-scale and special machines. Motors and generators such as traction or special designs take advantage of electromagnetic streamlining at low installation volumes. VEM builds asynchronous and synchronous machines from the low-voltage range up to 13.8 kV at an output of as much as 42 MW for customised applications.

Steel and rolling mill industry

- Right from the beginning we have high performance slow-running motors for the metal industry in our delivery program. After direct current motors having dominated for a long time, today dynamic, high-quality three-phase motors are used: for larger torques as synchronous machines as solid pole versions, for smaller torques as asynchronous squirrel-cage motors. The mechanical construction is designed for high loads in rolling mill operation; equally the electromagnetic dimensioning fulfils the requirements of overloads, adjusting range and control dynamics. The cooling is predominantly reliant on air-to-water heat exchangers.

Chemical, oil and gas industry

- The chemical and petrochemical plants require the employment of explosion-proof motors - dependent on the hazard potential (zone 1 and zone 2). At present we provide the ignition protection classes Increased Safety “e” and “n” (non sparking) (zone 2) for our low and medium capacity motors; our motors with high to extremely high capacity, as well as all synchronous motors, have the ignition protection class Pressurized enclosure “p“.

Power plant technology

- Conventional power stations, reliant on fossil sources of

energy, form the basic supply and reserve for the supply of electric power

and stable line operation. Keeping the environment and resources in view,

combustion and exhaust gas systems must be optimized further.

VEM motors, designed and built according to ZLM standardization, contribute to fulfilling the requirements for monitoring carbon emissions and also air pollution control of power plants. We supply motors, amongst other things, for boiler feeding, main cooling-water and absorber pumps as well as for oxi-compressors, coal mills and induced draught fans.

Renewable energy

- The stable and sufficient provision of electrical energy is decisive for the economic development of a country. Ecological aspects have increasingly played a primary role in the selection of energy sources for years now. The generation of energy via wind and hydro energy is therefore acquiring an enhanced importance as an environmentally-friendly alternative and is a secure source of energy for our future. We supply asynchronous and synchronous generators of up to 7 MW for wind turbines, as well as actuators for azimuth and pitch gearboxes. Hydro-electric power plants such as Germany's largest 1060 MW pumped storage plant at Goldisthal, Thuringia, feed electrical energy into the grid with the aid of VEM generators.

Water technology

- VEM supplies efficiency-optimized motors for driving high-performance pumps especially designed for large flow rates for water abstraction from artificial lakes, rivers and oceans, and for the transport of raw, pure and industrial water in industrial, water supply and sea water desalination plants and for large waste water treatment plants.

Shipbuilding

- VEM has many years of experience in building ship motors and it also has the licences from all of the important ship classification companies. We build and supply motors and generators for a wide range of all ship models. They range from the large-scale machine with a weight ranging from 200 tonnes to the broad spectrum of accessory drives. Our scope of delivery includes shaft, diesel and on-board electrical system generators, propeller drives, bow thrusters and transverse rudder drives, pump drives and drives from on-board auxiliary equipment.

Transportation

- VEM has been developing and producing rail traction machines for more than 100 years. This is a treasure trove of experience enabling us to meet the demanding needs of the international rail vehicle industry for high performance drive solutions. That includes highly efficient asynchronous traction motors for electrical or diesel/electrical locomotives, multiple units, trams and working vehicles.

Cement and mining industry

- Large infrastructure projects in the “boom regions“ are leading to a strongly growing demand for building materials such as cement, steel and non-ferrous metals which in turn results in a constant demand for an increase in efficiency for the development and processing procedures in view of finite resources. The mining industry is also developing rapidly at present, since the supply of iron and non-iron ores in sufficient quantities is a requirement for the production of various final products.

Services

Testing Laboratory Services and Contract Manufacturing

- Our high-performance testing equipment enables us to offer comprehensive testing laboratory services such as component, type and system tests in the capacity of a neutral partner. On request we can also undertake special testing in the scope of product development work. Our company has the necessary experts along with the extensive experience with the testing requirements from various official acceptance organisations at home and abroad (such as IbexU, Germanischer Lloyd, Det Norske Veritas, Lloyd´s Register of Shipping, Bureau Veritas, TÜV Nord and Deutsche Bahn). We would also be happy to draw up detailed test plans at your request.

Assembly and Start-up

- It takes a lot of experience and dexterity to assemble,

start up, repair and inspect heavy industrial machines. Only seasoned

experts have the skills to manage the burgeoning complexity of these

machines and systems and handle local circumstances whilst working to tight

deadlines. Our external assembly team has proven time and again that it can

meet these demands all over the world.

We put our heads together with you to draw up flowcharts for your project, take on local activities with qualified assembly or supervising personnel and provide the engineering guidance for you right down to successful start-up. Detailed reports and measuring protocols document the quality of work done while providing a fingerprint of the condition of the machine.

Technical Services

- We guide you through the statutory period of limitation

for liability for defects, providing you with selected service modules to

guarantee constant availability for your systems after start-up. Pinpoint

service agreements define the specific type and scope of service to be

performed.

Our team works closely with specific departments such as calculation and engineering, meaning they can provide consultation in all issues regarding the drive and associated periphery.

Supply of Spare Parts

- Our team of replacement part experts are the people to talk to when it comes to technical and commercial issues concerning the supply and stockpiling of replacement parts. We also recommend you set up a local store of replacement parts to ensure fast service in the event of breakdown. We will be happy to draw up a suitable recommendation. On request we can also maintain your replacement parts at our plant in Dresden.