MTS Sensor Technologie

Videos

Loading the player ...

- Offer Profile

- Following the founding of MTS Systems Corporation in 1951, the company rapidly developed into a leading supplier of intelligent hardware and software products in the fields of test and simulation systems and in measuring and automation technology. Today MTS has over 2300 employees worldwide – 400 of whom are employed by MTS Sensors at three sites in the USA (Cary, N.C.), Germany (Lüdenscheid) and Japan (Tokyo). At MTS, intensive basic research is efficiently merged with a consistent focus on practical requirements. The results are innovative solutions for a wide range of potential industrial and non-industrial applications.

Product Portfolio

Industrial Sensors (R/G/E/L-Series)

Temposonics® R-Series Position Sensors

- Optimum performance for industrial applications – this

is what the Temposonics R-Series position sensors offer. As a high end

product, this sensor series is the racehorse of MTS. Powerful electronics

and unrivalled immunity against interference are a warranty of the

transducer's high-accuracy measurement results.

RP / RH Position Sensor

RF Position Sensor

RD4 Position Sensor

RS IP68 / IP69K Position Sensor

Temposonics® G/GB-Series Position Sensors

- Reliability is the feature which makes the G-Series smart sensors for industrial position measurement so convincing. G-Series transducers are available with analog or digital start/stop output and can be programmed very easily.

GP / GH Position Sensor

GT Position Sensor

GTE Position Sensor

GBF Position Sensor

GBS Position Sensor

Temposonics® E-Series Position Sensors

- The E-Series is the basic sensor in the product range of magnetostrictive position sensors. Its excellent price-performance ratio is an unbeatable asset even for traditional users of different position measurement technologies.

EP and EL Position Sensor

ER Position Sensor

EH Position Sensor

EE Position Sensor

Temposonics® L-Series Position Sensors

LD Position Sensor

LH Position Sensor

ATEX - Explosion-Proof Position Sensors

3D/3G Position Sensor

High Pressure Housing (HPH)

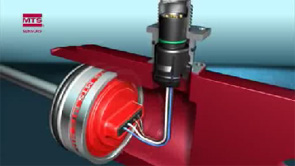

Mobile Hydraulic Position Sensors

Temposonics® MH-Series Position Sensors

-

Integrated in the hydraulic cylinder, the compact Temposonics

position sensors for mobile off-road agricultural and construction

machinery measure displacement and velocity safely even in an

extremely harsh environment.

MH5 Position Sensor

MH Position Sensor

- Standard in Mobile Hydraulics

MH Safety

- SIL 2 certified applications of

functional safety according to

ISO 13849

MS Position Sensor

- Compact Design

MT Position Sensor

- Twice redundant

MB Position Sensor

- Compact Sensor for Mobile Hydraulics

MXR Position Sensor

- For external mounting

and retrofitting mobile applications

MH-Series Test Software

- for MH-Series:

- CANopen

- CANopen Safety

- SAE J1939

MH-Series Testkit (analog / PWM)

- for MH-Series:

- analog

- PWM

MH5 - The new Generation

-

Tailored Position Sensor for Mobile Machines

The Temposonics® MH5 is the new sensor generation for position measurment in mobile machinery!

It is specially developed for large-scale applications. For high volume projects it offers all advantages of magnetostrictive sensor technology at a competitive rate. The new InterConnection Plug simplifies the cylinder installation and ensures the safe connection of the sensor.

The MH5 perfectly fulfills the needs of mobile machinery for:- a position sensor for large-scale applications

- at a competitive price

- for direct, reliable and maintenance-free stroke measurement inside the hydraulic cylinder

- 12 / 24 VDC power supply

- Current/voltage output

- 125 up to 1450 mm stroke range

- 10 mm pressure resistant rod

- 350 bar operating pressure, 450 bar peak

- 100 g single shock, 20 g vibration rating

- EMC tested to ISO 14982

- Temposonics® M12 connector system (IP69k) with the New InterConnection Plug

-

Tailored Position Sensor for Mobile Machines

Temposonics® Connector System

-

Advantages

- Easy and fast integration of position sensors into the hydraulic cylinder

- Simple click-on mounting without the need of tool

- Rugged metal housing protection IP69K

- Prefabricated for high operating safety

- Minimum construction height

- Connection of the position sensor using M12x1 connector

Position Sensors for SIL2 Applications

- Temposonics® position sensors meet the requirements of Safety Integrity Level 2 (SIL2) to EN 61508 and therewith also the requirements of Performance Level d to EN 13849-1. This means they are approved for safety functions on mobile and stationary machines. They support the functional safety and contribute to meeting the safety targets of the entire machine.

Hall-Effect Sensor

- The new HE linear position sensor features hall-effect, non-contact technology and is designed to cover stroke length measurement ranges from 100 to 400 mm. Multiple mechanical packages are available to allow installation into the hydraulic cylinder through internal methods. When installed, there is virtually no dead zone and the full hydraulic stroke range will be shown completely as an electrical output. The M12 connection system (IP69K) simplifies installation and elimantes miswiring, while provided sealing and protection from high pressure spray. Ideal for maintenance free applications, the robust sensor delivers a stable output under the harshest EMI conditions and provides industry leading repeability to support critical control functions.

Light Industrial Sensors

Temposonics® C-Series Position Sensors

- Compact construction, a reasonable price for large-series production, complete functionality and modularity: the C-Series position trandsducers provide persuading solutions for all requirements of the OEM-market.

C-Series OEM-Sensor

C-Series H2 Sensor

C-Series M1 Sensor

Liquid-Level Sensors

Level Plus® Liquid Level Gauges

- Level Plus liquid level transmitters utilize the inherent advantages of magnetostrictive technology to provide the product level, interface level, and temperature measurement of a tank from one process opening. Accurately measuring multiple process variables from one opening lowers the installed costs of adding feedback to a storage tank or process vessel.

MC 420

USTD II

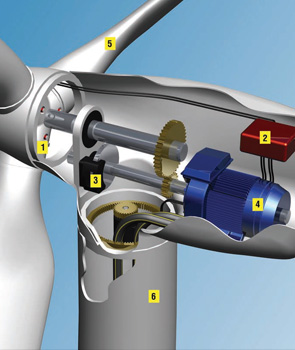

Magnetostrictive Linear Position Sensors for WIND ENERGY

Temposonics® Magnetostrictive Linear-Postion Sensors

-

Wind Energy Growth Market

Wind energy is on the rise, reaching a power output of nearly 57,000 Megawatts in 2007 and continuing to increase. However, we must continue to focus on ways to build, test, deliver, and maintain wind turbines more effectively. MTS Systems can help by delivering position sensor technology that improves the energy efficiency of the turbines while providing greater safety and reducing maintenance costs.

A Green Future...

The call for reducing greenhouse gas emissions is growing throughout the world. Wind power has demonstrated great potential satisfying energy demand with a clean, safe and highly-efficient energy source. At the same time, there is increasing demand for reliable and rugged components because wind turbines are subjected to tremendous aerodynamic forces and continuously changing wind conditions.

…with Temposonics

Temposonics position sensors are reliable, non-contact and maintenance-free. The R-Series sensor, for example, measure position and velocity with high accuracy and speed thanks to:

• High performance, integrated electronics

• IP 67 sealing

• Linearity <± 0.01% full stroke

• Repeatability <± 0.001% full stroke

• Resolution down to 1 micron

• Update time up to 10 kHz

• Operating temperature -40 °C (-40 °F) to 75 °C (167 °F)